Regeneration system and method for synergistically removing multiple pollutants in flue gas

A regeneration system and pollutant technology, applied in separation methods, combustion methods, filter regeneration, etc., can solve the problems of increasing device operating costs, increasing equipment investment, and low wear and loss, and achieve reduced power consumption, low operating costs, and The effect of high degree of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in further detail below:

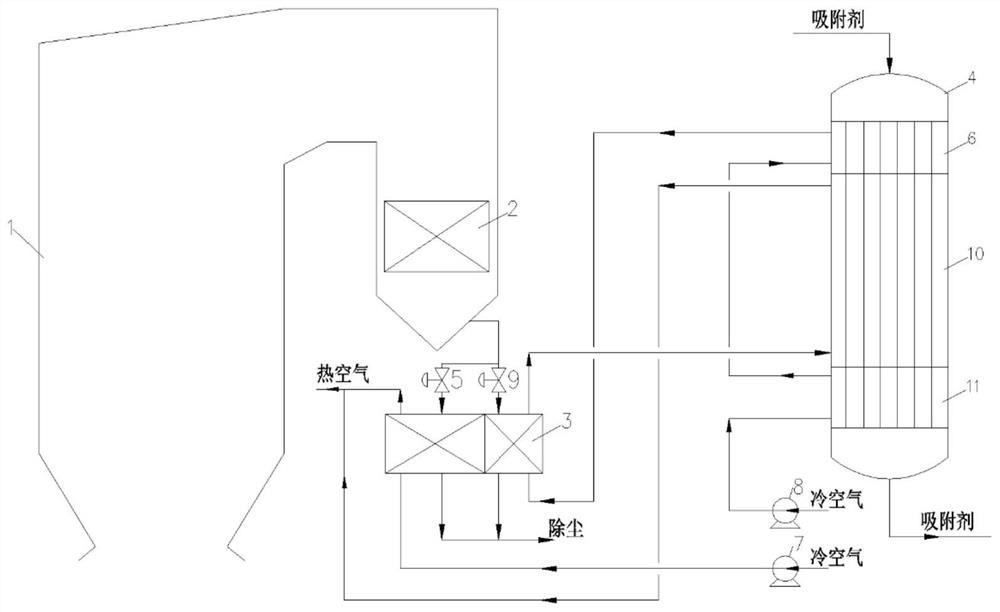

[0024] Such as figure 1 As shown, a regeneration system for synergistic removal of multi-pollutants in flue gas, including boiler 1, primary economizer 2, air preheater 3, regeneration tower 4, main flue baffle valve 5, preheating section 6 , Main air blower 7, regeneration air blower 8, regeneration flue gas regulating valve 9, heating section 10, cooling section 11.

[0025] The flue gas generated by the furnace of the boiler 1 is cooled by the primary economizer 2 and divided into two paths, one path is connected to the flue gas inlet of the main area of the air preheater 3 through the main flue baffle valve 5, and the other path is regenerated The flue gas regulating valve 9 is connected to the flue gas inlet of the regeneration area of the air preheater 3, and the two streams of cooled flue gas are collected to remove dust.

[0026] The air preheater 3 is divided into two areas, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com