Lubricating and cooling device and method for walking box of coal mining machine

A technology for lubricating and cooling the travel box, which is applied in gear lubrication/cooling, transmission parts, earthwork drilling and mining, etc. It can solve the problems of large number of transmission gears, high heat dissipation, large size, etc., and achieves simple installation and layout, low investment cost Low, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

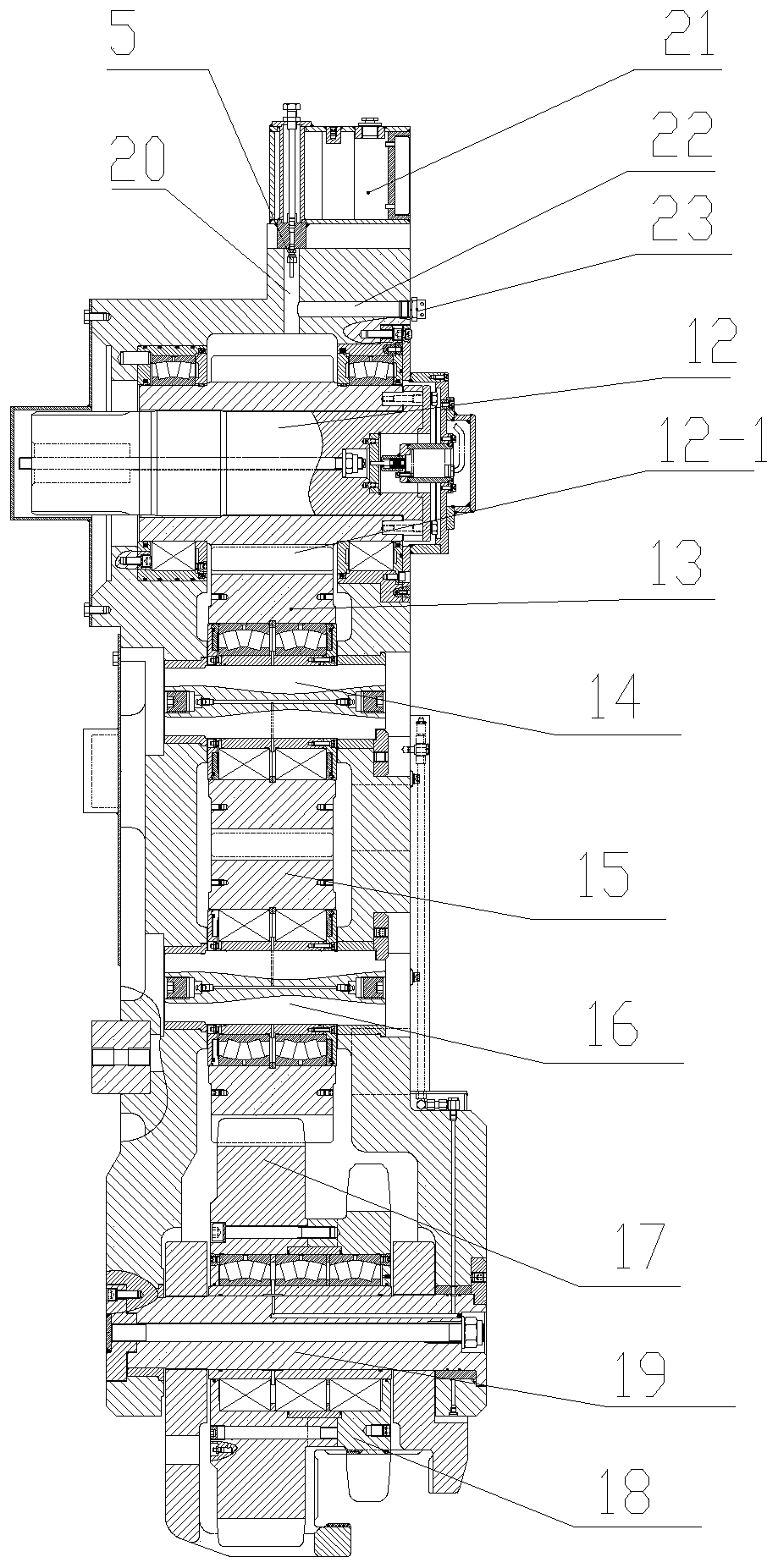

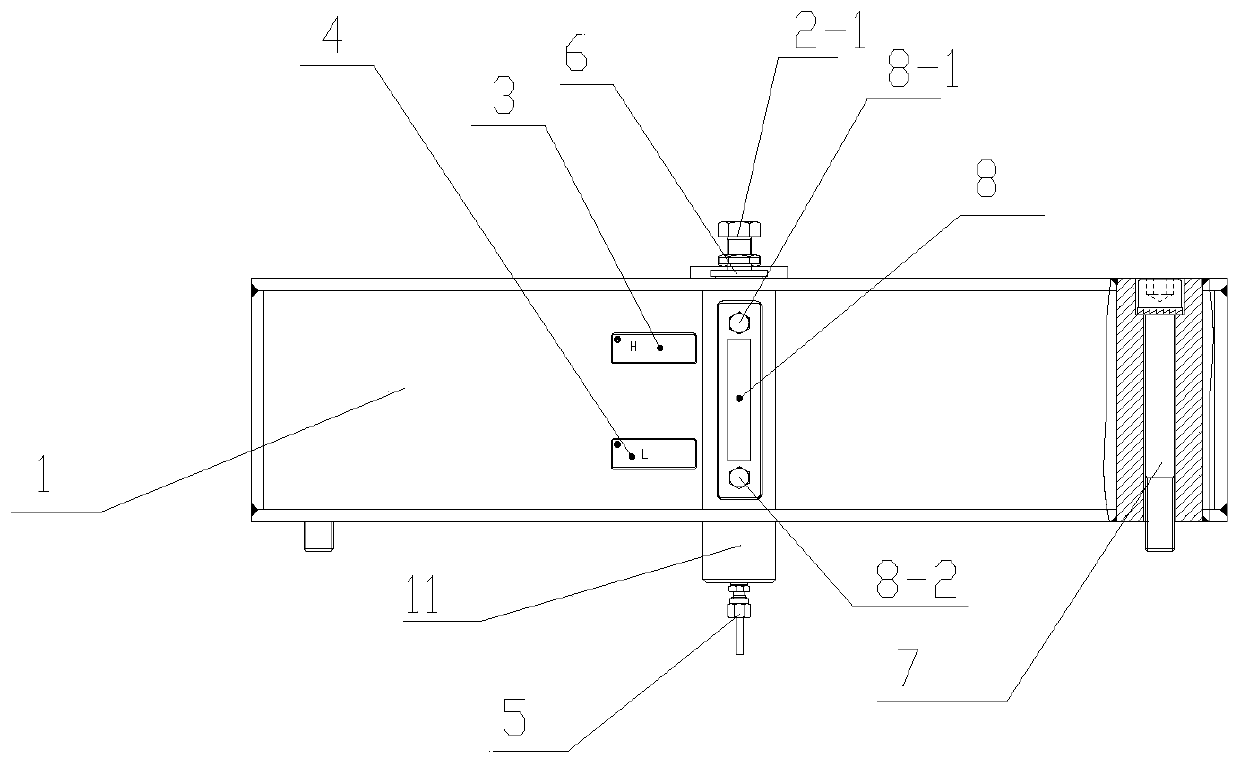

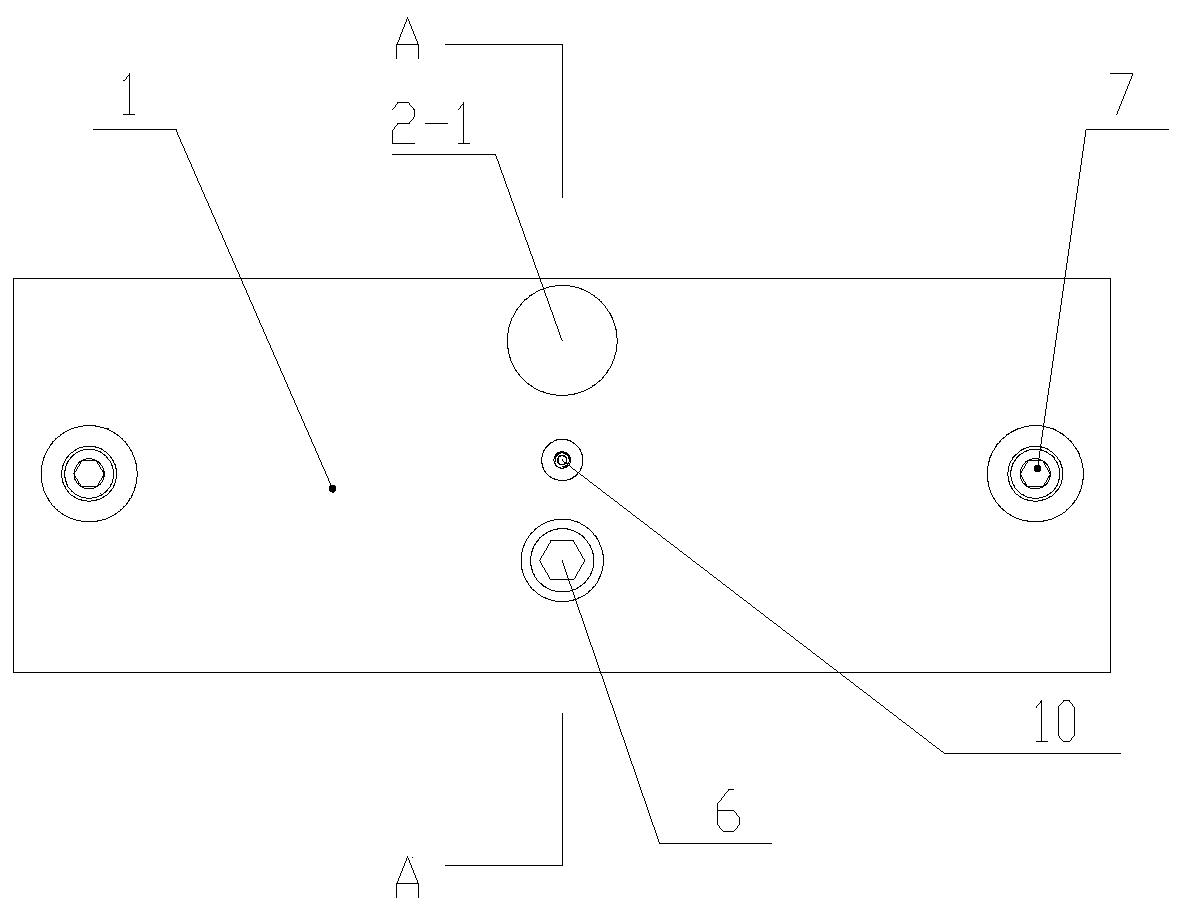

[0074] Such as Figure 1 to Figure 5 The shown lubricating and cooling device for the traveling box of the coal mining machine includes an oil dripping lubrication mechanism 21 arranged on the top of the traveling box of the coal mining machine and a cooling mechanism arranged on the traveling box of the coal mining machine. The oil dripping lubrication mechanism 21 includes Drip oil box 1, the drip tube 5 that is arranged on the bottom of the oil drip box 1 and the oil drip regulating part that is arranged in the oil drip box 1, the top of the described oil drip box 1 is provided with the top that is installed for the described oil drip regulating part The installation hole, the drip oil regulating part includes a cover 9-3 installed on the upper installation hole, an adjustment screw 2 that is installed in the cover 9-3 and can move up and down in the vertical direction, and is arranged on the drip The circular casing 9-1 inside the oil tank body 1 and sleeved outside the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com