Lithium chloride liquid purification method and lithium chloride liquid purification equipment

A purification method, lithium chloride technology, applied in chemical instruments and methods, lithium halide, separation methods, etc., can solve the problem that the material liquid cannot meet the purity requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below by the purification method and purification equipment of lithium chloride feed liquid of the present invention, described lithium chloride feed liquid is the lithium chloride that reacts under agitation condition with industrial lithium carbonate and industrial hydrochloric acid as raw material Liquid.

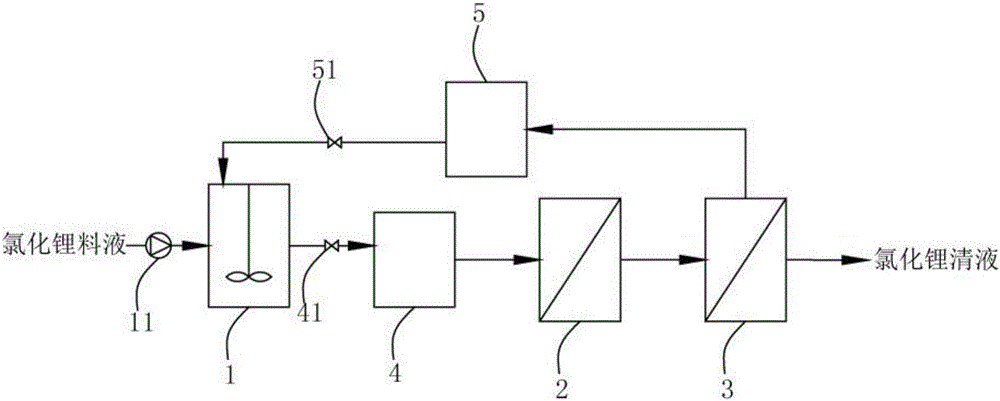

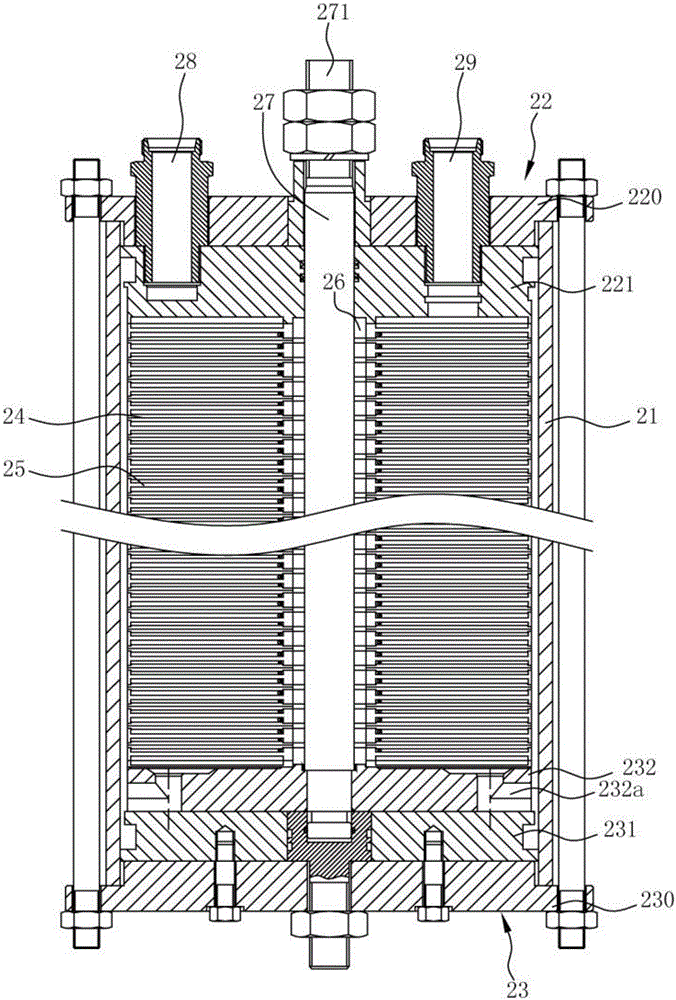

[0028] Such as figure 1 Said, the purification equipment of the lithium chloride feed liquid of the present invention comprises the reaction tank 1 that is connected successively, the first filtering equipment 2 that filter particle diameter is 0.1-50 μ m, the pair of first filtrate outlet that is connected with the first filtering equipment 2 The second filter equipment 3 with interception rate ≥ 99.95% of substances with a molecular weight ≥ 300, pumps for making the feed liquid flow along each equipment, and measuring devices for measuring the content of calcium ions and magnesium ions in the feed liquid in each l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com