Filter element with automatic brushing function

A technology of filters and filter elements, which is applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve problems such as insufficient backwashing effect, and achieve the effect of improving backwashing effect and decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] Referring to the accompanying drawings, the specific implementation is as follows:

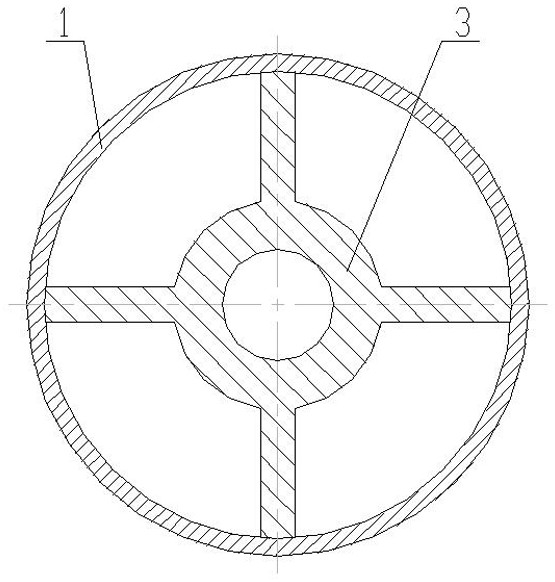

[0015] A filter element with automatic scrubbing function, comprising a filter element body 1 in a cylindrical structure, and a rotating shaft 2 is mounted on the inner side of the filter element body 1 through two bearing seats 3, such as image 3 As shown, the bearing seat 3 is a hollow cross member, and the four ends of the cross are all connected to the filter body 1, so that the bearing seat 3 will not affect the flow of backwash water in the filter body 1. The axis of the rotating shaft 2 coincides with the axis of the filter core body 1. The rotating shaft 2 is fitted with a brush assembly 4 and a driving blade assembly 5. One end of the rotating shaft 2 is screwed with a screw for limiting the axial displacement of the driving blade assembly 5. Lock nut 6.

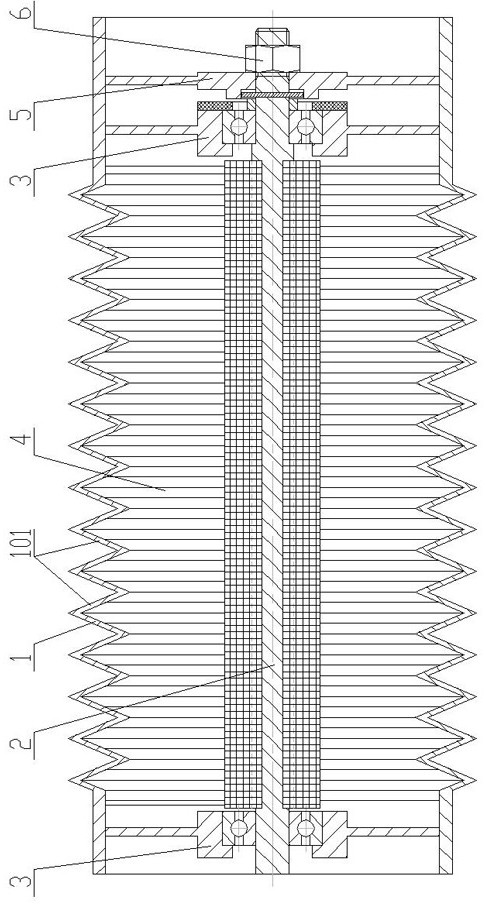

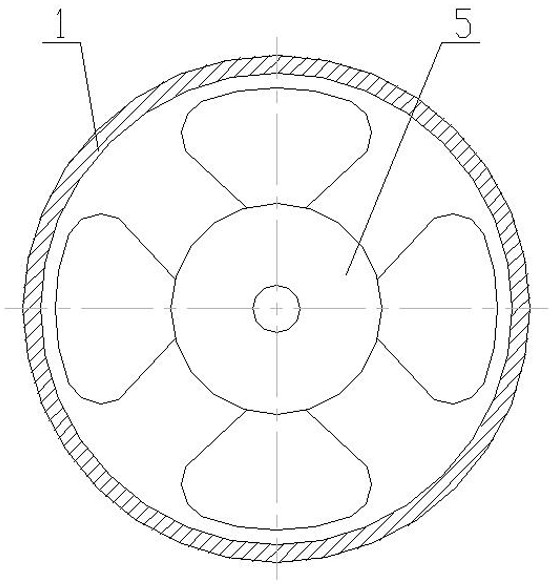

[0016] Such as figure 1 As shown, the position corresponding to the brush assembly 4 on the filter element body 1 is a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com