Non-shaft conveyor

A conveyor, shaftless technology, applied in the field of material supply device, can solve the problems of high maintenance labor intensity, low transmission efficiency, bulky volume, etc., and achieve the effects of compact structure, high transmission efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

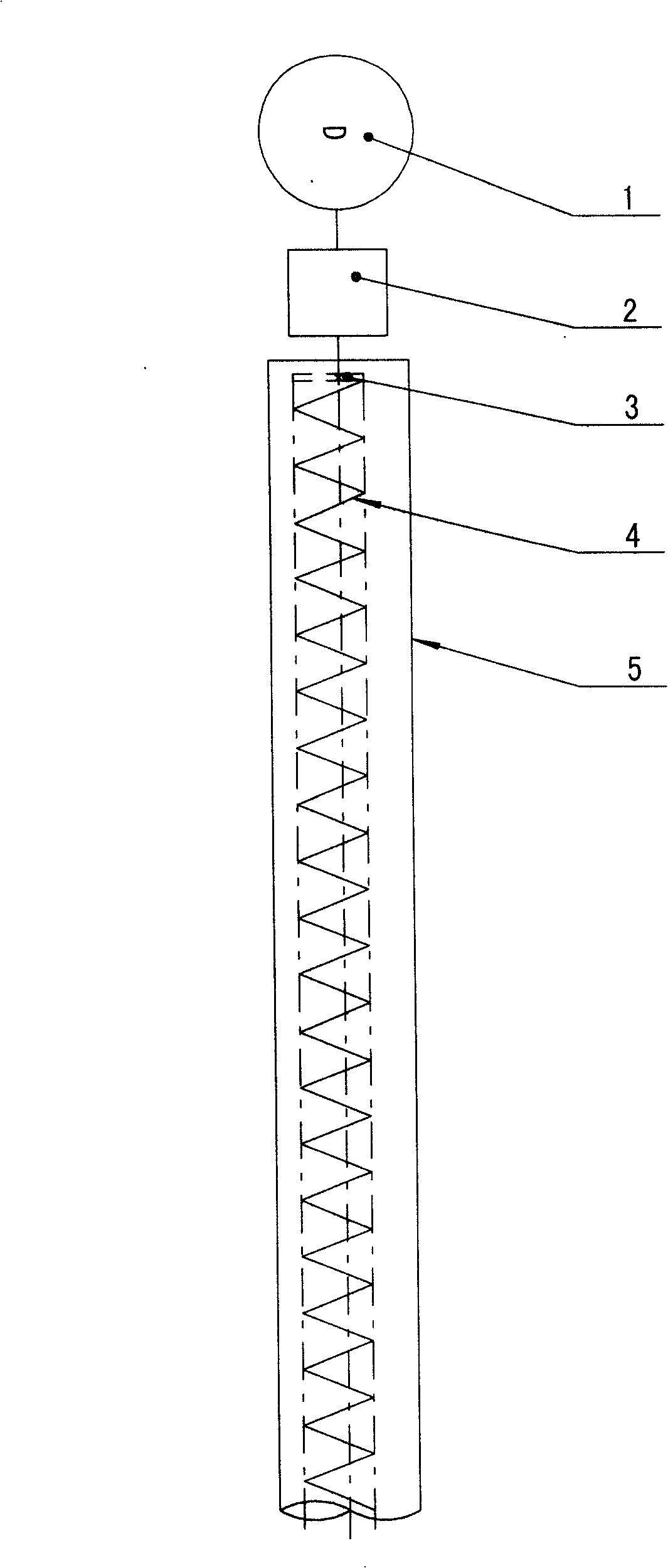

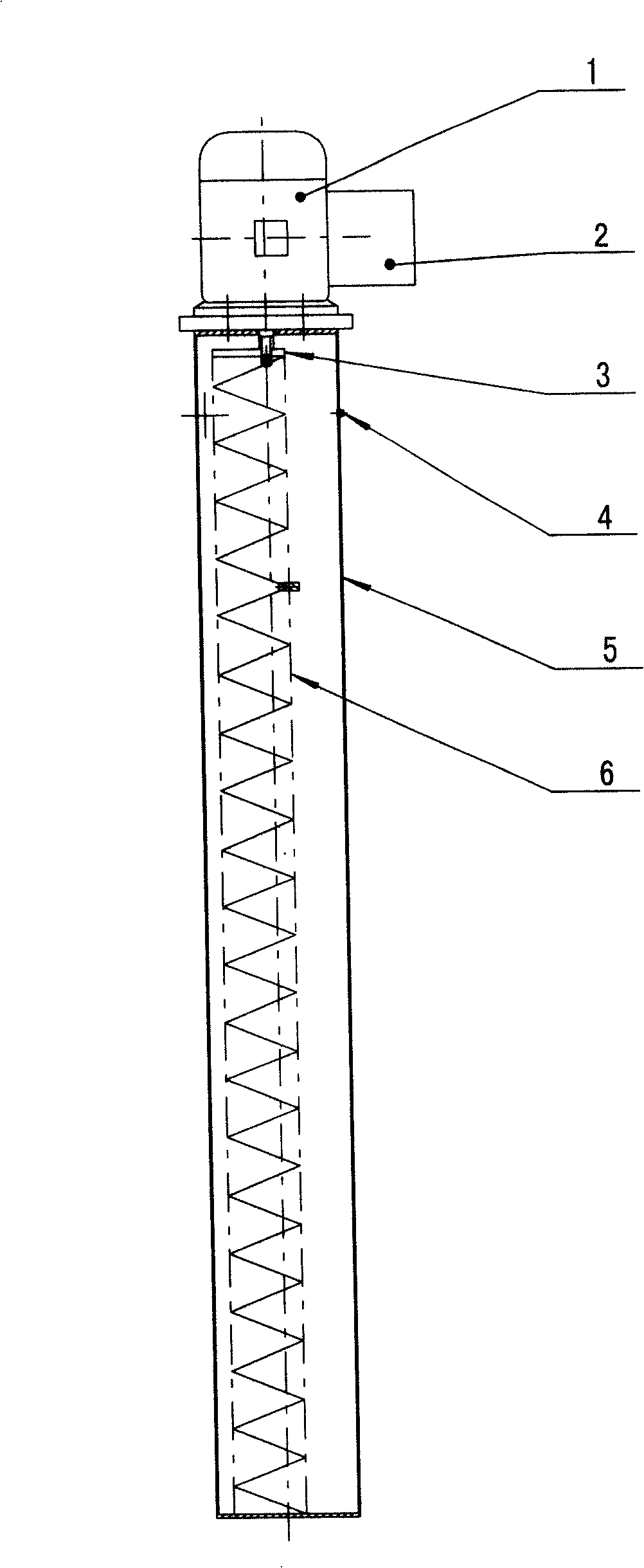

[0009] figure 1 Among them, the power source (1), the transmission (or) transmission system (2) is rigidly connected with the delivery pipe (3), the eccentric connector (4), and the delivery body (5) sequentially. The power source is an electric motor or other power machine; the speed change system can adopt mechanical, numerical control or frequency conversion speed regulation (or constant speed ratio speed changer), and its cross section is a long rectangle or other shapes that are convenient for material transmission; the conveying pipeline is metal or non-metal or composite The material is rigid or plastic or flexible, and the conveying line is straight or curved. The inlet and outlet can be set at the appropriate part of the conveying pipeline according to actual needs; the eccentric connector is circular or other shapes, and the eccentric arc is processed on it. Or curved groove, in order to adjust the eccentricity, it can also be processed into a round hole according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com