Online normal-pressure chemical vapor deposition film-plating reactor through floatation process

A technology of atmospheric pressure chemical vapor phase and reactor, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of affecting the coating quality, no exhaust waste heat, weakening of convective heating mode, etc., to achieve equipment Simple maintenance, convenient flow adjustment, and novel design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

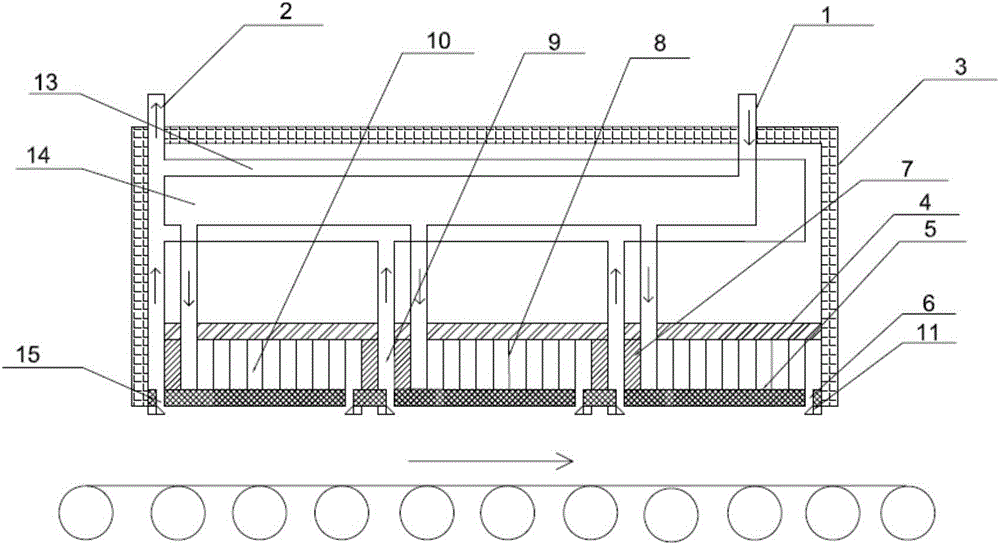

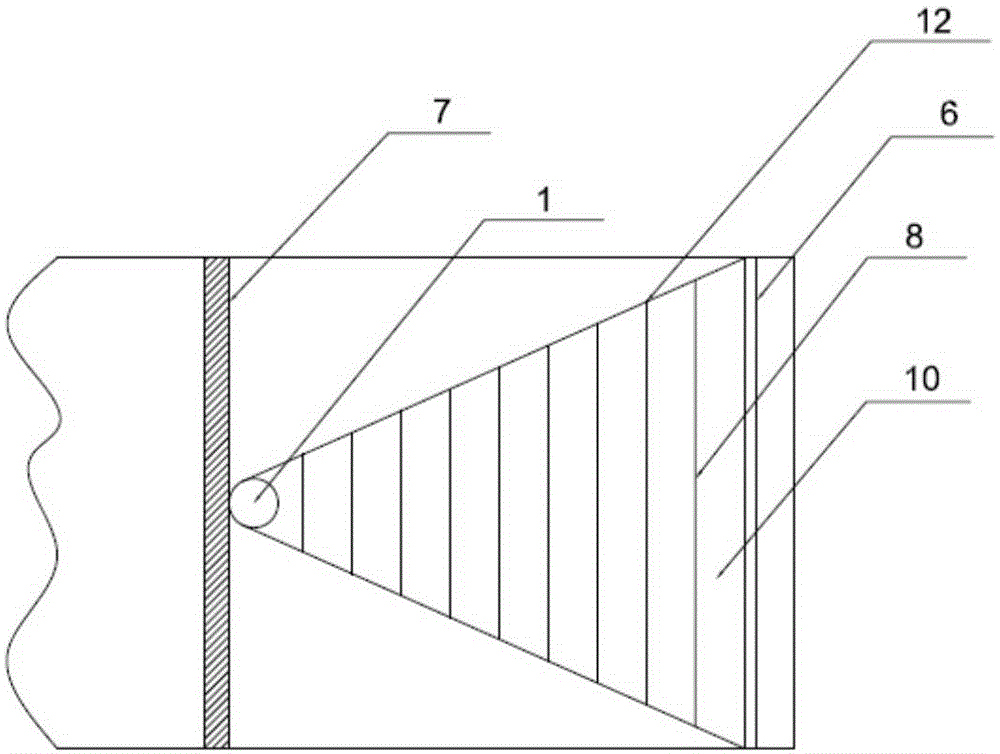

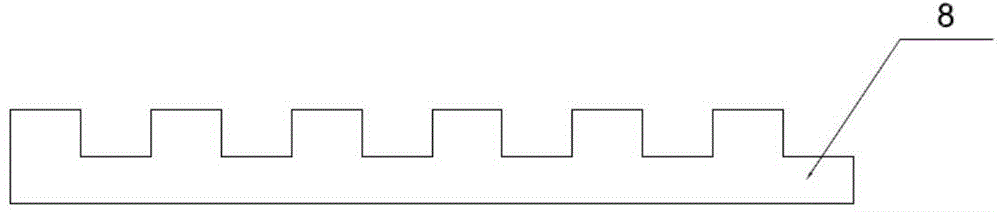

[0023] Such as figure 1 As shown, the float online atmospheric pressure chemical vapor deposition coating reactor in this embodiment is placed above the deposition substrate or the glass ribbon, including the heat preservation shell 3 and the bottom plate 5, and the heat preservation shell 3 is provided with six cuboids as the main body of the reactor. Gas mixing chamber, insulation layer 4 covering the top of the mixing chamber, slit 6 as the coating nozzle of the reactor, long strip graphite stopper 11 at the exit of the slit, and supporting air inlet pipe 1 and exhaust pipe 2 And reactor support, moving mechanism.

[0024] Six non-completely symmetrical rectangular parallelepiped gas mixing chambers are alternately connected together through partitions 7, including three inlet chambers 10 and three exhaust chambers 9, and the volume of the inlet chambers 10 is much larger than that of the exhaust chambers 9, forming a coating The main structure of the reactor is distribute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com