Heat supply conveying pipeline of heating tank in chemical plant

A technology for transportation pipelines and chemical plants, applied in the field of heating transportation pipelines, can solve problems such as noise pollution, loud noise, and impact on the environment, and achieve the effects of avoiding noise pollution, reducing noise, and slowing down the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

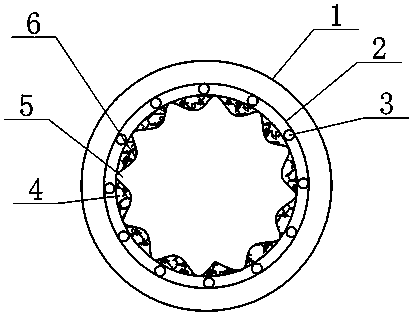

[0014] Such as figure 1 As shown, the present invention provides a heat supply pipeline for a heating tank in a chemical plant, comprising a silencing pipe 2 arranged in the pipe wall of the heating pipe 1, a silencing hole 3 is arranged in the side wall of the silencing pipe 2, and a silencing hole 3 is arranged in the wall of the silencing pipe 1. A plurality of protrusions 6 with a triangular cross-section are arranged on the inner wall of the pipe through hole of 2. The protrusions 6 are hollow structures filled with sound-proof cotton 4, and an arc surface that can buffer water flow is formed between each two protrusions 6. The buffer tank 5, the diameter of the silencer hole 3 is set to 4cm, the section height of the protrusion 6 is set to 6cm, the material of the protrusion 6 is rubber, and a shut-off valve (not shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com