Equipment and method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone

An ozone catalytic oxidation and refractory technology, applied in chemical instruments and methods, oxidized water/sewage treatment, textile industry wastewater treatment, etc., can solve the problem of high structural strength requirements of the reactor, no further use of ozone, and operation and maintenance costs High-level problems, to achieve the effect of strengthening oxidation capacity and utilization efficiency, convenient adjustment of flow rate and ozone dosage, and stable water output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

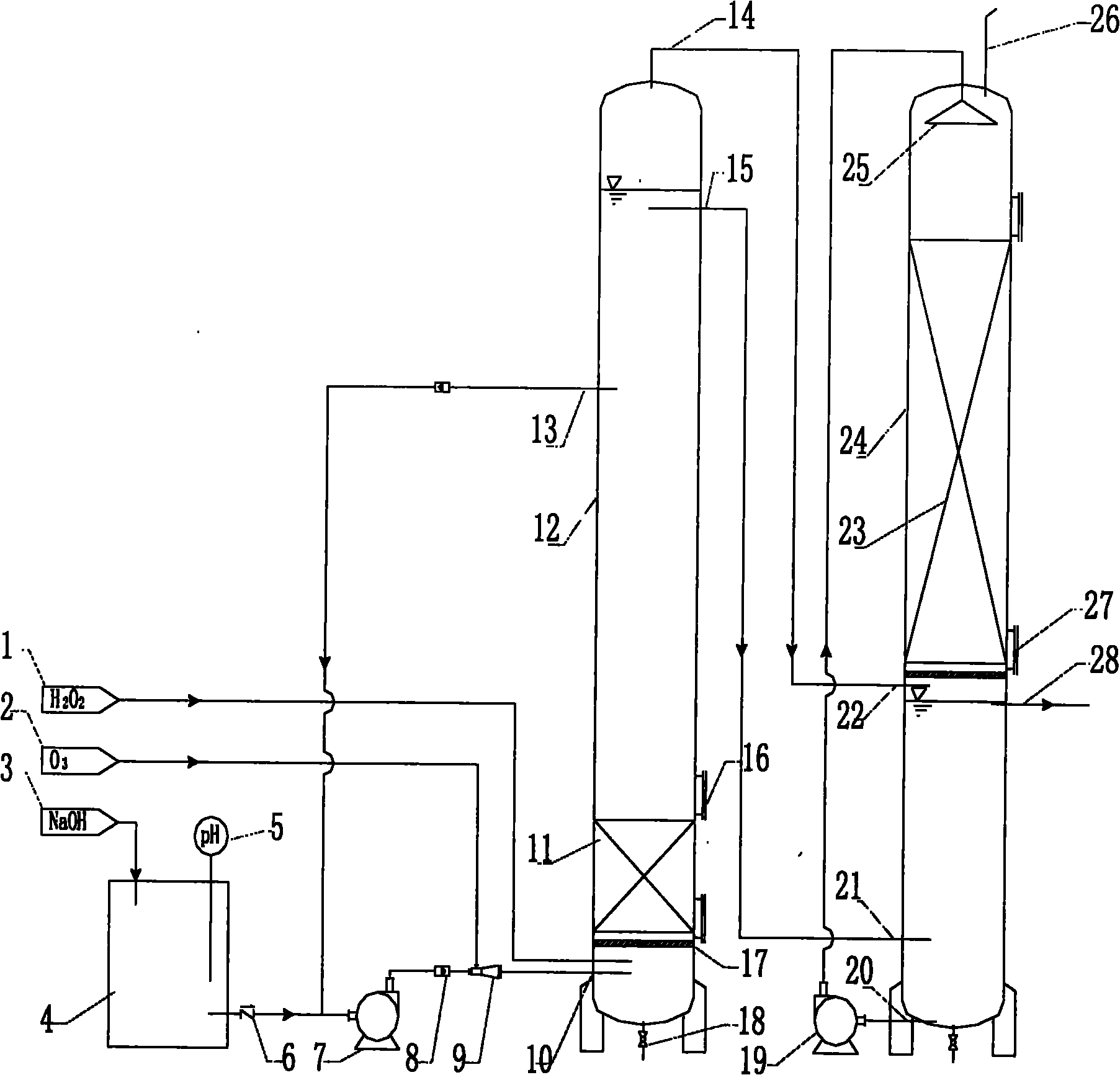

Method used

Image

Examples

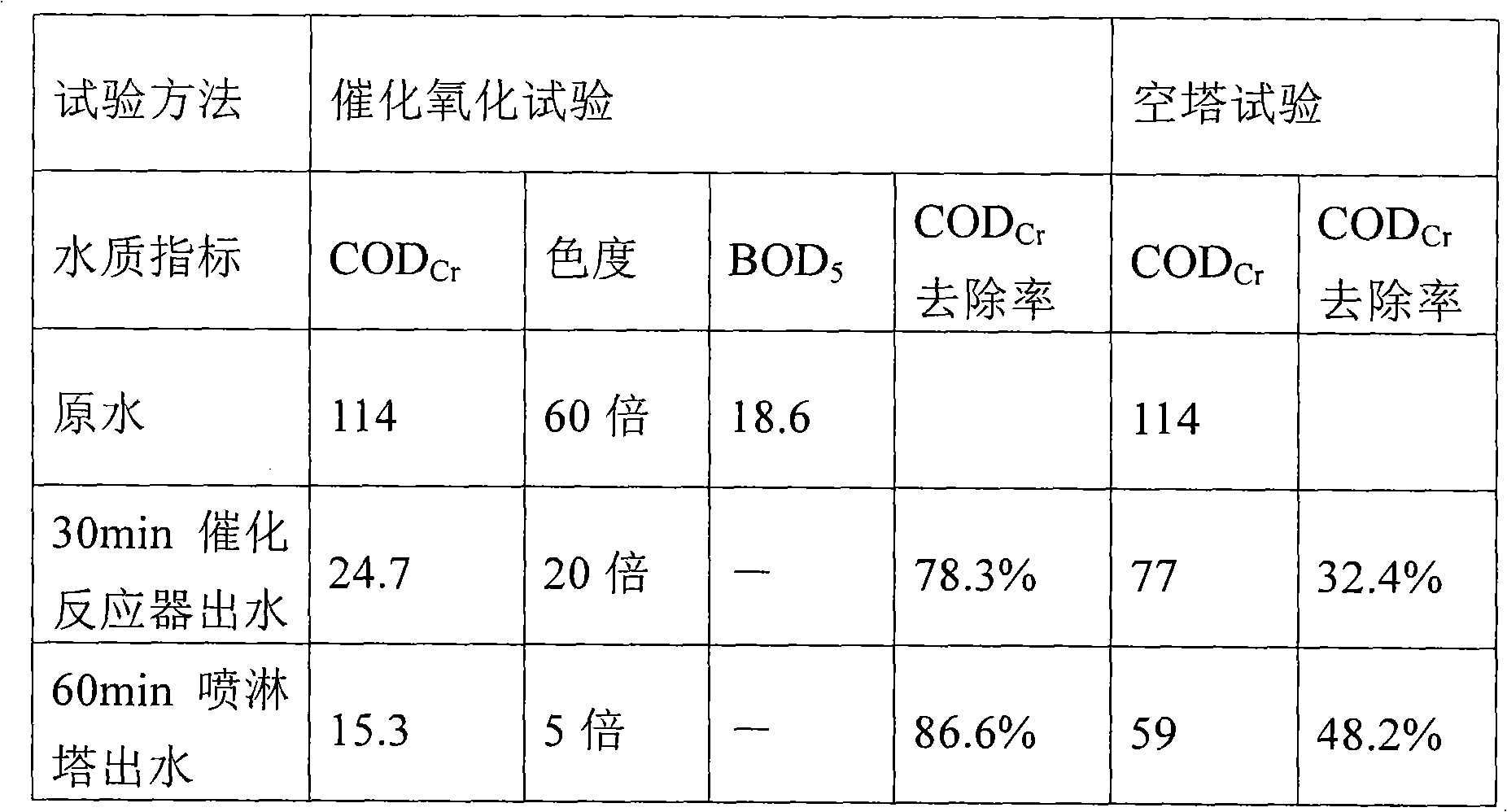

Embodiment 1

[0057] Using the effluent from the biochemical sedimentation tank of a printing and dyeing wastewater treatment plant as the water to be treated, the ozone catalytic oxidation treatment was carried out under the following reaction conditions, and a comparison test was carried out with the empty tower without catalyst under the same conditions:

[0058] Take 100L of wastewater, under normal pressure, the water temperature is 27°C, use 8% NaOH solution to control the pH value at 10.0±0.3, and pump it into the reactor continuously and quantitatively, the wastewater flow rate is 0.5L / min, and the circulation flow rate is 2.0L / min; 30% The dosage of hydrogen peroxide is 3mg / L, and the dosage of ozone is 3g / H;

[0059] The size of the catalytic reactor is 2.0 meters high, the inner diameter is 0.1 meters, the effective volume is 14L, the wastewater residence time is 28min, the catalyst is copper and iron composite metal oxide, and the carrier is volcanic rock.

[0060] The size of t...

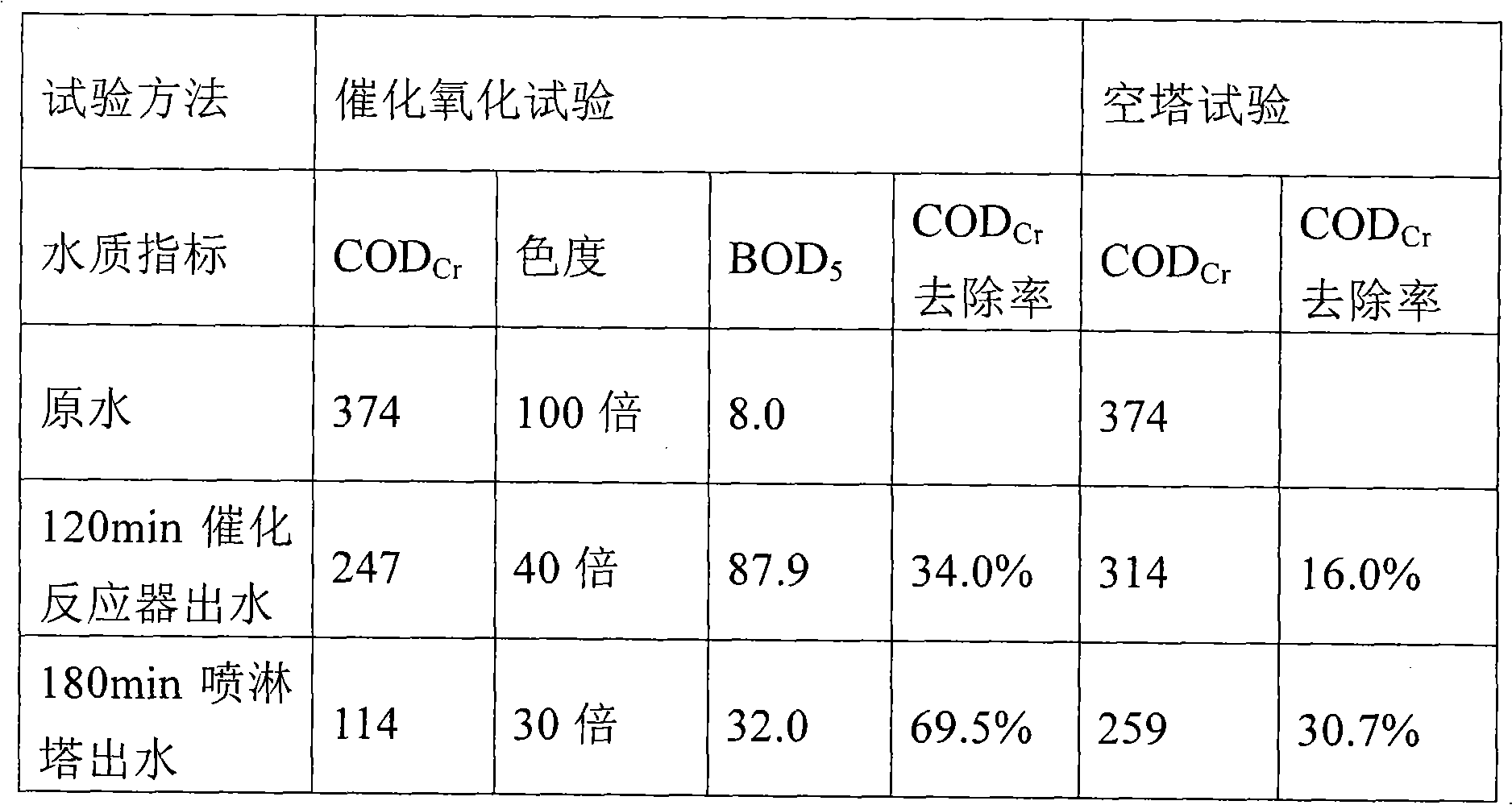

Embodiment 2

[0066]Using the effluent of coal gasification wastewater biochemical MBR (membrane bioreactor) as the water to be treated, the ozone catalytic oxidation treatment and the comparison test with the empty tower without catalyst were carried out under the following reaction conditions:

[0067] Take 200L of wastewater under normal temperature and pressure, use 8% NaOH solution to control the pH value at 10.0±0.3, and pump it into the reactor continuously and quantitatively, the wastewater flow rate is 0.2L / min, the circulation flow rate is 2.4L / min; the dosage of 30% hydrogen peroxide is 5mg / L, the dosage of ozone is 5g / H.

[0068] The size of the catalytic reactor is 2.0 meters high, the inner diameter is 0.1 meters, the effective volume is 14L, the wastewater residence time is 70min, the catalyst is copper and iron composite metal oxide, and the carrier is volcanic rock;

[0069] The size of the spray tower is 2.0 meters high, the inner diameter is 0.1 meters, and the second ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com