Electrode capable of reversing polarity, and application thereof

A polarity reversal and electrode technology, applied in the field of electrochemistry, can solve problems such as large chlorine gas and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

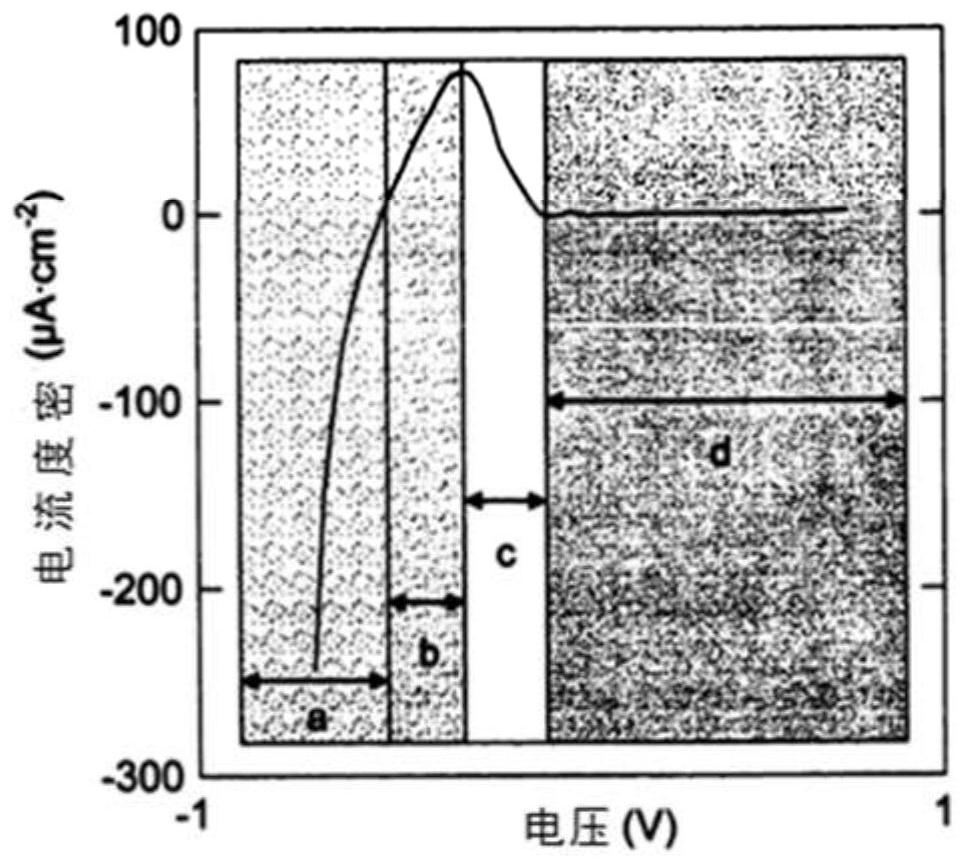

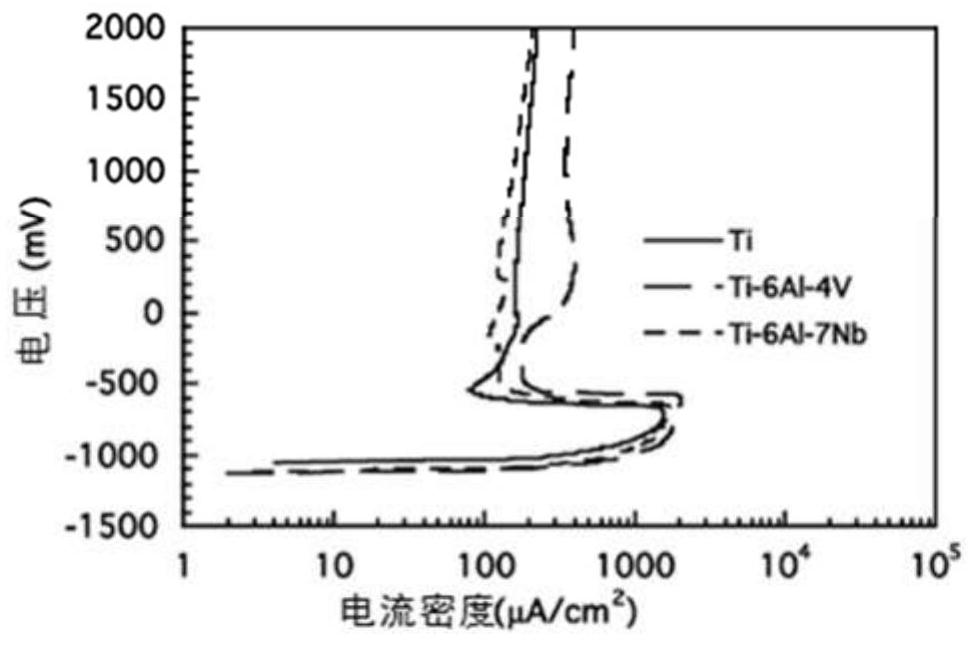

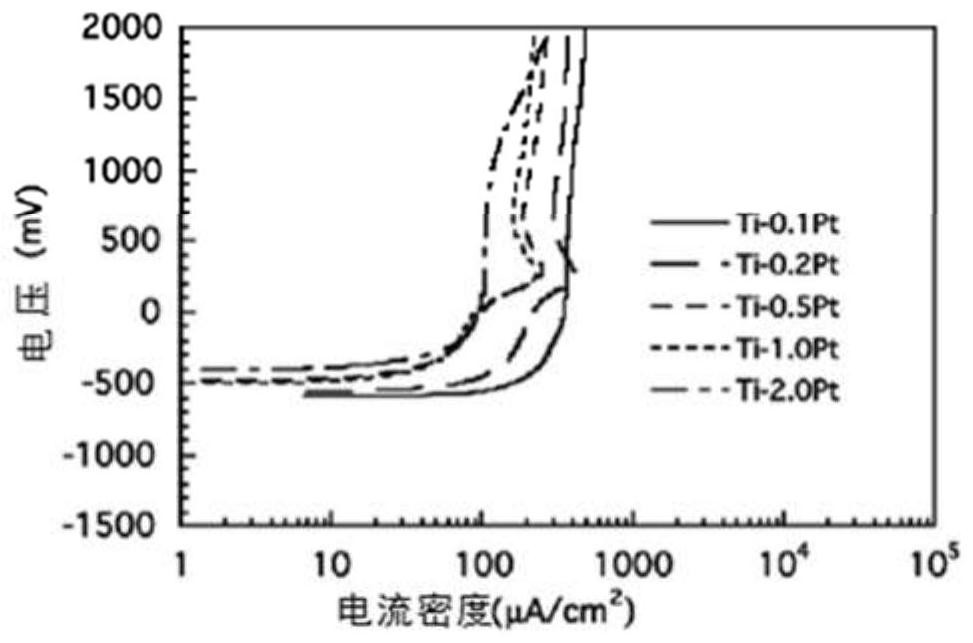

Image

Examples

Embodiment 1

[0048] TA1 grade industrial pure titanium was used as the substrate, after heat treatment at 500°C for 1 hour, etched in 30.0wt% sulfuric acid at 90°C for 4 hours, cleaned in ultrapure water with an ultrasonic device and dried in the air.

[0049] The middle layer coating solution is configured as a hydrochloric acid solution containing chloroiridic acid and chloroplatinic acid. Wherein, in terms of metal content, the mass ratio of platinum:iridium is 8:2, the platinum content is 4.8wt%, and the HCl concentration is 10.0wt% (added with saturated hydrochloric acid). Coating the intermediate layer coating solution on the metal titanium substrate by thermal decomposition method 4 times (each coating, in terms of metal content, the total amount of platinum and iridium is 1.0g / m 2 ), thermal decomposition at 500°C for 20 minutes after each coating, to obtain an intermediate layer containing metal platinum and iridium dioxide. In terms of metal content, the total amount of platinum...

Embodiment 2

[0071] TA1 grade industrial pure titanium was used as the substrate, after heat treatment at 500°C for 1 hour, etched in 30.0wt% sulfuric acid at 90°C for 4 hours, cleaned in ultrapure water with an ultrasonic device and dried in the air.

[0072] The middle layer coating solution is configured as n-butanol solution containing chloroiridic acid and chloroplatinic acid. Wherein, in terms of metal content, the mass ratio of platinum: iridium is 7:3, the platinum content is 4.2wt%, the HCl concentration is 2.0wt% (added with saturated hydrochloric acid), and the remaining components are n-butanol. Coating the intermediate layer coating solution 8 times on the metal titanium substrate by the thermal decomposition method (each coating, in terms of metal content, the total amount of platinum and iridium is 1.25g / m 2 ), thermal decomposition at 500°C for 20 minutes after each coating, to obtain an intermediate layer containing metal platinum and iridium dioxide. In terms of metal co...

Embodiment 3

[0091] Use TA1 grade industrial pure titanium as the substrate, heat treatment at 500°C for 1 hour, place in 7.5wt% oxalic acid at 90°C for etching for 1 hour, cool down to 80°C and continue etching for 12 hours. Wash in ultrapure water using a sonication device and allow to dry.

[0092] The middle layer coating solution is configured as n-butanol solution containing chloroiridic acid and chloroplatinic acid. Wherein, in terms of metal content, the mass ratio of platinum: iridium is 5:5, the platinum content is 3.0wt%, the concentration of hydrochloric acid is 2.0wt% (added with saturated hydrochloric acid), and the remaining components are n-butanol. Coating the intermediate layer coating solution on the metal titanium substrate by thermal decomposition method 2 times (each coating, in terms of metal content, the total amount of platinum and iridium is 1.0g / m 2 ), thermal decomposition at 500°C for 20 minutes after each coating, to obtain an intermediate layer containing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com