Hydraulic lifting and descending belt conveyor

A belt conveyor, hydraulic lifting technology, applied in the direction of conveyor objects, transportation and packaging, support frame, etc., can solve the problems of only loading or unloading car skins, not being able to carry out at the same time, impact on loading and unloading efficiency, etc., to achieve convenient goods. The effect of transportation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

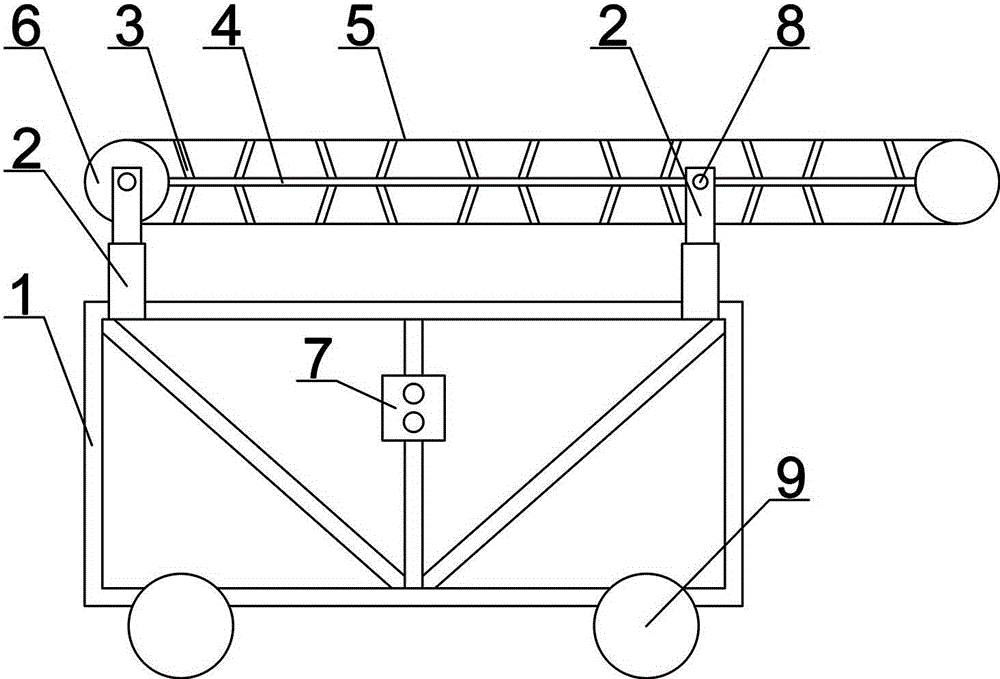

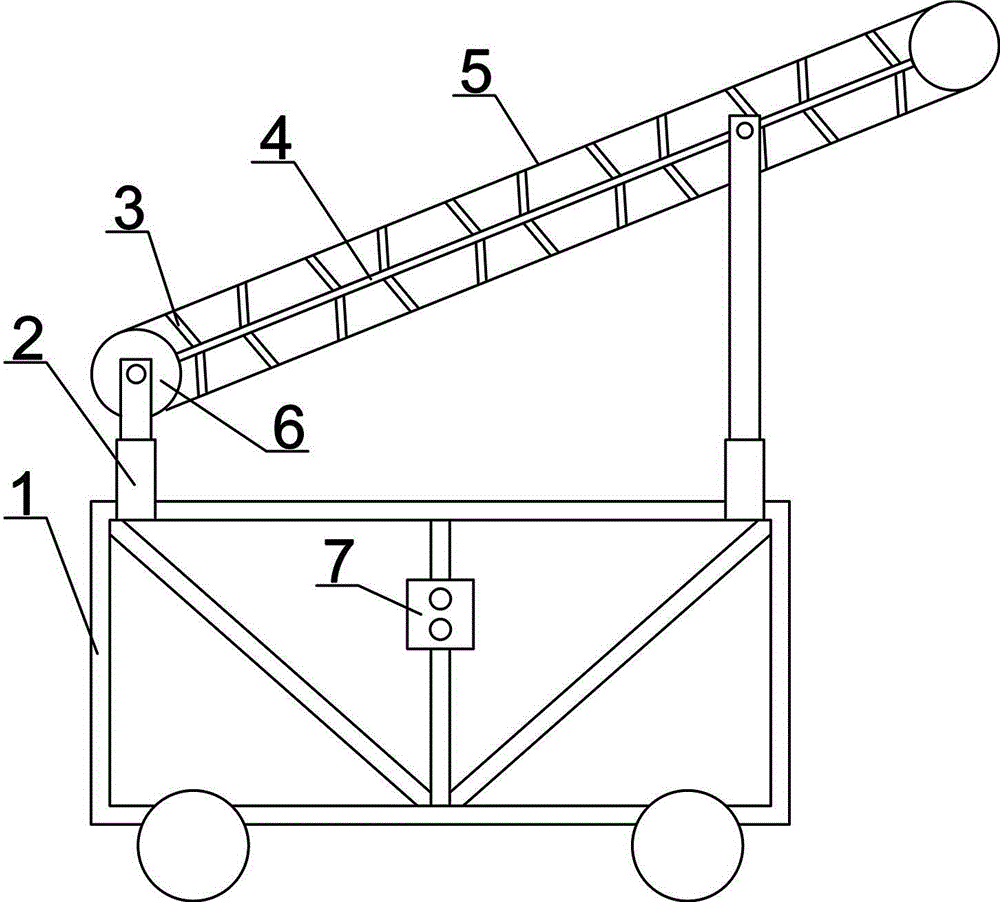

[0013] As shown in the figure, a hydraulic lifting belt conveyor includes a vehicle frame 1, a first hydraulic strut 2, a second hydraulic strut 2', and a belt 5. The vehicle frame 1 is provided with the first hydraulic strut 2 and the second hydraulic strut. The hydraulic strut 2', the first hydraulic strut 2 and the second hydraulic strut 2' are connected with a belt support 3, and a belt 5 is arranged on the belt support 3.

[0014] In a preferred solution, the belt bracket 3 is provided with a guide rail 4 parallel to the surface of the belt 5, the first hydraulic strut 2 is hingedly connected to the center of the runner 6 at one end of the belt bracket 3, and the top of the second hydraulic strut 2' A horizontal slide bar 8 is hingedly provided, and the slide bar 8 is arranged on the guide rail 4 and the slide bar 8 can slide in the guide rail 4 . By adopting the above structure, the height and inclination of the belt can be adjusted to meet the requirements of various wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com