ZG-SY09MnCrNiMo RE steel and method for manufacturing casting of ZG-SY09MnCrNiMo RE steel

A steel casting and casting technology, which is applied in the field of ZG-SY09MnCrNiMoRE steel casting preparation, can solve the problems of low strength and rigidity, difficulty in meeting the performance requirements of low-carbon engineering structural steel, and low C element, so as to reduce production costs and improve strength , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0057] The final composition of embodiment 5) corresponds to Table 2-1 to Table 2-5 respectively;

[0058] Table 2-1, the final composition table (element mass content, %) of the embodiment of the present invention 1

[0059] C Si mn S P Cr 0.07 0.25 1.29 0.009 0.01 0.58 Ni Mo Ti Nb B 0.48 0.35 0.01 0.04 0 N: 70ppm H: 2.5ppm O: 50ppm

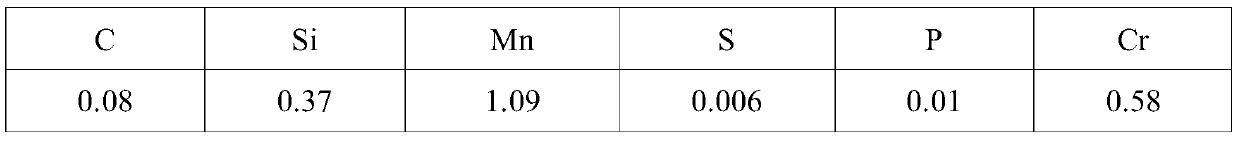

[0060] Table 2-2, the final composition table (element mass content, %) of the embodiment of the present invention 2

[0061] C Si mn S P Cr 0.08 0.28 1.06 0.009 0.012 0.51 Ni Mo Ti Nb B 0.45 0.36 0.012 0.046 0 N: 69ppm H: 2.0ppm O: 45ppm

[0062] Table 2-3, the final composition list (element mass content, %) of the embodiment of the present invention 3

[0063]

[0064]

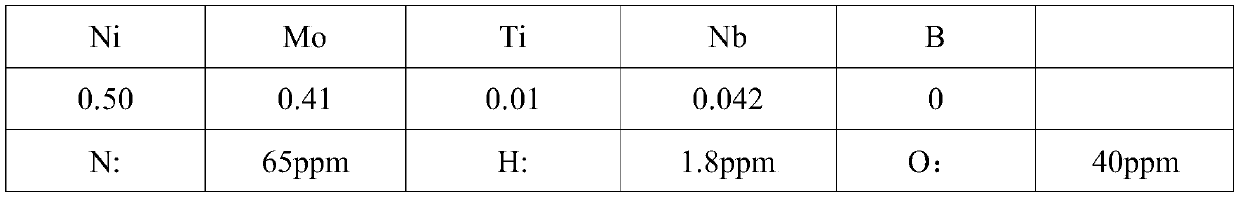

[0065] Table 2-4, the final composition table (element mass content, %) of the embodiment of the present invention 4

[0066] C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com