High-speed airflow through type air-cooled heat dissipation airborne antenna

A high-speed airflow and through-type technology, which is applied to antennas, antenna parts, antennas suitable for movable objects, etc., can solve the problems of difficult air inlet design and high antenna protection requirements, and meet the requirements of the working environment of the equipment, good Environmental adaptability and high ability to resist harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

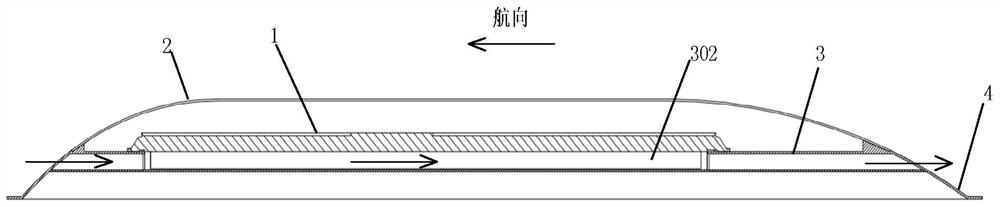

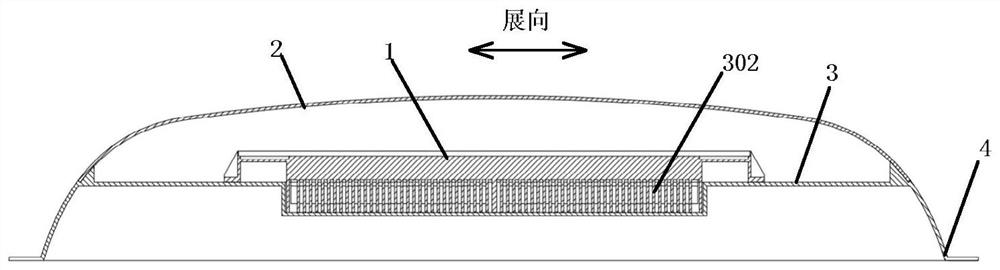

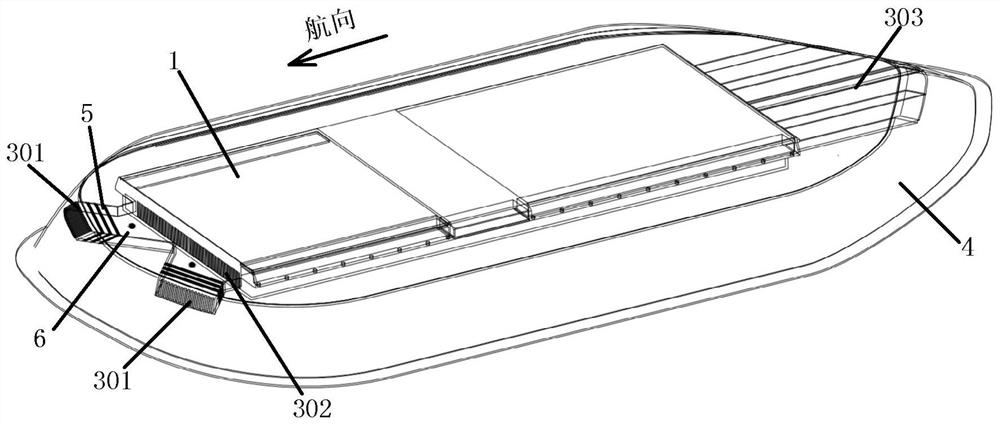

[0019] refer to Figure 1-Figure 4. In the preferred embodiment described below, a high-speed air-cooled airflow heat dissipation airborne antenna includes: an antenna body 1, a radome 2 and a fairing 4 that surround the enclosed space for protecting the antenna with the aircraft skin, and the antenna body 1 is carried The carrier board 3, and the heating resistance wire 5 and the wind speed sensor 6 distributed in the air inlet area 201 are characterized in that: the fairing 4 and the radome 2 form a closed space for protecting the antenna body 1, and the fairing 4 passes through The outer wall ring of the carrier board 3 is connected to the radome 2 in a smooth transition; the front end of the carrier board 3 is designed with an air intake area 201 along the course, and the antenna body 1 is embedded through the rectangular concave cavity designed in the middle and the exhaust area 202 designed at the rear end. In the position of the rectangular concave cavity of the carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com