Extremely high temperature resistant and adjustable pneumatic loop sealing valve device

A sealing valve and high-temperature-resistant technology, which is applied in the field of chemical engineering, can solve problems such as difficult to meet production needs, difficult selection of materials and structures, and material surge, so as to save materials, facilitate wire-cut processing, and prevent high-temperature oxidation of tungsten. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

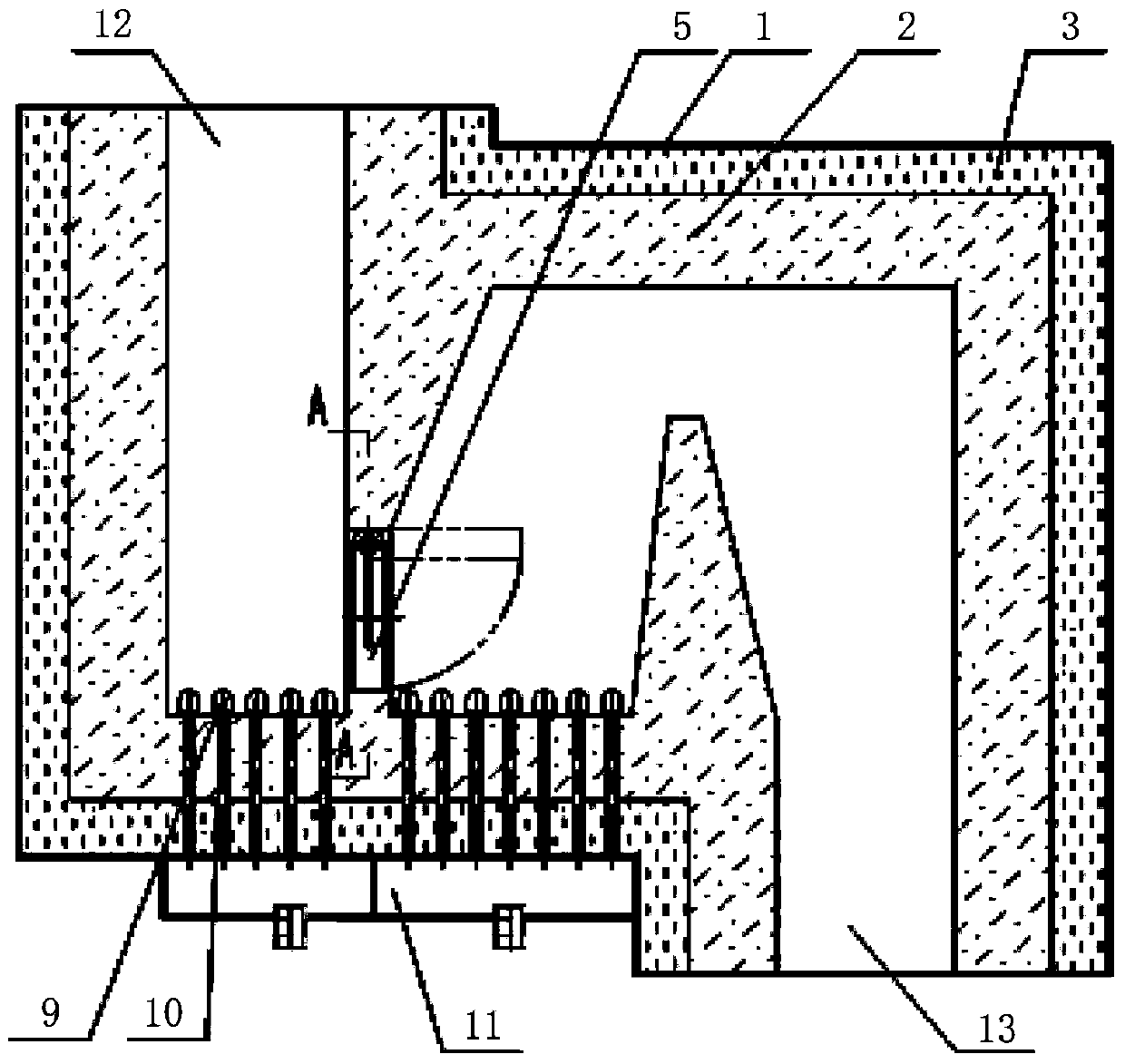

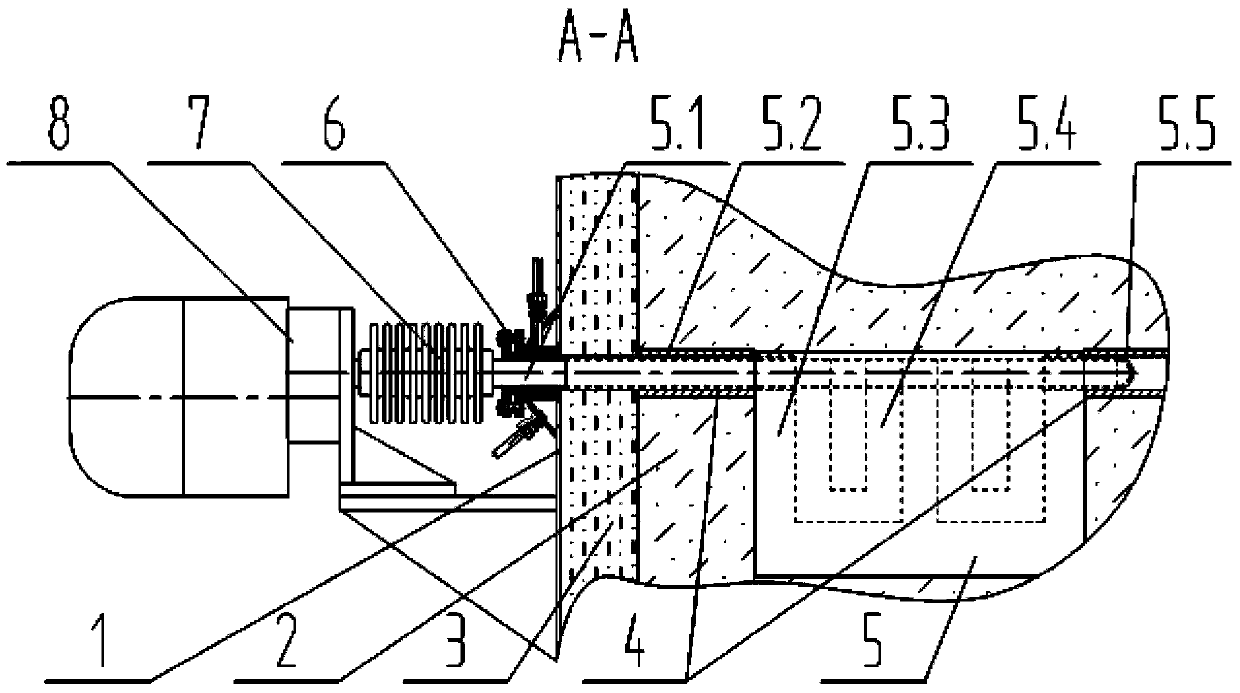

[0024] like figure 1 , figure 2 As shown, an extremely high temperature resistant adjustable loop sealing valve device is provided. The extremely high temperature resistant adjustable loop sealing valve includes: a shell 1, a high temperature resistant lining 2, a high temperature resistant insulation layer 3, and a bearing sleeve 4. Extremely high temperature resistant rotating valve body 5, high temperature dynamic sealing device 6, radiator 7, electric actuator 8, wind cap 9, air duct 10, air chamber 11, material inlet 12 and material discharge outlet 13. The following will refer to figure 1 and figure 2 Describe the fit, fit and connection of the various components.

[0025] The inner wall of the housing 1 is lined with a high-temperature-resistant insulation layer 3, which forms the wall of the sealing valve, and a high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com