Preinstalled transformer substation

A prefabricated substation and cable technology, applied in the field of substations, can solve the problems of inconvenient operation and maintenance of high-voltage rooms, difficulty in heat dissipation of transformer rooms, and high cost of basement construction, and achieves easy installation and electrical connection operations and high waterproof requirements. , The effect of improving the cooling environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

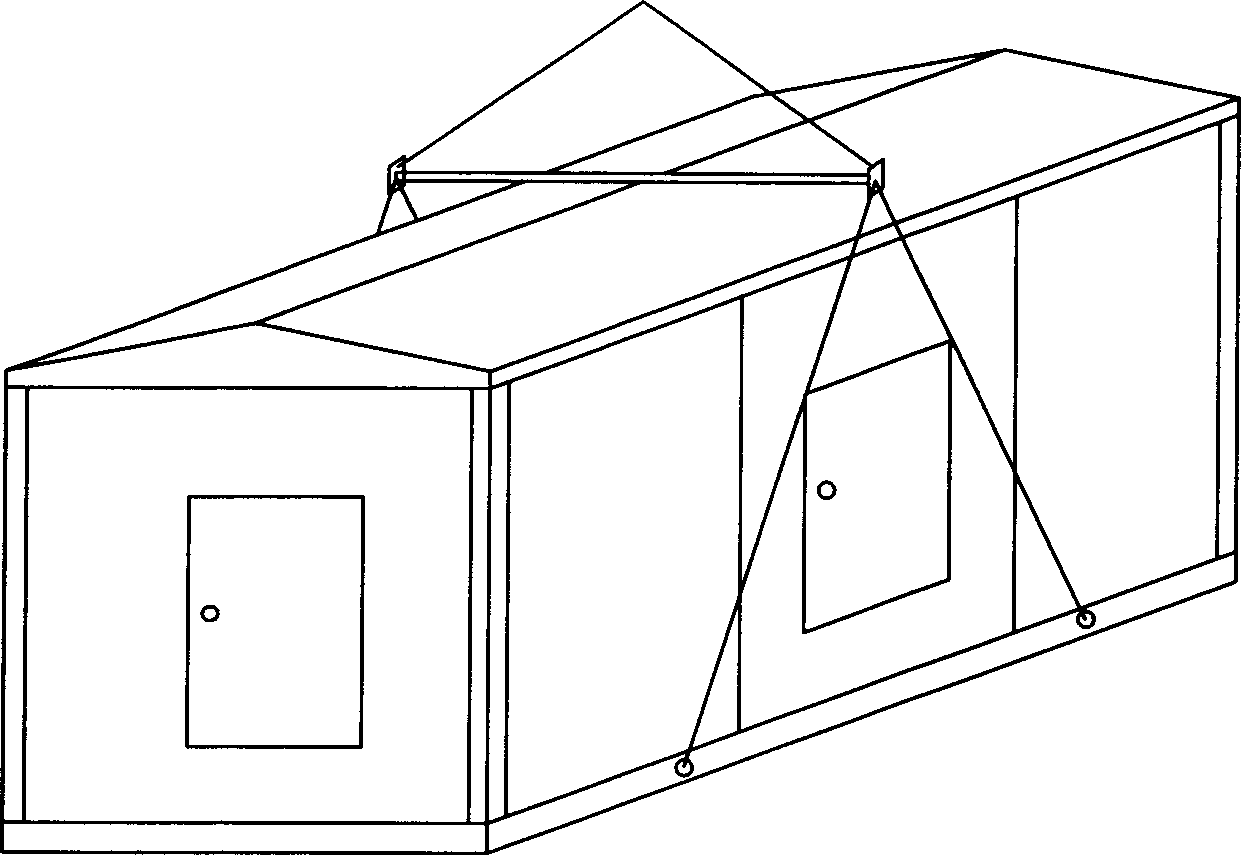

[0024] The specific embodiments of the prefabricated substation of the present invention will be further described below in conjunction with the accompanying drawings.

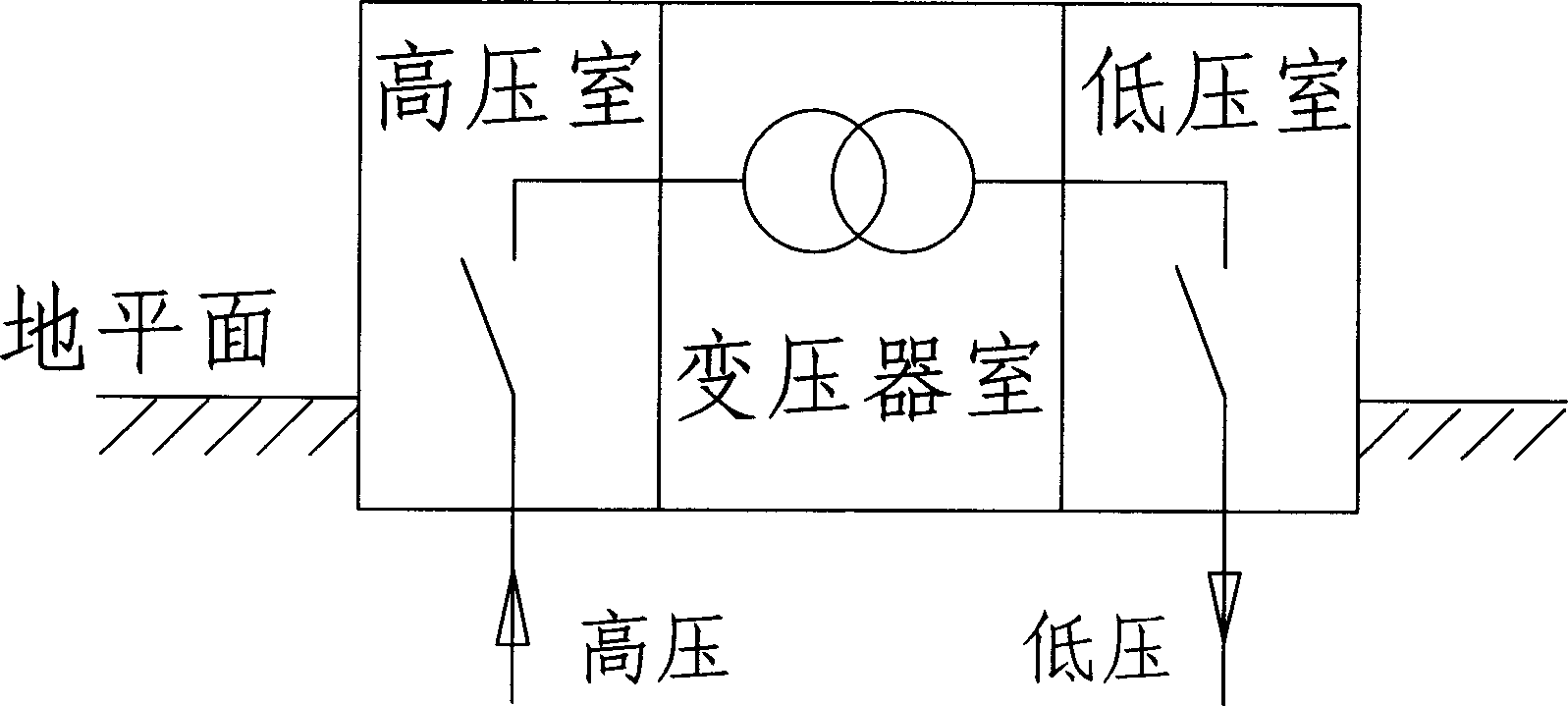

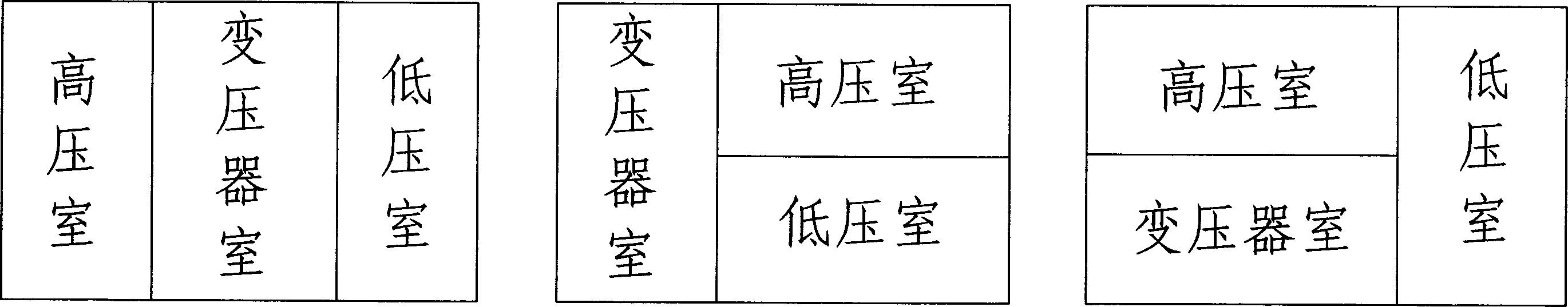

[0025] Such as Figure 4 , 5 As shown in , the prefabricated substation of the present invention includes a high-voltage room 1, a low-voltage room 2, a transformer room 3, a ventilation window 4, and a cable inlet and outlet 5. The high pressure chamber 1 and the low pressure chamber 2 are provided with a door 9 .

[0026] A heat-insulating and fire-proof layer 6 is provided between the high-voltage chamber 1 and the low-voltage chamber 2 and the transformer chamber 3 to prevent the heat emitted by the transformer 14 in the transformer chamber 3 from being uploaded to the high-voltage chamber 1 and the low-voltage chamber 2, thereby affecting the Appliance control. The whole station body is an integral frame structure, including frame 11, high-voltage chamber 1, low-voltage chamber 2, side panels 10 of tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com