Vehicle air conditioning system and condensate water recycling system thereof

A vehicle air conditioner and condensate technology, which is applied in the field of vehicles, can solve the problems of reduced condensate flow, less condensate, and high power consumption of compressors, so as to reduce power consumption, prevent overfilling of water storage, and ensure secondary utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] It should be noted that, in the case of no conflict, the embodiments and features in the embodiments of the present invention can be combined with each other.

[0053] In addition, in the embodiments of the present invention, "electrical connection" is used to describe a signal connection between two components, such as a control signal and a feedback signal, and an electric power connection between two components. In addition, the "communication" involved in the embodiments of the present invention refers to pipeline communication, which may be direct pipeline communication or indirect pipeline communication through other components.

[0054] The present invention will be described in detail below with reference to the drawings and in combination with embodiments.

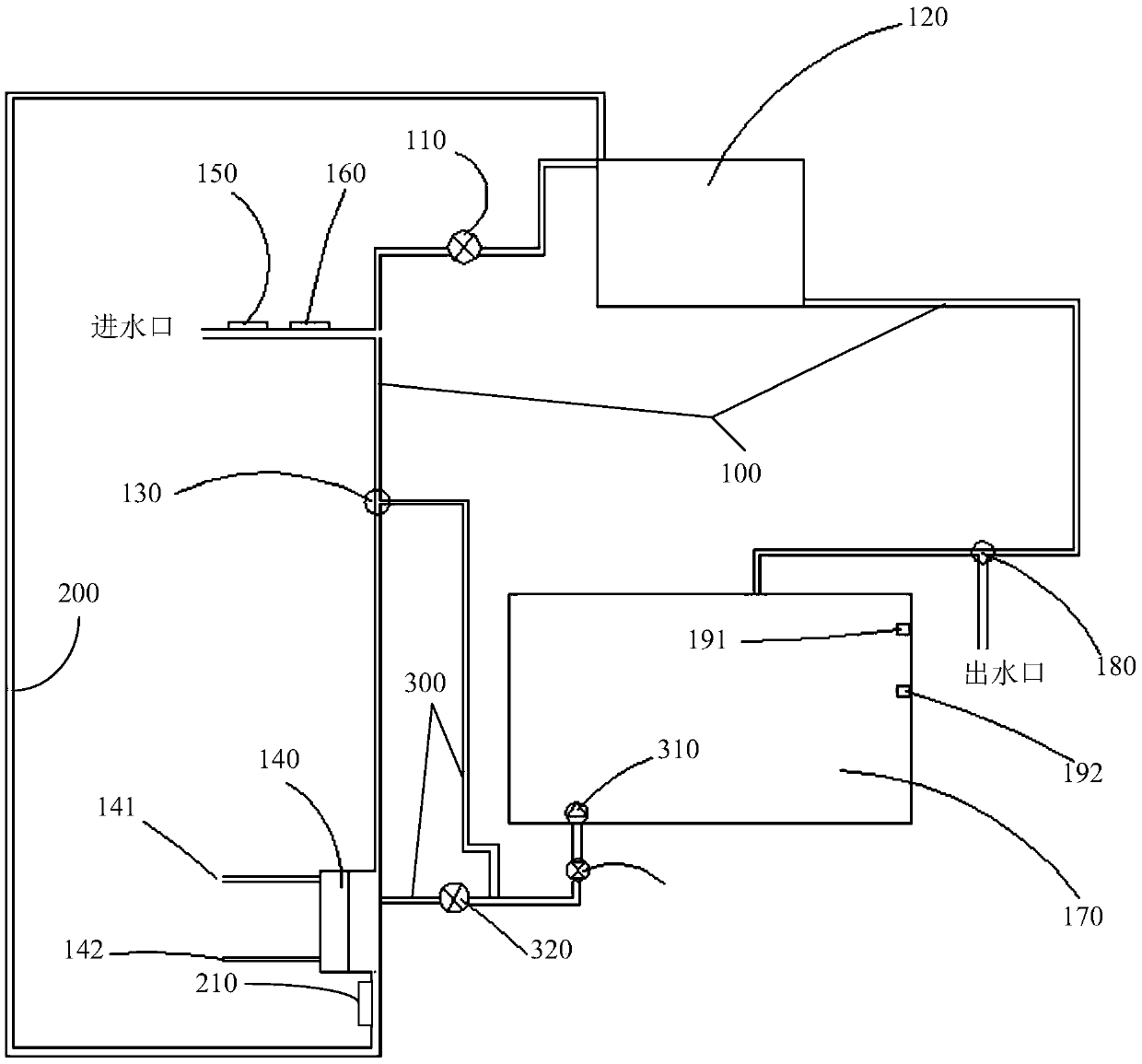

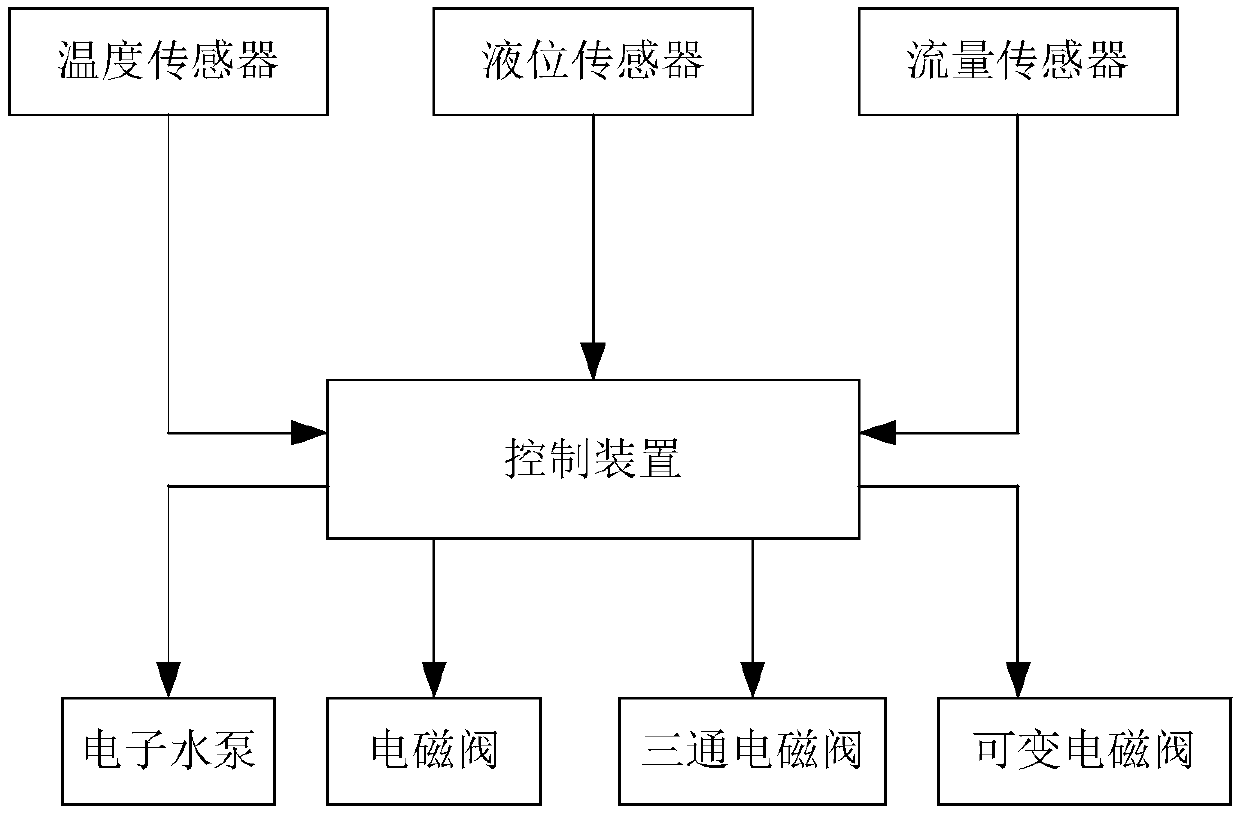

[0055] figure 1 It is a structural schematic diagram of a condensed water reuse system of a vehicle air-conditioning system according to an embodiment of the present invention, wherein the condensed water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com