Aluminum trichloride-immobilized catalyst boiling bed production apparatus and preparation technology thereof

A technology of aluminum trichloride and production device, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes and other directions, and can solve the problem that the catalyst technology is difficult to industrialize production, the product quality cannot be guaranteed, and the hydroxyl group loses the carrier crystal form. and other problems, to achieve the effect of reducing equipment costs and maintenance costs, uniform loading, and uniform heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

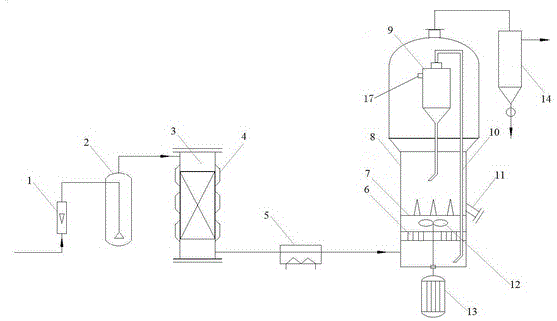

[0016] 0.5 Kg γ-Al was charged into the ebullated bed reactor 2 o 3 (60-80 mesh) carrier, preferably double hole γ-Al 2 o 3 (60-80 mesh), high-purity nitrogen passes through N 2 The flow meter (1) enters the CCl at a flow rate of 0.4 L / min 4 storage tank(2), N 2 carry CCl 4 Gas, piped into AlCl 3 generator (3). AlCl 3 The generator (3) is filled with γ-Al 2 o 3 1.0 Kg, by jacket in AlCl 3 An inductive heater (4) on the generator (3) controls the AlCl 3 The reaction temperature in the generator (3) reaches 450 o c. CCl 4 with Al 2 o 3 The reaction produces AlCl 3 The gas, after being cooled by the condenser (5), enters the bottom of the ebullated bed reactor (8), and the temperature of the thermostat (6) at the bottom of the ebullated bed reactor (8) is controlled at 300 o c.

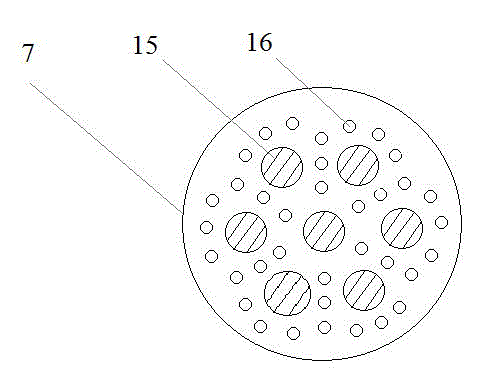

[0017] The airflow generated by the motor (13) driving the impeller (12) to rotate at a high speed 3 The gas passes through the thermostat (6) and the cone sieve compound distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com