Method for preparing high-content alpha-lauryl betaine by solvent-free quaternization

A high-content alkyl betaine technology, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, can solve problems such as difficult to increase the concentration of reaction materials and mass transfer and heat transfer, and achieve simplified purification processes, The effect of cost reduction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

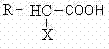

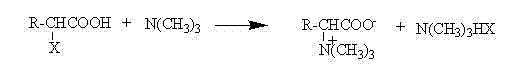

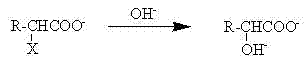

Method used

Image

Examples

Embodiment 1

[0024] The synthesis of embodiment 1 α-butyl betaine

[0025] In an autoclave reaction kettle with a stirring and temperature control system, add 0.1 mol α-chlorocaproic acid and 1.0 mol liquid trimethylamine in sequence, and stir and autoclave at 70 °C for 10 h, evaporate and recover trimethylamine and By recycling, the solid product of α-butyl betaine is obtained, the yield is 89.4%, and the mass percentage of α-butyl betaine in the product reaches 60.5%.

Embodiment 2

[0026] The synthesis of embodiment 2 α-decyl betaine

[0027] In the autoclave reaction kettle with stirring and temperature control system, add 0.1 mol α-chlorododecanoic acid, 0.5 mol liquid trimethylamine in sequence, in the autoclave reaction kettle with stirring and temperature control system, at 90 After constant temperature stirring and autoclaving at ℃ for 6 h, trimethylamine was recovered by evaporation and recycled to obtain a solid product. The product content was analyzed by high performance liquid chromatography external standard method, and the yield of α-decyl betaine was 56.7%.

[0028] The crude product was purified to obtain pure α-decyl betaine crystals, which were characterized by spectroscopy. The experimental results show that the carbonyl group in the IR spectrum is at 1624cm -1 There is strong absorption at the wave number; with D 2 O is the solvent, D 2 O (δ=4.70 ppm) is the internal standard 1 In the H NMR spectrum, the chemical shifts are δ? 0.7...

Embodiment 3

[0029] The synthesis of embodiment 3 α-dodecyl betaine

[0030] In an autoclave reaction kettle with a stirring and temperature control system, add 0.1 mol α-bromotetradecanoic acid and 0.8 mol liquid trimethylamine in sequence, raise the temperature to 100°C, stir and react at constant temperature for 8 hours, evaporate and recover trimethylamine and circulate Utilize, utilize the high-performance liquid chromatography external standard method to carry out product content analysis, the yield of α-dodecyl betaine reaches 86.2%, and there is no α-hydroxytetradecanoic acid generation in the product; Gained product adds ethanol and desalts through hot filtration, Then the ethanol is evaporated and recovered, and the content of α-dodecyl betaine in the obtained solid product is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com