Heat conduction powder/monomer cast nylon nanometer composite material, method for preparing same and application of heat conduction powder/monomer cast nylon nanometer composite material

A technology of nanocomposite materials and cast nylon, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor thermal conductivity, achieve good thermal stability, improve mechanical properties and thermal conductivity, and low water absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

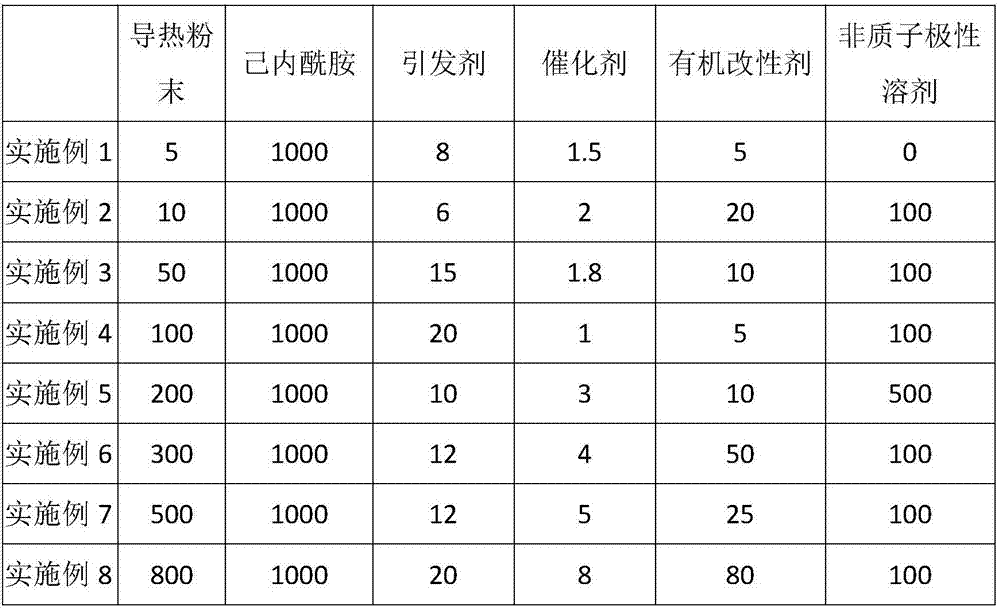

[0047] The ratio of raw materials in Table 1 is selected, and the heat-conducting powder is silicon dioxide.

[0048] S1. Add the heat-conducting powder, aprotic polar solvent and organic modifier according to the above proportions into the kettle A containing caprolactam monomer 1, adjust the temperature of the kettle A to 70-85°C, and carry out the stirring reaction for 0.5 ~ 2h;

[0049] S2. Warm up the kettle A in step S1 to 130-140° C., and vacuumize for 15-60 minutes under a certain degree of vacuum. The vacuum degree of the vacuum-evacuation is 99000-99997 Pa; then add an initiator to react in a vacuum for 15-30 minutes;

[0050] S3. Put the caprolactam monomer 2 into the kettle B, heat until the caprolactam monomer 2 melts and start vacuuming, the caprolactam monomer 2 is completely melted, add the catalyst and heat up to 130-140°C, and continue vacuuming for 10-15 minutes;

[0051] S4. After mixing the materials obtained in kettle A and kettle B, pour them into a mol...

Embodiment 2

[0054] This embodiment selects the ratio of raw materials in Table 1, and the difference from Example 1 is that the heat-conducting powder is selected from aluminum nitride. Its preparation method is identical with embodiment 1.

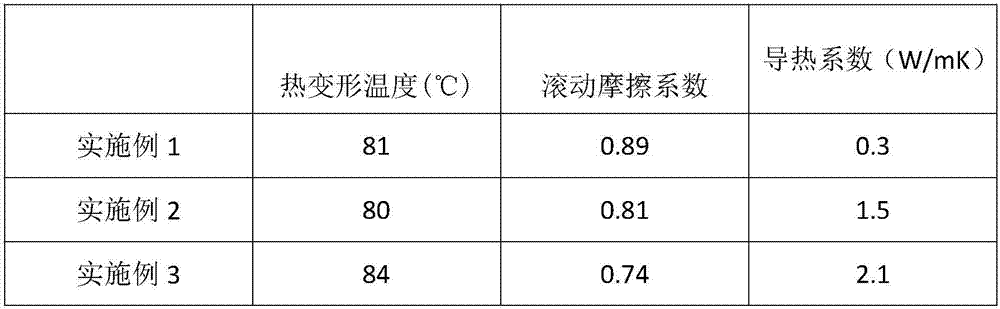

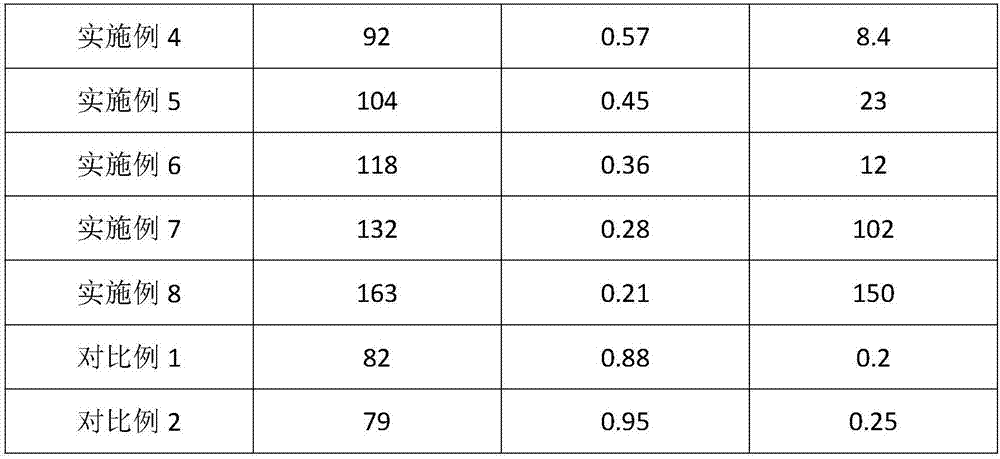

[0055] The properties of the prepared thermally conductive powder / monomer cast nylon nanocomposite are shown in Table 1.

Embodiment 3

[0057] This embodiment selects the ratio of raw materials in Table 1, and the difference from Example 1 is that the heat-conducting powder is selected from aluminum oxide. Its preparation method is identical with embodiment 1.

[0058] The properties of the prepared thermally conductive powder / monomer cast nylon nanocomposite are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com