Device and method for increasing yield of low-carbon olefins

A technology of low-carbon olefins and equipment, applied in the field of high-yield low-carbon olefins, can solve problems such as unsatisfactory heat transfer performance, achieve the effects of improving overall activity and reaction efficiency, improving reaction efficiency, and increasing the yield of low-carbon olefins in the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

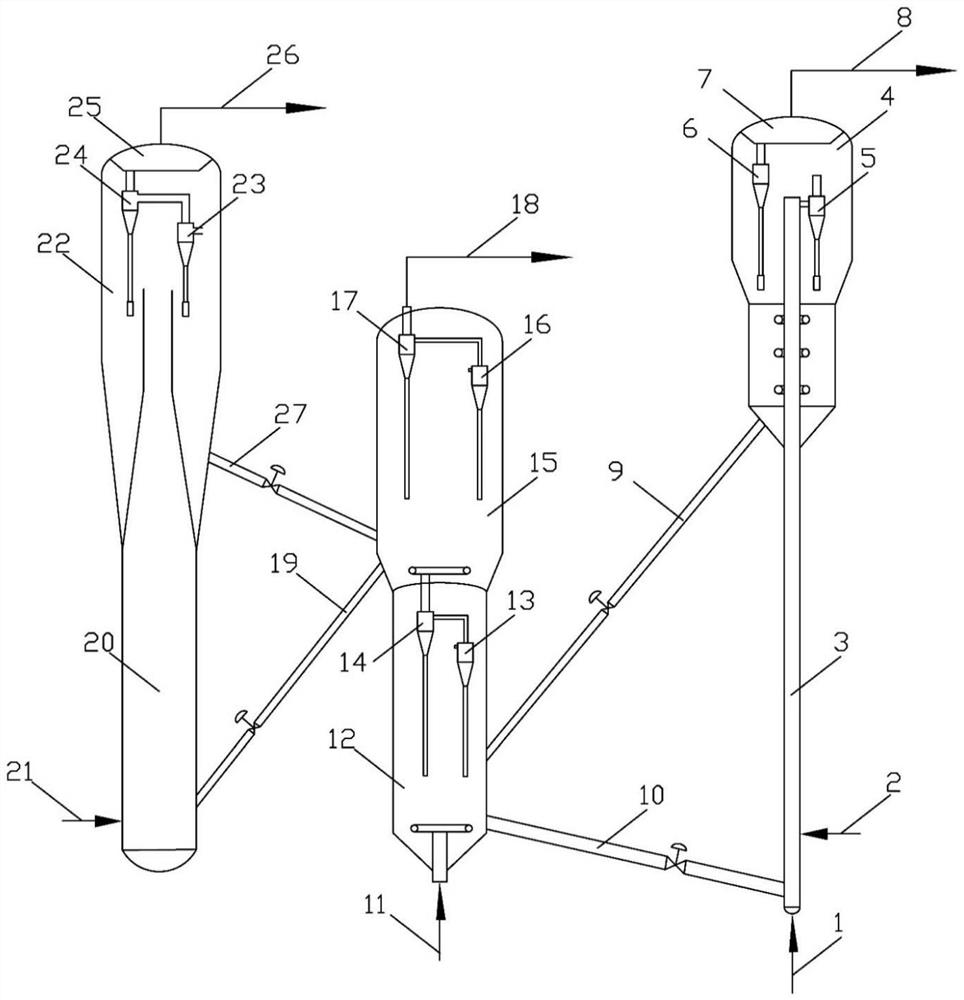

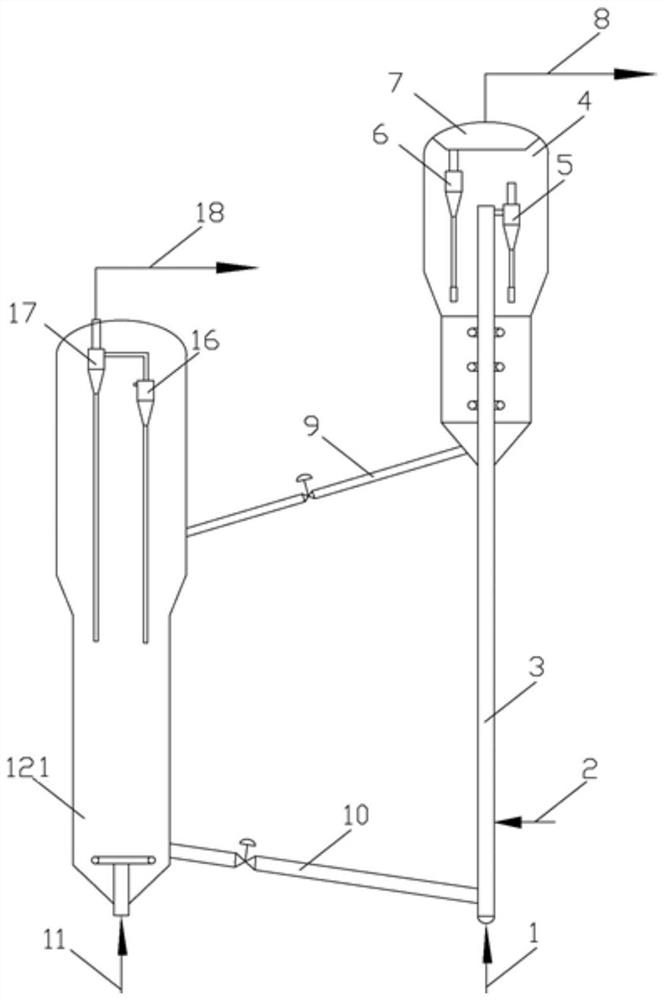

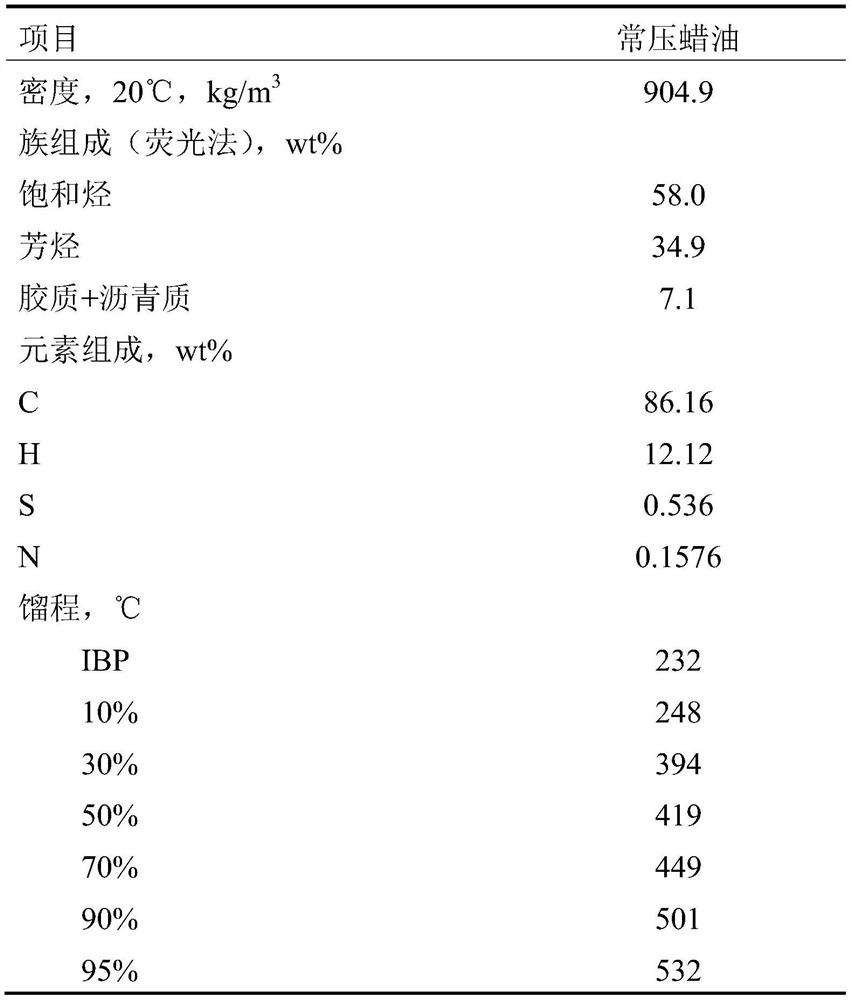

[0109] Such as figure 1 In the device shown, the heavy oil feed is a normal pressure wax oil, and the normal pressure wax oil property is shown in Table 1, the alkane feed is the propane and butane proposed in the apparatus.

[0110] The heavy oil lysis catalyst is a Y-type molecular sieve catalyst, and the catalyst grade can be DFC-1. Alkane dehydrogenation catalyst is in Al 2 O 3 For the carrier, the oxide of the GA element is the active center, and the component is promoted in the active center of the oxide of Zn. 2 O is a catalyst for catalyst acid base regulation components.

[0111] Heavy oil riser reactor 3 processing volume is 1 million tons / year, heavy oil lift tube outlet temperature is 510 ° C, the reaction time is 2.7S, the reaction pressure is 0.2 MPa, the weight ratio of 7; alkane dehydrogenation reactor (flow The bed reactor 20) The amount of processing is 133,200 tons / year, the reaction temperature is 600 ° C, the reaction pressure is 0.05 MPa, and the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com