Multi-tube-row integrated header automatic adjusting dispensing condenser

An automatic adjustment and integrated technology, applied in steam/steam condensers, tubular elements, heat exchanger shells, etc., can solve the constraints of the application range of condensers due to liquid separation technology effects, without considering micro-scale diameter heat exchange tubes, Problems such as the inability of the gas-liquid separator to separate liquid reasonably, to avoid fixing and pipe welding, improve the uniformity of working fluid distribution, and improve the flow and heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

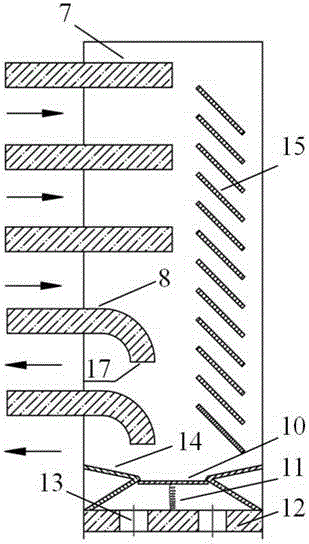

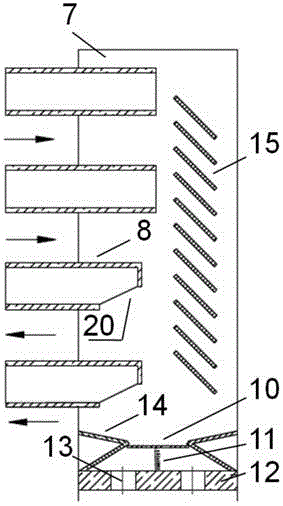

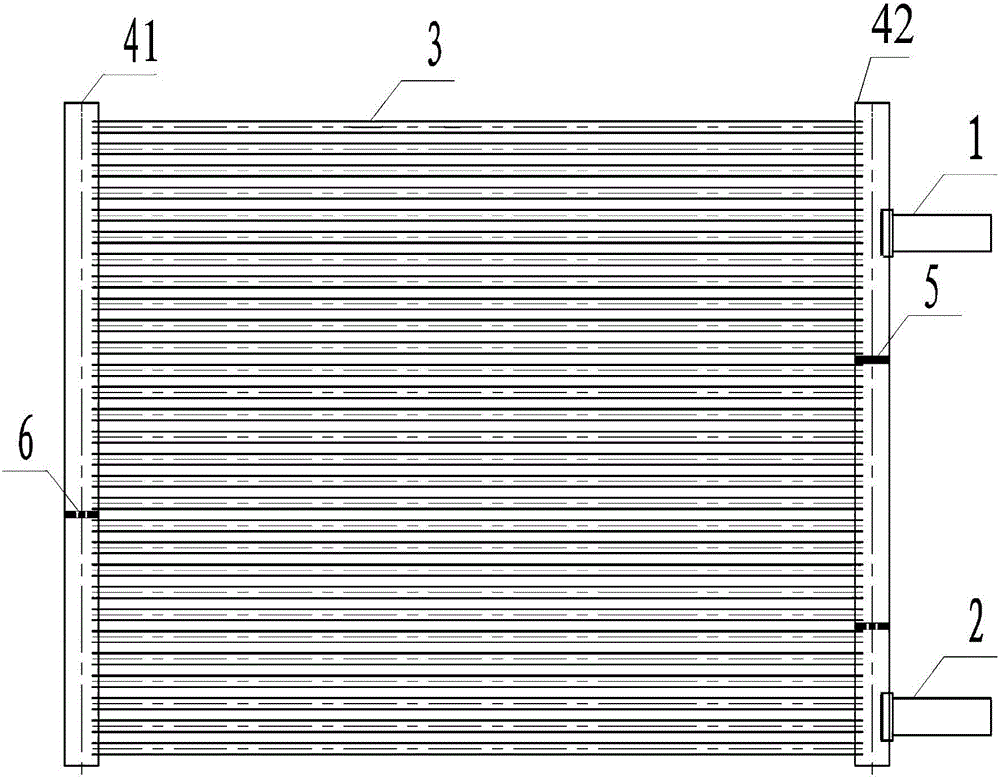

[0028] Multi-pipe row integrated header with automatic adjustment liquid separation condenser, such as Figure 1-5 As shown, it includes a first header 41, a second header 42 and heat exchange tubes 3, and several heat exchange tubes 3 are arranged in parallel between the first header 41 and the second header 42. The inner cavity of the heat exchange tube 3 communicates with the inner cavity of the first header 41 and the second header 42, and the inlet pipe 1 and the outlet pipe 2 are installed on the first header 41 or the second header 42. A partition 5 is arranged in the header (the first header 41 or the second header 42) where the inlet pipe 1 is installed, and a gas-liquid separator 6 is arranged in the first header 41 and the second header 42; The outlet pipe section 8 of the heat exchange tube 3 (at the outlet of the medium) extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com