Method for achieving staggered reverse spinning of pairs of wheels

A technology of reverse spinning and staggered distance, applied in the field of spinning manufacturing, it can solve the problems of deformation instability and unbalanced spinning force, and achieve the effects of consistent deformation rate, avoiding deformation instability and high single-pass deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

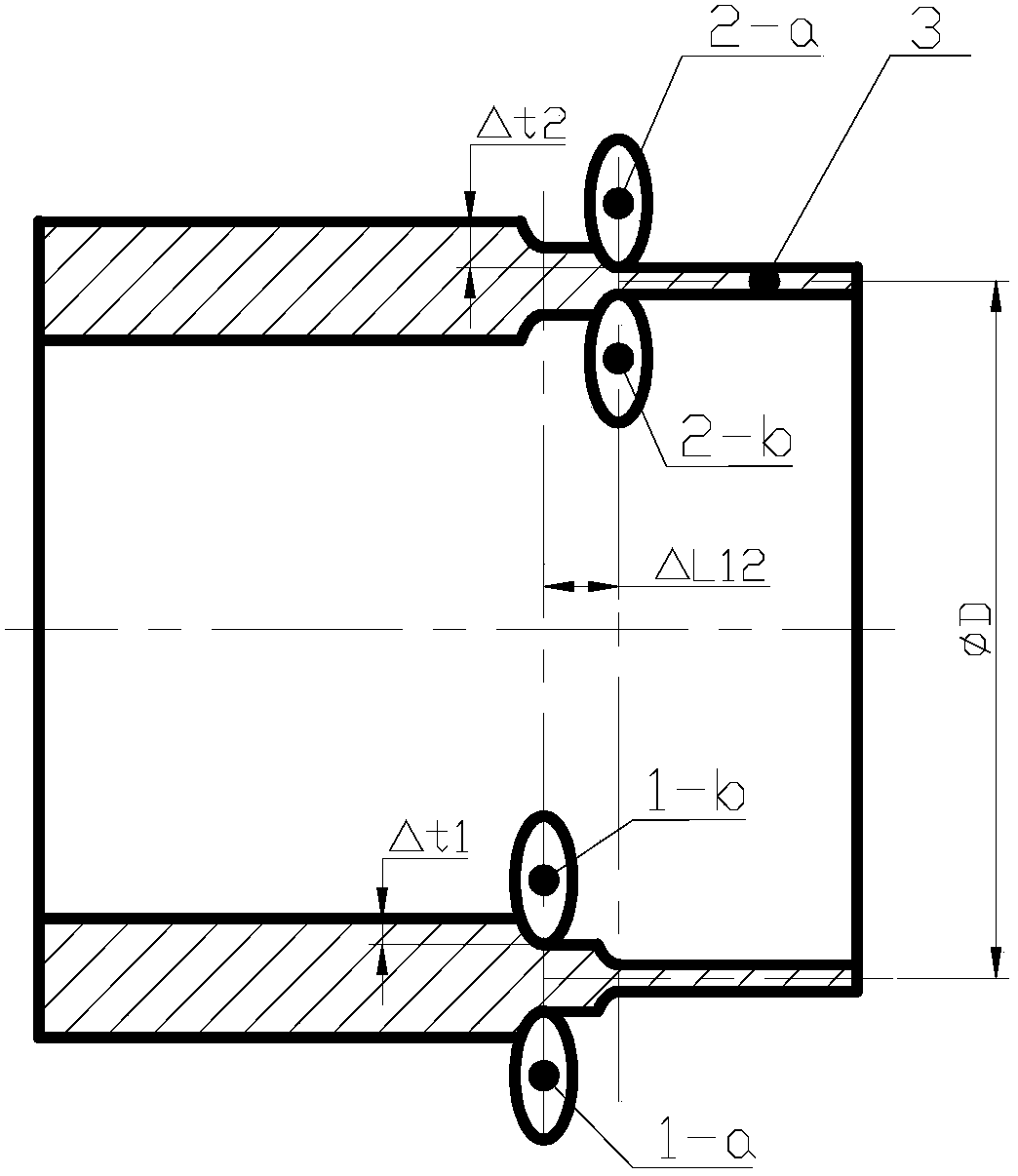

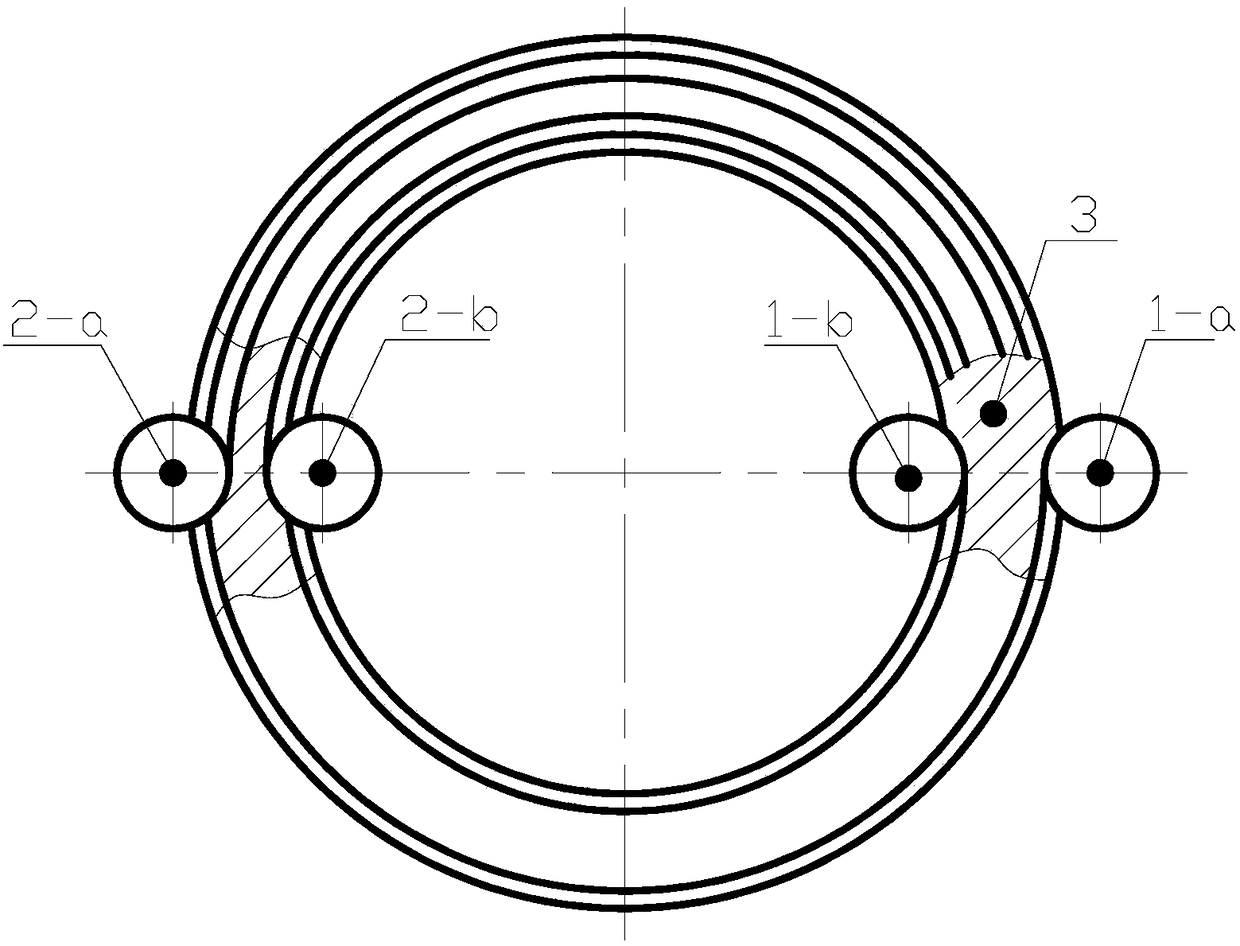

[0064] The staggered pitch spinning of the opposite wheels requires 2 to 4 sets of opposite wheels. n is the number of pairs of wheels, n=2~4

[0065] In this embodiment, two pairs of wheel staggered pitch spinning methods are used to process large-diameter thin-walled cylindrical parts. The concrete process of this embodiment is:

[0066] Step 1: Prepare spinning blank.

[0067] Preparation of spinning blanks for thin-walled cylindrical parts. The spinning blank is a cylindrical part of 3A21 aluminum alloy, and the wall thickness of the blank is t 0 =14mm, inner diameter D=400mm.

[0068] Step 2: Heating the spinning blank.

[0069] Before spinning, place the spinning blank in a circulating box-type heating furnace and heat it to 250°C to make the temperature of the inner and outer layers of the spinning blank uniform. Since a large amount of deformation heat will be generated during the spinning process, in order to avoid defects such as grain growth and instability ca...

Embodiment 2

[0106] In this embodiment, three pairs of wheel staggered pitch spinning methods are used to process large-diameter thin-walled cylindrical parts.

[0107] The concrete process of this embodiment is:

[0108] Step 1: Prepare a spinning blank of a thin-walled cylindrical part.

[0109] Prepare spinning blanks for 20# steel cylinders. Blank wall thickness t 0 =10mm, inner diameter D=450mm;

[0110] Step 2: Heating the spinning blank.

[0111] Before spinning, place the spinning blank in a circulating box-type heating furnace and heat it to 250°C to make the temperature of the inner and outer layers of the spinning blank uniform;

[0112] Step 3: Install the spinning blank.

[0113] During installation, the faceplate of the main shaft of the spinning machine tool is mounted on one end of the spinning blank so that one end of the spinning blank is a fixed end and the other end is a free end. Take the free end as the spin end.

[0114] The spindle speed is set to 120r / min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com