Processing method for balancing moisture in wood

A microwave treatment and wood technology, applied in the direction of heating to dry solid materials, drying solid materials, furnaces, etc., can solve the problems of low efficiency, large capital occupation, material occupation, etc., and achieve high operating efficiency, balanced water distribution, and reduction Effect of Small Drying Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

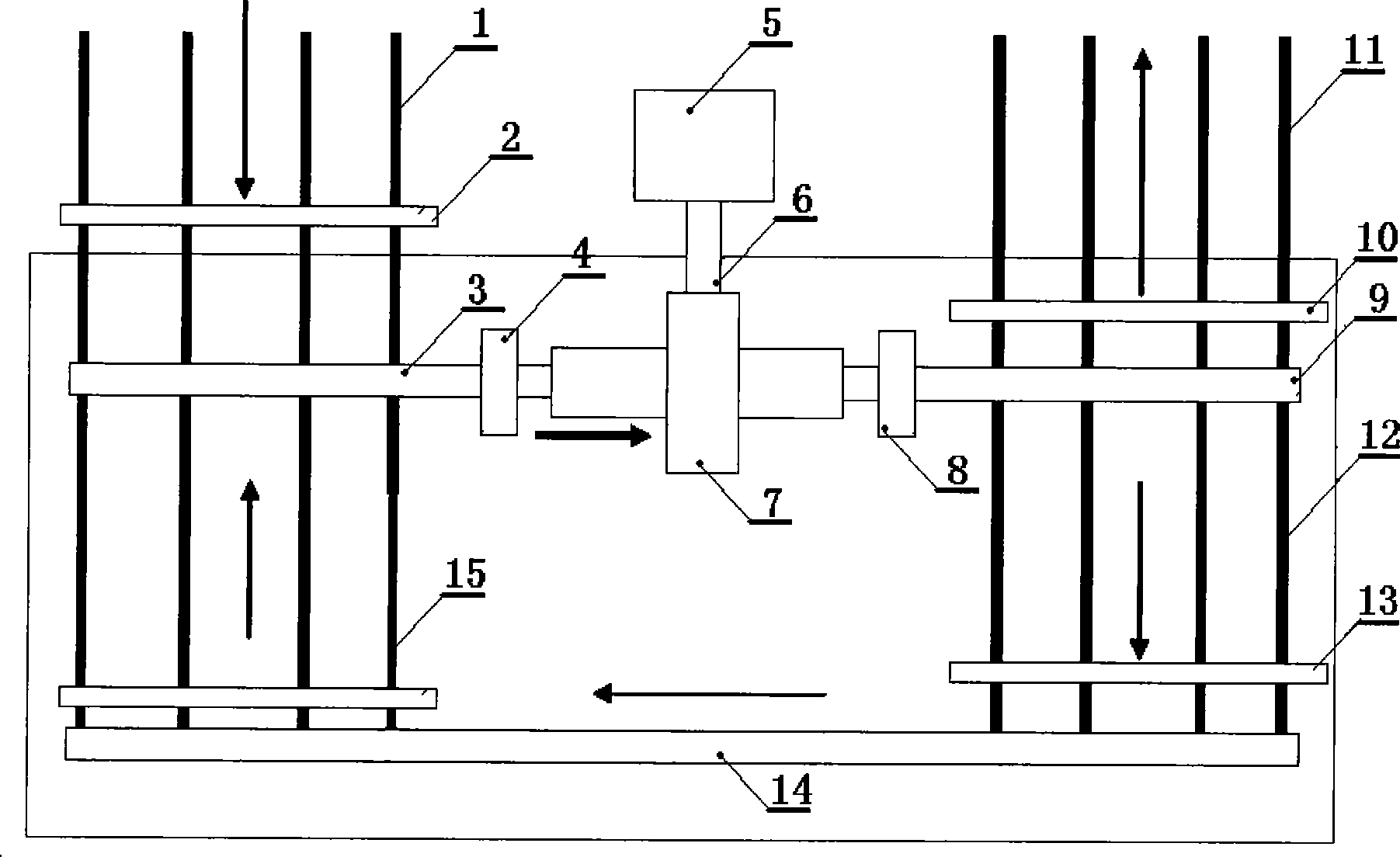

example 1

[0015] Take ash floor blanks with a thickness of 18mm, a width of 135mm, and a length of 1000mm. The moisture content is about 8%, and the moisture content gradient (moisture content of the central layer minus the moisture content of the surface layer) is 3.0%. The untreated wood board 2 is sent from the feed platform 1 to the moisture content detection device 4 before microwave treatment through the feed conveyor belt 3, and the output power of the microwave generator 5 is determined according to the detected moisture content, and the microwave energy is transported to the Wooden boards are processed at 7 places in the microwave radiation chamber, the radiation time is controlled at 15 seconds by the speed of the conveyor belt, and the radiation power is 0.5w / cm 3 , so that the internal temperature of the wood is controlled at 95°C. After the wood boards are treated with microwaves and tested by the moisture content detection device 8, the wood boards 10 with qualified moistur...

example 2

[0018] Take a poplar wooden door core board with a thickness of 50mm, a width of 105mm, and a length of 2000mm. After air-drying, the moisture content is 15%, and the moisture content gradient is 5%. The untreated wood board 2 is sent from the feed platform 1 to the moisture content detection device 4 before microwave treatment through the feed conveyor belt 3, and the output power of the microwave generator 5 is determined according to the detected moisture content, and the microwave energy is transported to the Wooden boards are processed at 7 places in the microwave radiation chamber, the radiation time is controlled at 3 seconds by the speed of the conveyor belt, and the radiation power is 5.0w / cm 3 , so that the internal temperature of the wood is controlled at 120°C, and after the microwave treatment, the wood board is tested by the moisture content detection device 8 after microwave treatment, and the wood board 10 with qualified moisture content is sorted by the transfe...

example 3

[0021] Take a eucalyptus frame material with a thickness of 50mm, a width of 75mm, and a length of 2000mm. After drying, the moisture content is 12%, and the moisture content gradient is 4.5%. The untreated wood board 2 is sent from the feed platform 1 to the moisture content detection device 4 before microwave treatment through the feed conveyor belt 3, and the output power of the microwave generator 5 is determined according to the detected moisture content, and the microwave energy is transported to the Wooden boards are processed in microwave radiation cavity 7, the radiation time is controlled at 30 seconds by the speed of the conveyor belt, and the radiation power is 2.0w / cm 3 , so that the internal temperature of the wood is controlled at 105° C., and after the microwave treatment, the wood board is tested by the moisture content detection device 8 after microwave treatment, and the wood board 10 with qualified moisture content is sorted by the transfer device 9 and sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com