Tea leaf fermentation process formula

A technology of tea fermentation and tea, which is applied in the direction of tea treatment before extraction, etc., can solve the problems of black tea processing such as long time consumption, low production efficiency, and affecting taste, and achieve the effect of reducing content, improving processing efficiency, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

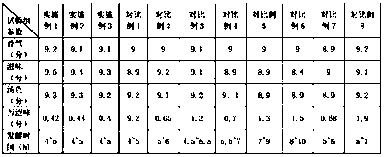

Examples

Embodiment 1

[0025] The present embodiment discloses a tea fermentation process, comprising the following steps:

[0026] (1) Pretreatment: Lay the picked fresh leaves flat with a thickness of 18-24mm, add Aspergillus oryzae to the fresh leaves; shake and stir the fresh leaves, and irradiate the tea leaves with infrared light for 2-3 hours ;

[0027] (2) Kneading: add starch with a weight of 2-3% of the tea leaves to the tea leaves obtained in step (1), rub and knead the tea leaves, after kneading for 0.2-0.3h, add starch with a weight of 2-3% of the tea leaves Starch, continue to knead for 0.6-0.9h, and control the water content of the tea leaves between 30-38%; every 3-5min of kneading, stop for 1.5-2min.

[0028] (3) Steaming: steam the tea leaves with high-temperature steam at 100-108°C for 8-10 minutes after rolling;

[0029] (4) Inoculation: prepare fermented liquid by the raw material of following mass parts, 9 parts of lactic acid bacteria, 5 parts of acetic acid bacteria, 15 par...

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is: 10 parts of lactic acid bacteria, 4 parts of acetic acid bacteria, and 13 parts of saccharomyces.

Embodiment 3

[0035] The difference between embodiment 3 and embodiment 1 is: 8 parts of lactic acid bacteria, 6 parts of acetic acid bacteria, and 10 parts of saccharomyces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com