Preparation method for liquid polyborosilazane

A technology of polyborosilazane and polysilazane, which is applied in the field of preparation of liquid polyborosilazane, can solve the problems of lack of fluidity and preparation of SiBCN ceramic matrix composite materials, etc., to improve high temperature oxidation resistance, The synthesis process is simple and the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Under the protection of an inert atmosphere, weigh 10 g of vinyl liquid polysilazane, put it into a Schlenk reaction bottle, and in a nitrogen atmosphere, distill xylene through sodium-benzophenone to remove water, and then distill the resulting Xylene 5.0g is transferred in the Schlenk reaction flask, stirs to obtain the mixed solution;

[0023] 2) Under the protection of an inert atmosphere, add 1 g of 9-borabicyclo[3,3,1]nonane into the mixed solution obtained in step 1);

[0024] 3) In a 50°C oil bath, the reaction was continuously stirred for 24 hours;

[0025] 4) After the reaction was completed, xylene was removed by distillation under reduced pressure to obtain 10.4 g of liquid polyborosilazane.

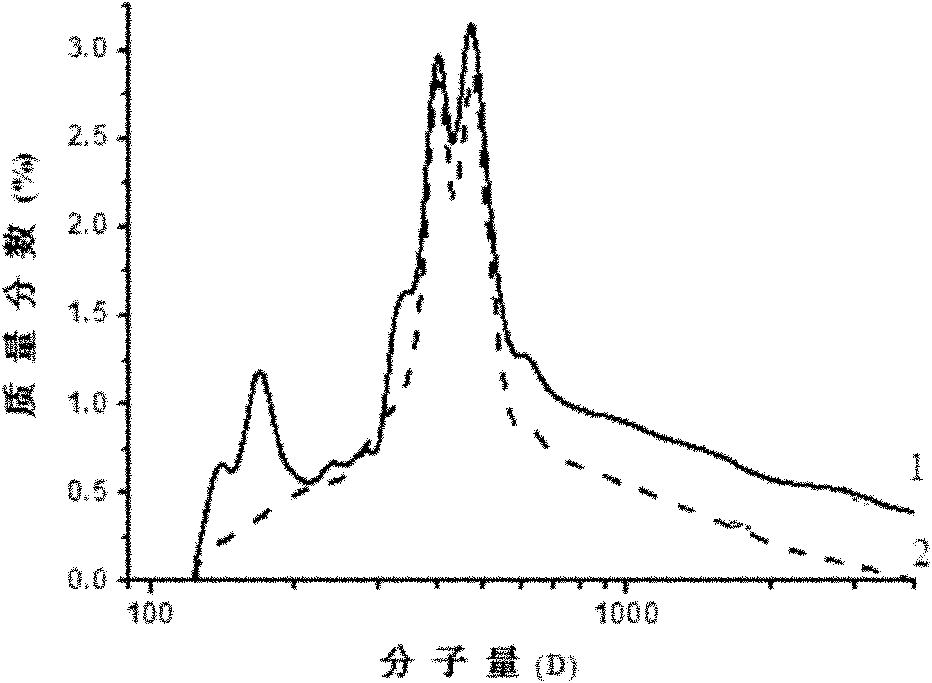

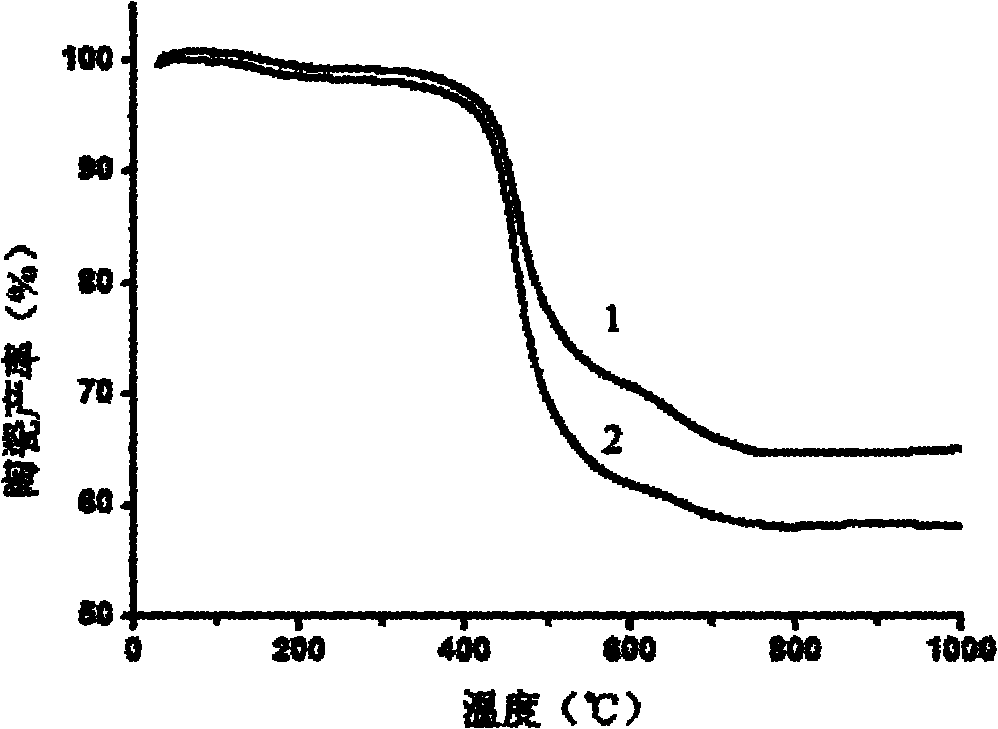

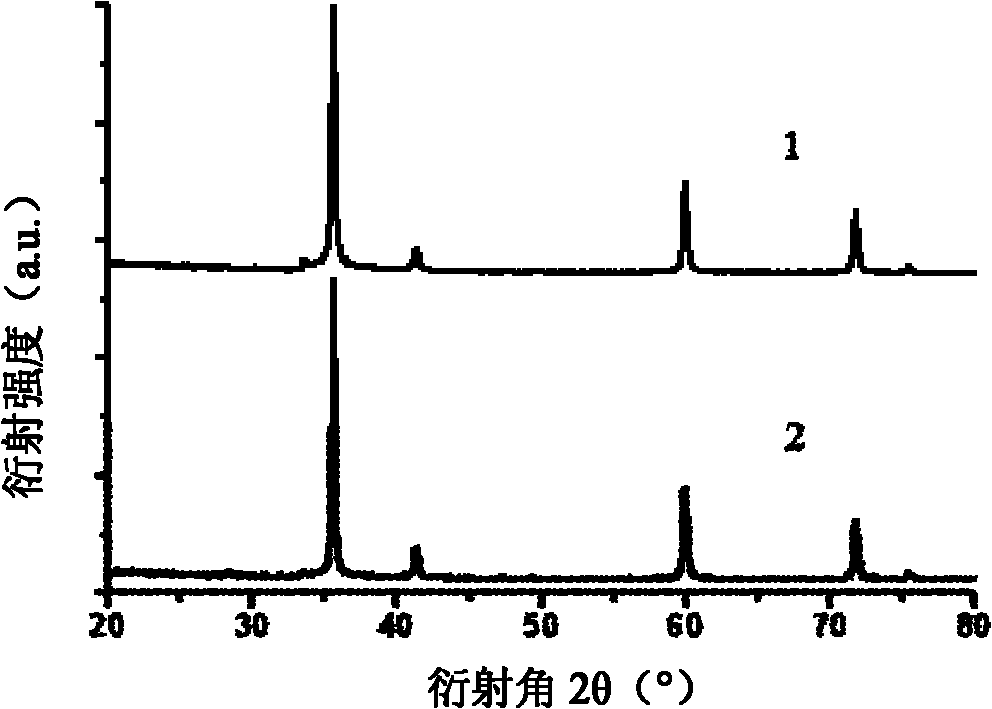

[0026] The average structural formula of the raw material liquid polysilazane used is [SiH(CH=CH 2 ) 0.24 (CH 3 ) 0.76 NH] n , measure its molecular weight and molecular weight distribution thereof by gel permeation chromatography (GPC), eluent is tetrahydrofu...

Embodiment 2

[0028] 1) Under the protection of an inert atmosphere, weigh 10 g of vinyl liquid polysilazane, put it into a Schlenk reaction bottle, and in a nitrogen atmosphere, distill toluene through sodium-benzophenone to remove water, and then distill 20 g of the obtained toluene Transfer to the Schlenk reaction bottle, stir the mixed solution;

[0029] 2) Under the protection of an inert atmosphere, add 5 g of 9-borabicyclo[3,3,1]nonane into the mixed solution obtained in step 1);

[0030] 3) After the dropwise addition is completed, keep stirring and reacting for 6 hours in an ice-salt bath at -10°C;

[0031] 4) After the reaction was completed, the toluene was removed by distillation under reduced pressure to obtain 13.9 g of liquid polyborosilazane.

[0032] The average structural formula of the raw material liquid polysilazane used is [SiH 0.77 (CH 3 )(CH=CH 2 ) 0.23 NH] n , measure its molecular weight and its molecular weight distribution by gel permeation chromatography (...

Embodiment 3

[0034] 1) Under the protection of an inert atmosphere, weigh 10 g of n-butynyl liquid polysilazane, put it into a Schlenk reaction bottle, and in a nitrogen atmosphere, distill ether through sodium-benzophenone to remove water, and then distill the obtained Diethyl ether 30g was transferred to the Schlenk reaction flask, and stirred to obtain a mixed solution;

[0035] 2) Under the protection of an inert atmosphere, add 10 g of 9-borabicyclo[3,3,1]nonane into the mixed solution obtained in step 1);

[0036] 3) In a liquid nitrogen acetone bath at -78°C, continue to stir and react for 10 hours;

[0037] 4) After the reaction was completed, diethyl ether was removed by distillation under reduced pressure to obtain 19.3 g of liquid polyborosilazane.

[0038] The average structural formula of the raw material liquid polysilazane used is [SiH 1.35 (CH 2 CH 2 C≡CH) 0.2 (CH 3 ) 0.45 NH] n , measure its molecular weight and its molecular weight distribution by gel permeation c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com