Continuous casting crystallizer protecting slag for medium-high carbon steel

A continuous casting crystallizer, medium and high carbon technology, applied in the field of smelting, can solve problems such as cracks and slab slag grooves, achieve the effect of improving the yield of rolled products, solving slag grooves and cracks, and improving corporate brand benefits

Inactive Publication Date: 2020-04-10

WUHU XINXING DUCTILE IRON PIPES

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve defects such as slag grooves and cracks in the casting process through a continuous casting mold mold slag for medium and high carbon steel, thereby improving the surface quality of the continuous casting slab

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

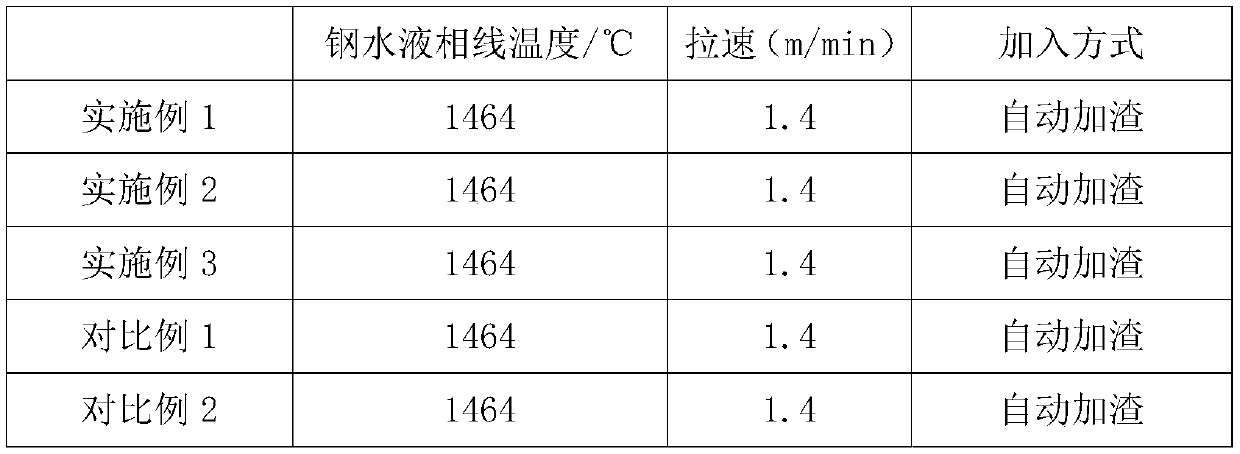

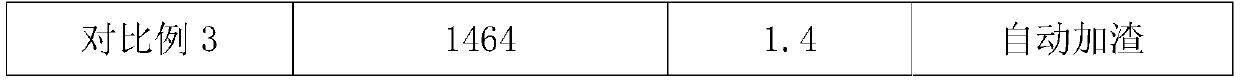

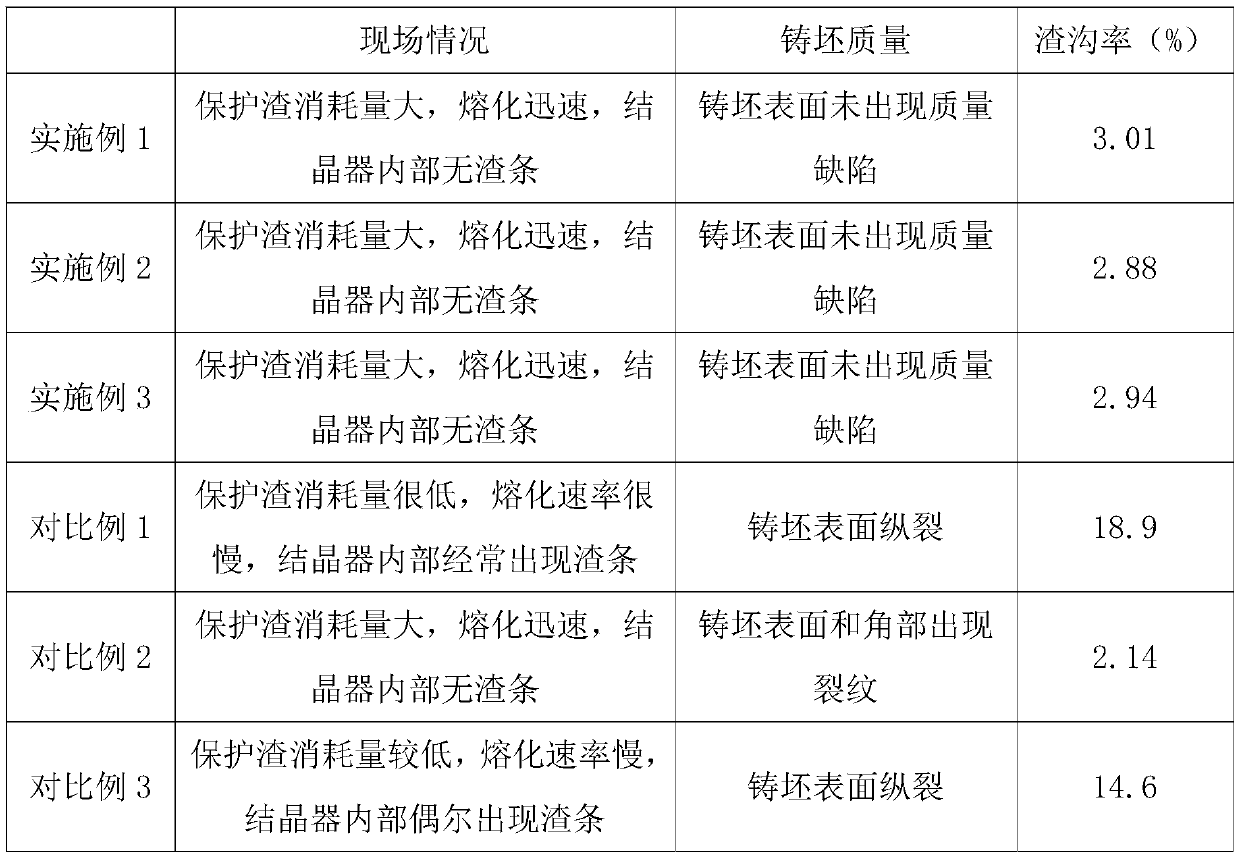

Embodiment 1- Embodiment 3

[0029] A mold flux for continuous casting molds for medium and high carbon steels, comprising the following components by mass percentage: see Table 1 below.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides continuous casting crystallizer protecting slag for medium-high carbon steel. The continuous casting crystallizer protecting slag comprises, by mass percentage, 20.2-26.2% of CaO, 25.3-31.3% of SiO2, 1.1-2.7% of Al2O3, 5.5-8.3% of MgO, 7.4-12.2% of F, 9.5-14.1% of Na2O and 13.5-16.5% of C. Compared with the prior art, by designing the formula of the protecting slag, the problem that during practical use, lubrication of the protecting slag contradicts with heat transfer is solved, and thus the problem that currently, surface defects such as slag troughs and cracks frequently occur in medium-high carbon steel is solved. In the meanwhile, the yield of rolled products is increased, and the benefit of enterprise brands is increased.

Description

technical field [0001] The invention belongs to the field of smelting, and in particular relates to a mold slag for continuous casting molds for medium and high carbon steels. Background technique [0002] Medium-high carbon steel usually refers to carbon steel and carbon-manganese steel with a carbon content greater than 0.4%. This type of steel has the characteristics of low liquidus temperature, small shell section shrinkage, high strength and hardness, and good fatigue resistance. During the continuous casting process, the gap between the slab shell and the inner wall of the mold is narrow. When the process conditions are unstable, such as low superheat of molten steel, fluctuations in the liquid level of the mold, and misalignment of the nozzle, the mold slag cannot be completely melted. It is easy to form "slag strips" near the meniscus. The slag strips are involved in the gap and will be bonded to the wall of the crystallizer to form slag blocks. When the soft billet ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D11/111

CPCB22D11/111

Inventor 赵立左小坦杨伟勇黄雁

Owner WUHU XINXING DUCTILE IRON PIPES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com