High-cleanness diesel fuel

A diesel and clean technology, applied in the direction of fuel, fuel additives, liquid carbon-containing fuel, etc., can solve the problems of insufficient fuel saving rate, achieve the effect of simple and feasible preparation method, solve high fuel consumption, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

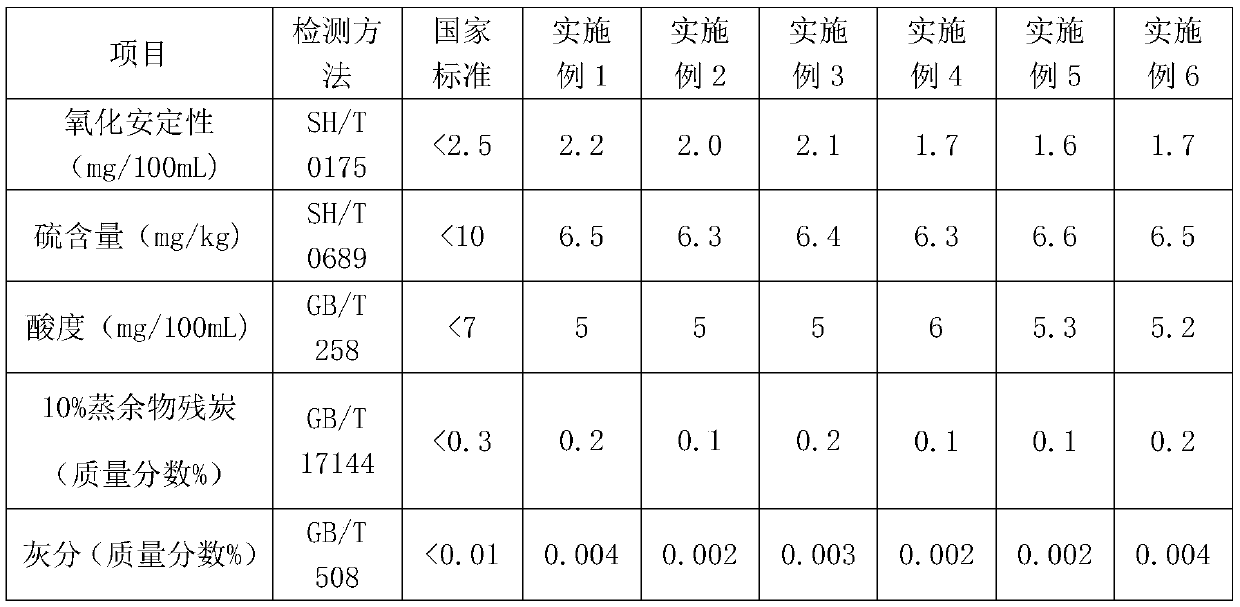

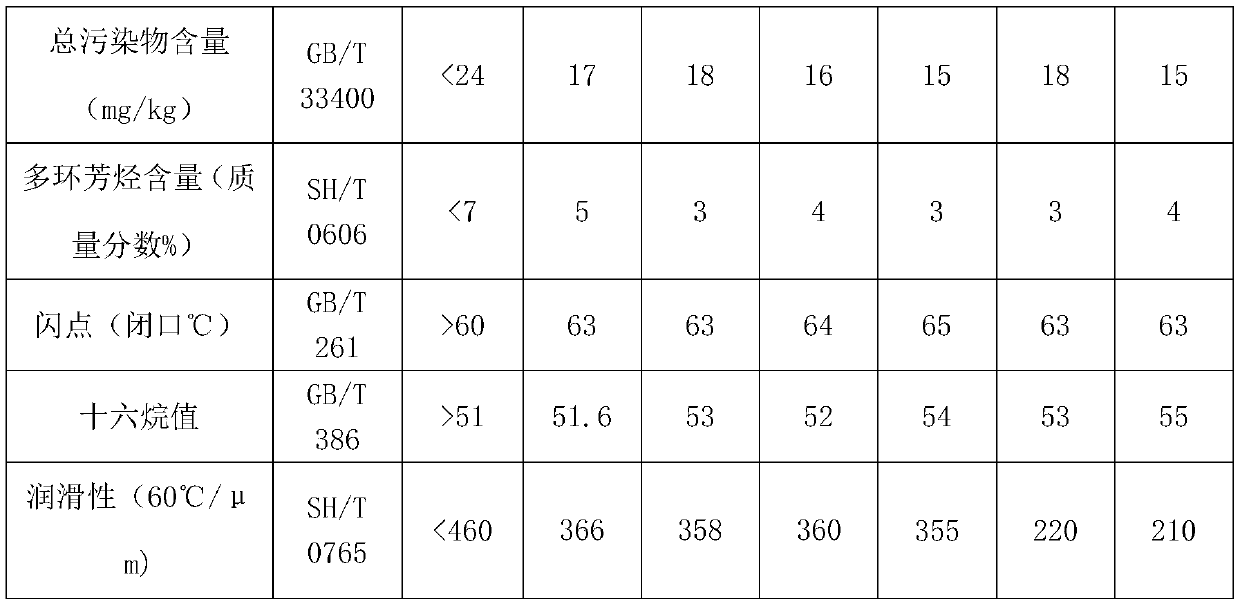

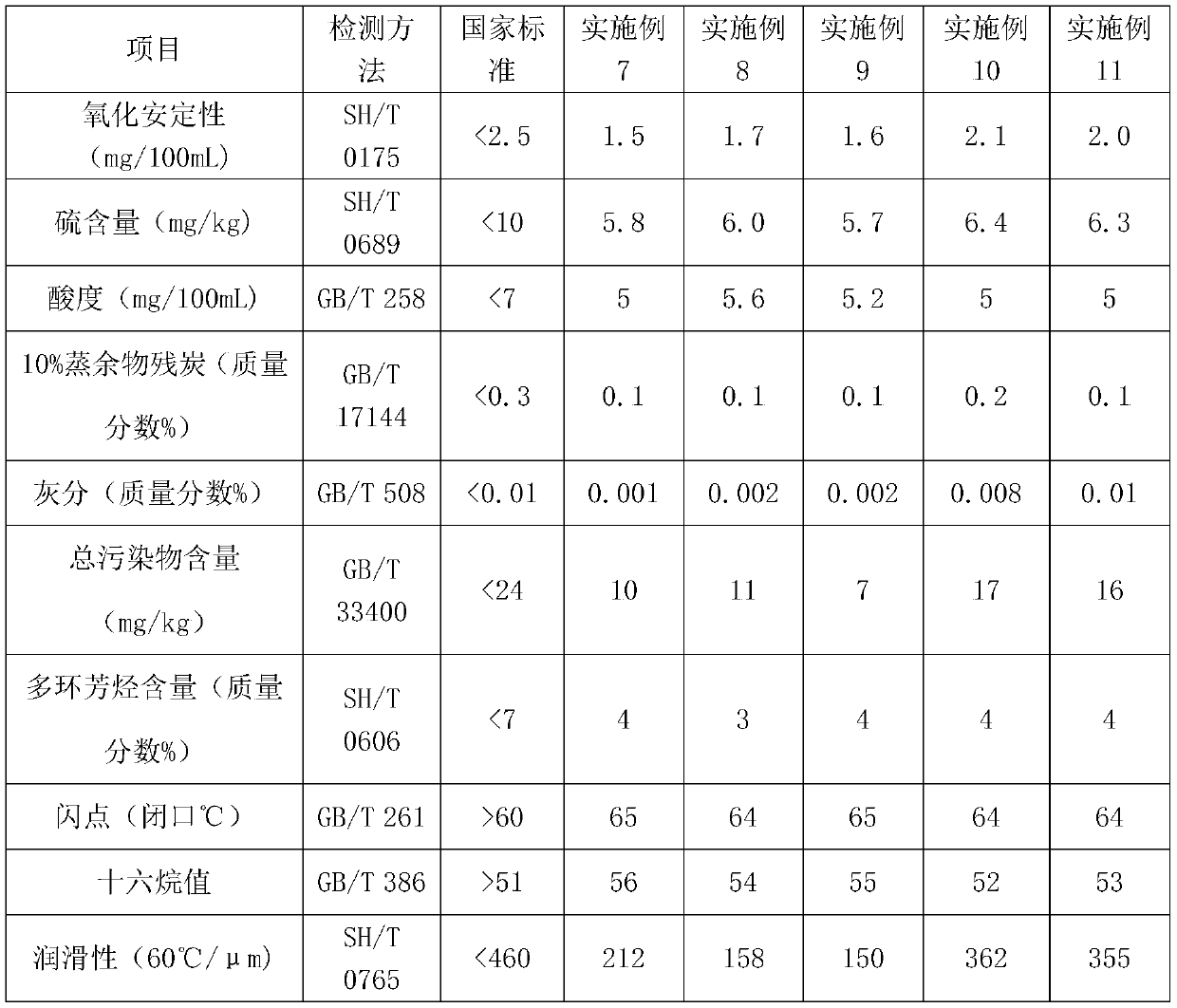

Examples

Embodiment 1

[0031] This embodiment provides a high-clean diesel fuel, which is composed of the following raw materials: 45 kg of coal-based Fischer-Tropsch synthetic liquid wax, 10 kg of No. 3 jet fuel, 75 kg of coal-based diesel fraction and 5 kg of compound additives. Each raw material is weighed according to the weight of each component and put into a stirring tank, and stirred evenly to obtain a high-clean diesel fuel.

[0032] The compound auxiliary agent is composed of the following raw materials: 2.30 kg of fatty acid ester, 1.92 kg of dimethyl sulfoxide, 0.39 kg of dibutyl oxalate and 0.39 kg of cerium naphthenate.

[0033] The preparation method of the composite auxiliary agent is as follows: Weigh fatty acid ester, dimethyl sulfoxide, dibutyl oxalate and cerium naphthenate salt into the reaction tank, raise the temperature to 60°C, and Under the condition of stirring for 80 minutes, then let it stand for 2 hours, that is, too.

Embodiment 2

[0035] This embodiment provides a high-clean diesel fuel, which is composed of the following raw materials: 5 kg of coal-based Fischer-Tropsch synthetic liquid wax, 40 kg of No. 3 jet fuel, 20 kg of coal-based diesel fraction and 45 kg of compound additives. Each raw material is weighed according to the weight of each component and put into a stirring tank, and stirred evenly to obtain a high-clean diesel fuel.

[0036] The above composite auxiliary agent is composed of the following raw materials: 26.00 kg of fatty acid ester, 1.74 kg of dimethyl sulfoxide, 8.65 kg of dibutyl oxalate and 8.65 kg of cerium naphthenate.

[0037] The preparation method of the composite auxiliary agent is as follows: Weigh fatty acid ester, dimethyl sulfoxide, dibutyl oxalate and cerium naphthenate salt into the reaction tank, raise the temperature to 30°C, and Under the condition of stirring for 80 minutes, then let it stand for 2 hours, that is, too.

Embodiment 3

[0039] This embodiment provides a high-clean diesel fuel, which is composed of the following raw materials: 12kg of coal-based Fischer-Tropsch synthetic liquid wax, 18kg of No. 3 jet fuel, 45kg of coal-based diesel fraction and 25kg of compound additives. Each raw material is weighed according to the weight of each component and put into a stirring tank, and stirred evenly to obtain a high-clean diesel fuel.

[0040] The above compound auxiliary agent is composed of the following raw materials: 15.00 kg of fatty acid ester, 3.75 kg of dimethyl sulfoxide, 3.75 kg of dibutyl oxalate and 2.50 kg of cerium naphthenate.

[0041]The preparation method of the composite auxiliary agent is as follows: weigh fatty acid ester, dimethyl sulfoxide, dibutyl oxalate and cerium naphthenate salt into the reaction tank, raise the temperature to 40°C, and Under the condition of stirring for 80 minutes, then let it stand for 2 hours, that is, too.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com