Minimal quantity lubrication cutter and lubrication method thereof

A kind of micro-lubrication and tool technology, which is applied in the direction of tools for lathes, manufacturing tools, accessories of tool holders, etc. It can solve the problems of inaccurate cooling points, unsatisfactory lubrication and cooling effects, etc., and achieve easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

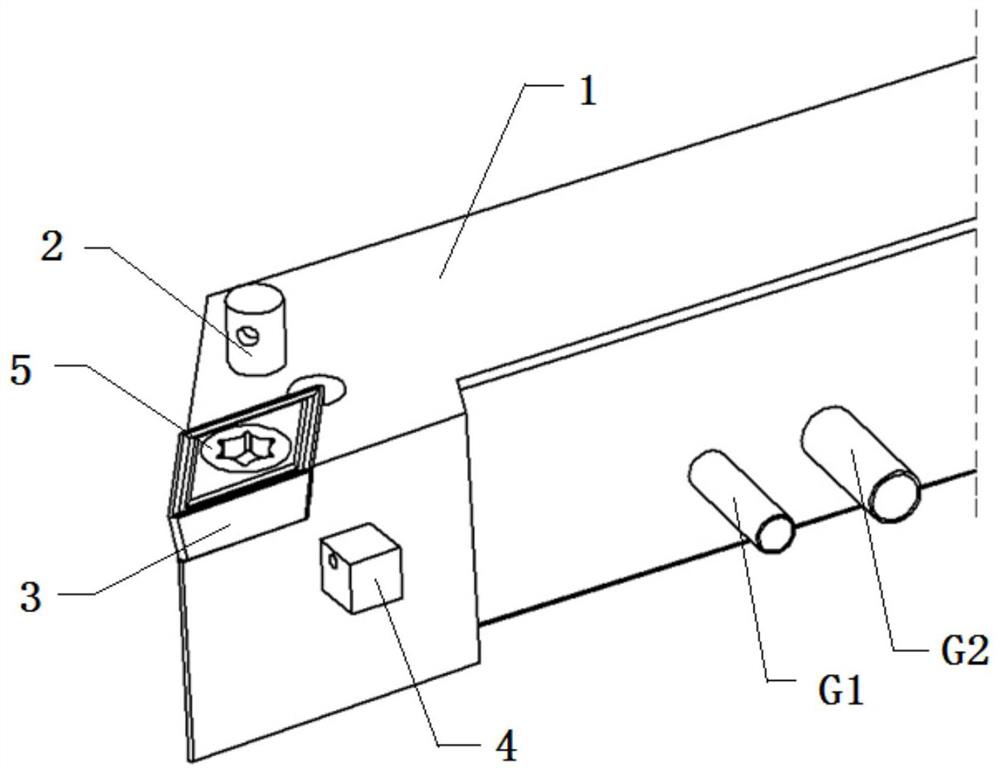

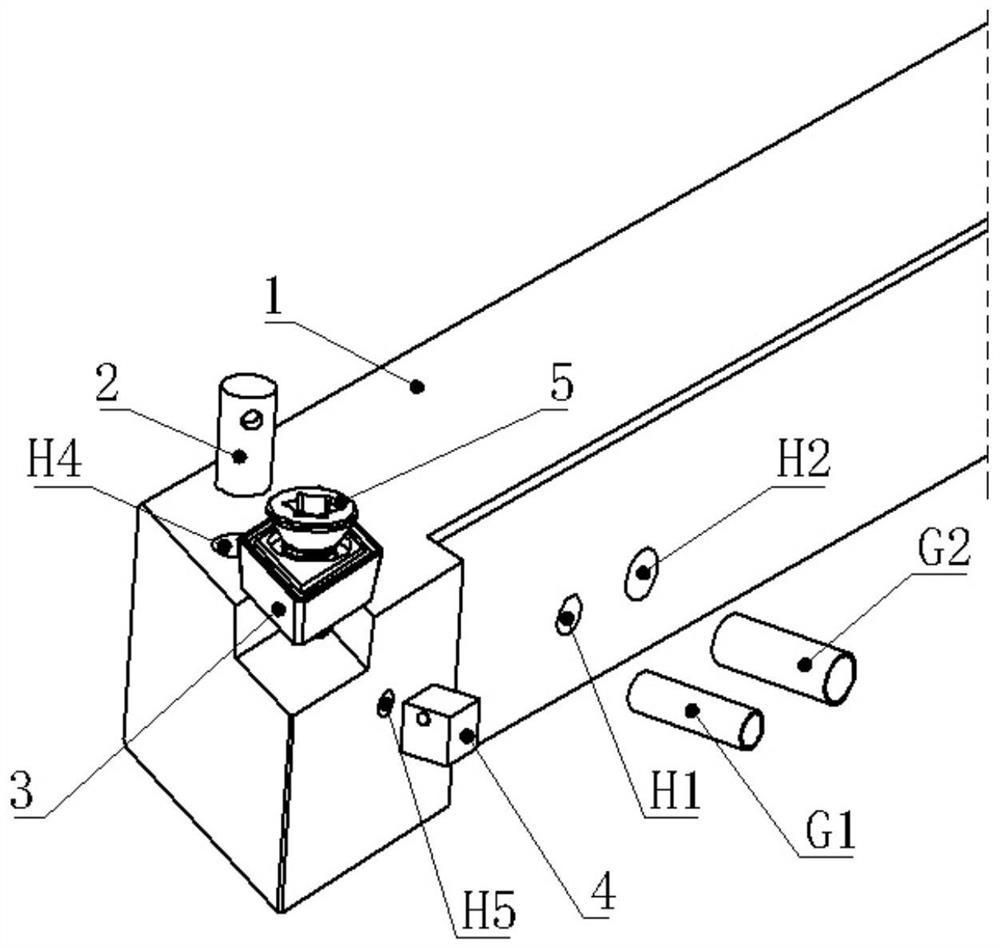

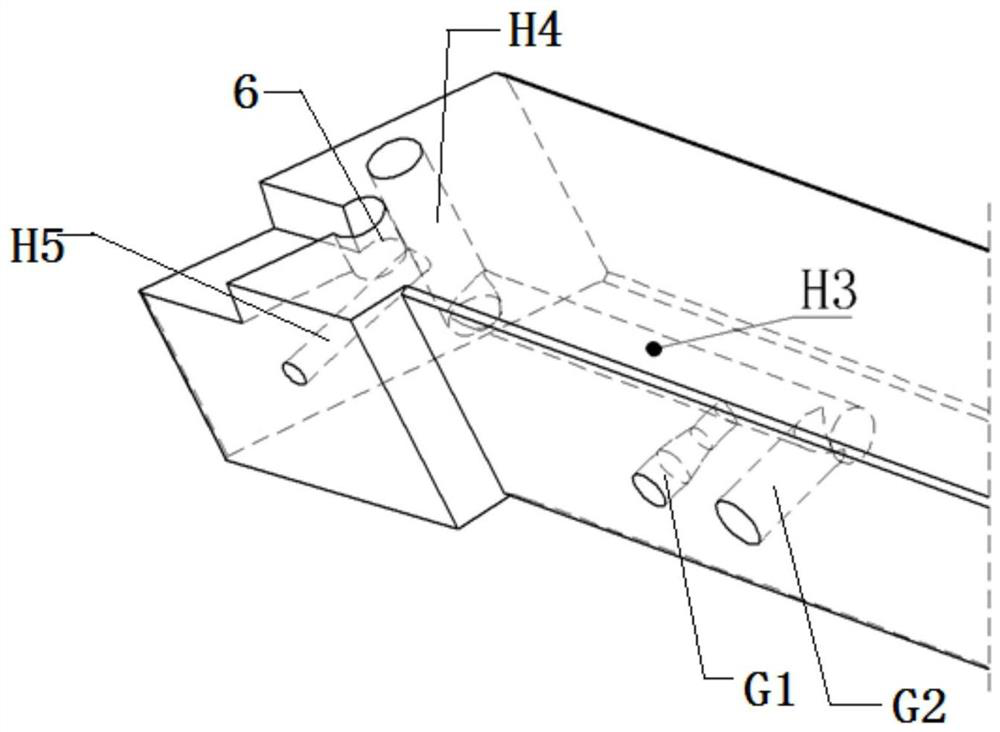

[0043] The embodiment is basically as attached figure 1 And attached figure 2 Shown: the minimal quantity lubrication tool in this embodiment is suitable for minimum quantity lubrication and cooling cutting process. Solve the problem that the cooling position is not accurate in the minimal quantity lubrication and cooling cutting process, and the lubrication and cooling effect cannot reach the ideal state due to the change of the cutting system during the machining process.

[0044] Minimal quantity lubrication tool consists of the following parts:

[0045] The first pipeline G1 used to connect the micro-lubrication medium generator with the cutter body; its main function is to transport the medium generated by the micro-lubrication medium generator to the inside of the cutter body.

[0046] Used to connect the compressed high-pressure air to the second pipe G2 of the cutter body; its main function is to deliver the high-pressure gas to the inside of the cutter body.

[00...

Embodiment 2

[0063] The difference from Embodiment 1 is that in this embodiment, an electrostatic device is installed in the mixing channel, which can charge the MQL mixture with static electricity when it is formed, and can increase its adhesion to the blade.

Embodiment 3

[0065] The difference from Embodiment 1 is that the axial structure of the mixing channel in this embodiment is a tapered pipe structure whose two ends are connected in two directions and the longitudinal section gradually increases toward the two ends. Through such a structure, the high-pressure air and the micro-lubrication medium can be quickly accommodated into the mixing channel, and the two are quickly compressed due to the shape of the mixing channel, so that the micro-lubrication mixed gas is compressed and atomized to form a fine uniform liquid Drops of granules for better spraying onto the blades for lubrication and cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com