Cooling fan with hydraulic motor mounting support

A technology for installing brackets and cooling fans, which is used in engine cooling, pump devices, non-variable-capacity pumps, etc. to improve strength and reliability, improve product performance, and reduce wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

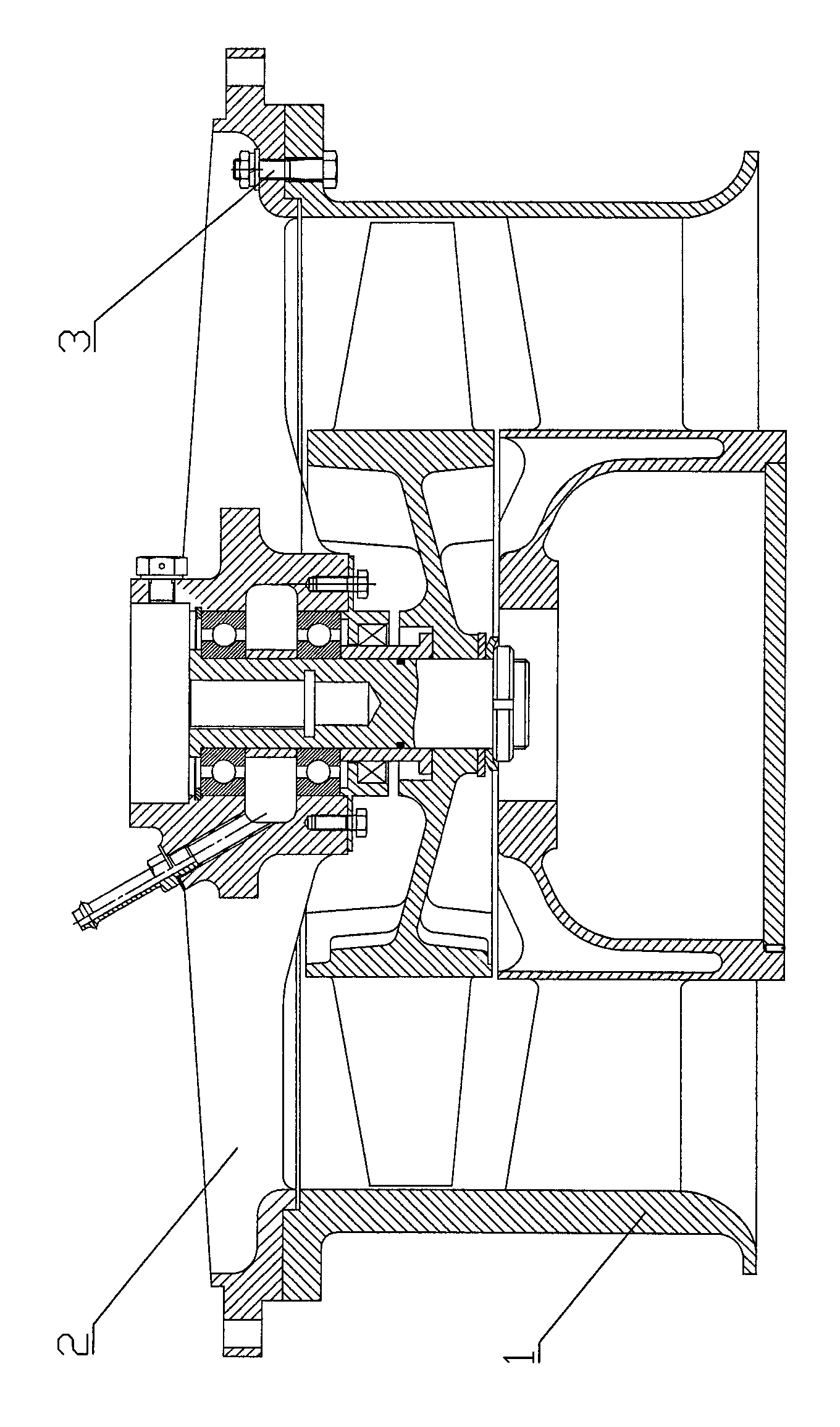

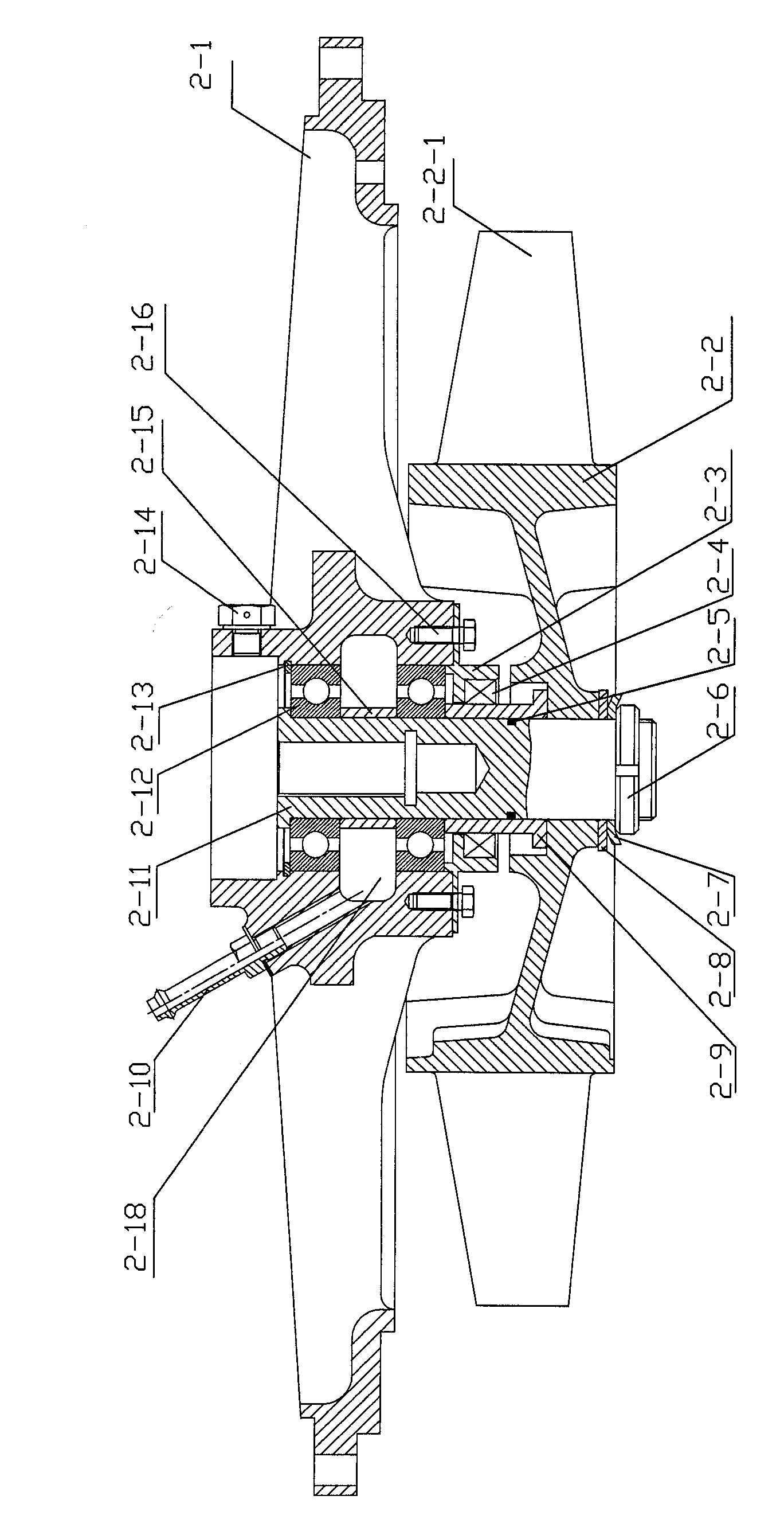

[0022] A cooling fan with a hydraulic motor mounting bracket is composed of a stationary impeller assembly 1 and a moving impeller assembly 2.

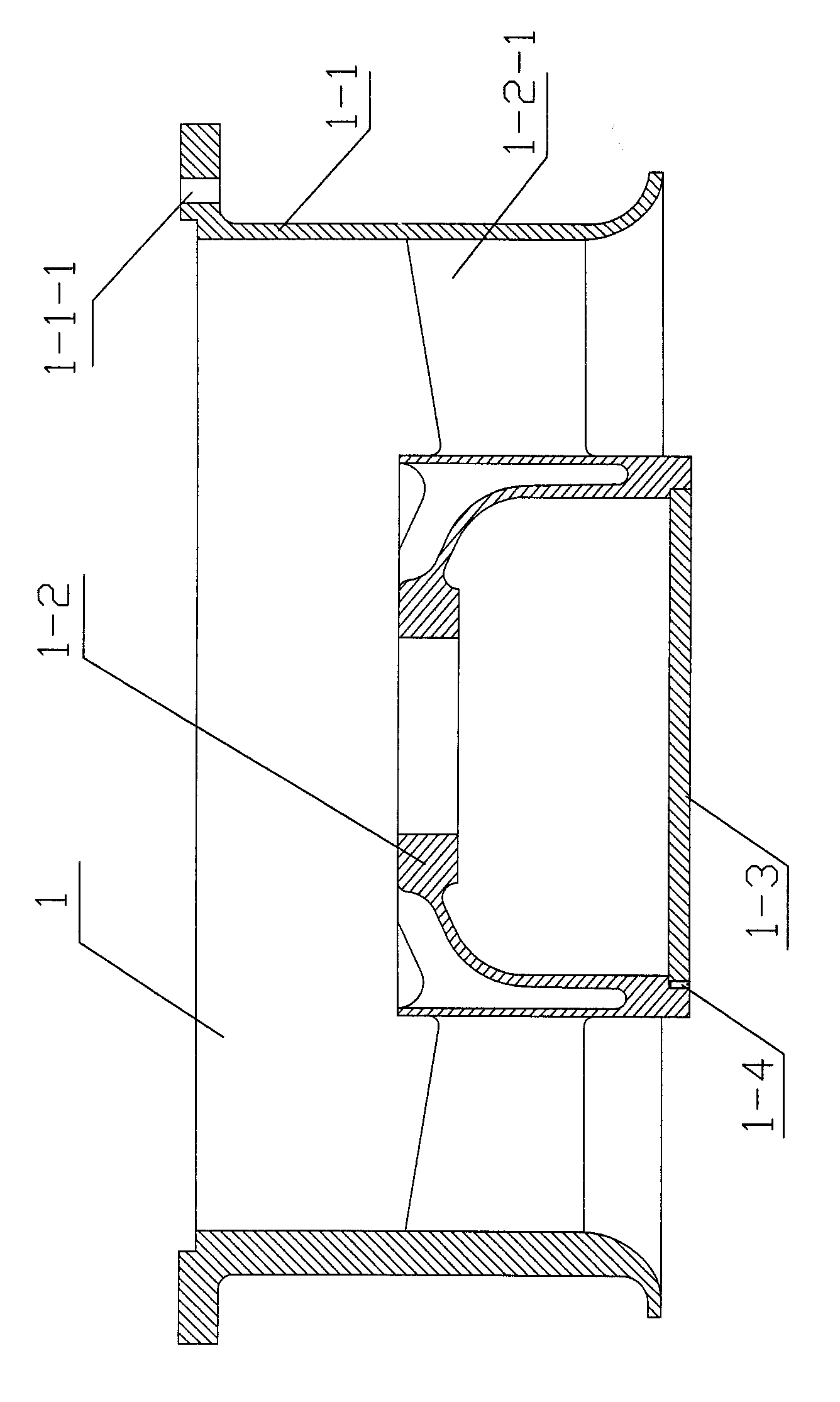

[0023] The stationary impeller assembly 1 is composed of a fixed ring 1-1, a stationary impeller 1-2, a cover plate 1-3 and a set screw 1-4. The fixing ring 1-1 is provided with a plurality of screw holes 1-1-1 for installing the bracket assembly 2, and the fixing ring 1-1 is also provided with a stepped hole 1-1 for installing the moving impeller assembly 2 -2, the outer circle of the stationary impeller 1-2 is provided with a plurality of stationary impeller blades 1-2-1, the stationary impeller blades 1-2-1 are evenly arranged on the outer circle of the stationary impeller 1-2, and the stationary impeller 1-2 is installed In the inner ring of the fixed ring 1-1, the stationary impeller 1-2 is pressed into the fixed ring 2-1 through the outer edge end surface of the stationary impeller blade 1-2-1 by hot pressing, and is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com