Parallel horn contact system

A contact system and contact technology, applied in advance contact arrangements, transformers, electrical components, etc., can solve the problems of short service life of tap changers, increased switch maintenance and material consumption, burning of main on-off contacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

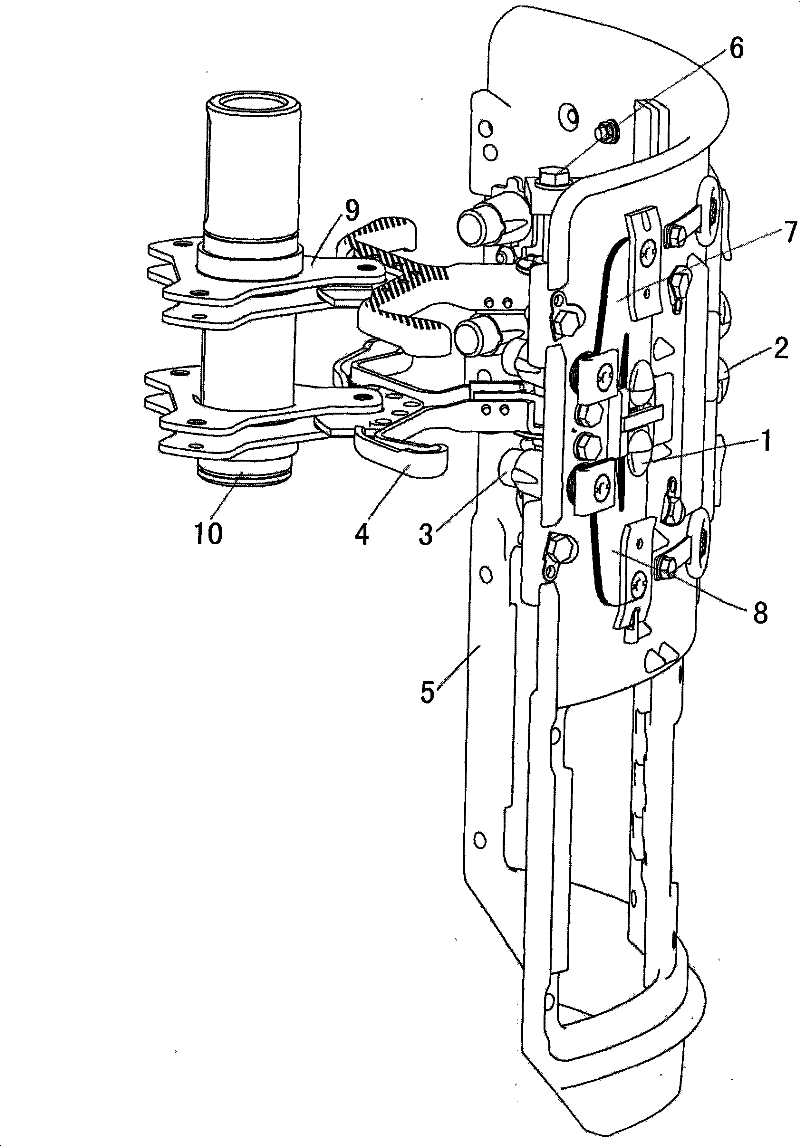

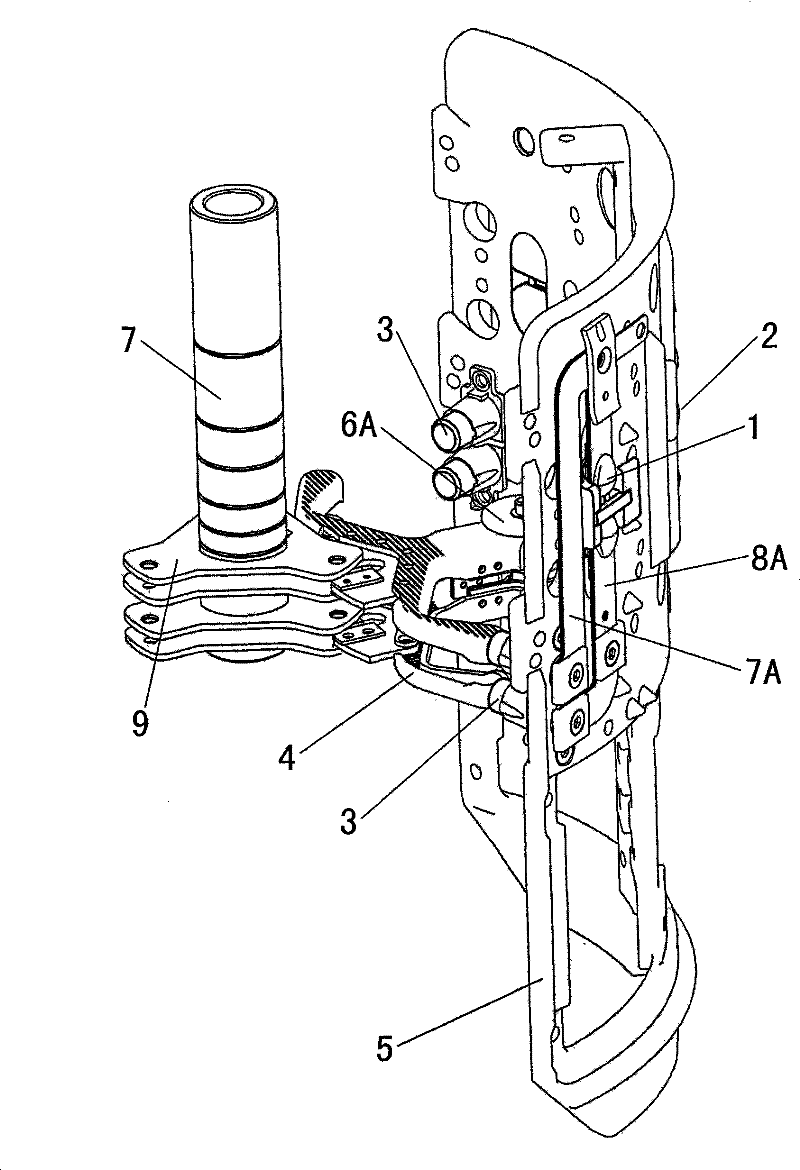

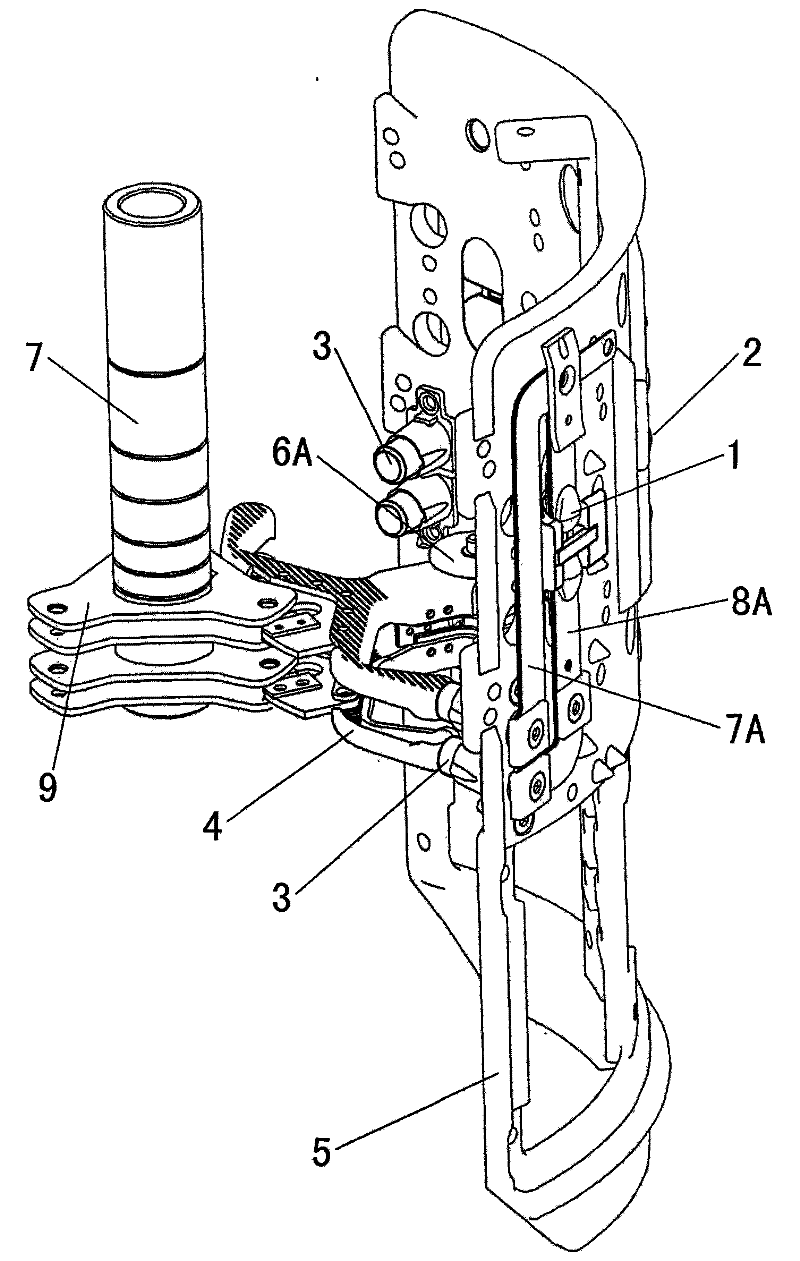

[0018] see figure 2 , the horn parallel contact system, including arc plate 5, two flexible connecting sheet groups 7A, 8A, two sets of fixed contacts 1, two pairs of bullet contacts 3, two horn contacts 4, a set of neutral points Contact 2, contact bracket 6A.

[0019] The shape and size of each arc-shaped plate 5 are the same as those of the original on-load tap-changer, so as to adapt to the diverter switch oil chamber of the on-load tap-changer. Two groups of fixed contacts 1 have the same structure as the existing fixed contacts, and are still installed on the original position on the arc plate 5, and each group of fixed contacts 1 is divided into two.

[0020] One group of neutral point contacts 2 has the same structure as the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com