Preparation process of integrated electric connector metal contact pin

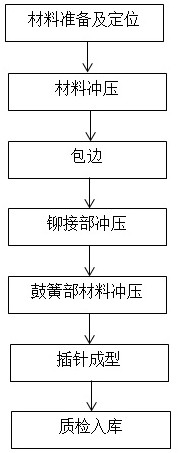

A technology of electrical connector and preparation process, which is applied in the field of preparation process of metal pins of integrated electrical connectors, which can solve problems such as strength limitation, failure to achieve anti-retraction effect, difficulty in inserting metal pins, etc., and solve the problem of installation position problems, reduce assembly steps, and ensure the effect of firmness of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

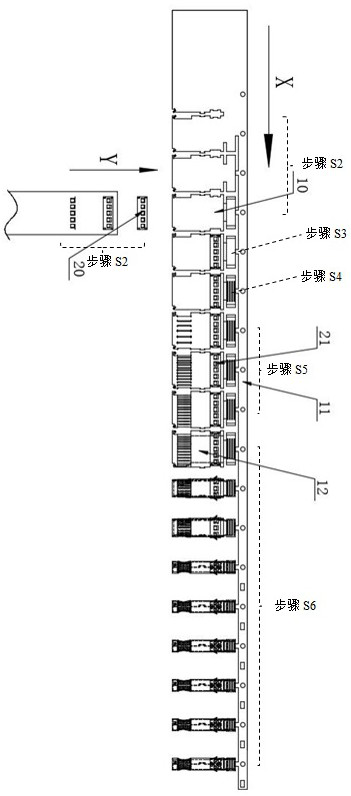

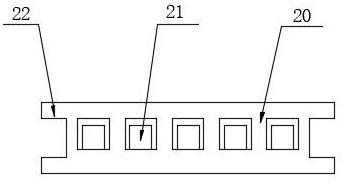

[0033] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

[0034] The pin in the present invention belongs to the metal pin (PIN) of the connector in a broad sense. Because the metal pins of the positive and negative connectors of the electrical connector need to be inserted into each other, the metal pins in the positive connector are often defined as pins, and the metal pins in the negative connector are defined as sockets; conversely It is also available; no matter it is defined as a pin or a socket, both belong to the metal pin (PIN) of the connector in a broad sense.

[0035] In the following embodiments, the preparation process will be described in detail by taking the negative metal pin, which is commonly referred to as the sleeve in this field, as an example. The sleeve in this embodiment is a sleeve with an integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com