Heat exchange device and semiconductor refrigeration equipment with same

A heat exchange device and heat exchange surface technology, applied in heat exchange equipment, lighting and heating equipment, refrigerators, etc., can solve the problems of unsuitable installation, pull down to 12°C, large installation space, etc., and reduce the front and rear thickness And the total volume, increase the air flow, increase the effect of air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

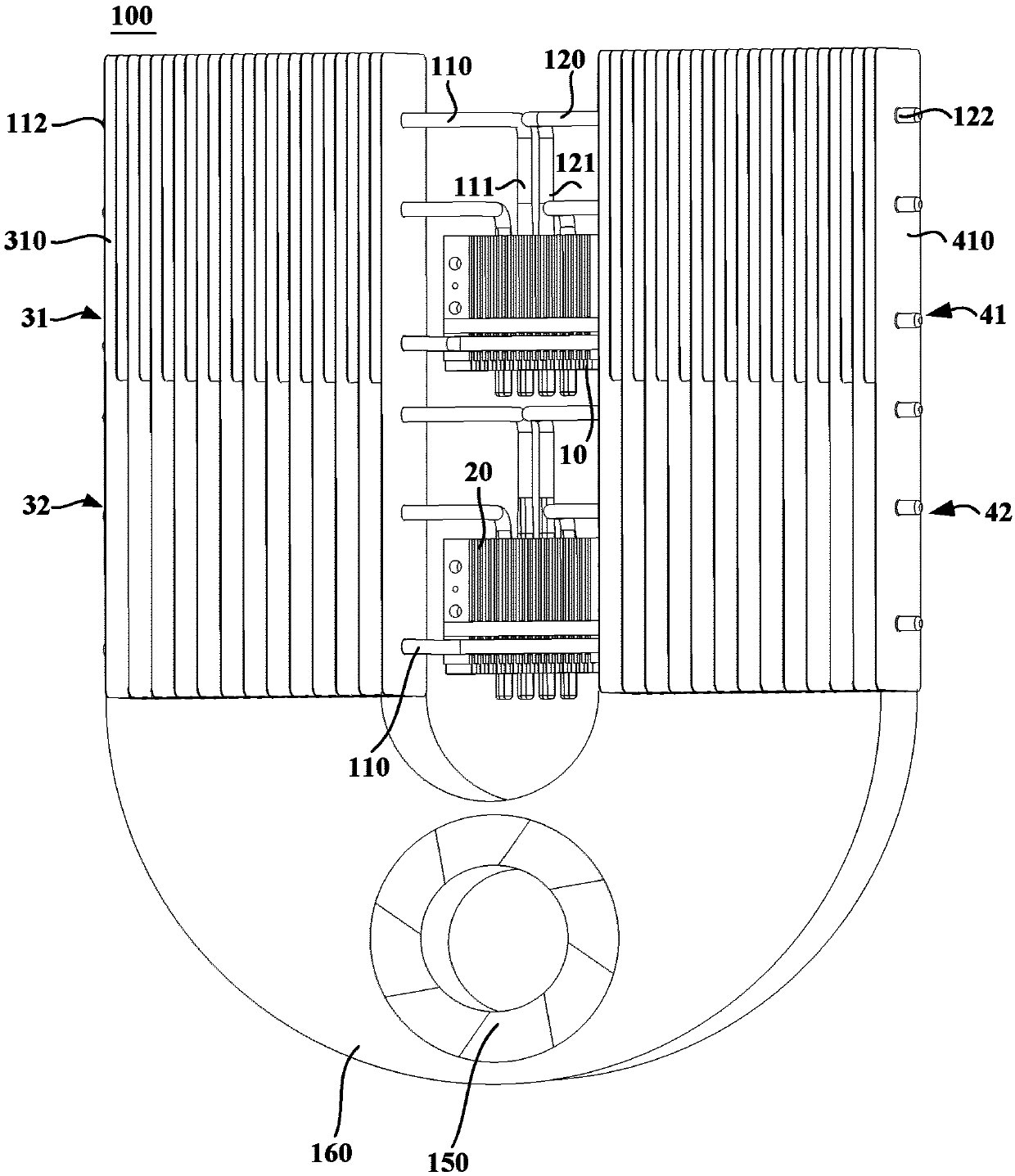

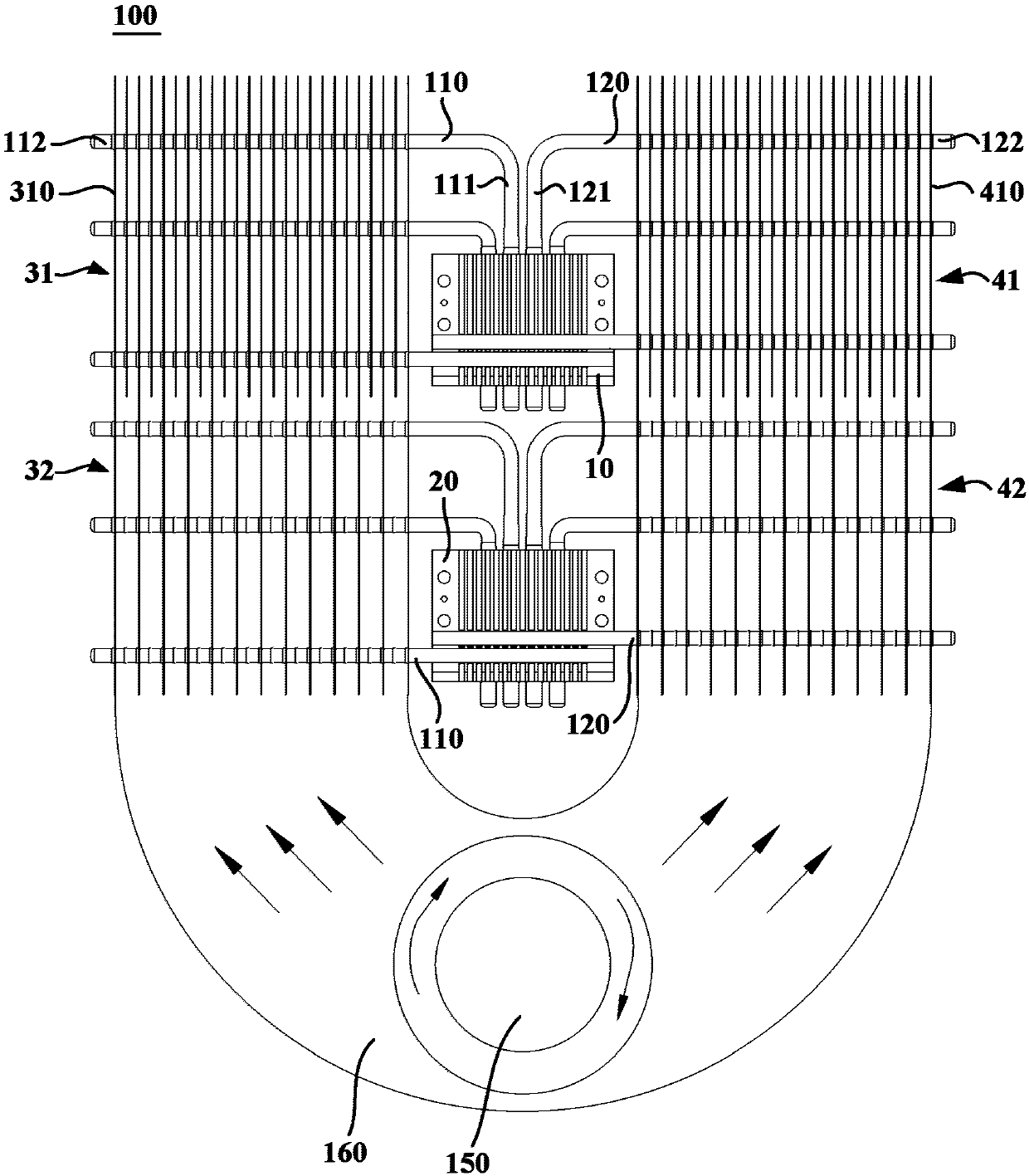

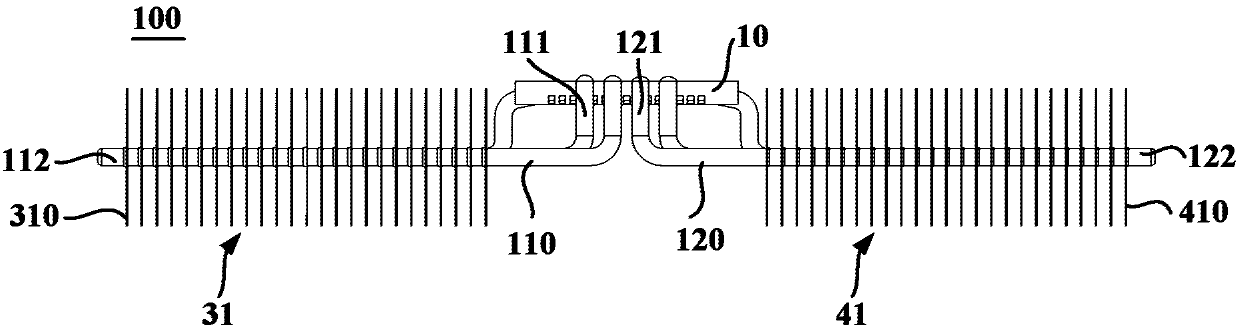

[0049] figure 1 is a schematic structural diagram of a heat exchange device 100 according to an embodiment of the present invention; figure 2 yes figure 1 A schematic front view of the heat exchange device 100 shown; image 3 yes figure 1 A schematic top view of the heat exchange device 100 shown. Such as Figure 1 to Figure 3 As shown, the heat exchange device 100 may include: at least one heat transfer substrate, at least one first heat pipe 110 , a first cooling fin group, and a fan 150 .

[0050] The heat transfer substrate has a heat exchange surface thermally connected to the heat source to receive heat from the heat source. The first heat pipe 110 has a connection section 111 thermally connected to a heat transfer substrate and a heat dissipation section 112 extending from one end of the connection section 111 toward one lateral side of the heat transfer substrate. The connection section 111 and the heat dissipation section 112 may be directly connected through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com