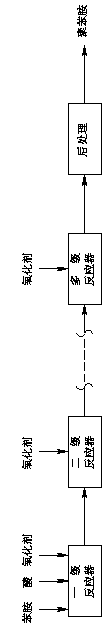

Multi-level continuous polyaniline synthesis process

A synthesis process, polyaniline technology, applied in the field of polyaniline continuous synthesis process, can solve the problems of restricting tubular reactors, polyaniline chain breaking, uniform mixing, etc., and achieve the effect of mass transfer and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Continuously drop sulfuric acid and aniline into the multi-stage series reactors with a constant flow pump, the flow rate of aniline is 0.547L / h, and 15% ammonium persulfate solution is added into the reactor in three stages with a constant flow pump, and the flow rate is as follows: 4.564L / h, 2.7384L / h, 1.825.6L / min, the reaction temperature is controlled at around 0°C. After the reaction product was washed with water, washed with acetone, and dried in vacuum, the yield of polyaniline was 80%, and the number average molecular weight was 1.8×10 4 , the molecular weight distribution value is 1.8, and the diameter of polyaniline particles is not greater than 25 μm. After doping with sulfuric acid, the conductivity is 10S cm -1 .

Embodiment 2

[0025] Continuously drop β-naphthalenesulfonic acid and aniline into the multi-stage series reactor with a constant flow pump, the flow rate of aniline is 0.547L / h, and 25% ammonium persulfate solution is added into the reactor in four stages with a constant flow pump , the flow rate is 2.1907L / h, 1.643L / h, 1.0954L / h, 0.5477L / h in turn, and the reaction temperature is controlled at about 5°C. After the reaction product was washed with water, washed with acetone, and dried in vacuum, the yield of polyaniline was 82%, and the conductivity was 10S cm -1 , number average molecular weight 2.3×10 4 , the molecular weight distribution value is 2.1, and the diameter of polyaniline particles is not greater than 25 μm.

Embodiment 3

[0027] Dodecylbenzenesulfonic acid and 2-chloroaniline are continuously added dropwise to the multi-stage series reactors with a constant flow pump, the flow rate of 2-chloroaniline is 0.750L / h, and 30% ammonium persulfate solution is used with a constant flow pump Add to the reactor in five stages, the flow rate is 1.369L / h, 1.369L / h, 1.369L / h, 0.958L / h, 0.411L / h, and the reaction temperature is controlled at about 5°C. After the reaction product was washed with water, washed with acetone, and dried in vacuum, the yield of polyaniline was 75%, and the conductivity was 2.0S cm -1 , number average molecular weight 3.8×10 4 , the molecular weight distribution value is 3.1, and the diameter of polyaniline particles is not greater than 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com