Fuel gas rotary furnace bio-organic matter heat treatment device

A technology of heat treatment device and treatment device, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of high energy consumption of the device and low calorific value of non-condensable gas, so as to improve treatment efficiency, increase batch processing, reduce Effect of water cooling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention and embodiment are further described to the present invention:

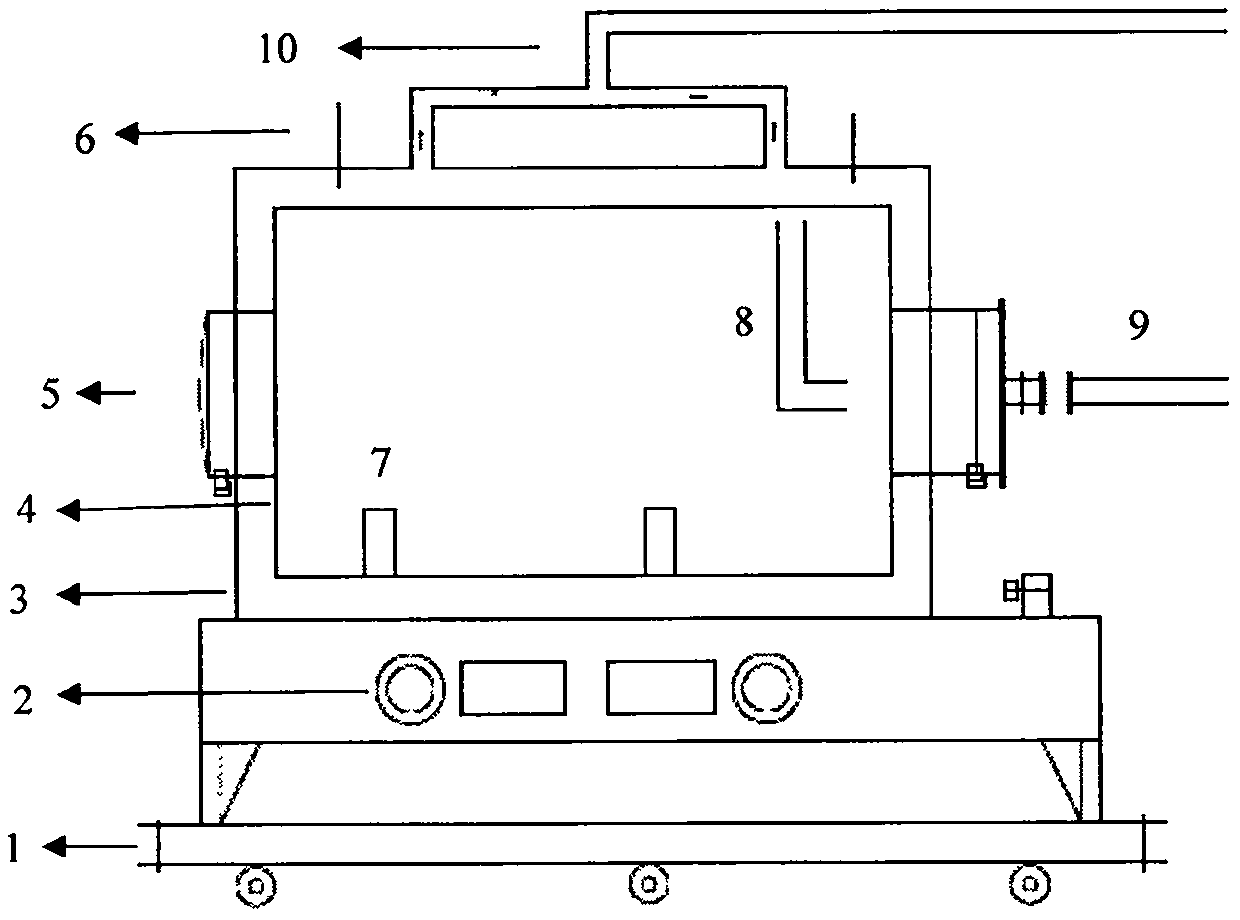

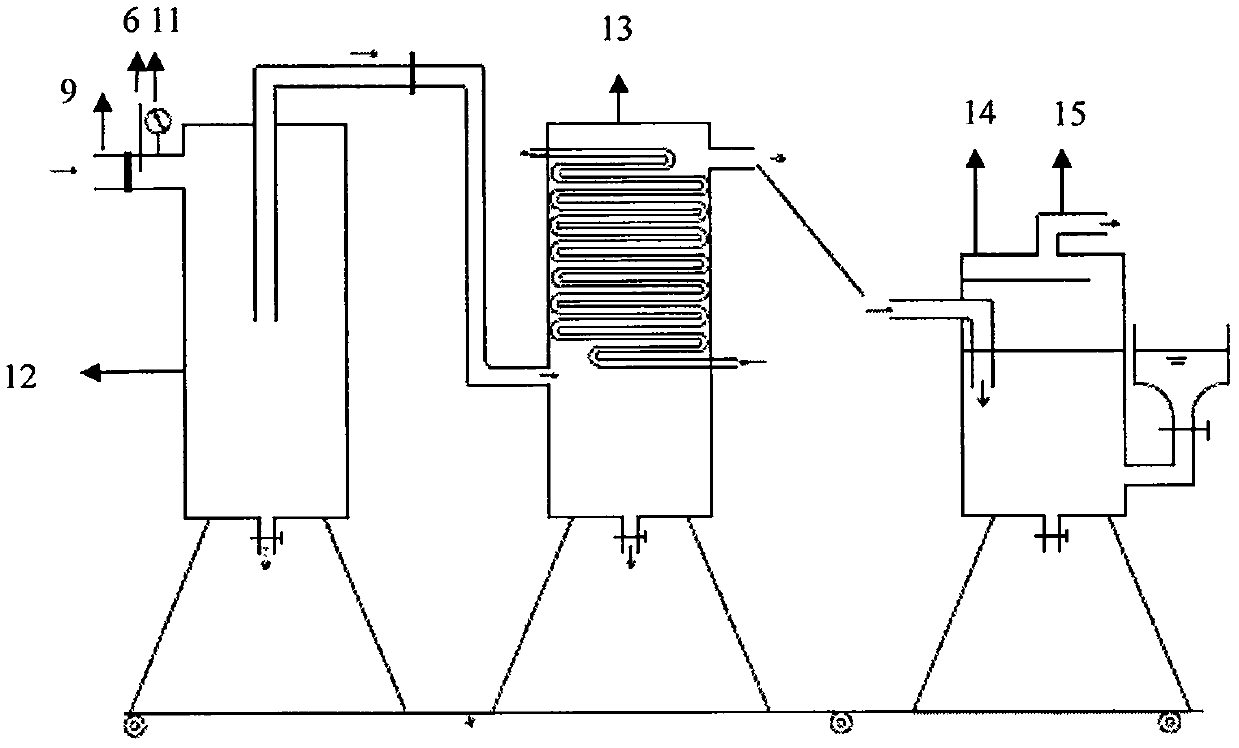

[0017] Such as figure 1 As shown: Base 1 is used to carry and fix various components. Base 1 is equipped with universal wheels to realize the moving function, and is also equipped with a height adjustment screw to realize the level of the base. temperature control; the combustion furnace 3 is made of stainless steel cover with insulation cotton to realize the heat preservation function. The shape of the furnace is square, neat and beautiful; It is made of stainless steel to achieve corrosion resistance. The wall thickness of the reactor is 6-12mm, which has good heat transfer efficiency. One end of the reactor 4 is the inlet and outlet 5, and a reverse discharge baffle is installed to realize the function of easy discharge. , the reactor 4 is welded with a stainless steel plate 7, which rotates with the rotation of the reactor 4 to real...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com