Air premixed type flare combustor capable of treating poisonous gas

An air premixed, flare combustion technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problem of ineffective cascade adjustment of the combustion temperature of the flare burner outlet regenerator, Incomplete combustion and decomposition of flare gas, uneven air distribution in the flame area, etc., to achieve the effects of compact structure, good premixing effect, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

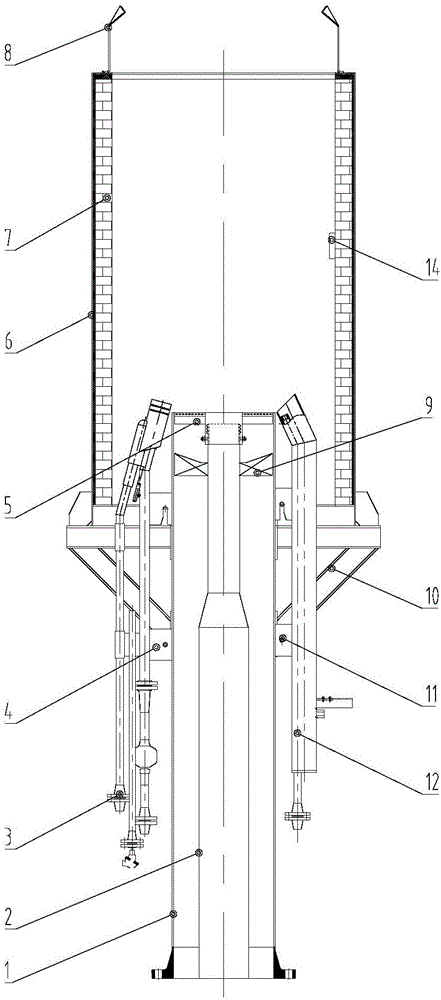

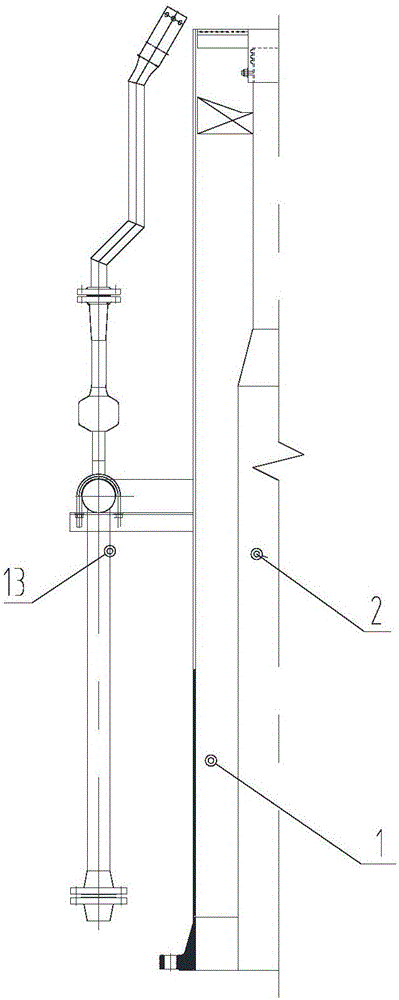

[0020] An air premixed torch burner capable of treating toxic gases according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

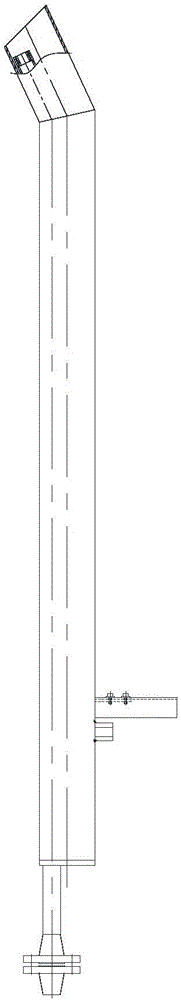

[0021] Such as figure 1 and figure 2 As shown, an air premixed torch burner that can handle toxic gases according to the present invention includes an air jacket cylinder body 1, a torch gas cylinder body 2, a torch gas nozzle 5, a swirl plate 9, an ever-burning lamp 3, Burner 13 , combustion chamber 6 , temperature monitoring element 15 , support assembly 10 .

[0022] The torch gas cylinder body 2 is arranged in the air jacket cylinder body 1 to form a jacket cylinder body structure, and a swirl plate 9 is arranged in the middle and upper part of the jacket cylinder body structure; the torch gas nozzle 5 is installed on the flare gas cylinder body 2 by bolts The upper end is detachable and replaceable.

[0023] The combustion chamber 6 is connected to the upper oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com