Patents

Literature

97results about How to "Reduce retention time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

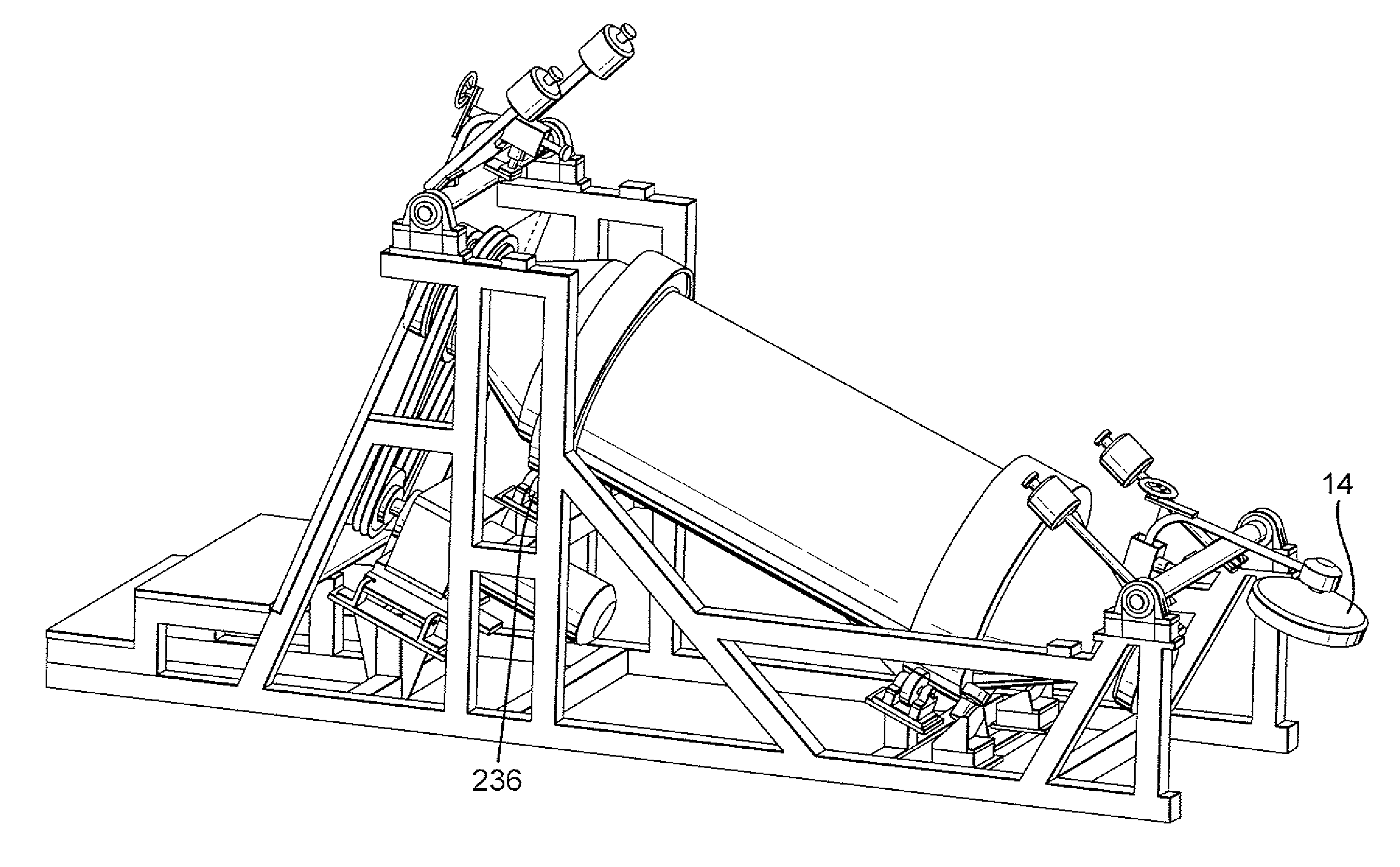

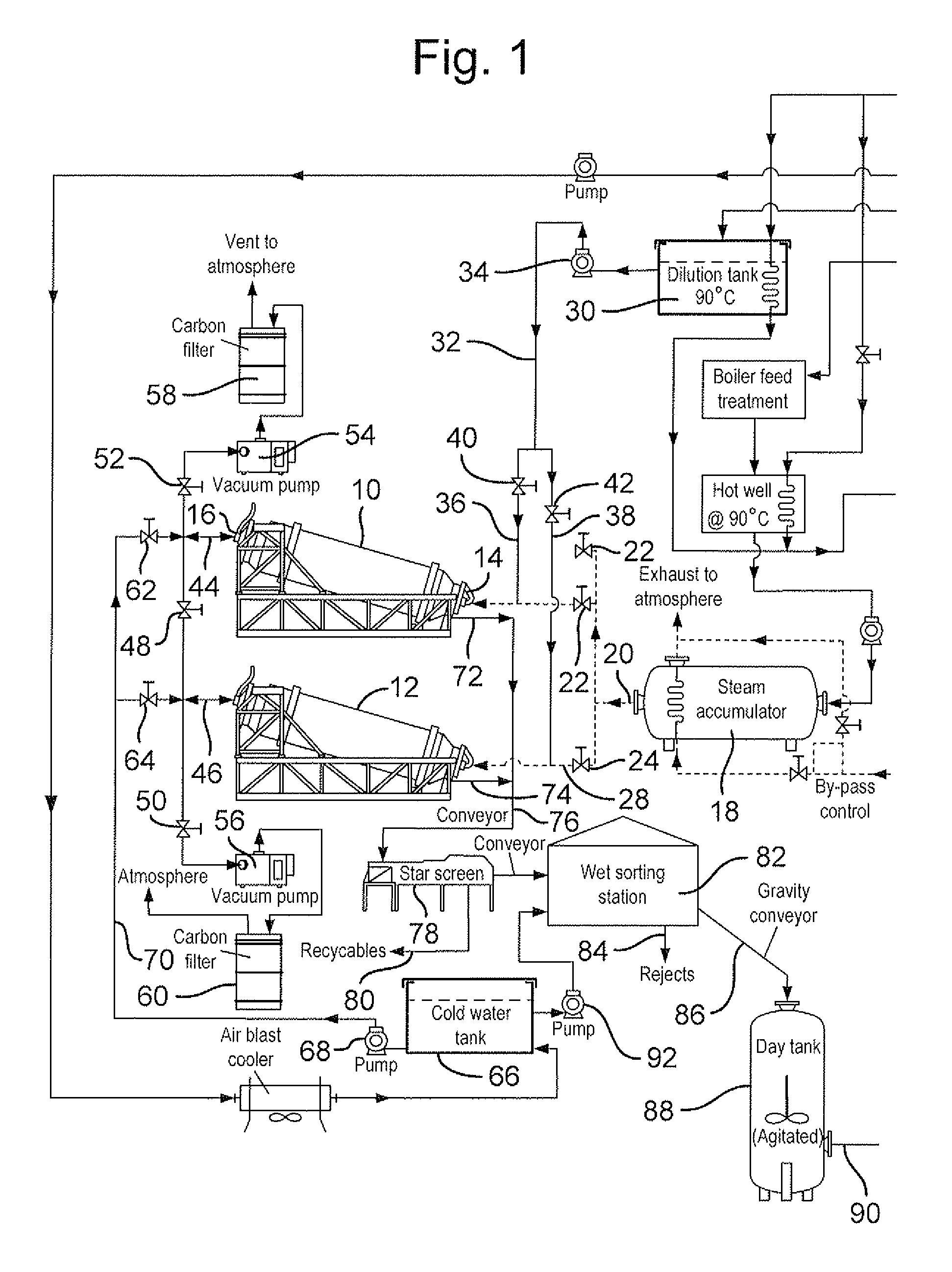

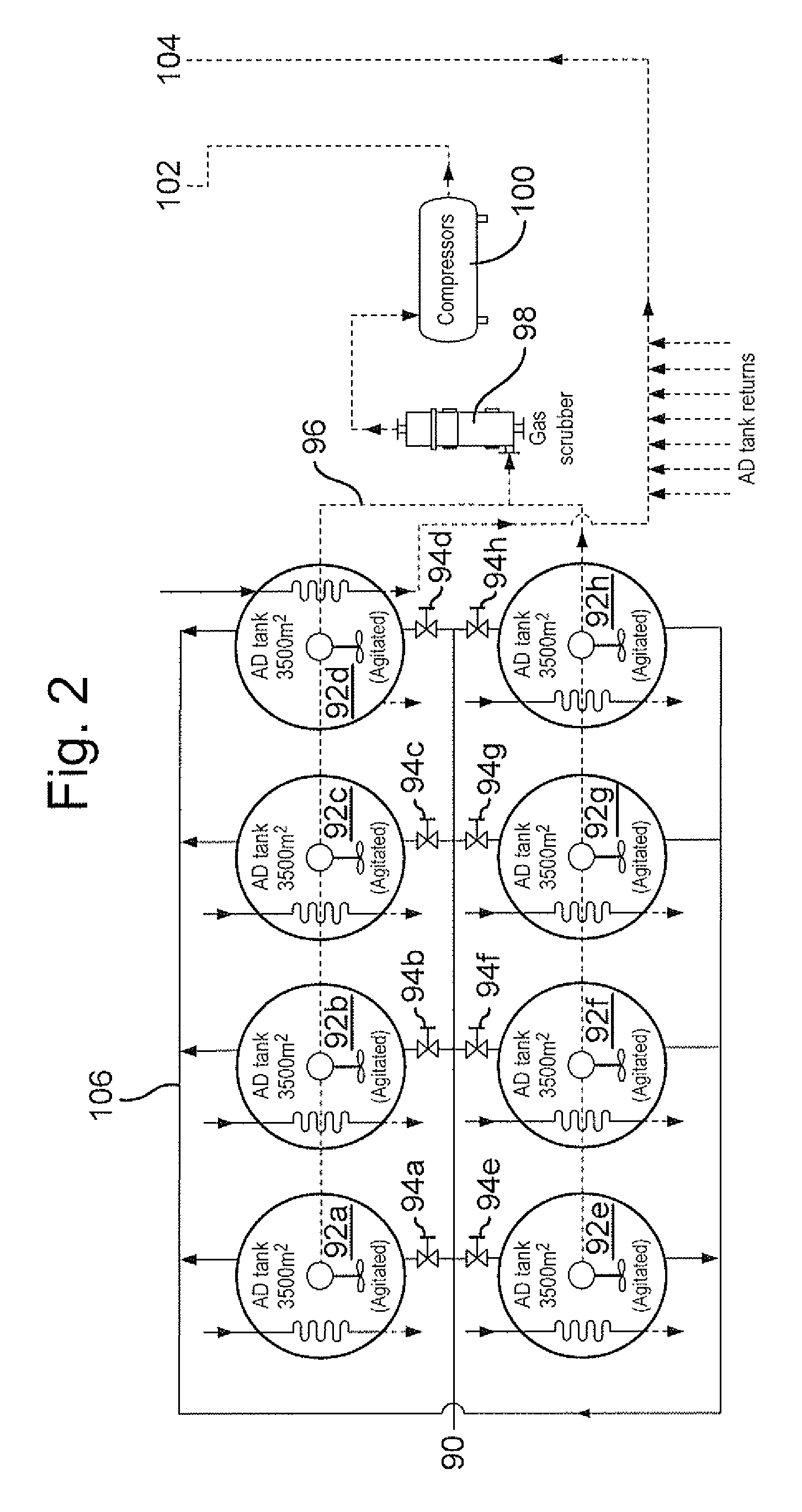

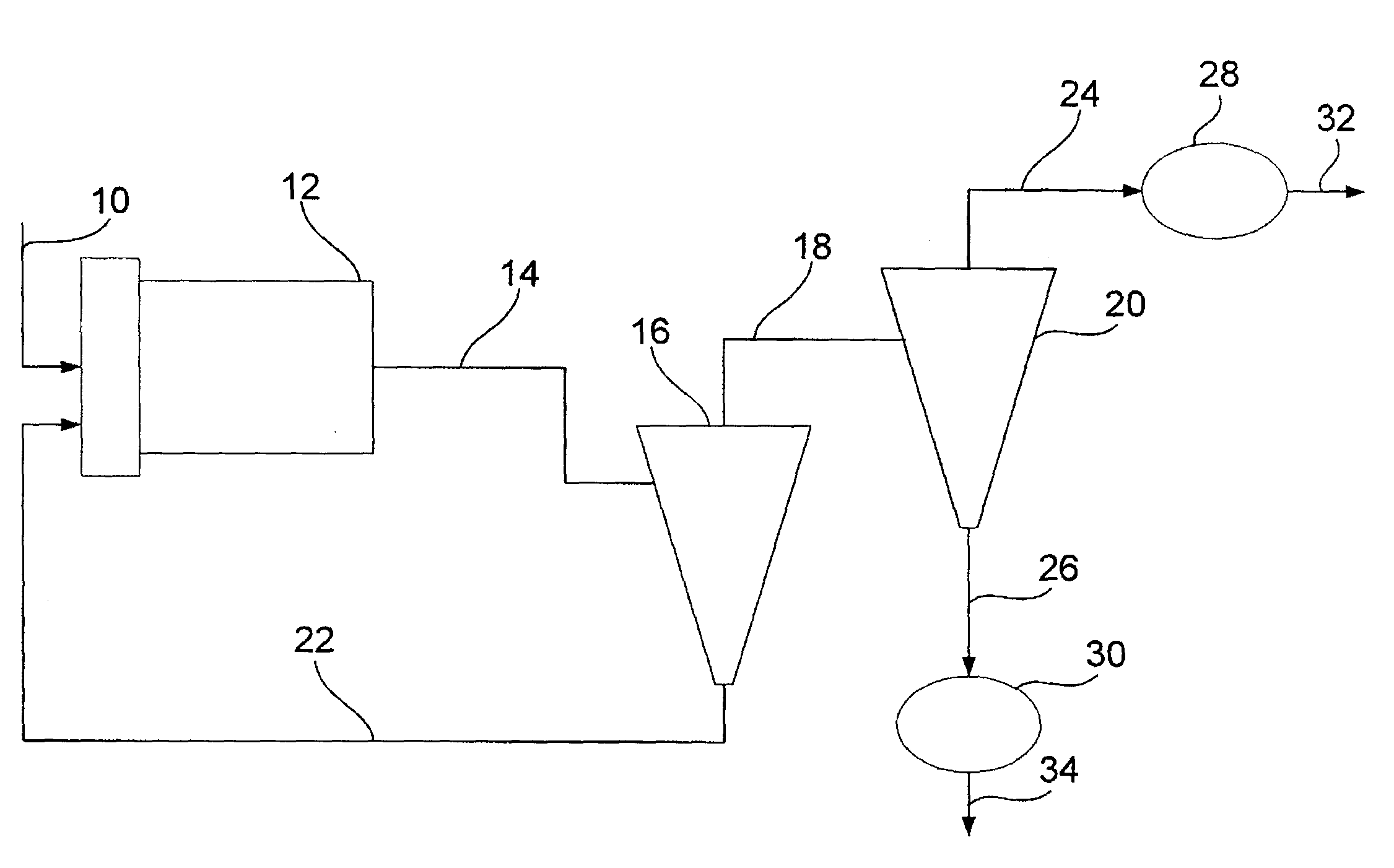

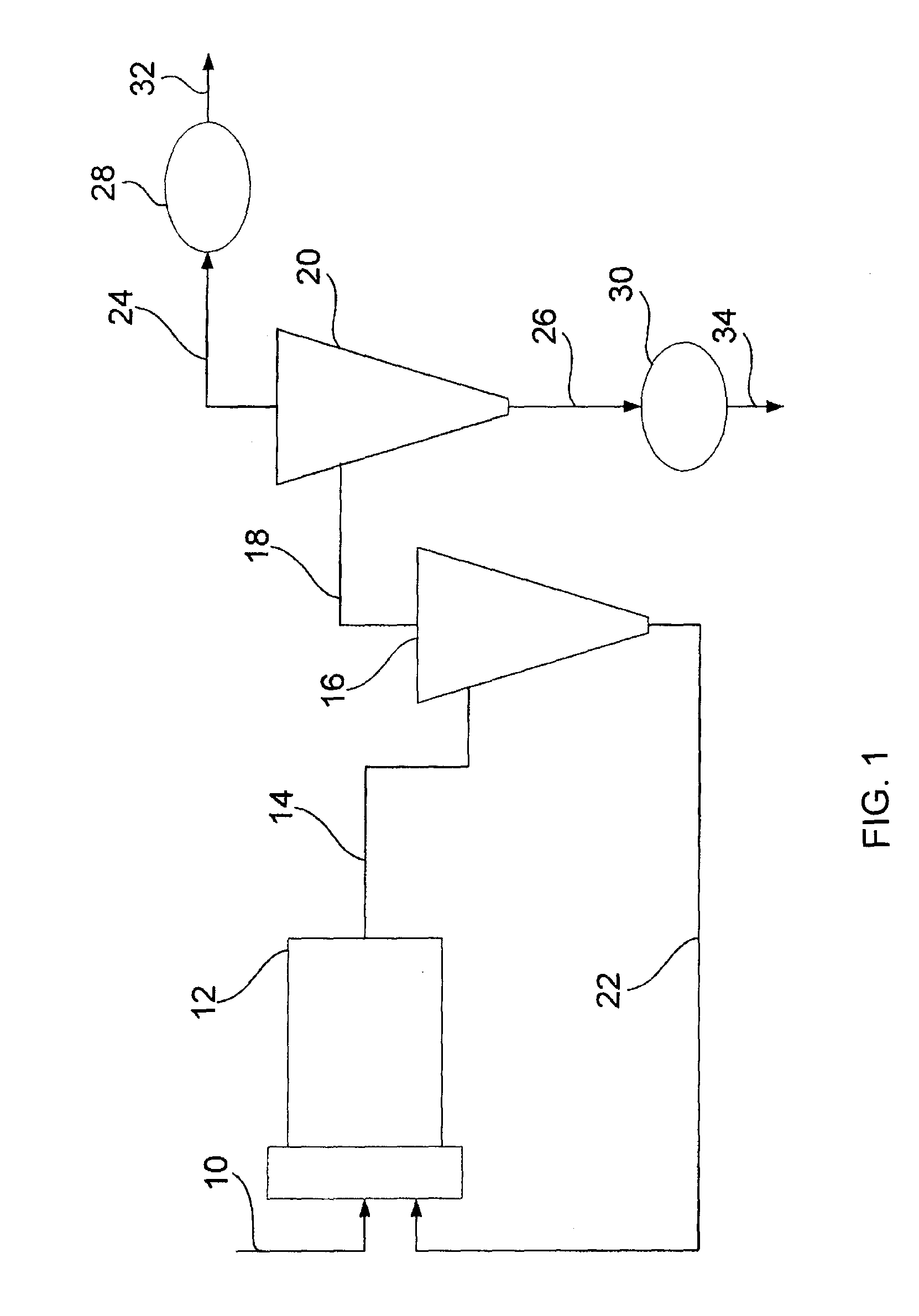

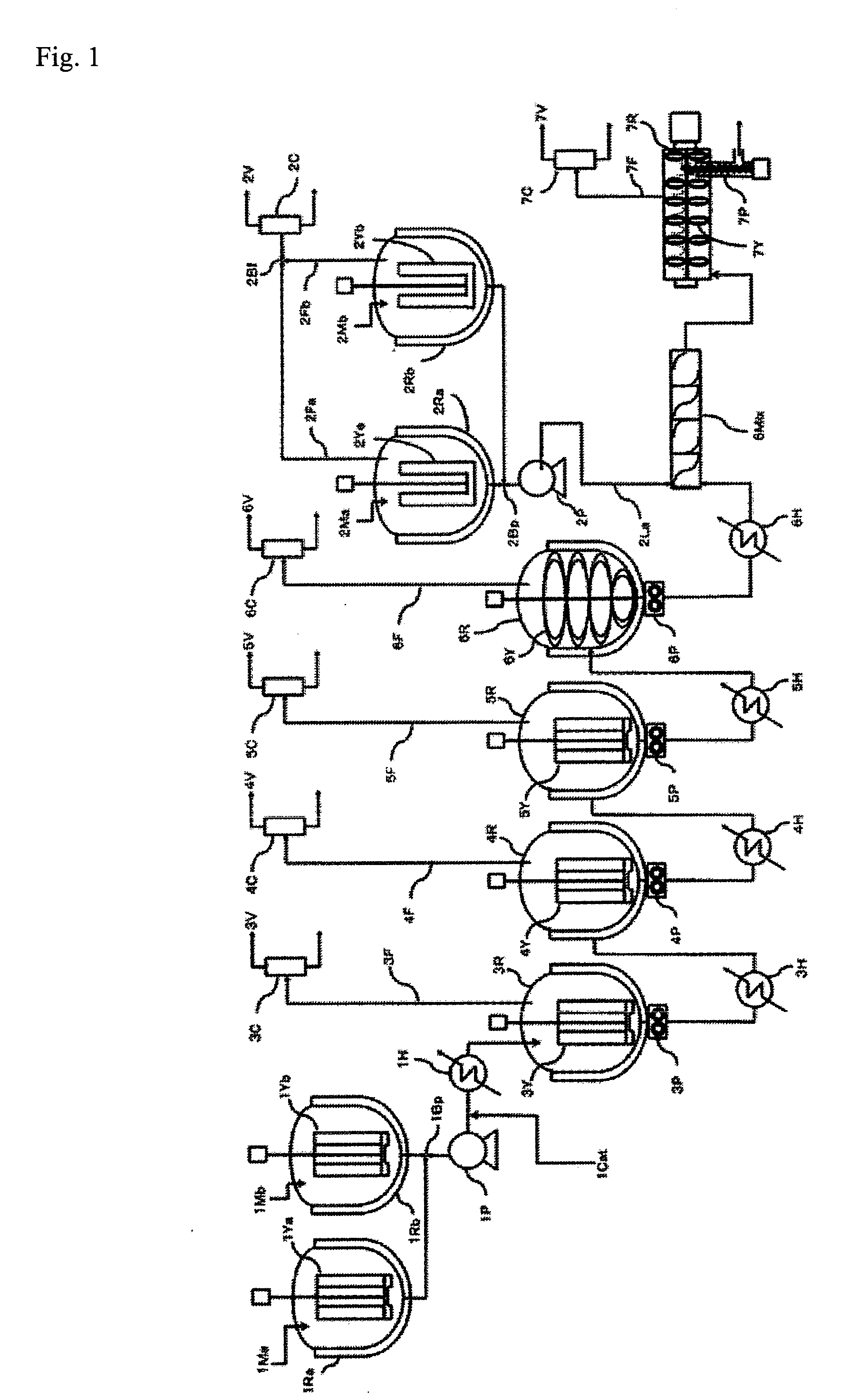

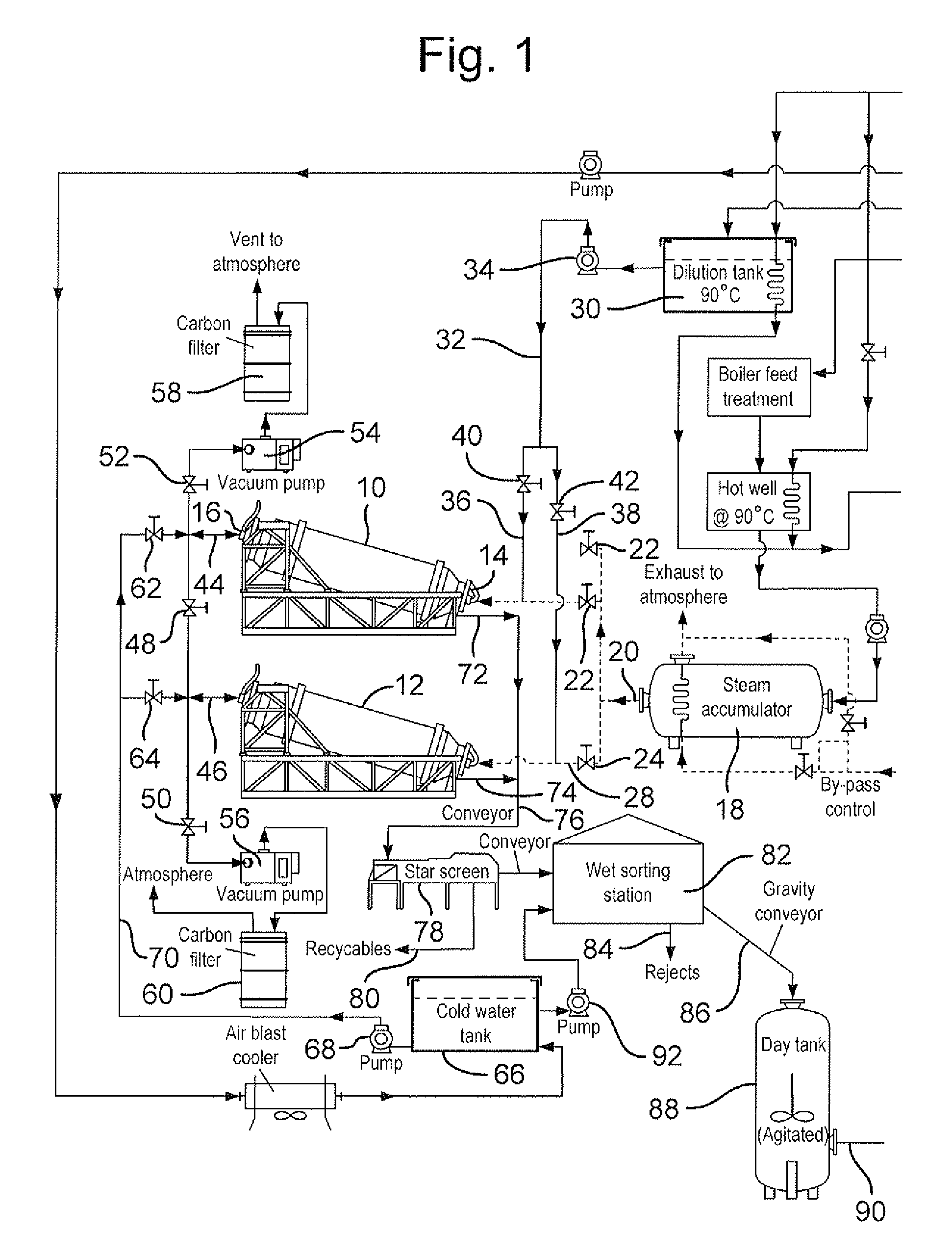

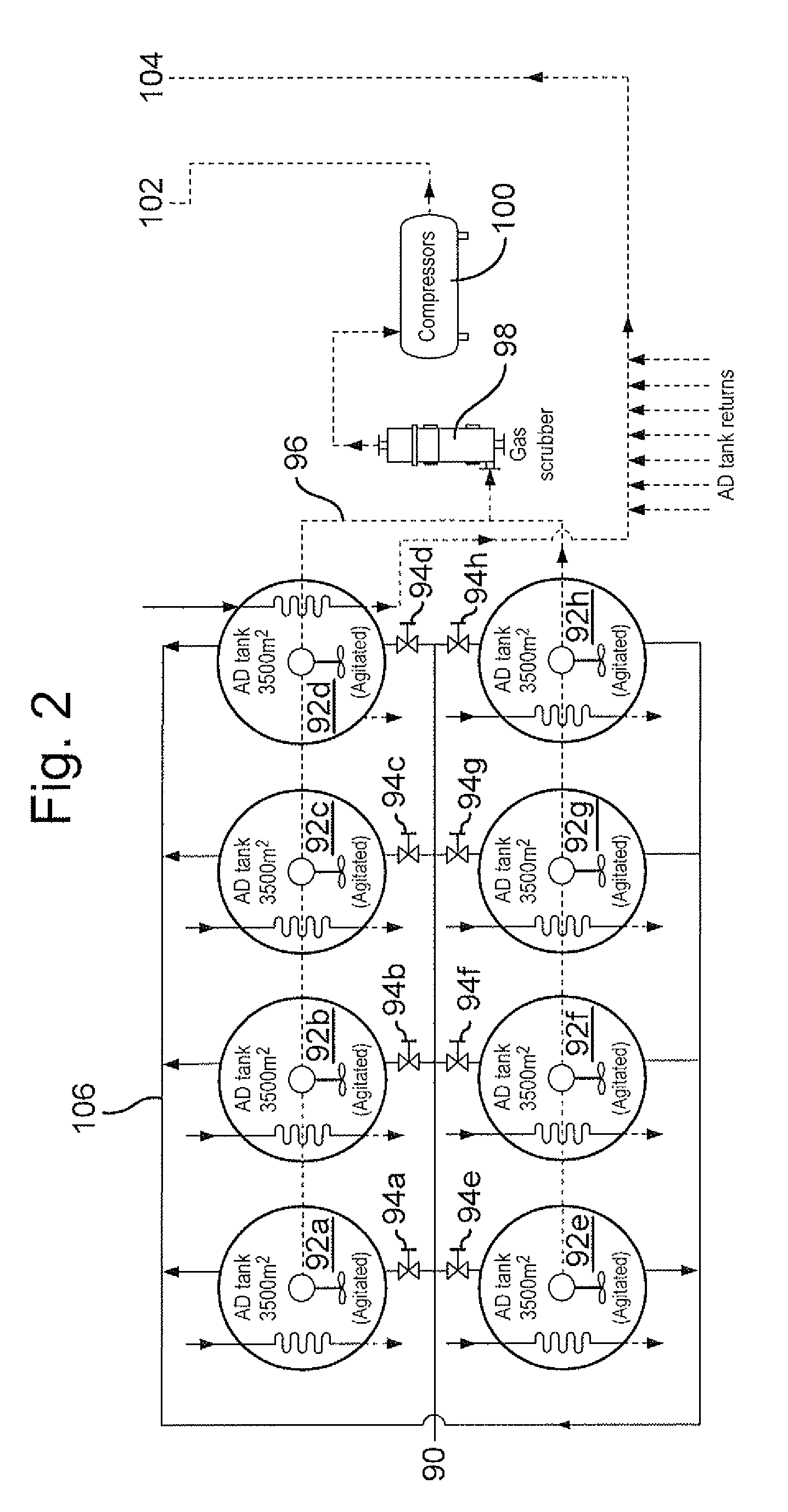

Apparatus and process for treating waste

ActiveUS20130029394A1Easy to separateEliminate needBioreactor/fermenter combinationsBiological substance pretreatmentsDigestionInternal combustion engine

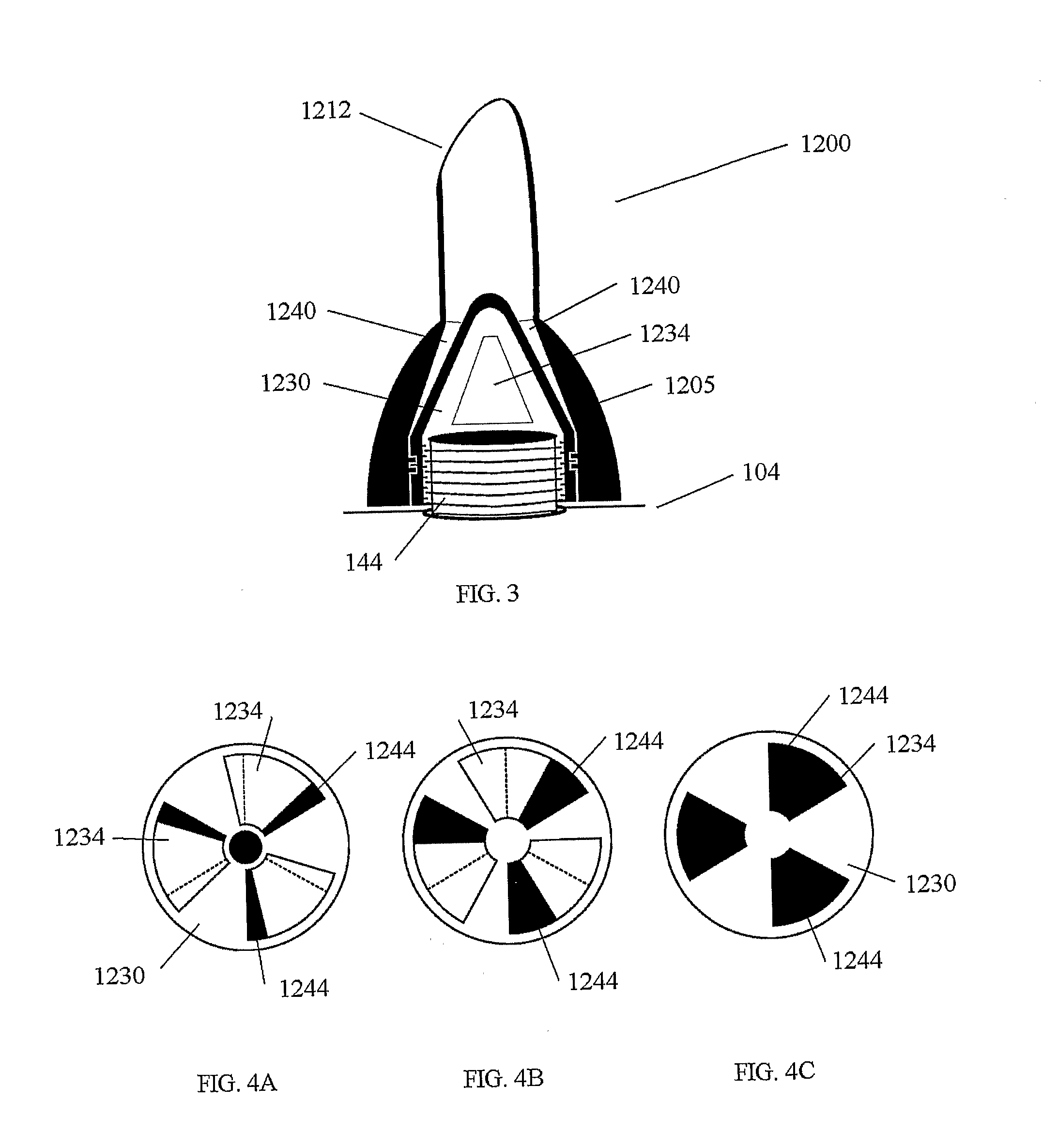

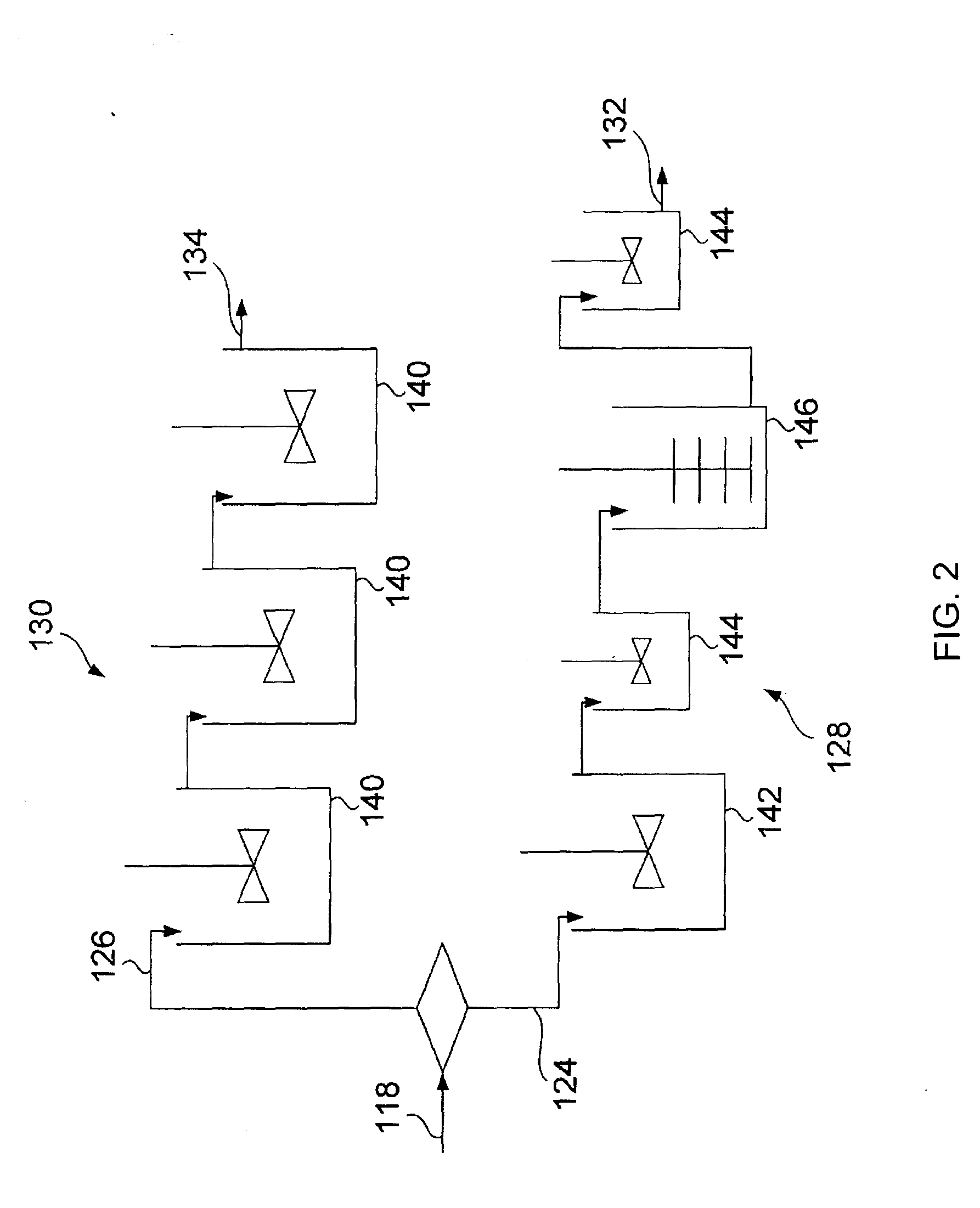

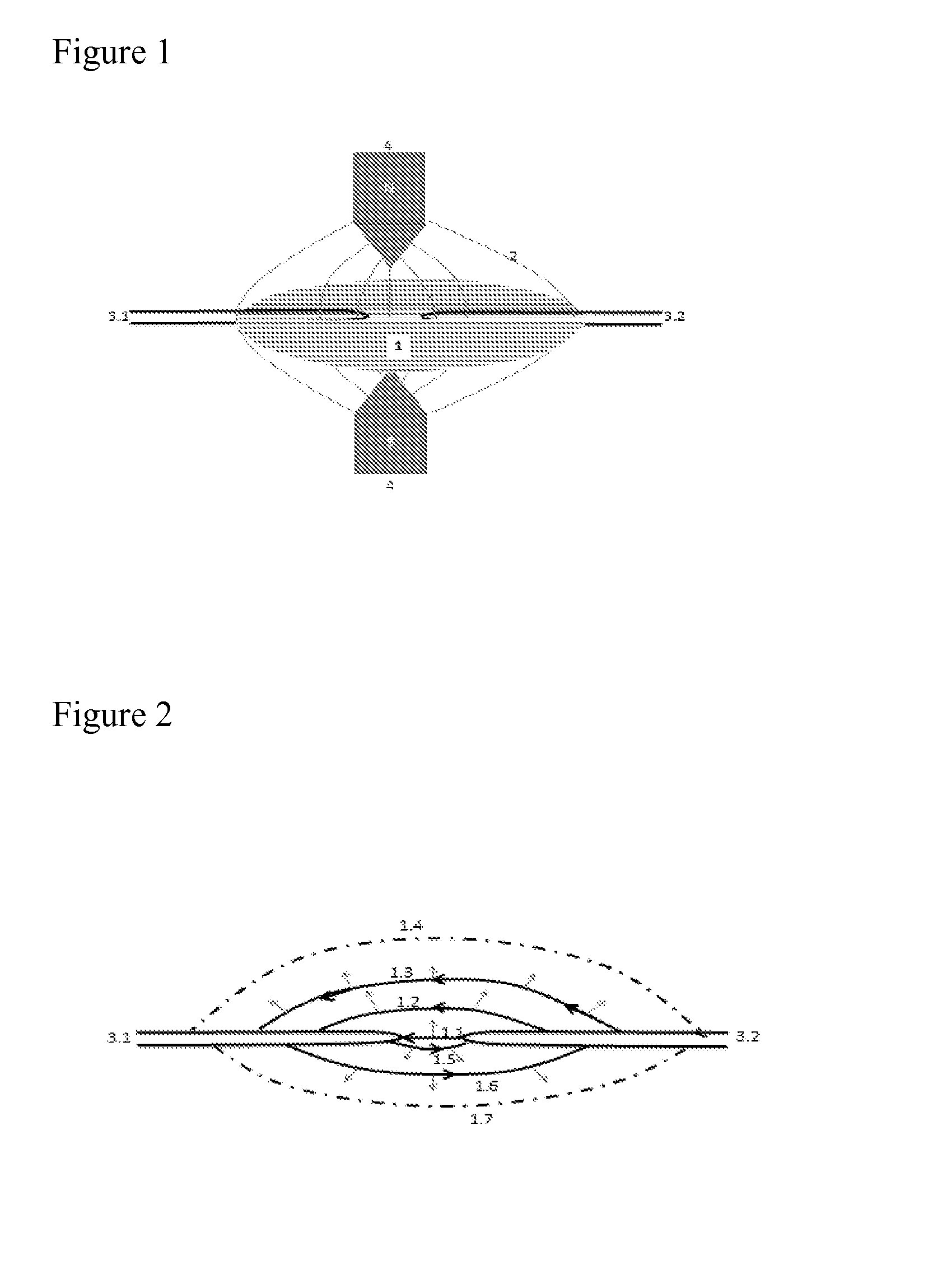

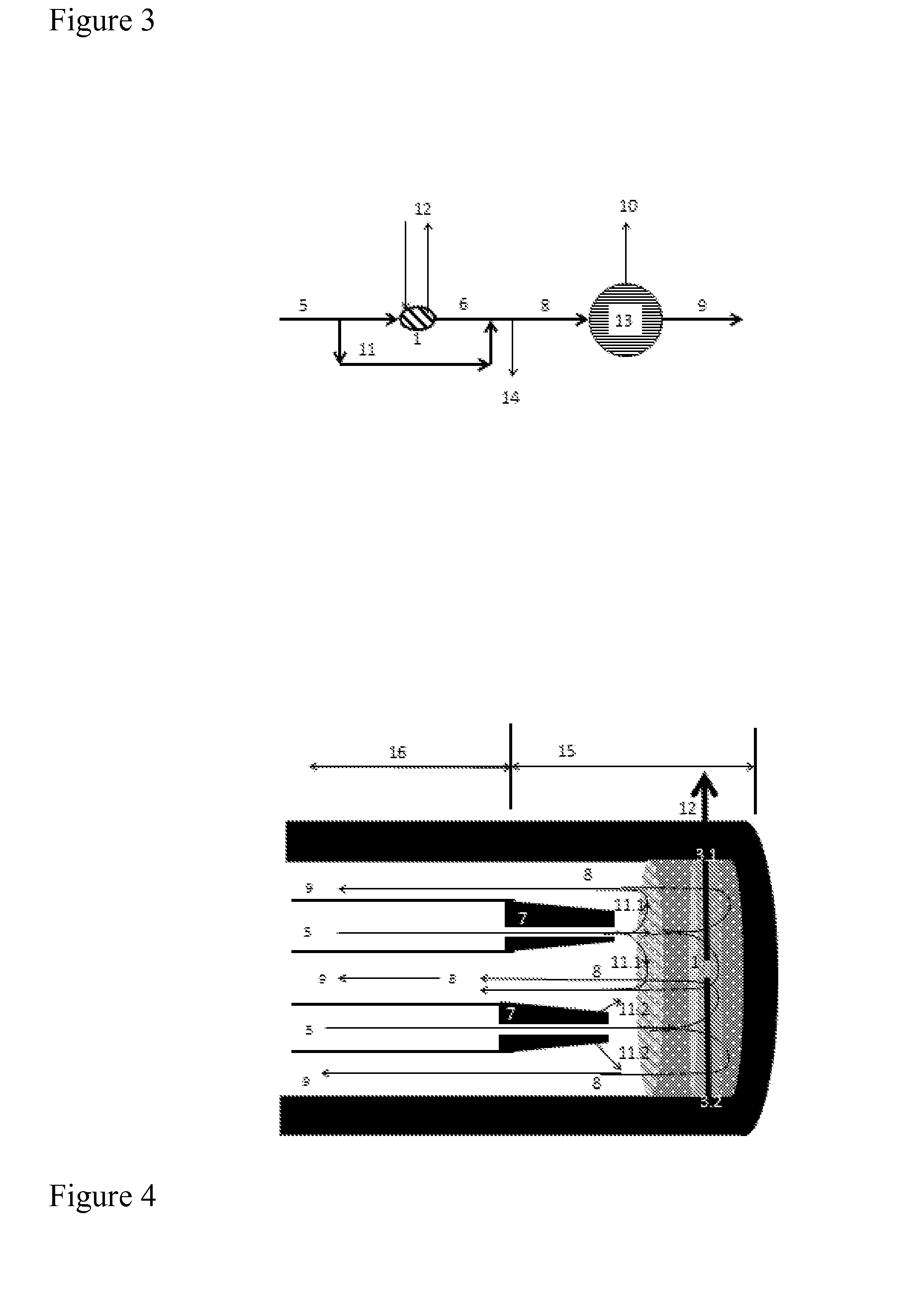

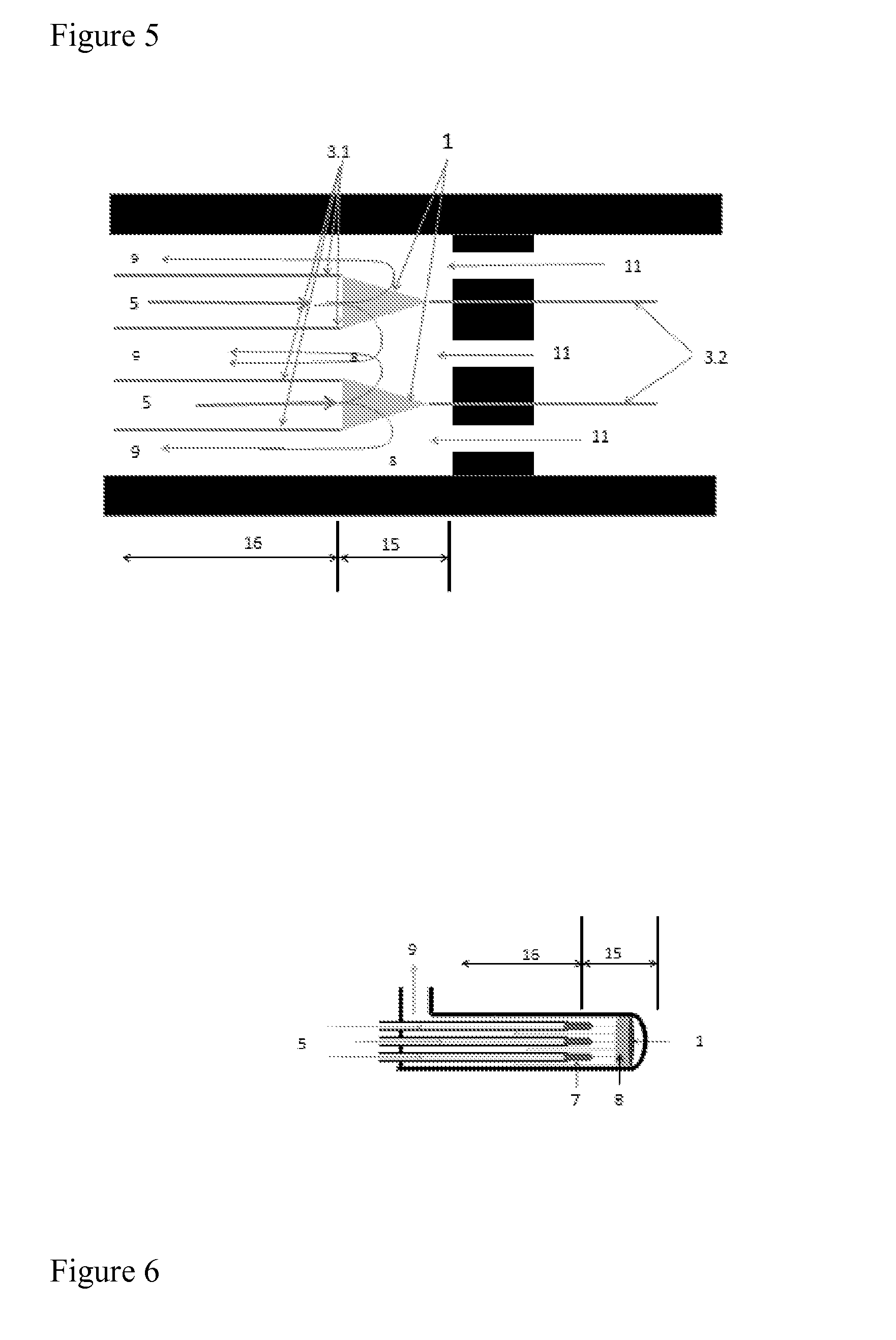

A method for treating municipal solid waste and other waste is provided which comprises: introducing said waste into a rotary autoclave which is downwardly inclined towards its discharge end and has a door at the discharge end; and injecting steam through said door into said autoclave to treat the load. A method is also provided for treating waste, comprising steam autoclaving the waste, anaerobically digesting an organic-rich fraction of the autoclaved waste, recovering methane-containing gas from anaerobic digestion, internally combusting the methane-containing gas to generate power and exhaust gas, and generating steam for autoclaving using the waste heat. A plant for treating the waste may comprise at least one autoclave for steam treating the waste, at least one anaerobic digestion tank for digesting an organic-rich fraction of the autoclaved waste, a recovery system for recovering methane-containing gas from the or each digestion tank, at least one internal combustion engine for combusting the methane-containing gas and generating power, and a steam generator fed with combustion gas from the internal combustion engine for generating and accumulating steam for supply to said at least one autoclave. Also provided is a method of treating waste material in a rotary autoclave, which comprises: loading the waste material into a top opening of the autoclave whilst rotating the autoclave in a first direction in which screw flights within the autoclave convey the waste forwardly along a downwardly inclined body of the autoclave towards a base of the autoclave; rotating the autoclave in a second direction opposite to the first direction so as to establish a circulation of the loaded material between the upper and lower ends of the autoclave to facilitate vacuum and / or steam treatment thereof; and monitoring the load imparted by the autoclave adjacent upper and lower ends thereof during the reverse rotation, increase of the load adjacent the upper end of the autoclave providing an indication of effective load circulation. A door structure for a commercial-scale autoclave based on a castellated door and a locking ring with lock blocks of inwardly facing U-structure is also provided.

Owner:AEROTHERMAL GROUP

Cosmetic compositions and methods for using same to improve the aesthetic appearance of skin

InactiveUS20040067245A1Treating and preventing and ameliorating sign of dermatological agingImprove aestheticsCosmetic preparationsSalicyclic acid active ingredientsPerilla oilCarboxylic acid

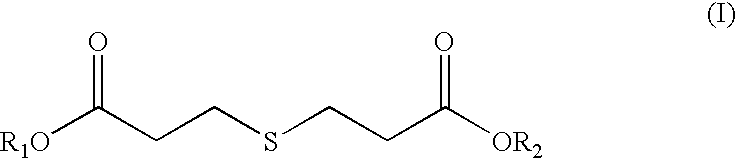

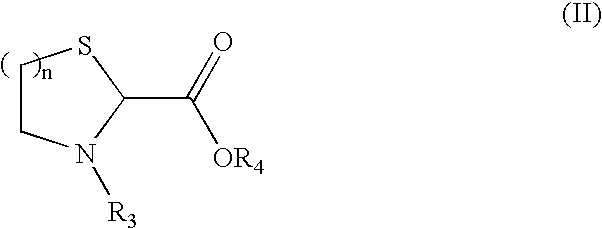

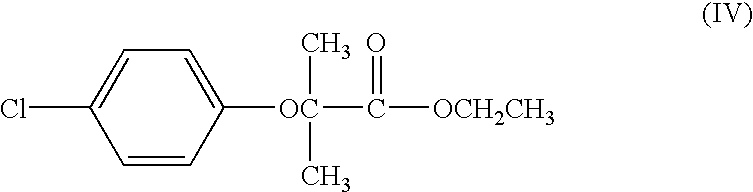

The present invention relates to compositions useful in treating hyperpigmentation and the various signs of dermatological aging in human skin. The present invention also relates to cosmetic compositions and methods of using such compositions that improve the aesthetic appearance of skin. Further, the present invention relates to methods of applying the compositions to the skin to effect treatment and to improve the aesthetic appearance of skin, particularly, by providing anti-aging benefits to the skin. These and other objects of the present invention are achieved by a method and composition that comprises (a) a de-pigmenting agent or anti-aging agent in an amount effective to prevent, treat and / or ameliorate pigmentation or the various signs of aging at an area of skin to which it is applied, and (b) a cosmetically or pharmaceutically acceptable vehicle. Suitable de-pigmenting agents include 3,3'-thiodipropionic acid, thiazolidine-2-carboxylic acid, Kaempferol-7-glucoside, perilla oil, and clofibrate and clofibrate analogs and / or derivatives, as well as those set forth below. Suitable anti-aging agents include 3,3'-thiodipropionic acid and / or its derivatives.

Owner:AVON PROD INC

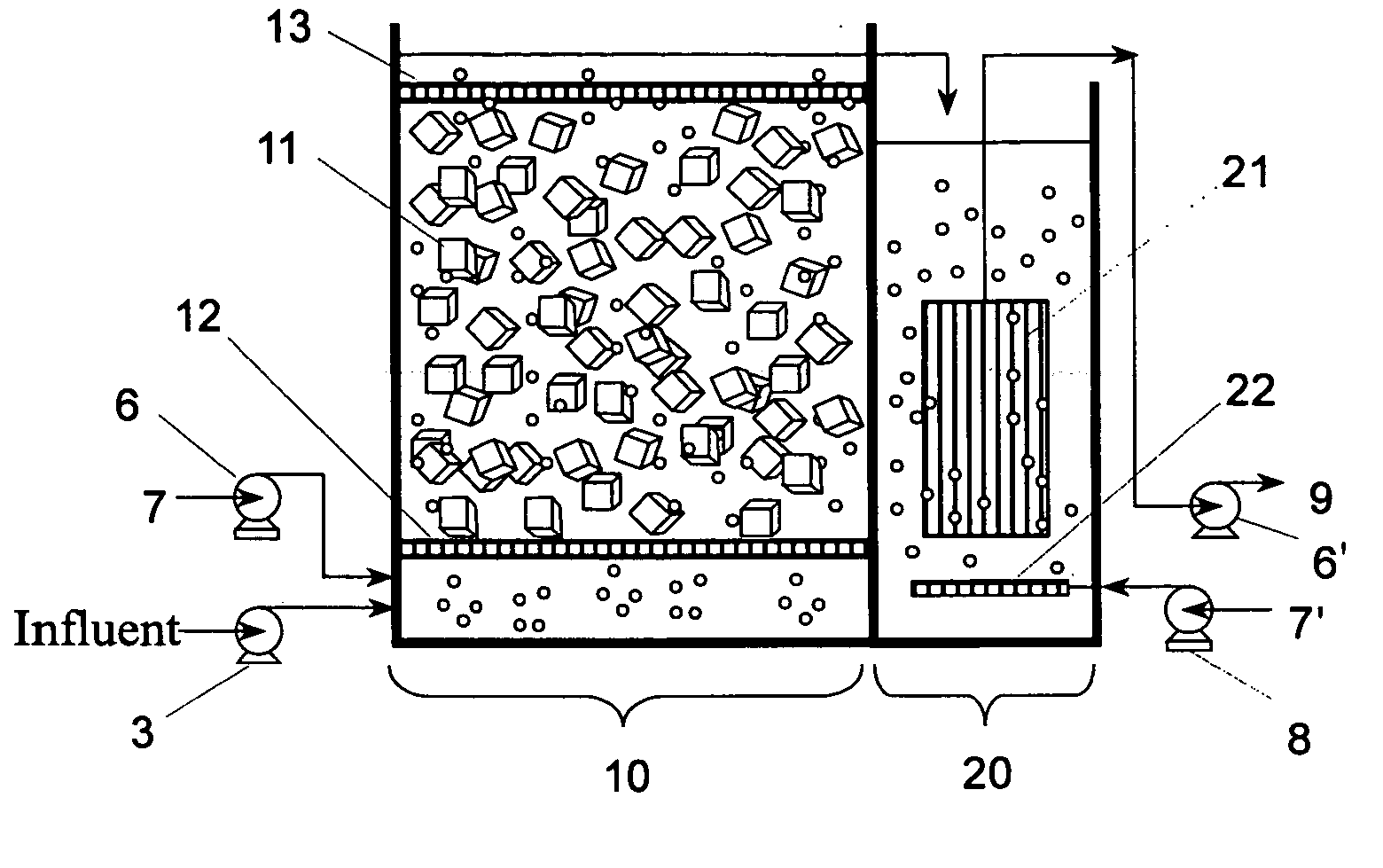

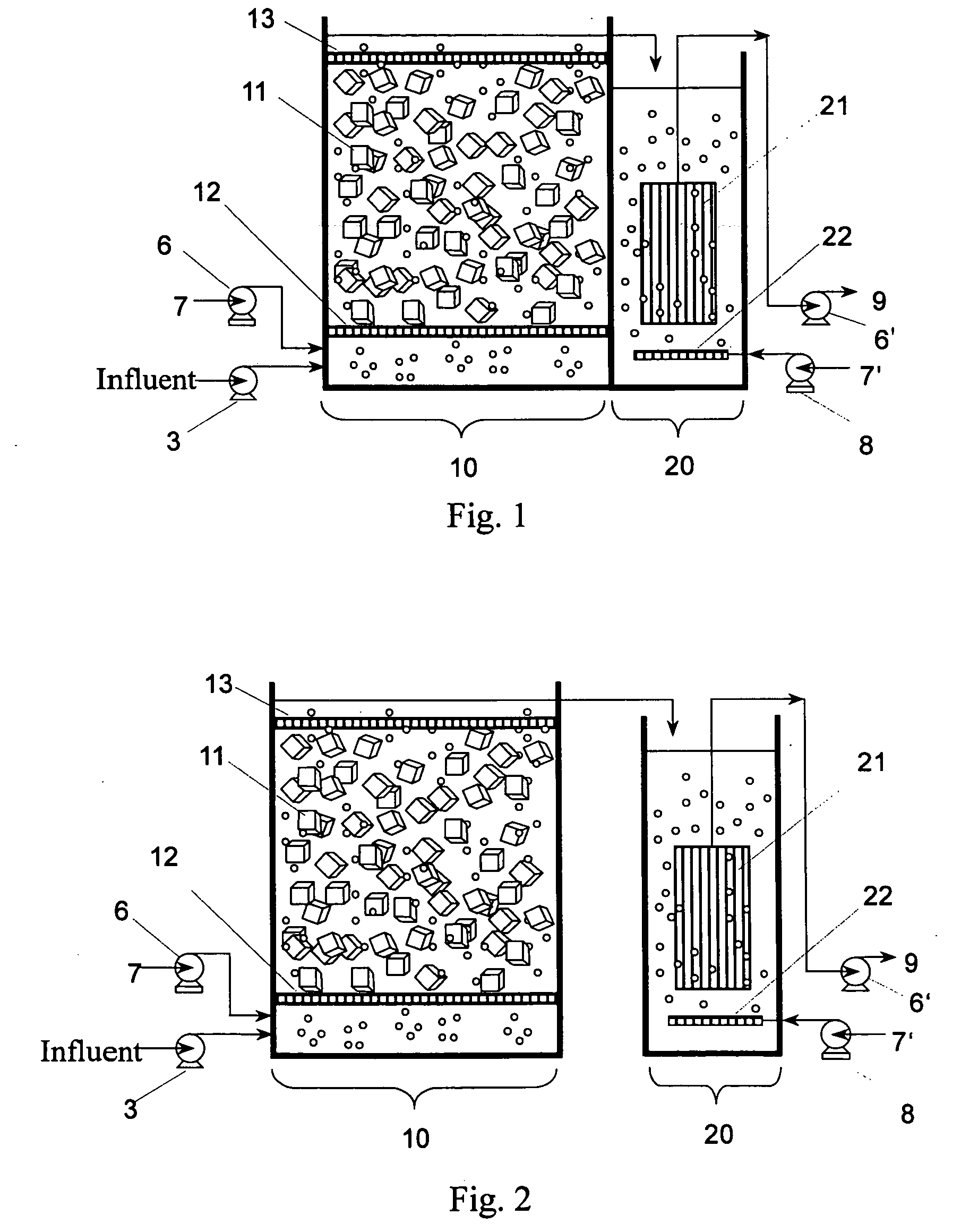

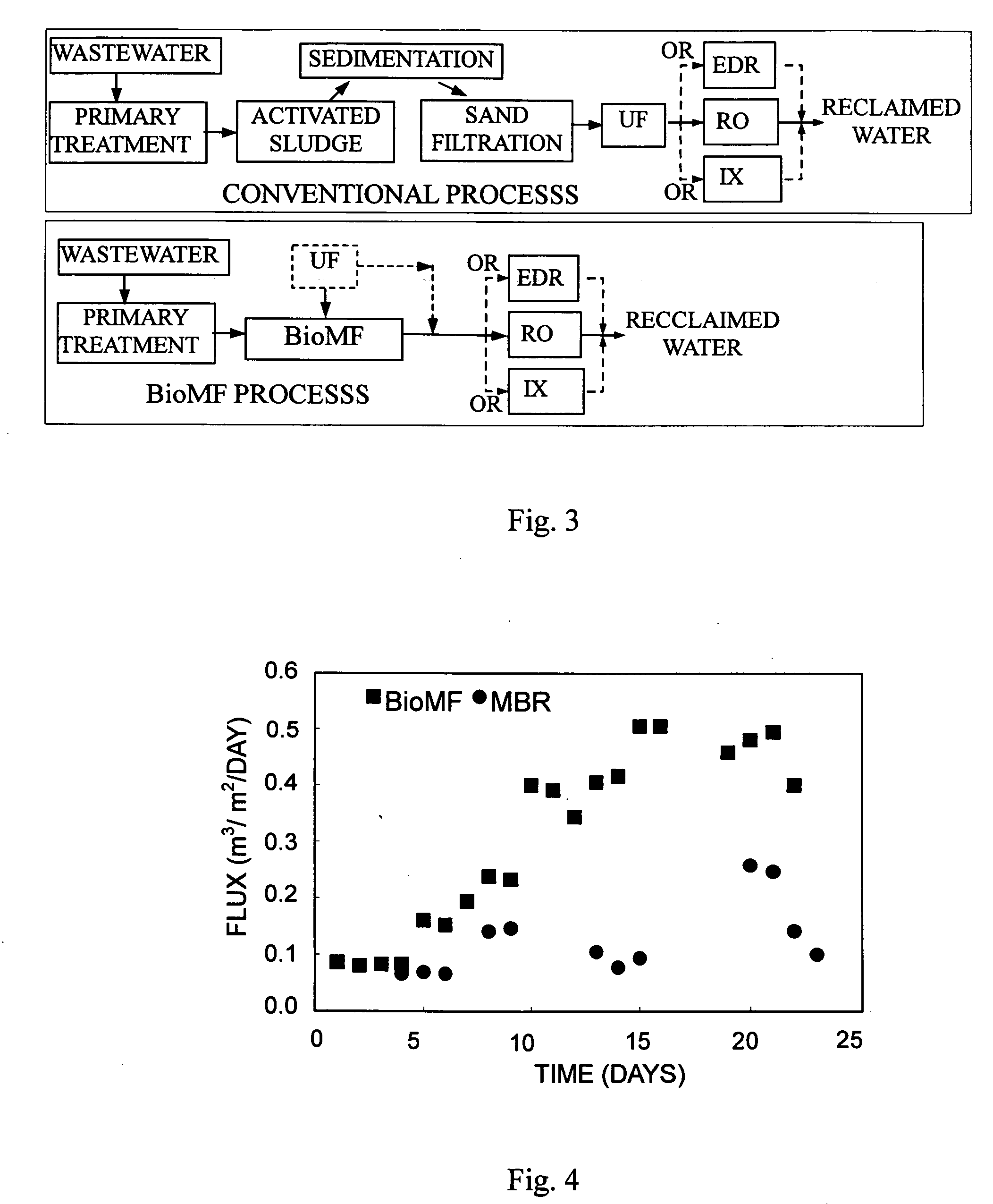

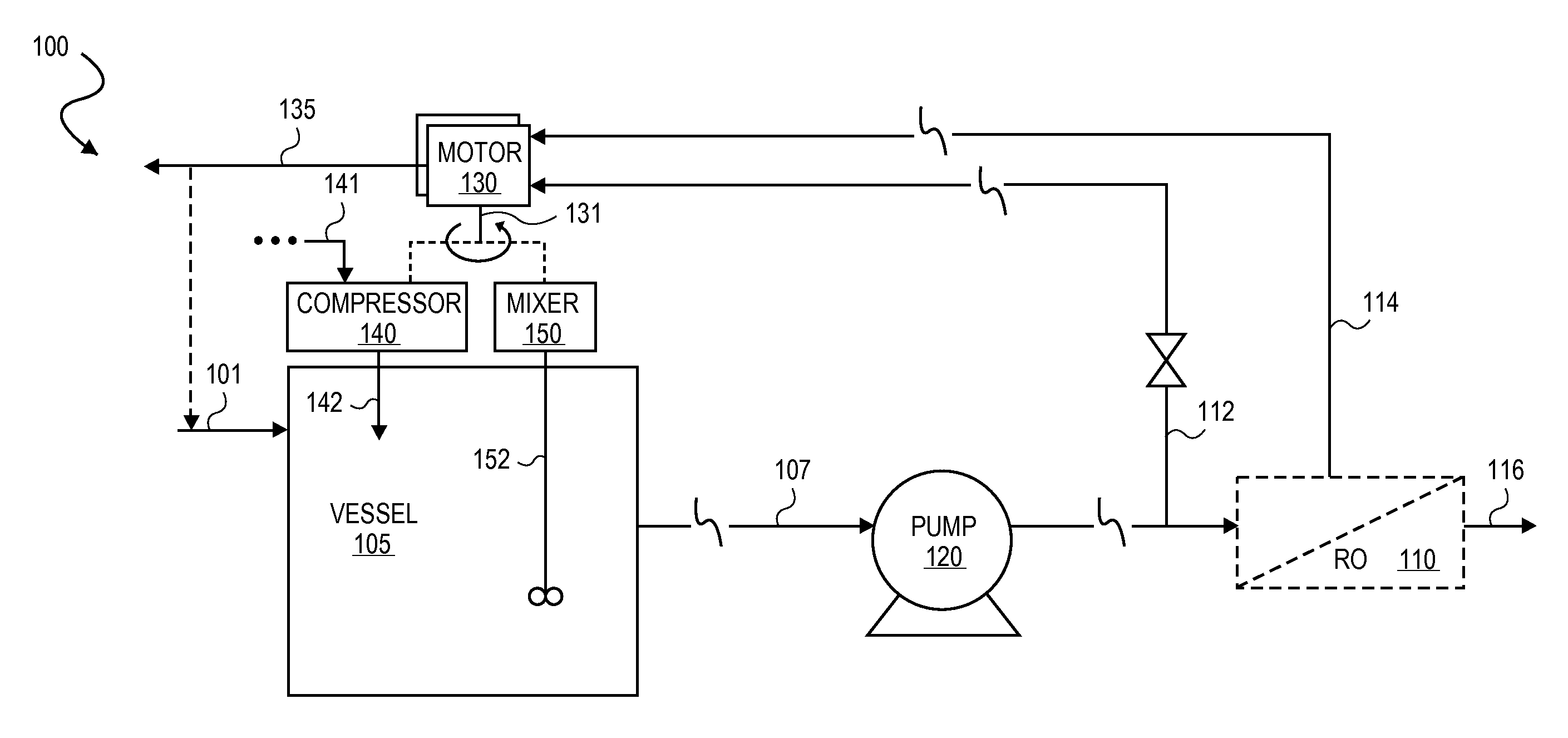

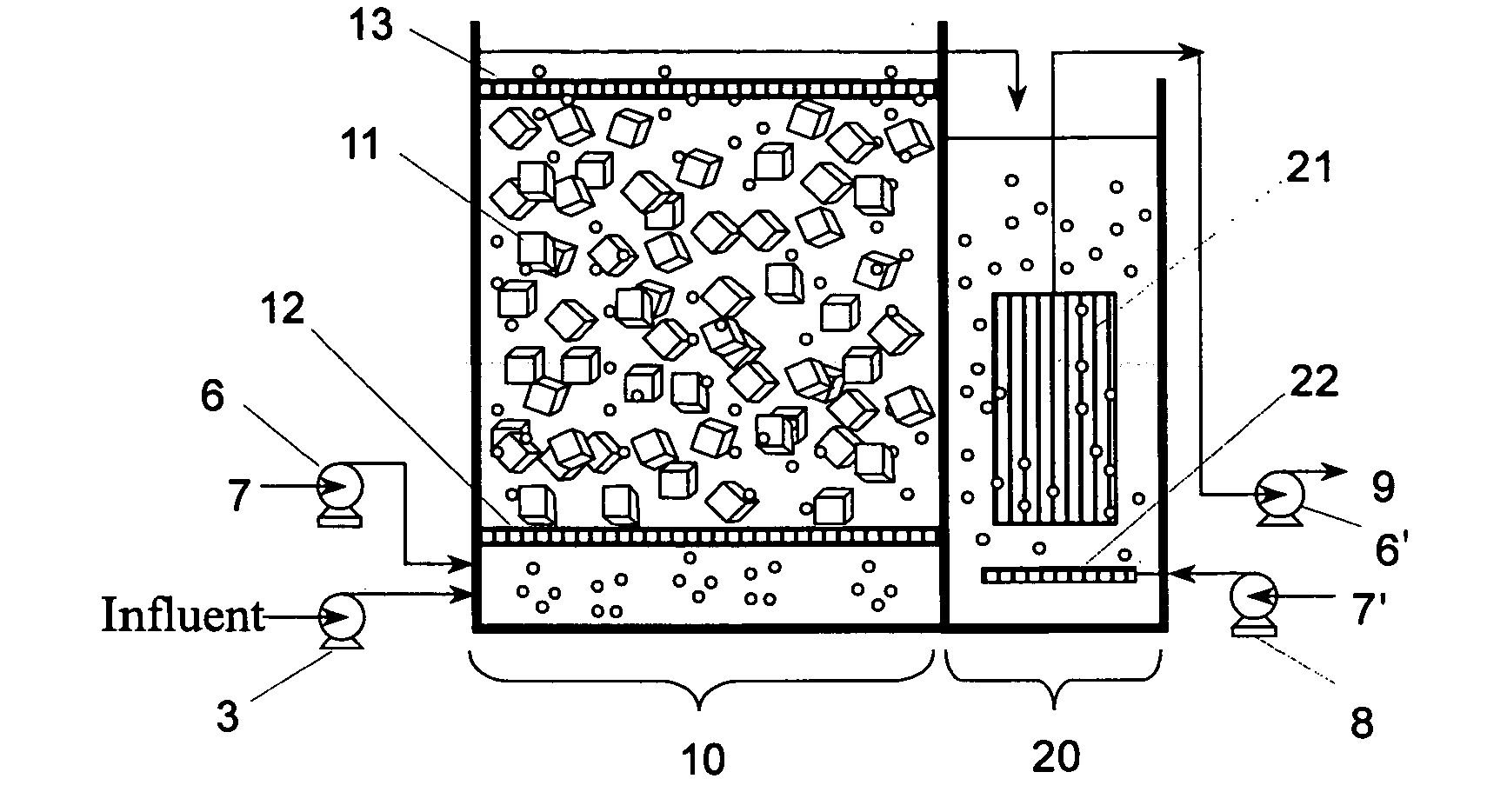

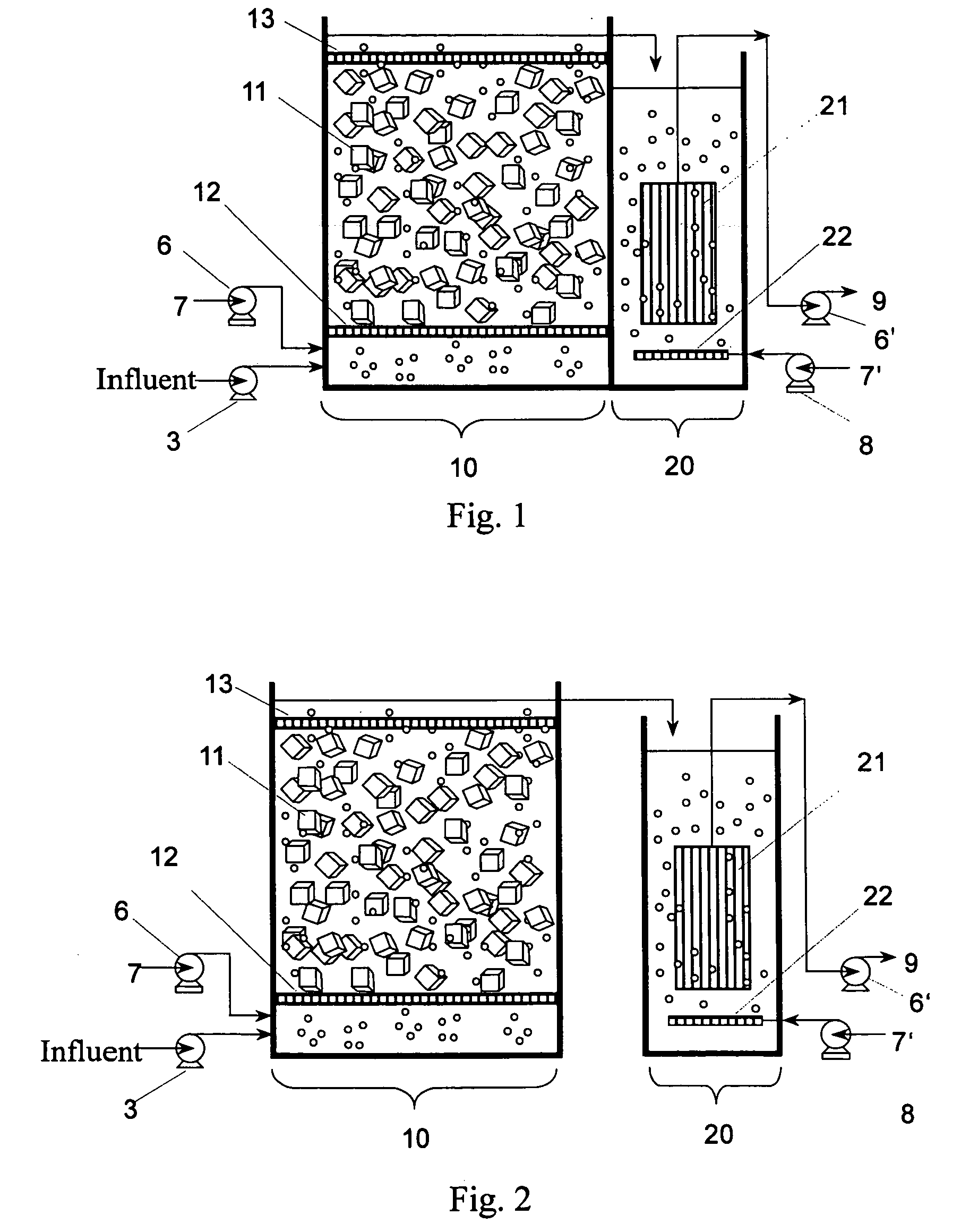

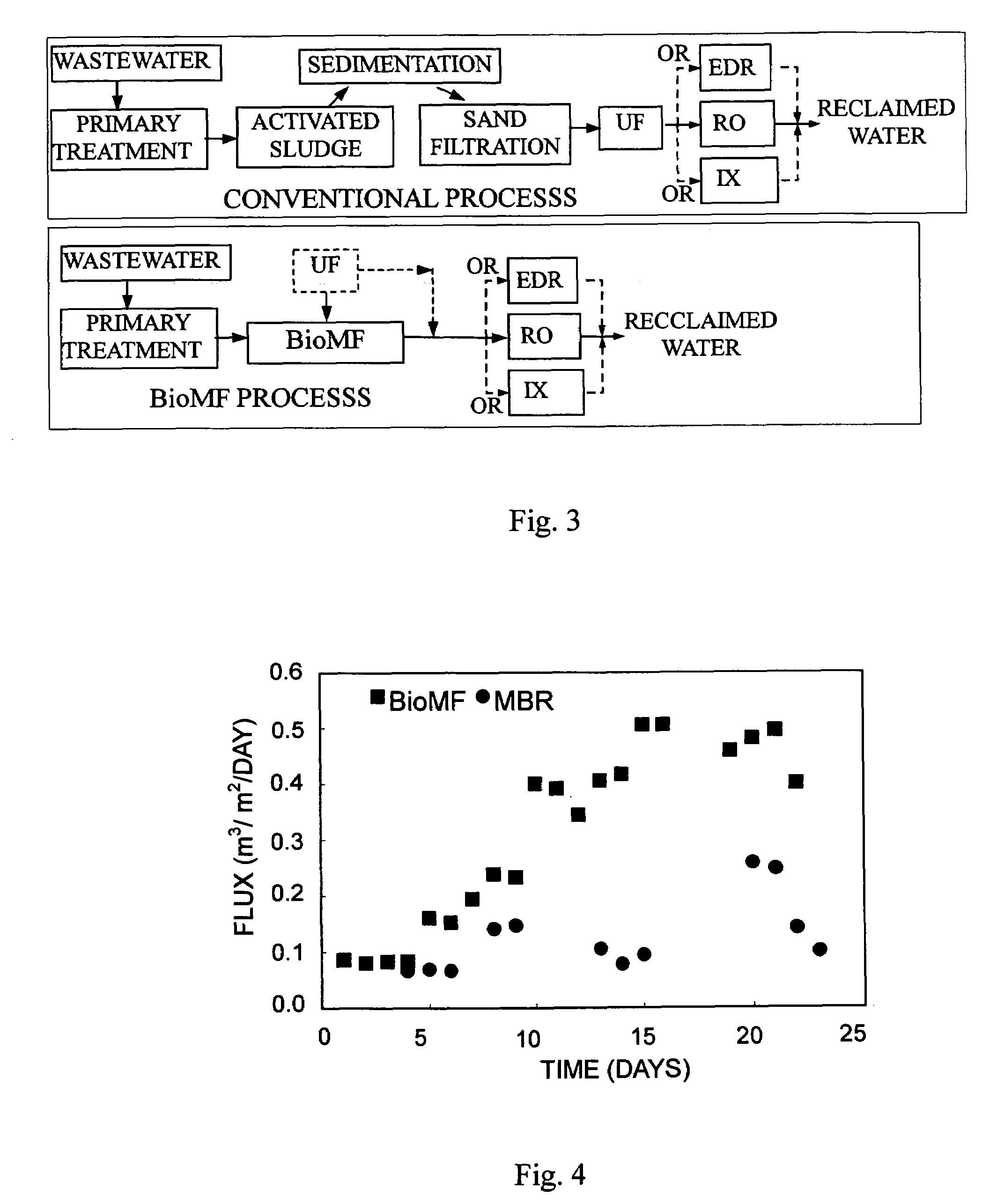

Biological membrane filtration system for water treatment and a water treatment process

ActiveUS20060131230A1Improve abilitiesReduce loadMembranesTreatment using aerobic processesWater treatment systemFiltration

The present invention discloses a biological membrane filtration wastewater treatment system including a porous biological filtration bed zone and a membrane separation zone. The porous biological filtration bed zone has the dual function of providing biological treatment and higher filtration rates, wherein a fixed bed or moving bed is utilized so that the porous biological filtration bed zone has the advantages of high loading rates, high removal efficiencies, high stability and ease of operation. The membrane separation zone utilizes a membrane filtration module to filter an effluent from the porous biological filtration bed zone, so that solid particles therein are separated and remain in the system. Therefore, a high quality of effluent is obtained.

Owner:IND TECH RES INST

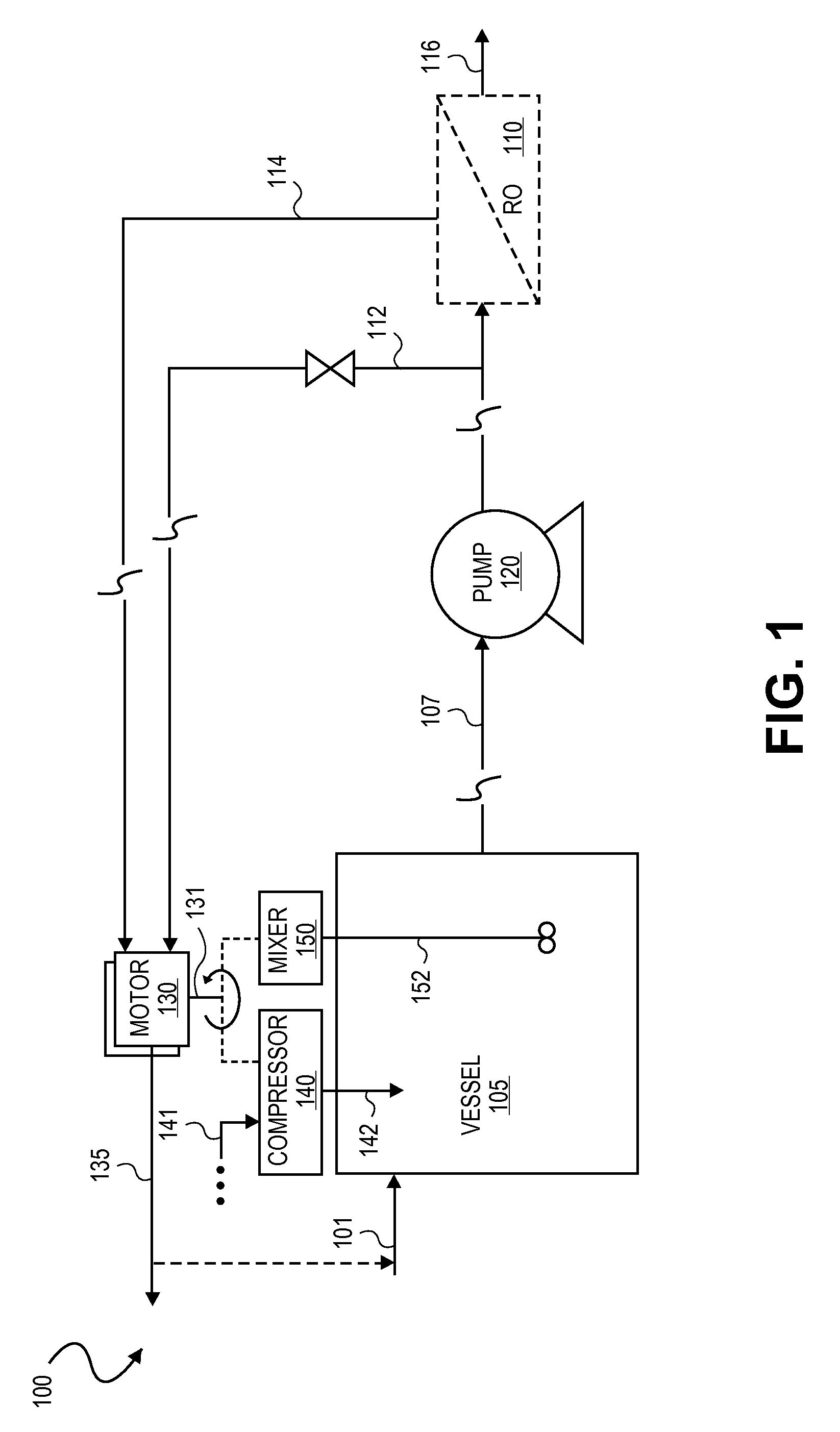

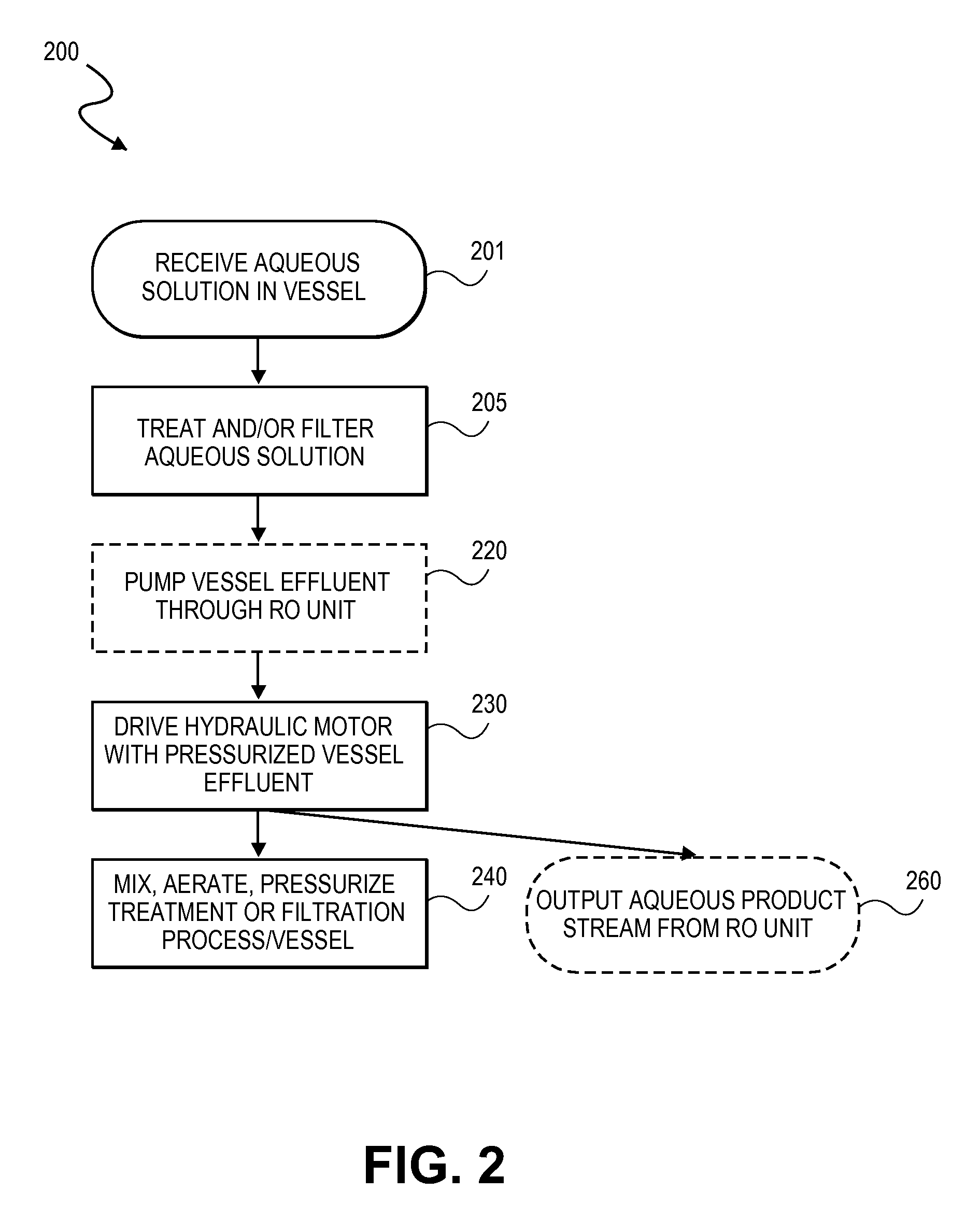

Integrated membrane system for distributed water treatment

InactiveUS20130032533A1Easy to operateLess-effectiveTreatment using aerobic processesTreatment by combined electrochemical biological processesChloramine BPh control

Integrated membrane treatment systems for treatment of an aqueous solution. In embodiments, components, such as an MBR, are integrated with means to recover energy from the system, for example from an RO concentrate, to operate the other components. In embodiments including biological treatment, RO is integrated with other components, such as an MBR with the ROs ability to remove inorganic nitrogen enabling biological treatment to be performed with only partial nitrification and the MBR operated without active pH control. In embodiments, RO is integrated with a chlorine generator to convert chlorides present in the RO concentrate for an in-situ source of oxidizing biocides for disinfection purposes. Chloramines may be generated in-situ from residual ammonia and chlorides in the RO reject. In embodiments, carrier media is employed in a membrane tank to enhance removal of residual organics by the MBR and to also improve effectiveness of membrane scouring.

Owner:ENVEERA

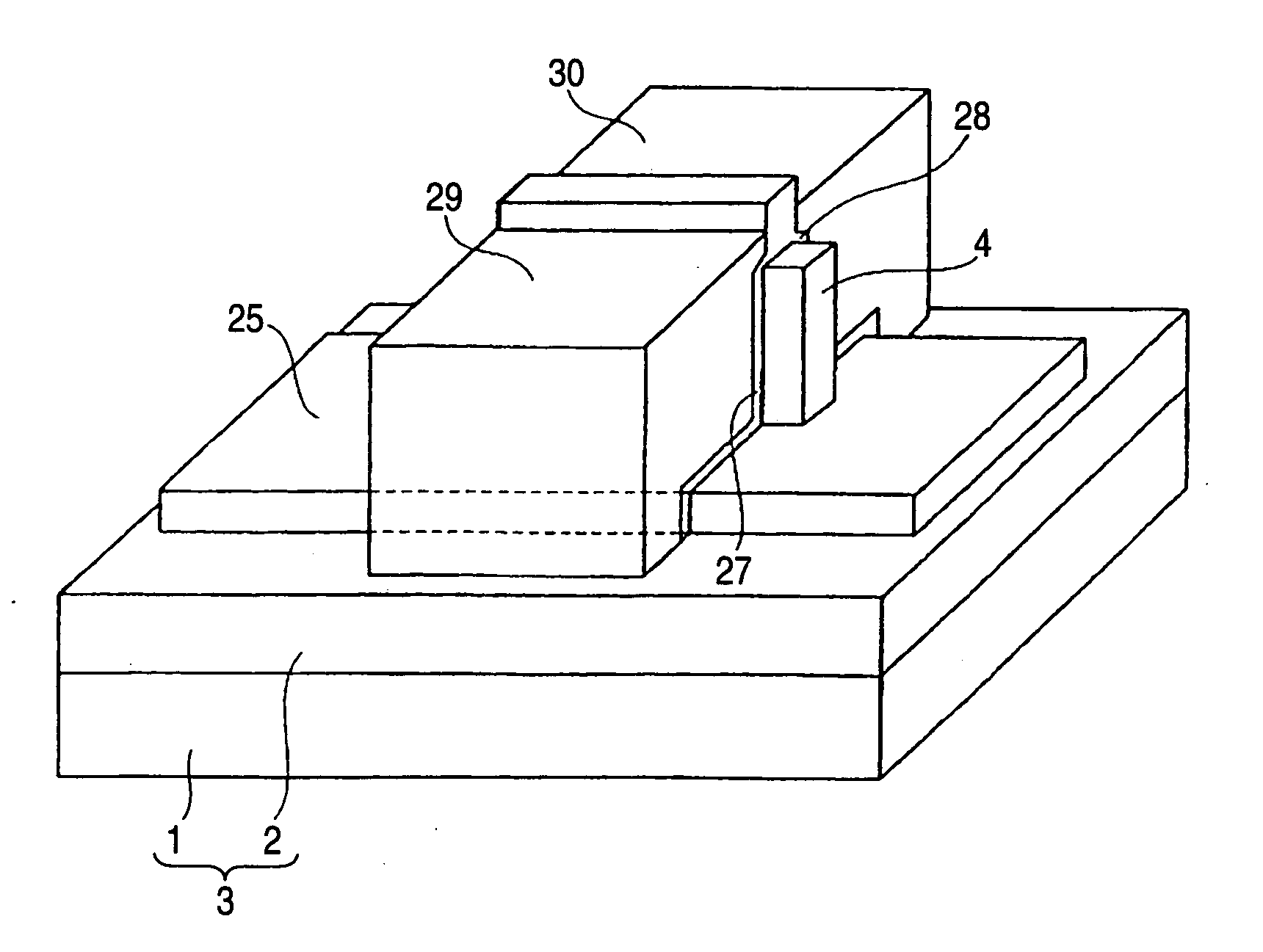

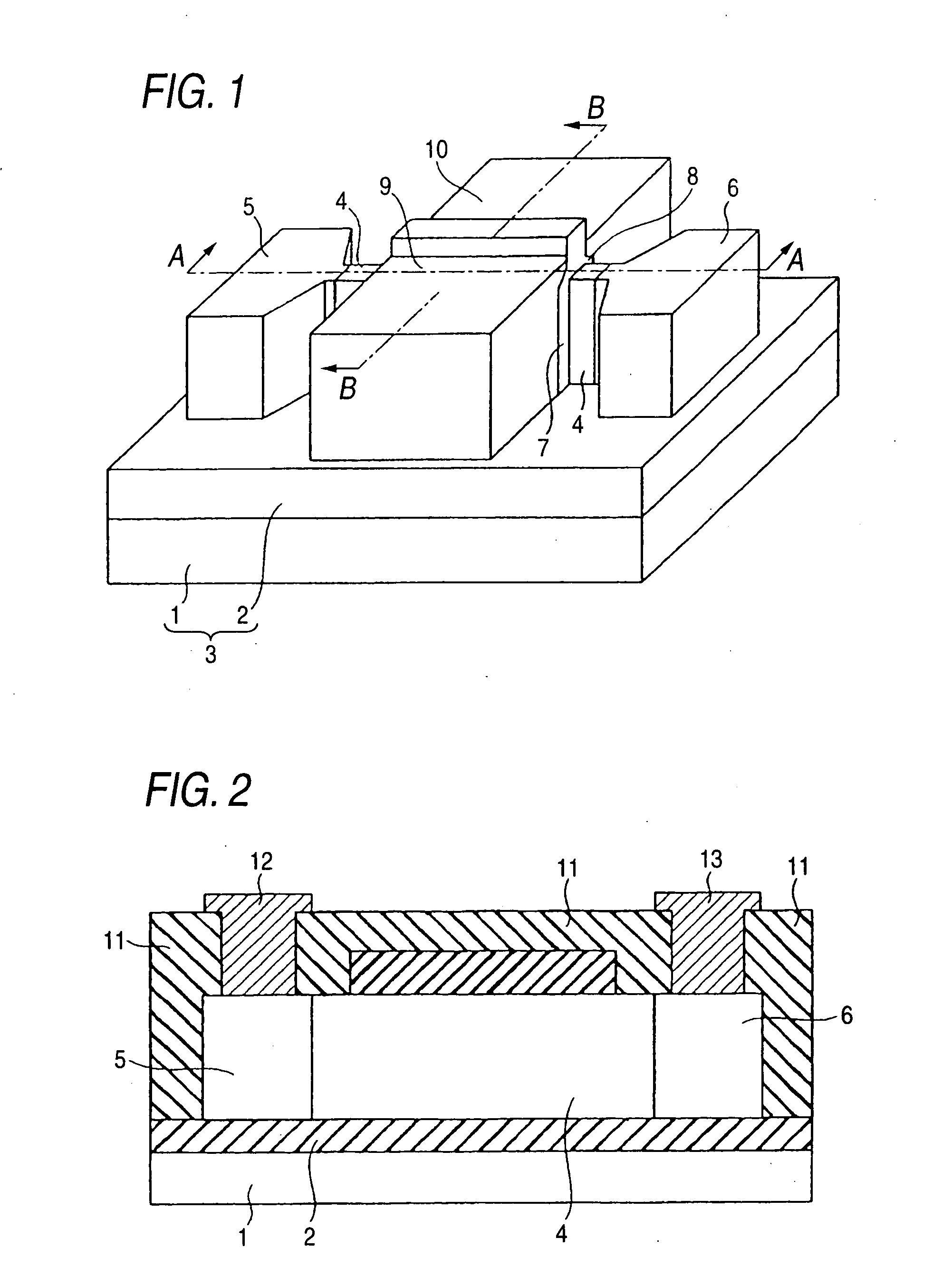

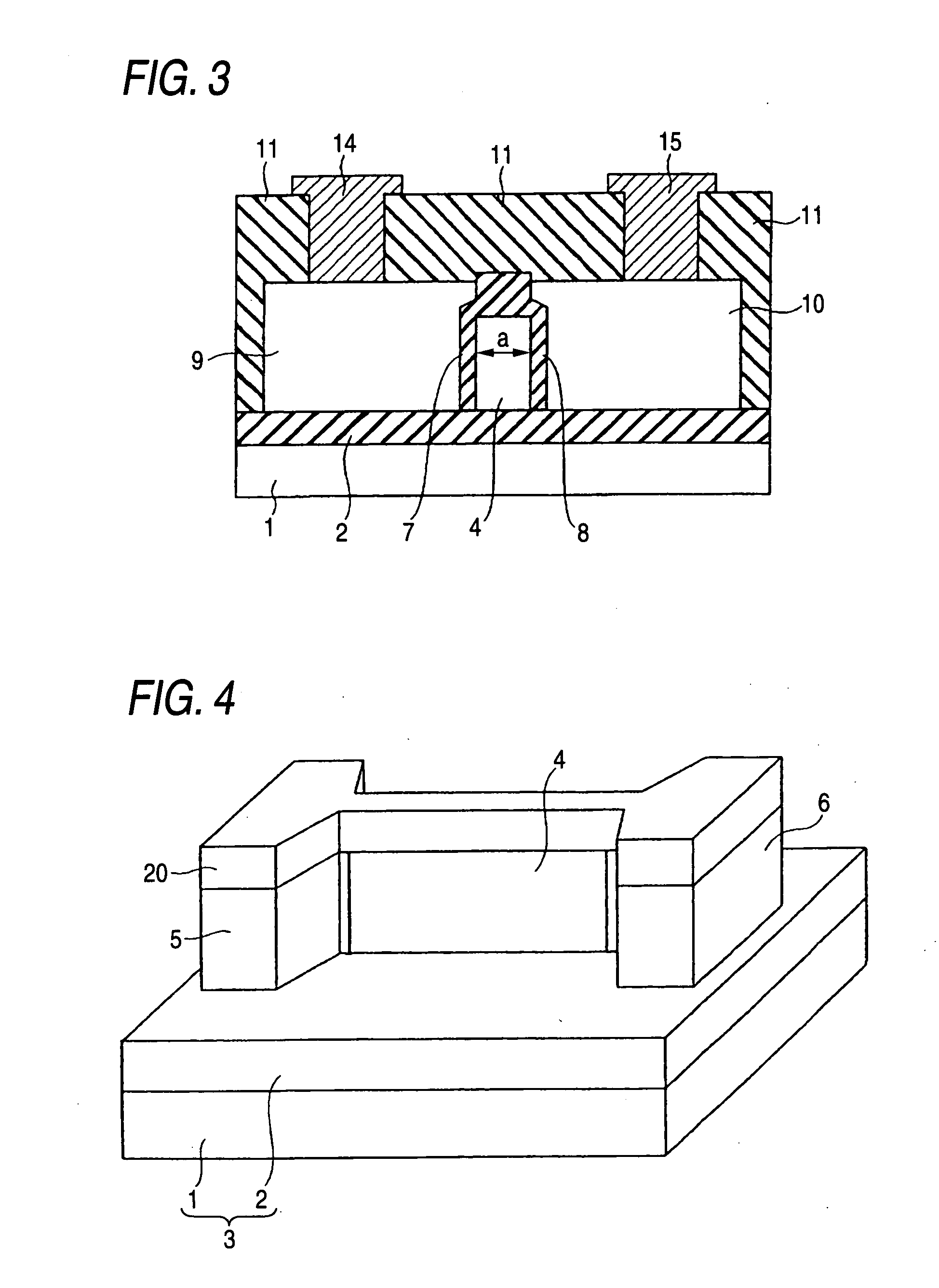

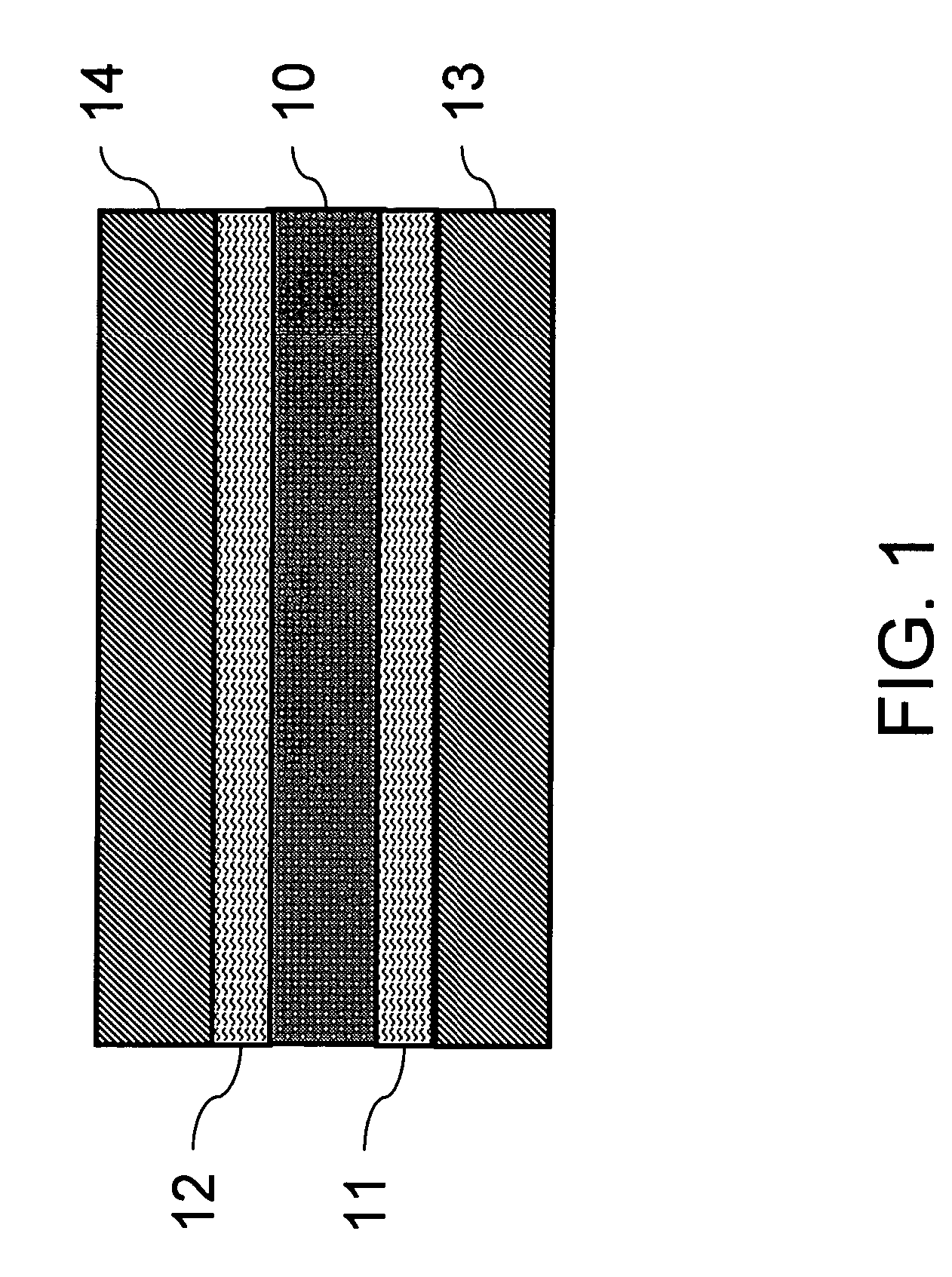

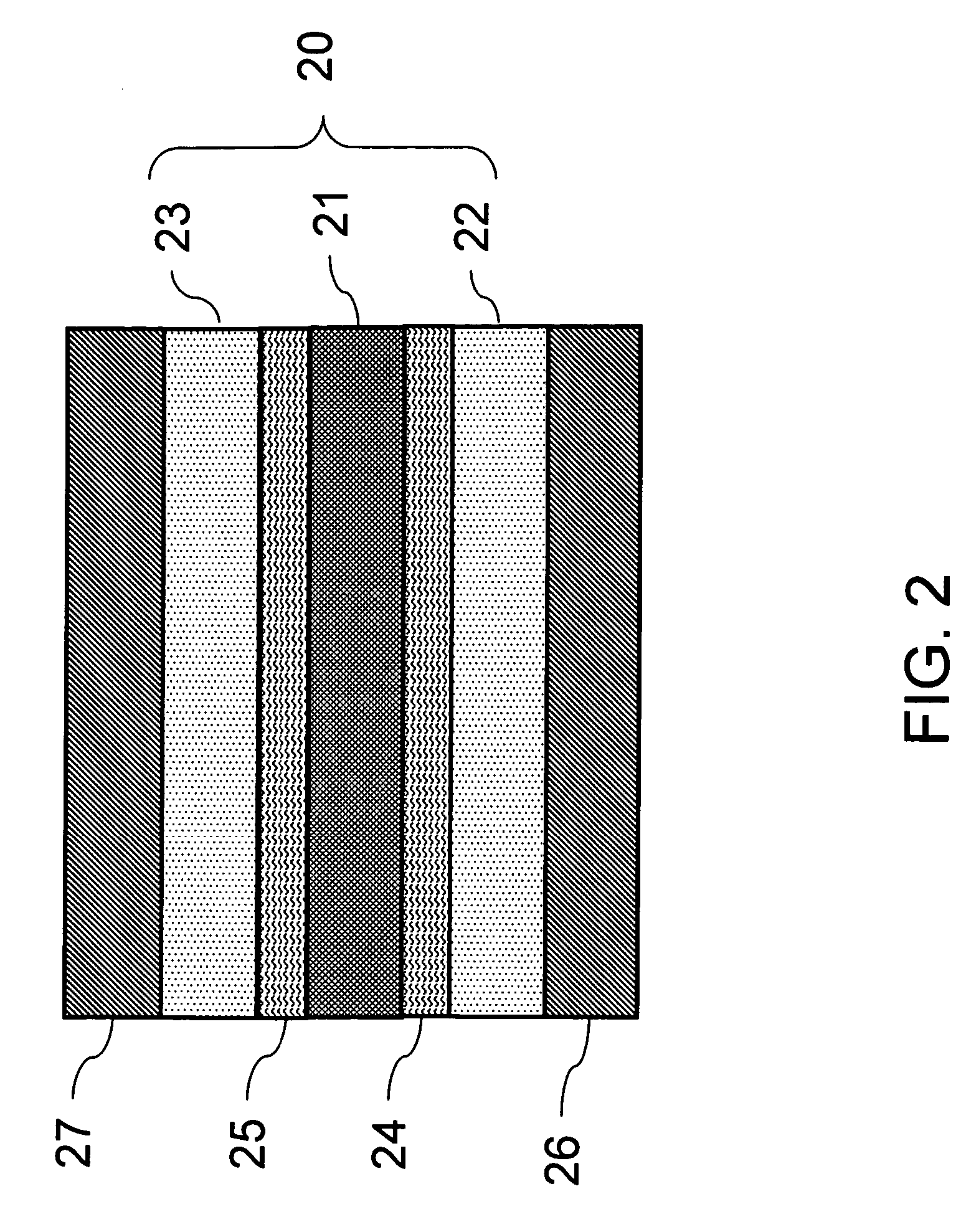

Semiconductor memory device

InactiveUS20060081851A1Reduce the refresh rateRun at high speedTransistorSolid-state devicesSemiconductorPhysics

A semiconductor memory device includes a semiconductor substrate, a semiconductor layer, a source / drain layer, first and second insulating films, and first and second gate electrodes. The semiconductor layer of one conductivity type is formed on a principal surface of the semiconductor substrate. The source / drain layer is formed on the principal surface with being in contact with one end of the semiconductor layer, and has a conductivity type opposite to the one conductivity type. The first insulating film is formed on one side surface of the semiconductor layer. The second insulating film is formed on another side surface of the semiconductor layer. The first gate electrode is formed on the one side surface via the first insulating film. The second gate electrode is formed on the other side surface of the semiconductor layer via the second insulating film, and is opposed to the first gate electrode.

Owner:KK TOSHIBA

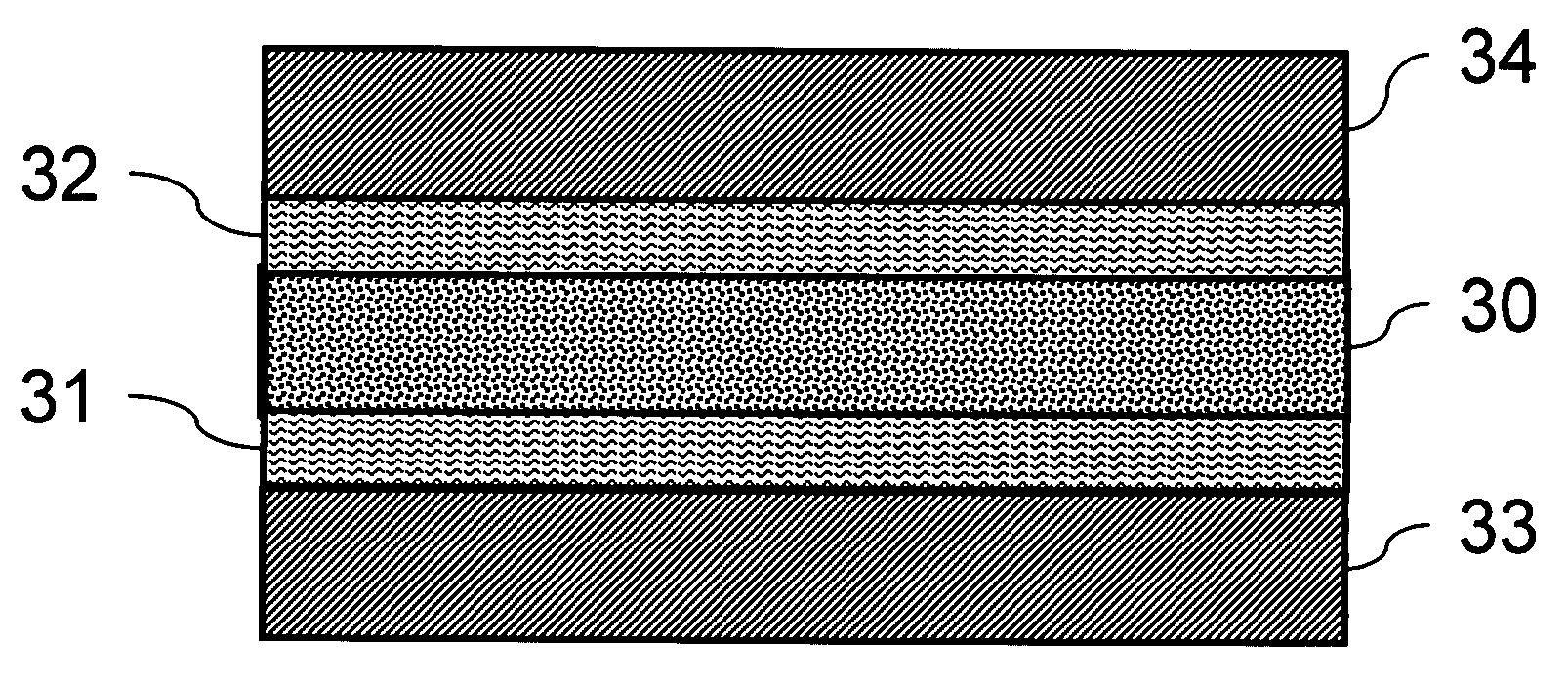

Organic bistable memory and method of manufacturing the same

InactiveUS20050274943A1Poor materialReduced on/off current ratioNanoinformaticsSolid-state devicesRetention timeOrganic layer

An organic bistable memory device has an organic layer with two sides, each having a dielectric layer with an electrode. When voltage is applied to the two electrodes, the memory may be switched and operated between a high impedance state and a low impedance state. This reduces negative effects on the memory device due to poor quality material or non-uniform manufacturing of the device, effects such as reduced on / off current ratio, shortened retention time and shorting failure in the device. Also, the disclosed organic bistable memory provides evidence to improve our understanding of bistable memory.

Owner:IND TECH RES INST

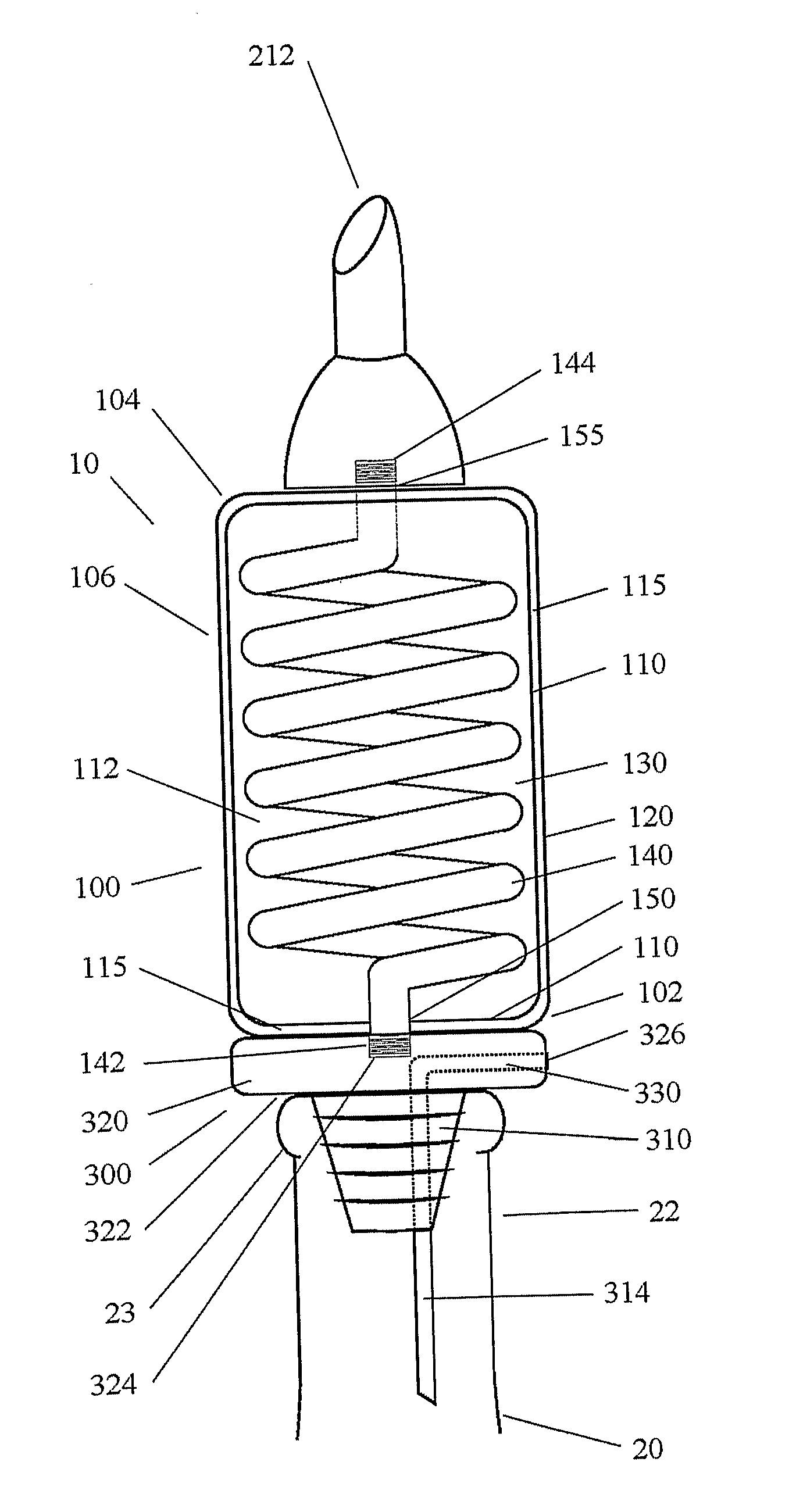

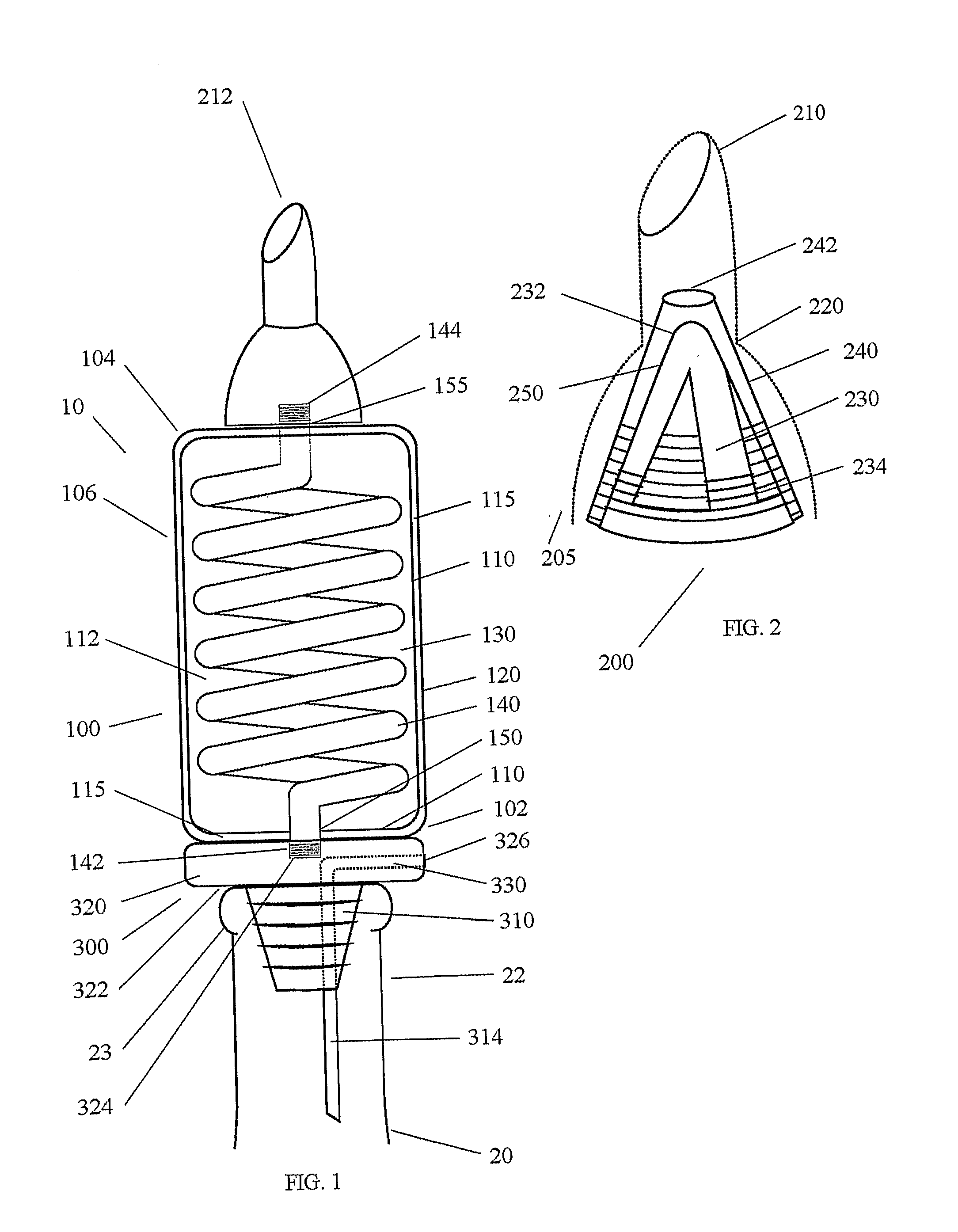

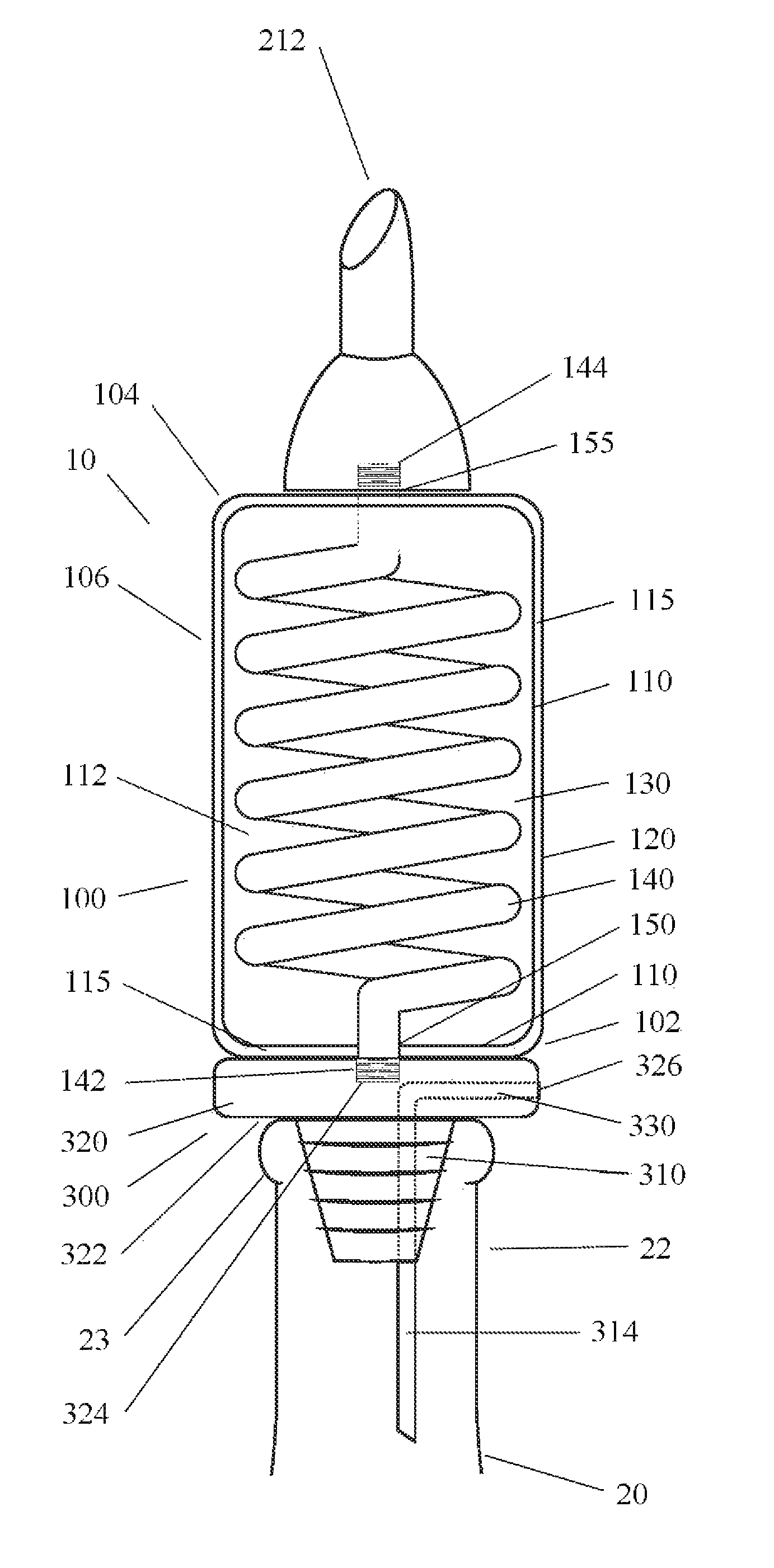

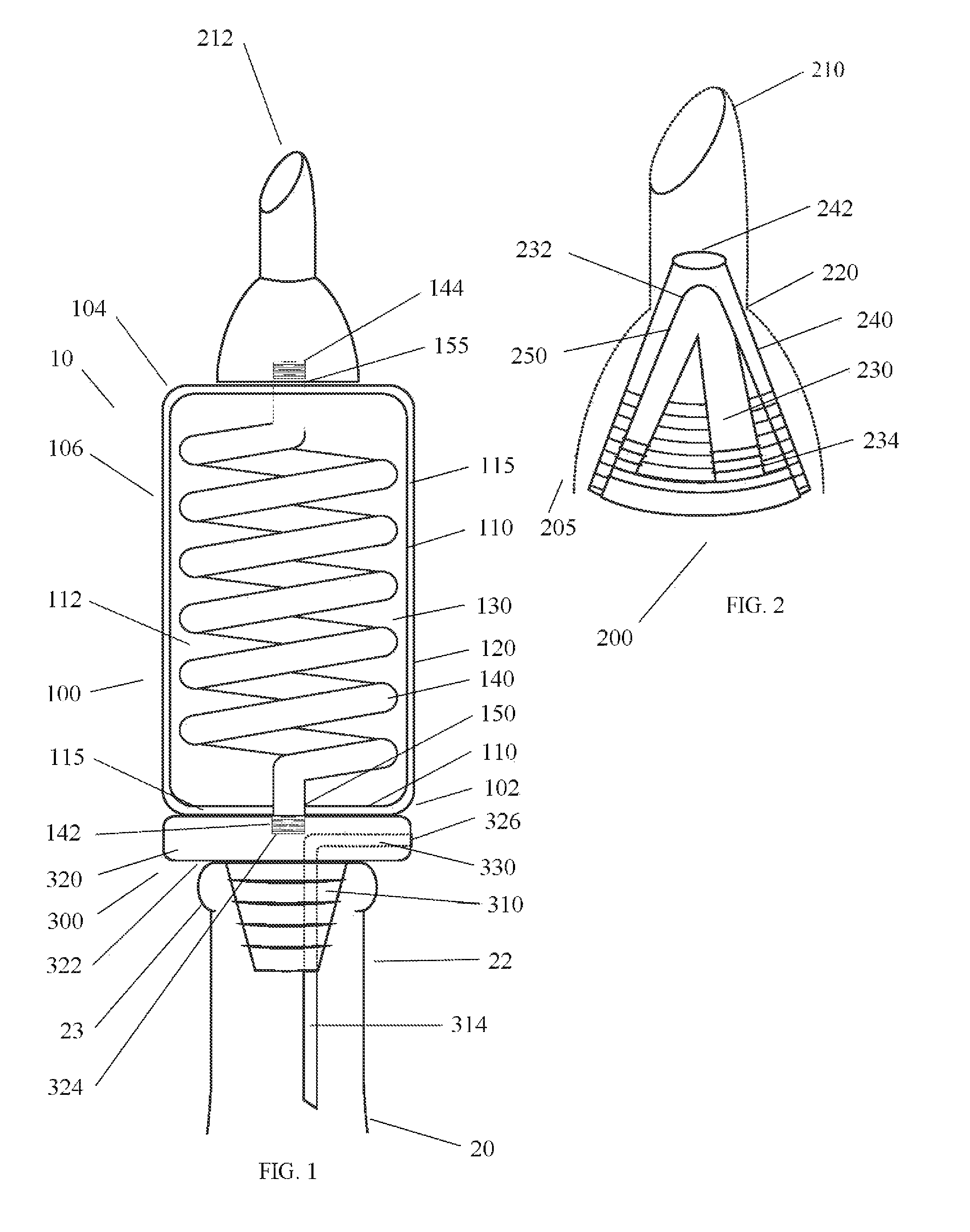

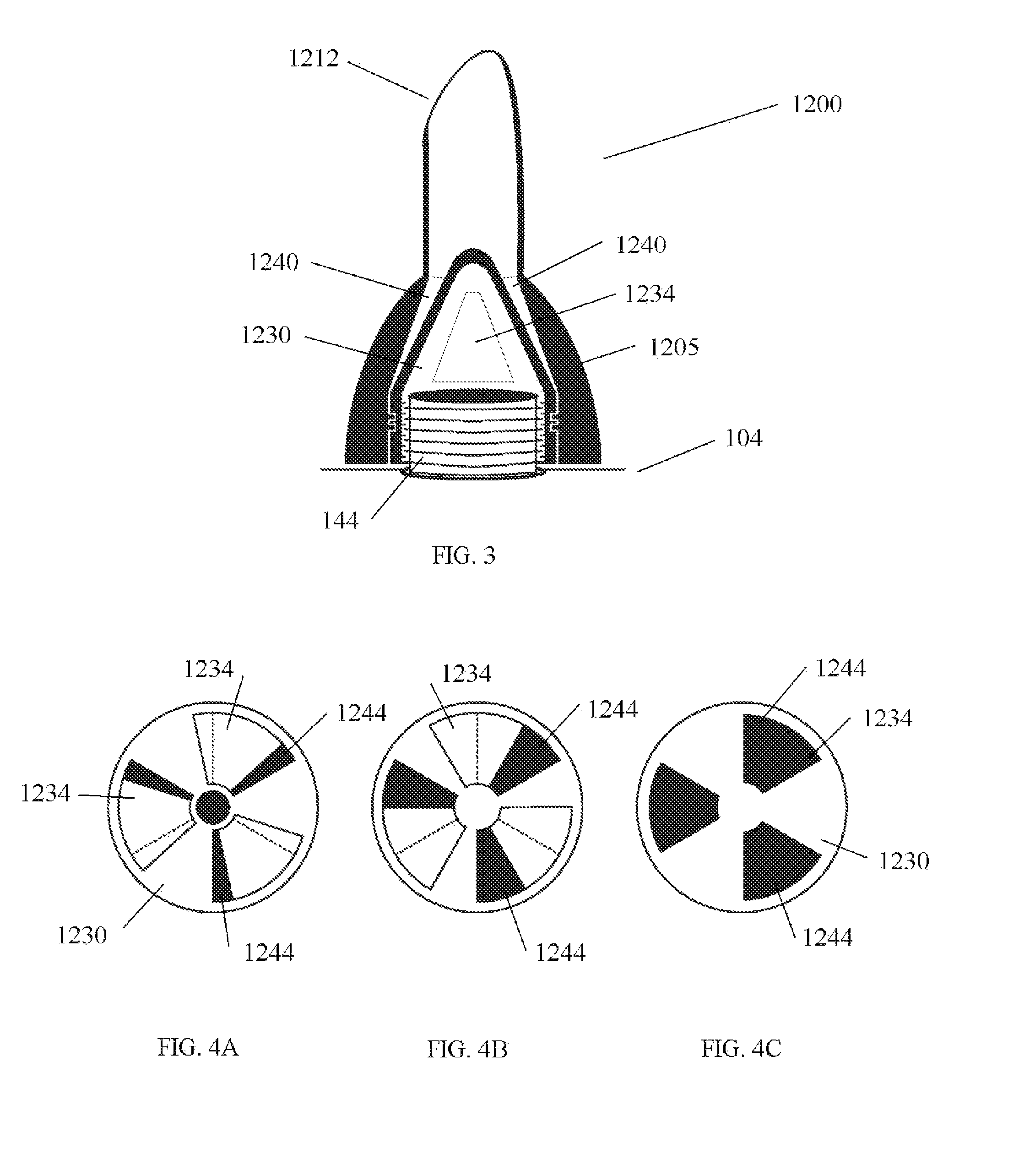

Liquid Cooling and Dispensing Device

InactiveUS20080302822A1Stable flow of liquidIncrease coolingDomestic refrigeratorsLiquid flow controllersEngineeringClose contact

A device to cool a liquid during the pouring procedure is provided. The device comprises an enclosure having a top portion and a bottom portion. Generally mounted to the bottom portion is a base for mounting the device to the neck of a bottle. Optionally mounted to the top portion is a spout which generally comprises a valve adapted to control the temperature of the poured liquid by controlling the flow thereof. The bottom portion and the top portion respectively comprise a first and a second openings between which extends a preferably metallic coil conduit. Within the enclosure, the conduit is surrounded by a low freezing cooling material. The device further comprises a vent passage extending in the base portion. Upon pouring the liquid from a bottle, the liquid circulates through the conduit which is in close contact with the cold cooling material, effectively cooling the liquid.

Owner:RAVI SOLUTION INC (CA)

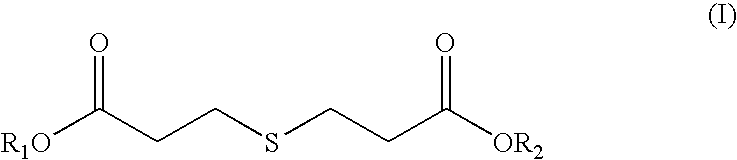

Compositions and methods for treating hyperpigmentation

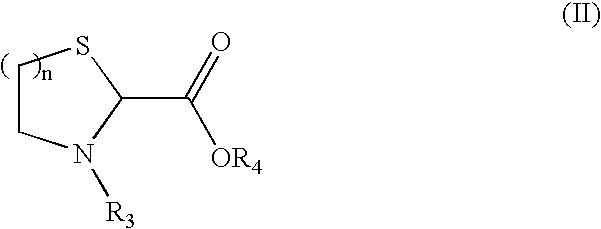

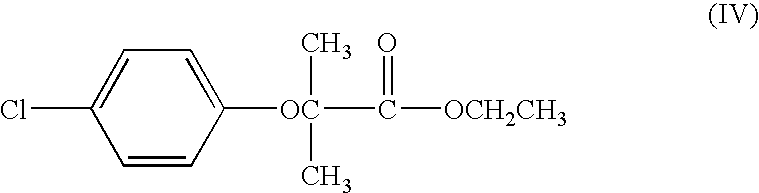

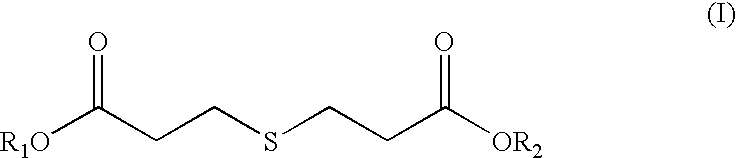

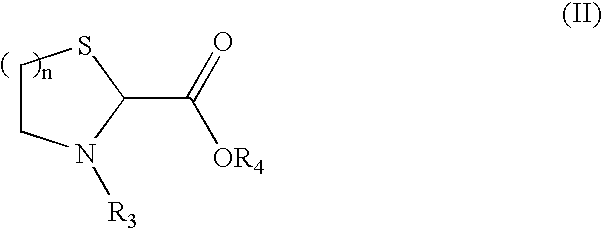

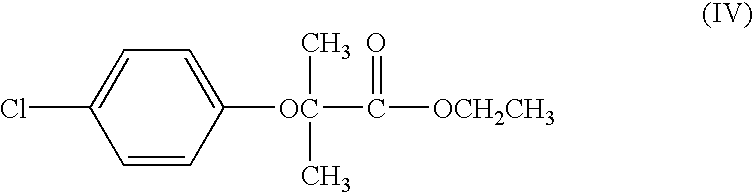

InactiveUS6562321B2Reduce retention timeImprove shipping rateCosmetic preparationsBiocidePerilla oilCarboxylic acid

There is provided a topical composition for treating, preventing or ameliorating hyperpigmentation in human skin. The composition has a de-pigmenting agent in an amount effect to reduce or diminish pigmentation at an area of skin to which it is applied, and a cosmetically or pharmaceutically acceptable vehicle. Suitable de-pigmenting agents include 3,3'-thiodipropionic acid, thiazolidine-2-carboxylic acid, kaempferol-7-glucoside, perilla oil, and clofibrate and clofibrate analogs and derivatives. There is also provided methods for treating, preventing or ameliorating hyperpigmentation in human skin.

Owner:AVON PROD INC

Preparation Method of Drug Loaded Emulsion

InactiveUS20120177699A1Reduce retention timeHigh energyBiocideAntimycoticsEmulsionBULK ACTIVE INGREDIENT

A preparation method of drug loaded emulsion is disclosed. The method comprises the steps of: preparing a non-self emulsifying O / W blank emulsion having no active ingredients; then, adding therapeutically effective amount of active ingredients to the 0 / W blank emulsion, adjusting pH to distribute the active ingredients through the membrane to obtain the desired emulsion.

Owner:SHANGHAI HENGRUI PHARM CO LTD +1

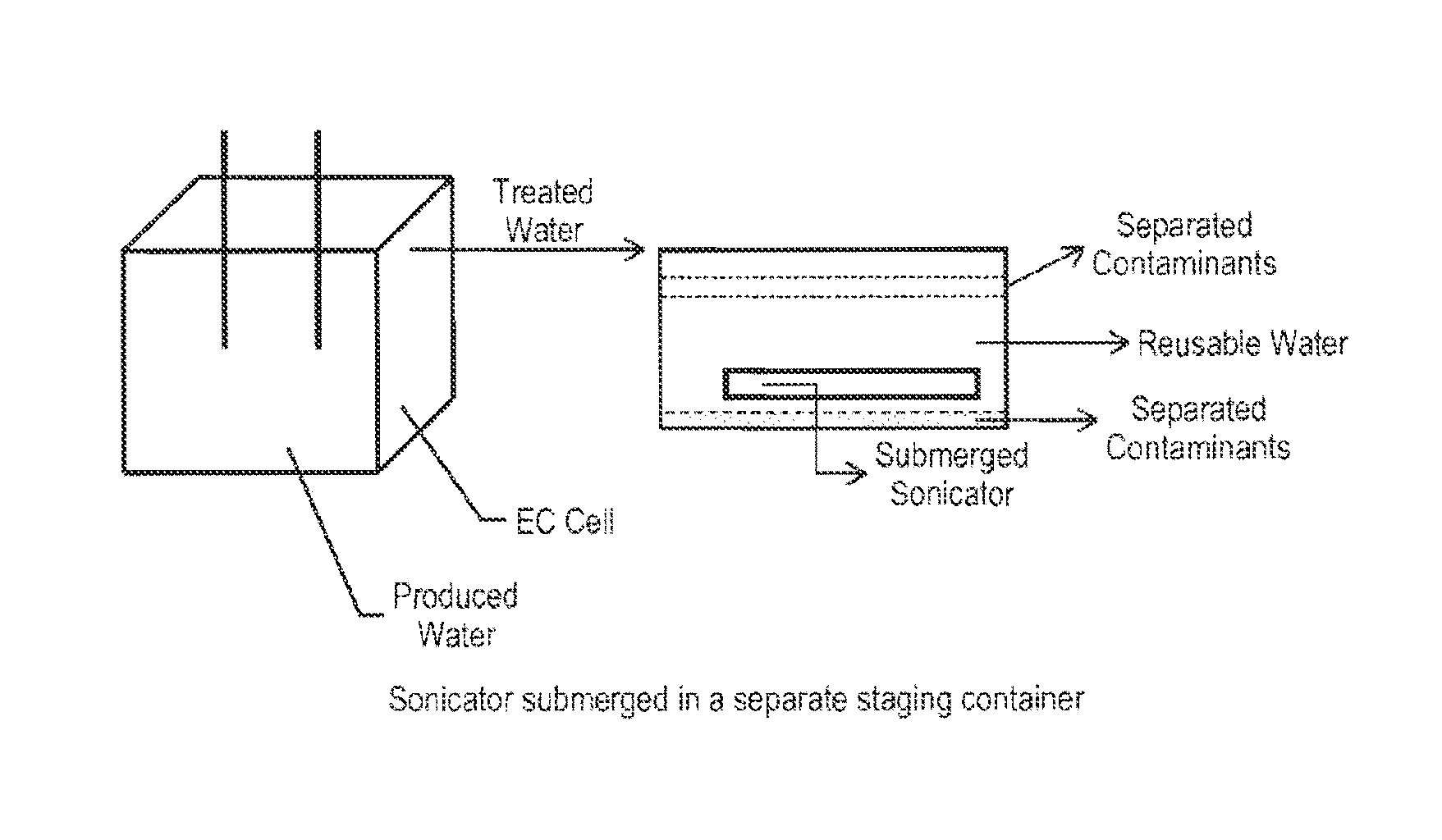

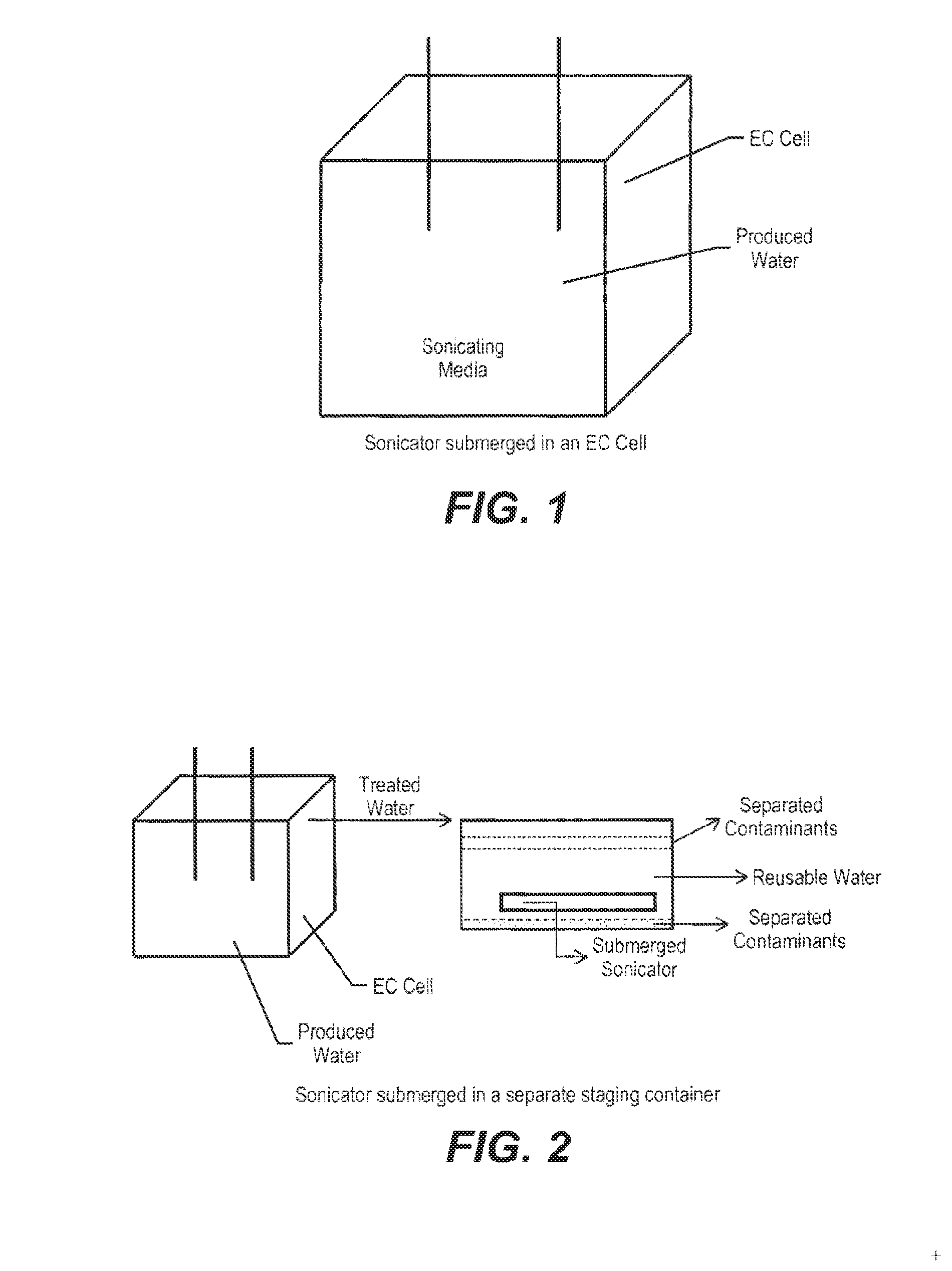

Method for Water Treatment Coupling Electrocoagulation and Sonic Energy

InactiveUS20140158550A1Reduce retention timeReduce amount of timeWater treatment parameter controlWater/sewage treatment with mechanical oscillationsElectrocoagulationProduced water

The onset of flocculation of undesirable chemicals within produced water is accelerated by treatment of the produced water with electrocoagulation and sonication. The sonoelectrochemical method described herein provides a faster and more dynamic means to reduce the requisite retention time for separation of flocculants.

Owner:BAKER HUGHES INC

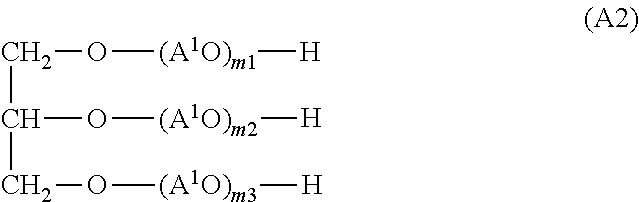

Additive composition for hydraulic composition

ActiveUS20110021668A1Good surface textureReduce retention timeInksGlycerol DerivativesPolymer science

Owner:KAO CORP

Method for production of easily polymerizable substance and purification apparatus

InactiveUS7282118B2Reduce retention timeEasily substanceLighting and heating apparatusMixing methodsDistillationEngineering

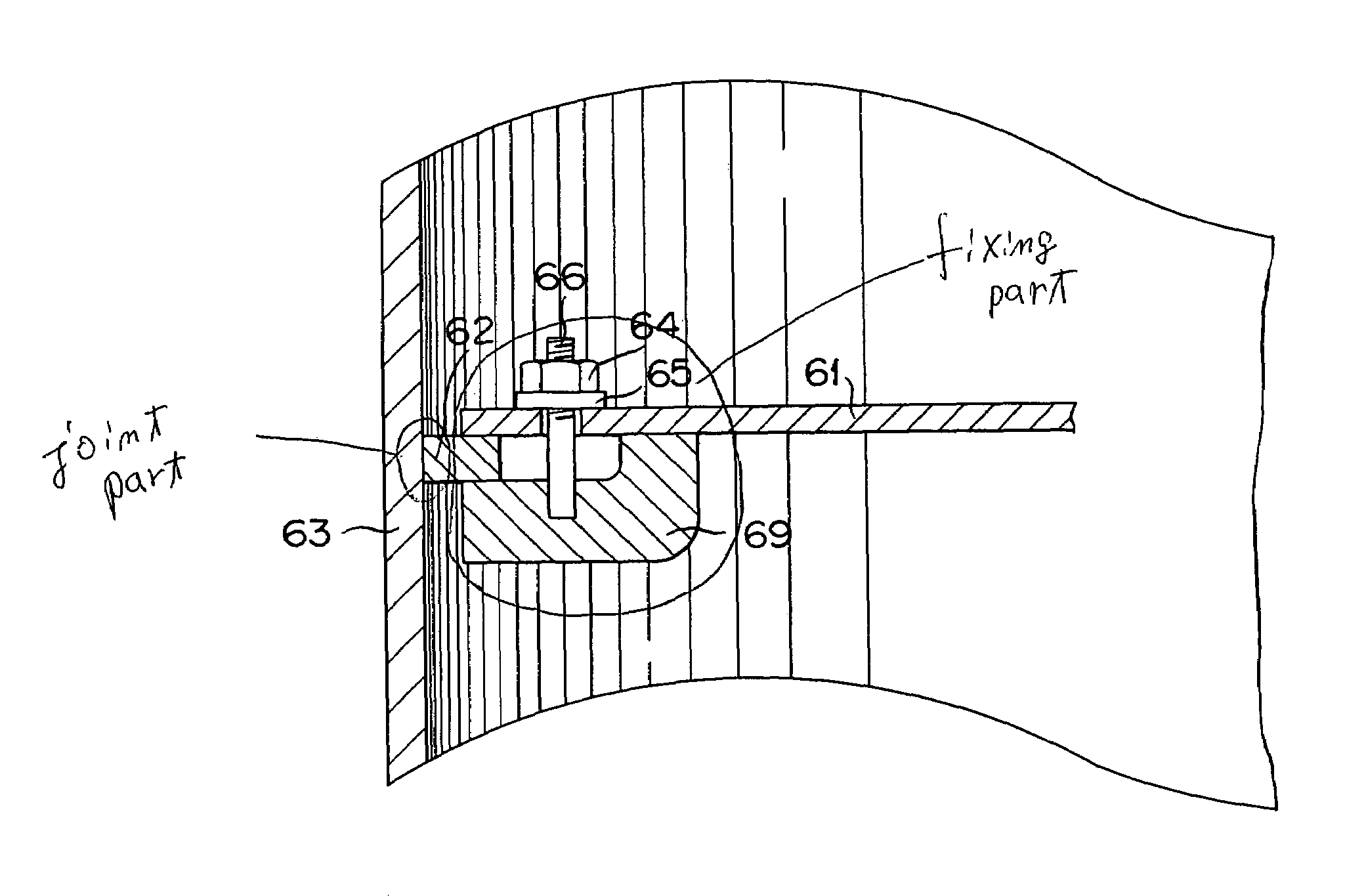

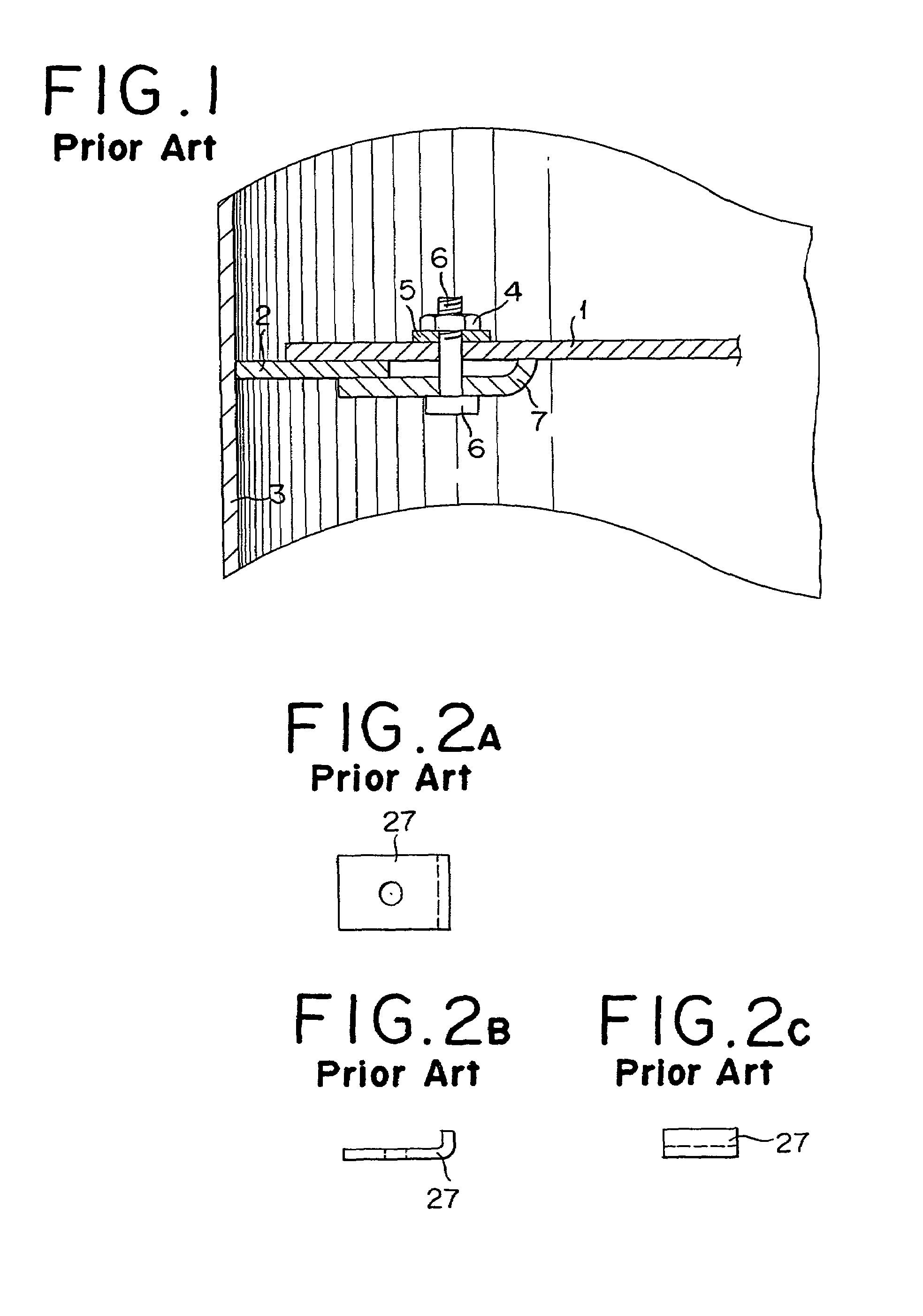

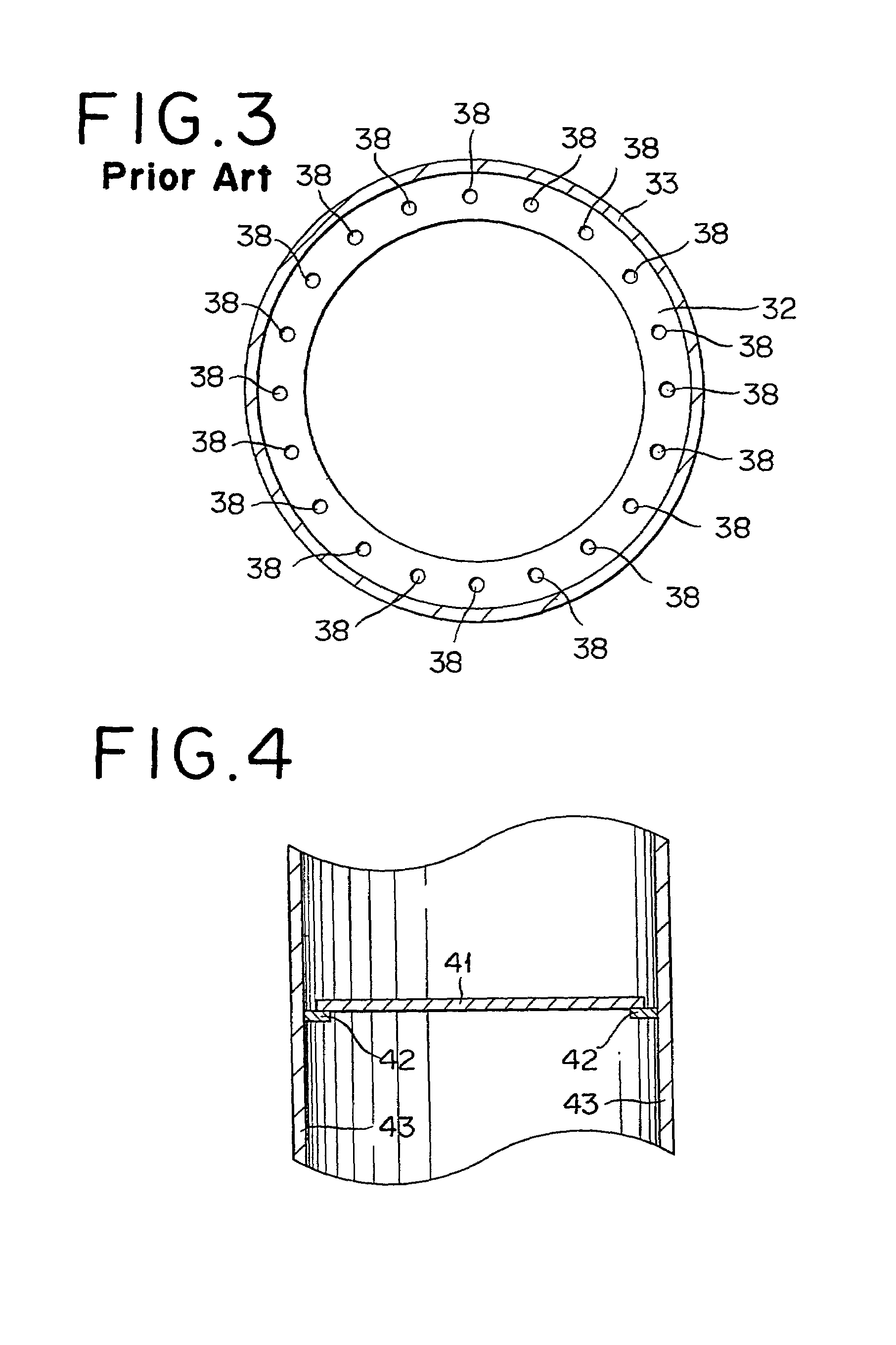

This invention resides in providing a method for the prevention of possible polymerization of the easily polymerizable substance during the purification thereof by a column provided with (a) at least one tray directly fixed to a support ring with a bolt and a nut and / or (b) at least one tray fixed to a support ring with a vertical clamp or a distillation column provided in the lower part thereof with a splash collision plate.

Owner:NIPPON SHOKUBAI CO LTD

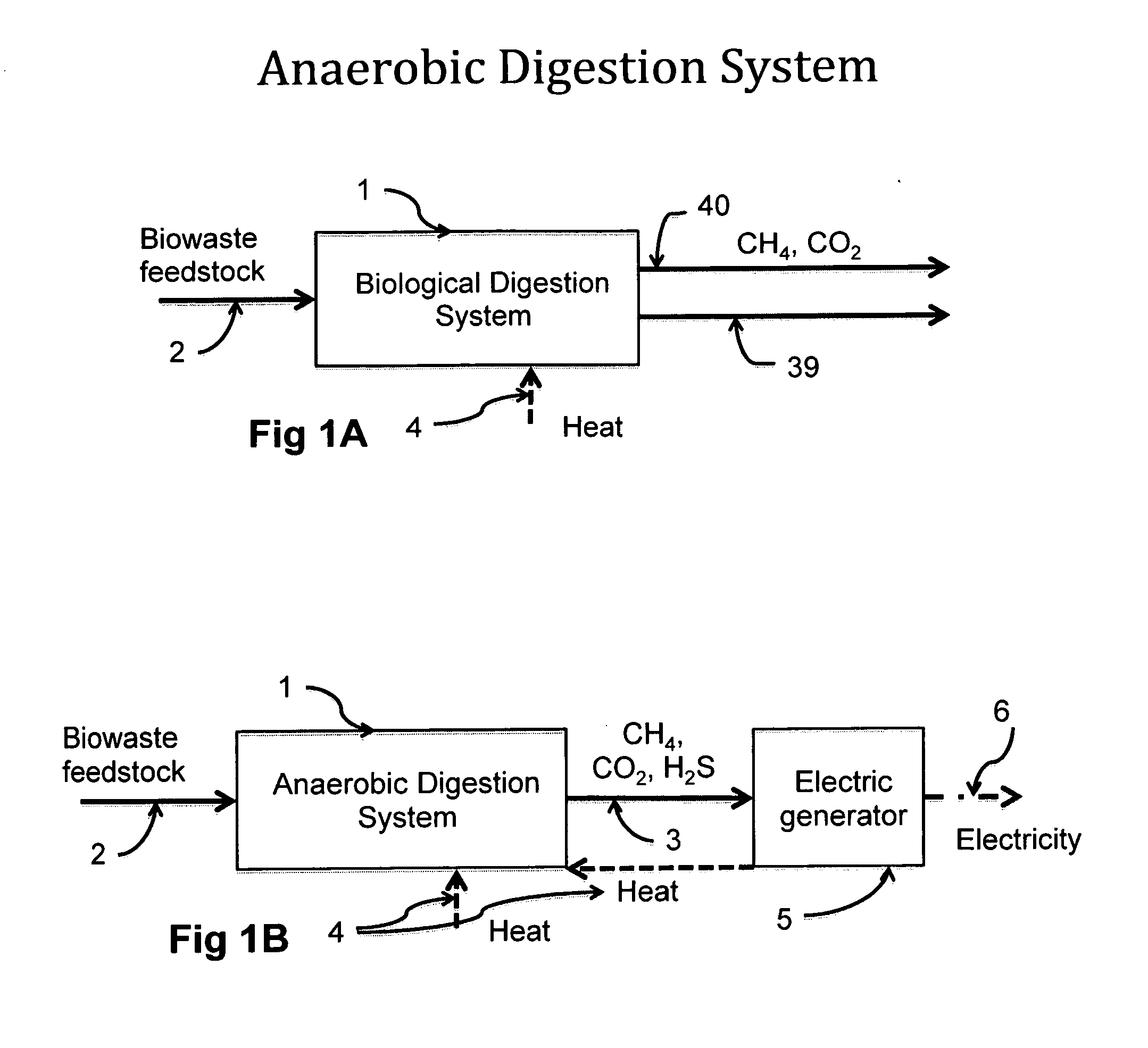

Biological solids processing system and method

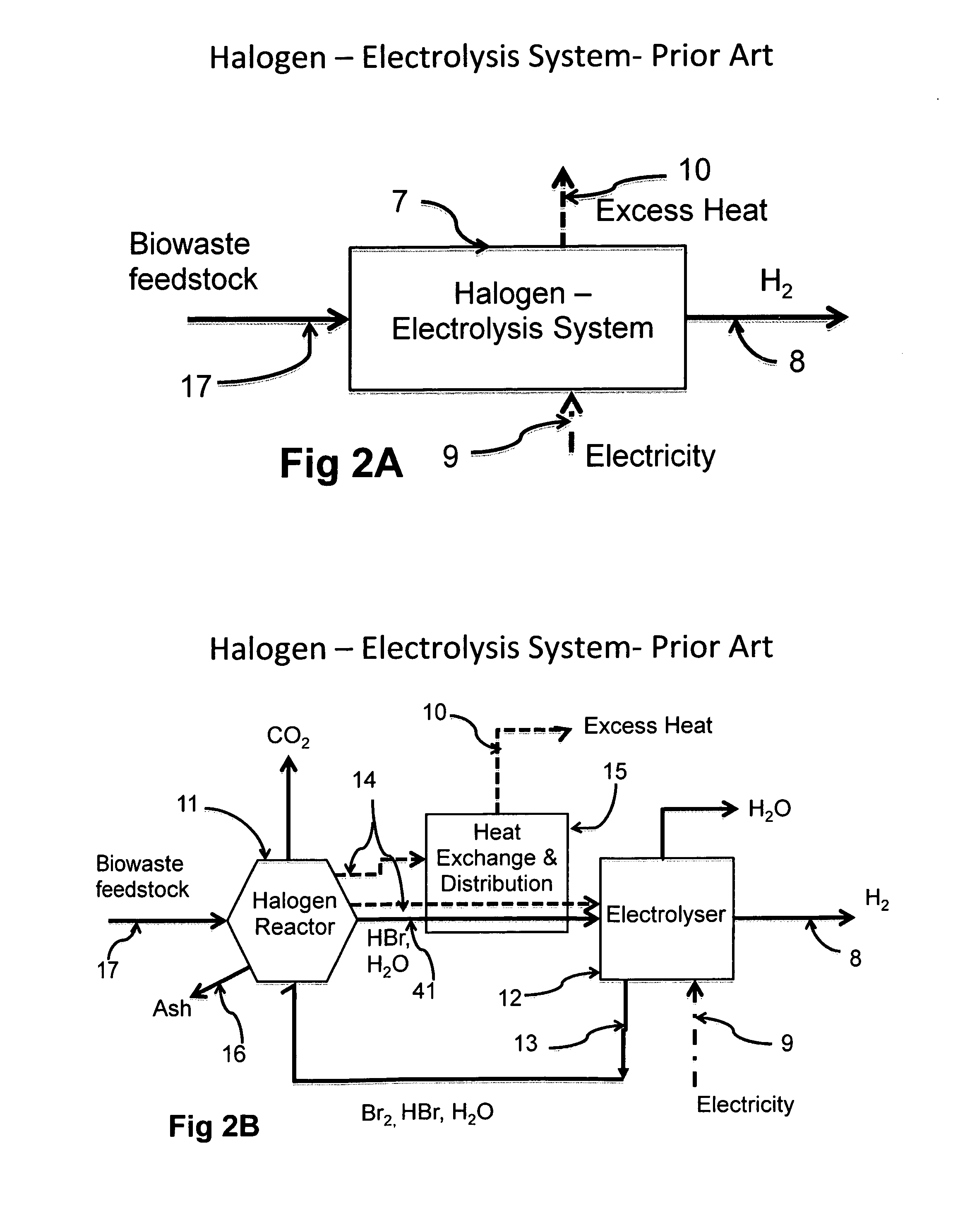

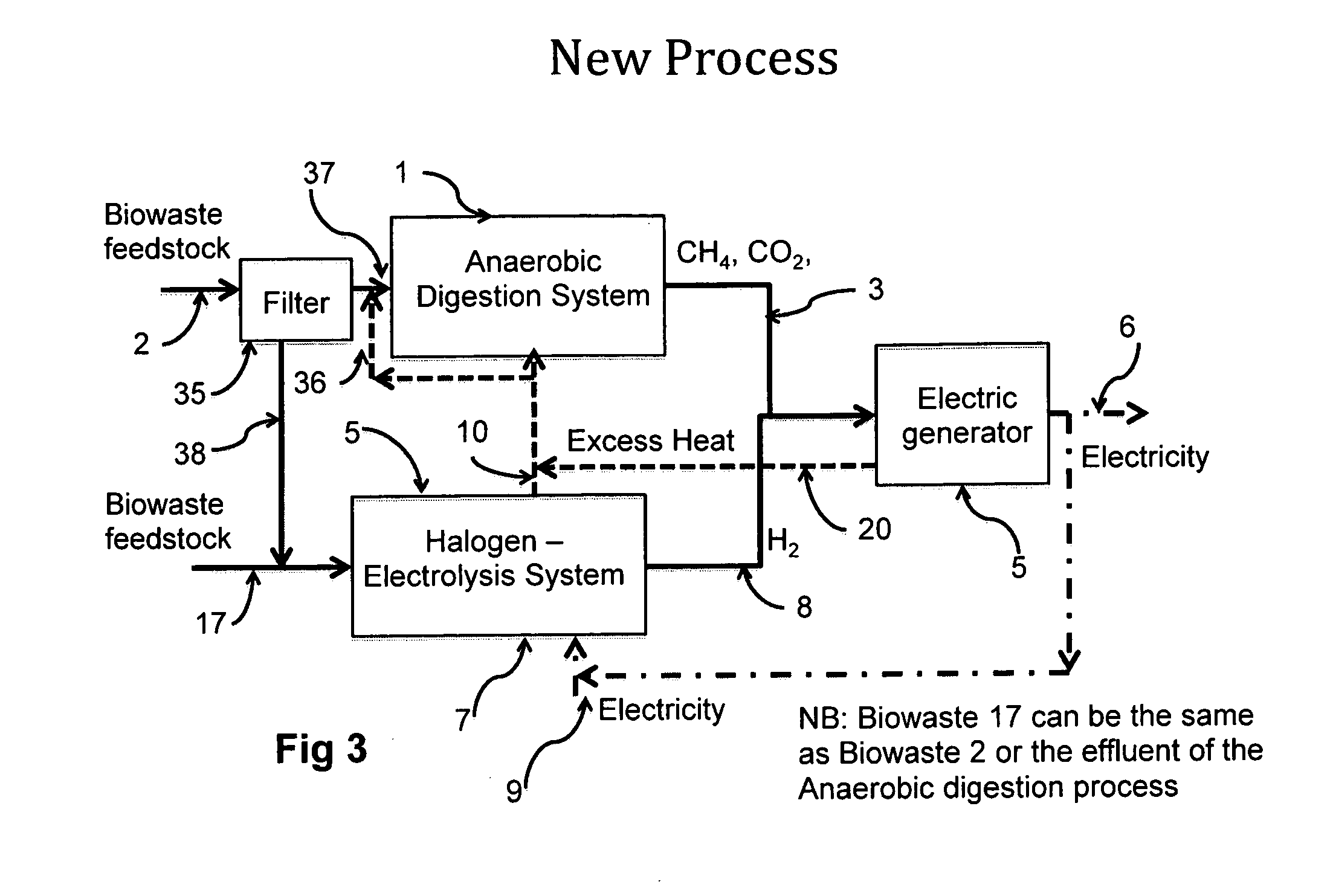

InactiveUS20110020862A1Optimizes energy extractionHigh digestionBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityHalogen

The consumption of organic solids with anaerobic digestion to generate usable gases including methane is made more efficient by maintaining the ideal digestion temperature, which is attained by combining the anaerobic digestion process with a halogen digester which produces heat energy and hydrogen gas. With a given biological feedstock four outputs can be generated (methane, hydrogen, electricity, and heat) in the ratio that makes the most economical sense. The process also provides a significant reduction in volume of output solids. The halogen oxidation process can be used on all the anaerobic digester effluent to extract more energy and oxidize a wet feedstock. If there are solids which are not easily digested with the anaerobic process, these solids can be diverted to the halogen digester to derive more energy from the feedstock. Pathogens common to other anaerobic digester effluents are removed. The mixture of methane and hydrogen gas can be compressed to produce an enriched compressed natural gas (CNG) with a variety of uses.

Owner:KAINOS POWER

Compositions and methods for treating hyperpigmentation

InactiveUS20020141953A1Reduce retention timeImprove shipping rateBiocideCosmetic preparationsPerilla oilCarboxylic acid

There is provided a topical composition for treating, preventing or ameliorating hyperpigmentation in human skin. The composition has a de-pigmenting agent in an amount effect to reduce or diminish pigmentation at an area of skin to which it is applied, and a cosmetically or pharmaceutically acceptable vehicle. Suitable de-pigmenting agents include 3,3'-thiodipropionic acid, thiazolidine-2-carboxylic acid, kaempferol-7-glucoside, perilla oil, and clofibrate and clofibrate analogs and derivatives. There is also provided methods for treating, preventing or ameliorating hyperpigmentation in human skin.

Owner:AVON PROD INC

Biological membrane filtration system for water treatment and a water treatment process

ActiveUS7288197B2Improve abilitiesExtended service lifeMembranesTreatment using aerobic processesFiltrationFixed bed

The present invention discloses a biological membrane filtration wastewater treatment system including a porous biological filtration bed zone and a membrane separation zone. The porous biological filtration bed zone has the dual function of providing biological treatment and higher filtration rates, wherein a fixed bed or moving bed is utilized so that the porous biological filtration bed zone has the advantages of high loading rates, high removal efficiencies, high stability and ease of operation. The membrane separation zone utilizes a membrane filtration module to filter an effluent from the porous biological filtration bed zone, so that solid particles therein are separated and remain in the system. Therefore, a high quality of effluent is obtained.

Owner:IND TECH RES INST

Liquid cooling and dispensing device

InactiveUS8066152B2Control flowLiquid flows smoothlyDomestic refrigeratorsLiquid flow controllersEngineeringBottle

A device that attaches to a bottle's neck has a base that secures to the bottle's neck and has two passages that traverse the base. The first passage leads to an enclosure located above the base that holds cooling material and optionally has a conduit that improves the heat exchange between a dispensing liquid and the cooling material retained in the enclosure. The exit passage of the enclosure has in at least one embodiment a valve. The second passage through the base forms a vent line that is located entirely below the enclosure and allows air to flow into the bottle as bottle's contents are dispensed through the first passage.

Owner:RAVI SOLUTION INC (CA)

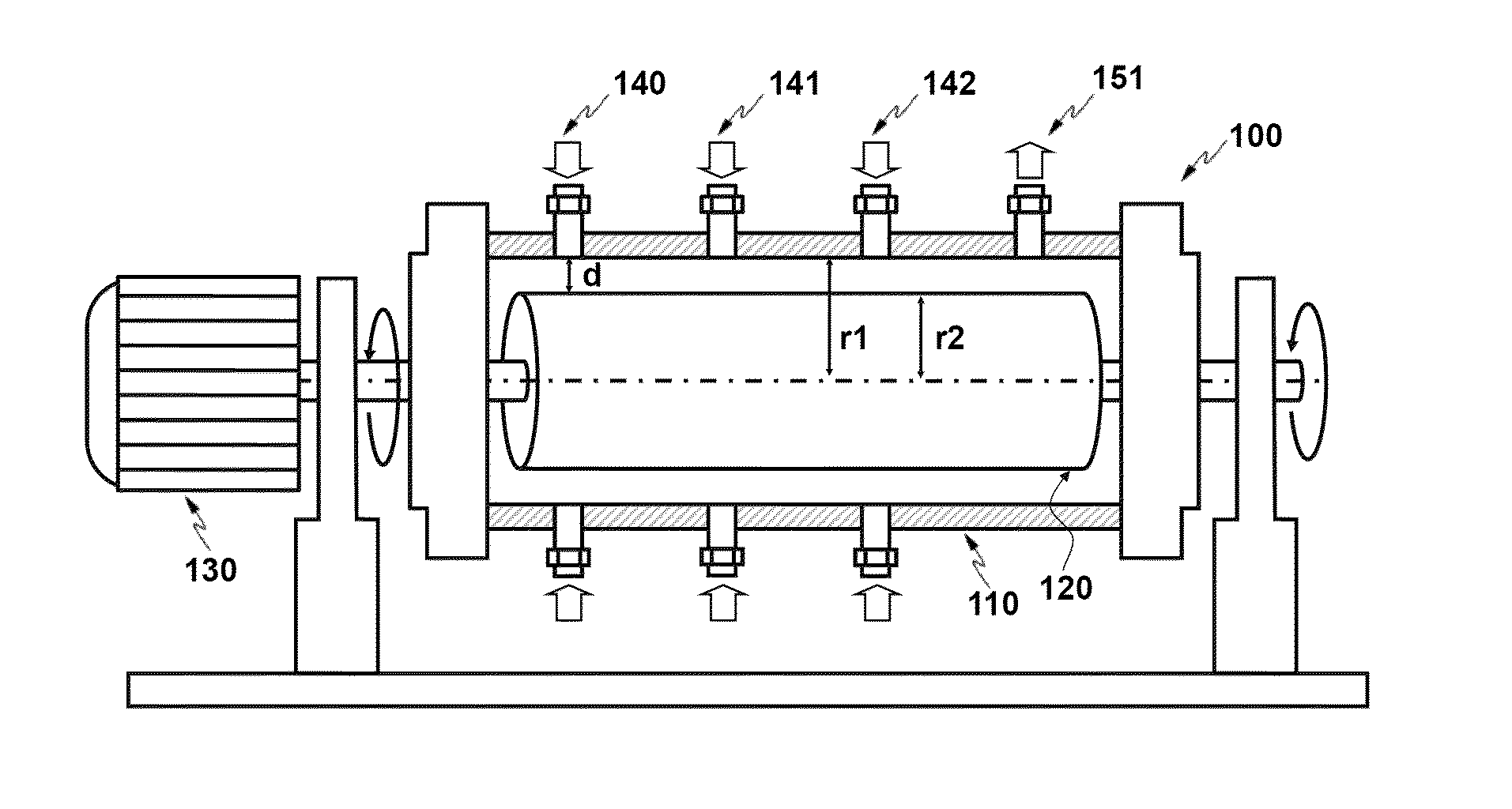

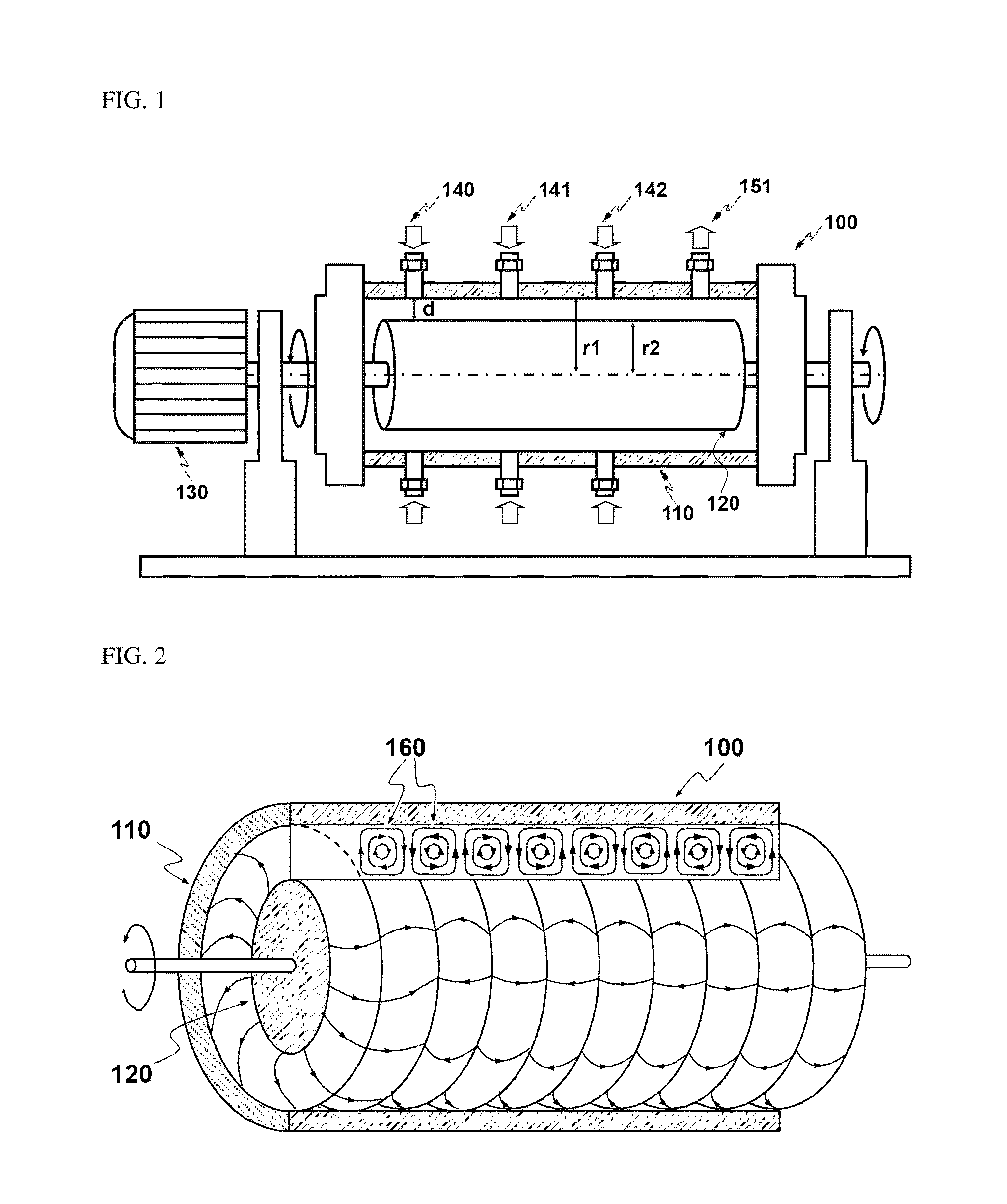

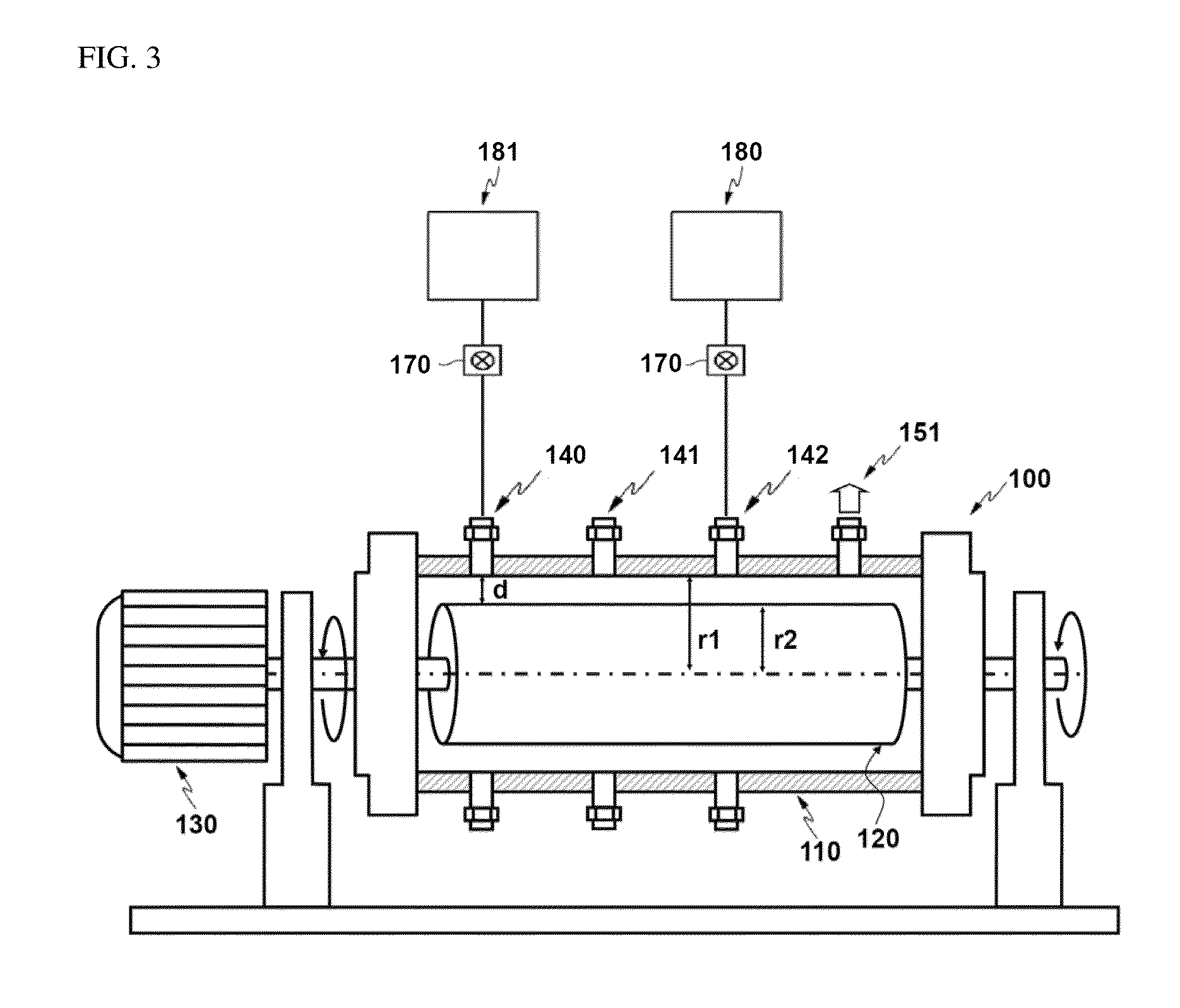

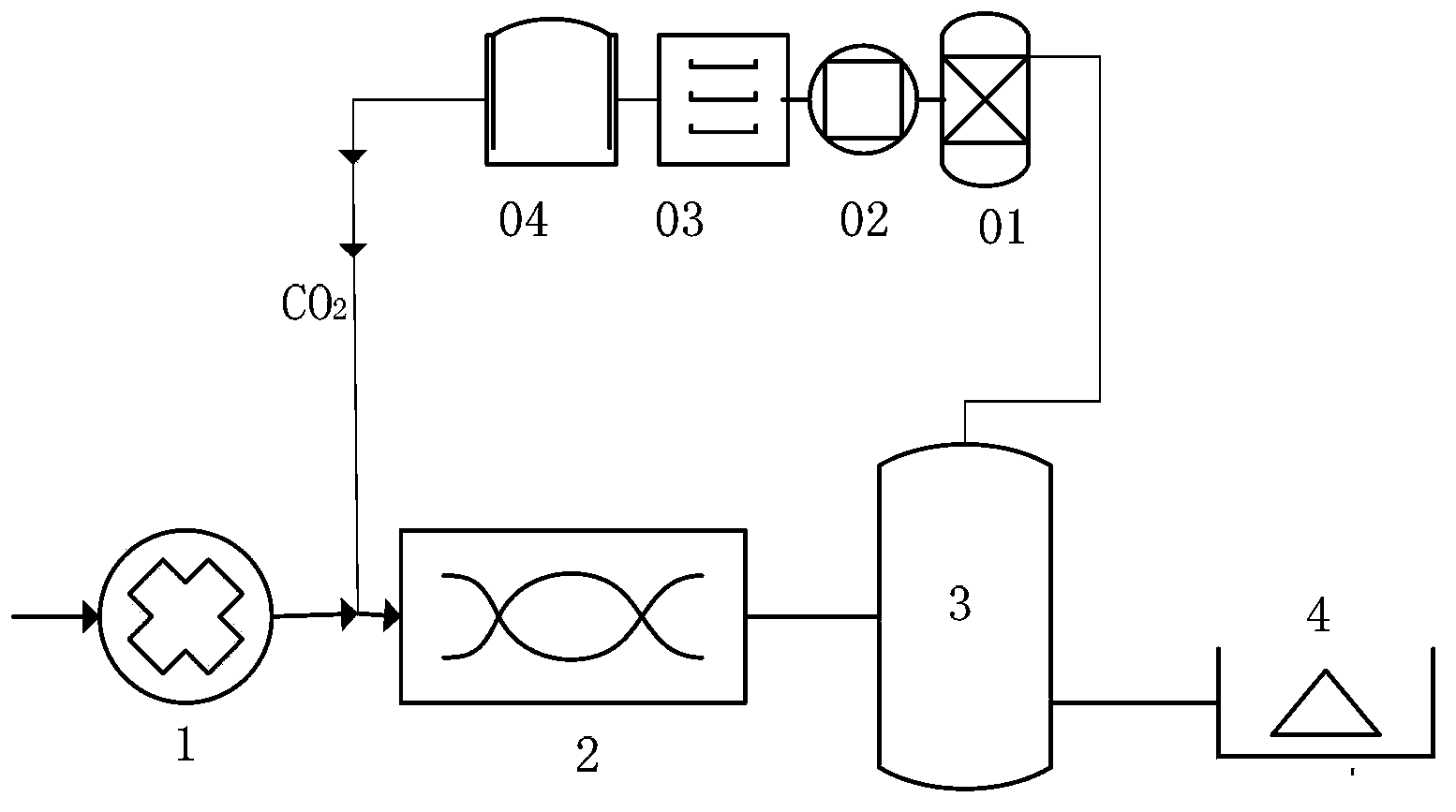

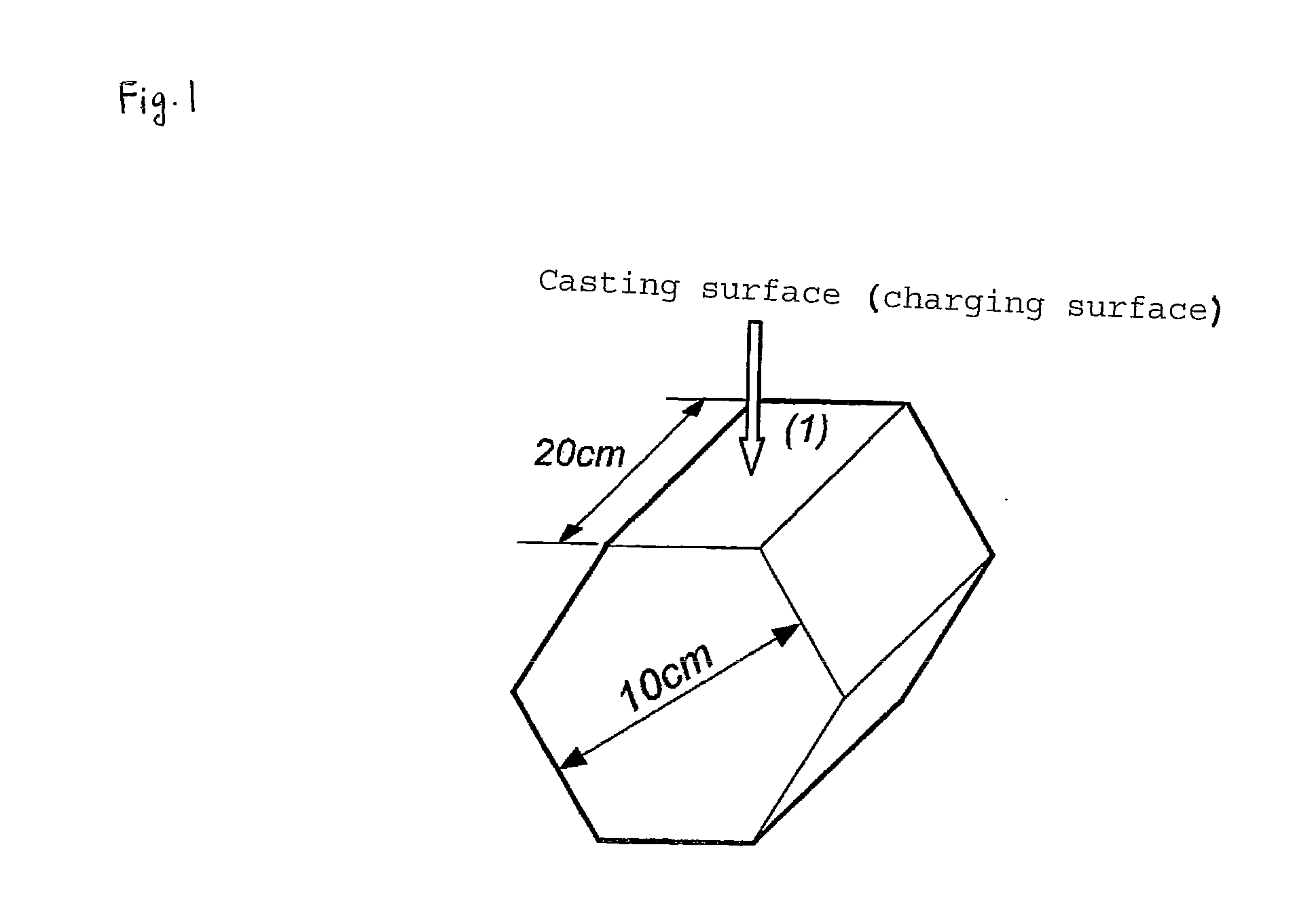

Reactor for preparing precursor of lithium composite transition metal oxide and method for preparing precursor

InactiveUS20140234203A1Reduce retention timeSmall sizeFinal product manufactureCell electrodesHollow cylinderEngineering

Disclosed is a reactor for preparing a precursor of lithium composite transition metal oxide for lithium secondary batteries, the reactor having a closed structure including a stationary hollow cylinder; a rotary cylinder having the same axis as the stationary hollow cylinder and an outer diameter smaller than an inner diameter of the stationary hollow cylinder, an electric motor to generate power, enabling rotation of the rotary cylinder, a rotation reaction area disposed between the stationary hollow cylinder and the rotary cylinder, wherein ring-shaped vortex pairs that are uniformly arranged in a rotation axis direction and rotate in opposite directions are formed in the rotation reaction area, and an inlet through which a reactant fluid is fed into the rotation reaction area and an outlet through which the reactant fluid is discharged from the rotation reaction area.

Owner:LG CHEM LTD

Recovery process for precious metals

InactiveUS20090031862A1Lower cost of capitalReduce operating costsProcess efficiency improvementGranularityReagent

A recovery process for at least one precious metal contained in an ore, includes: comminuting the ore to obtain particles smaller than a predetermined particle size; separating the particles into at least two groups, each group being characterized by a particle size range; and leaching separately each group of particles with a reagent adapted to dissolve the at least one precious metal.

Owner:COREM

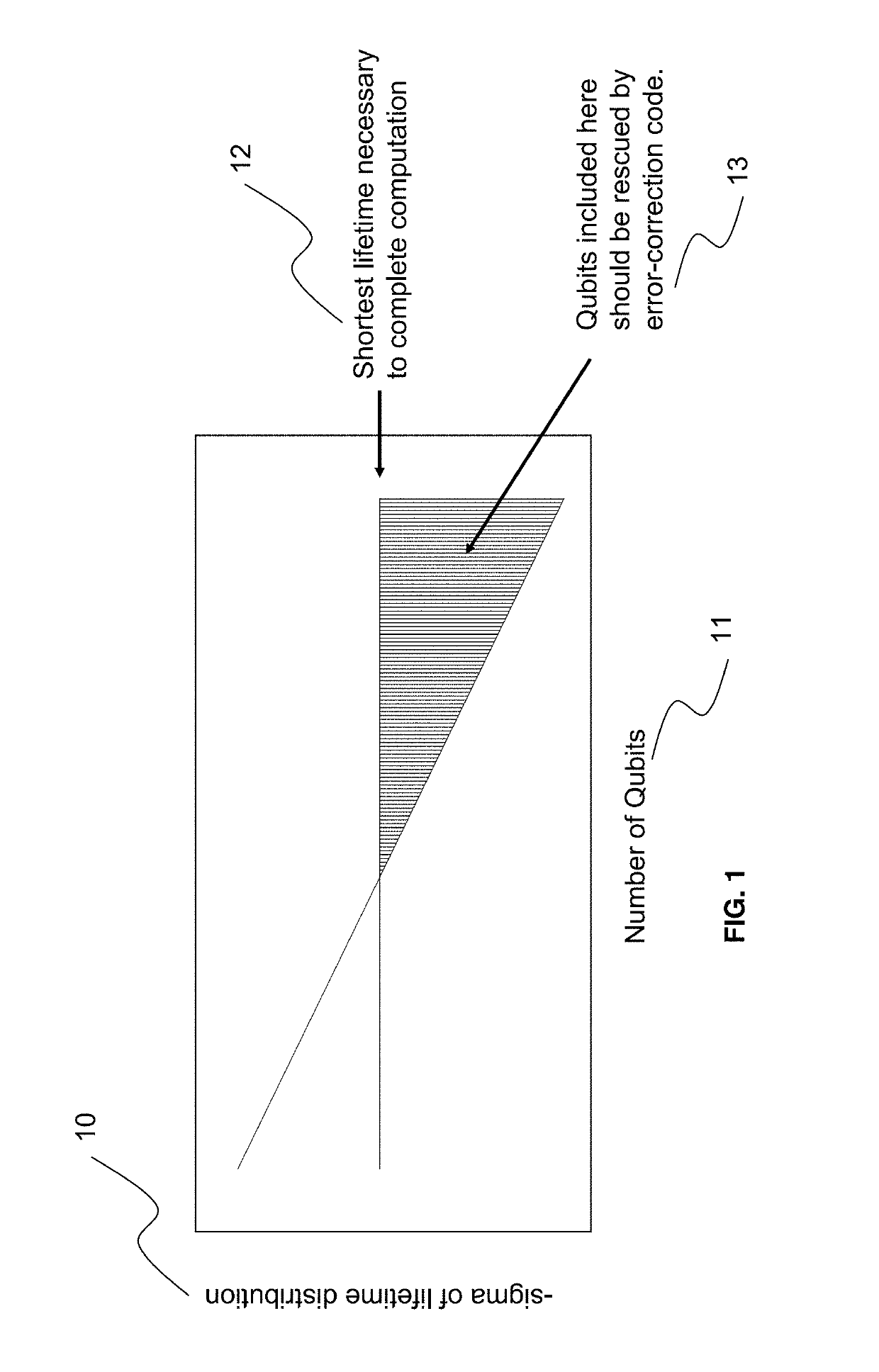

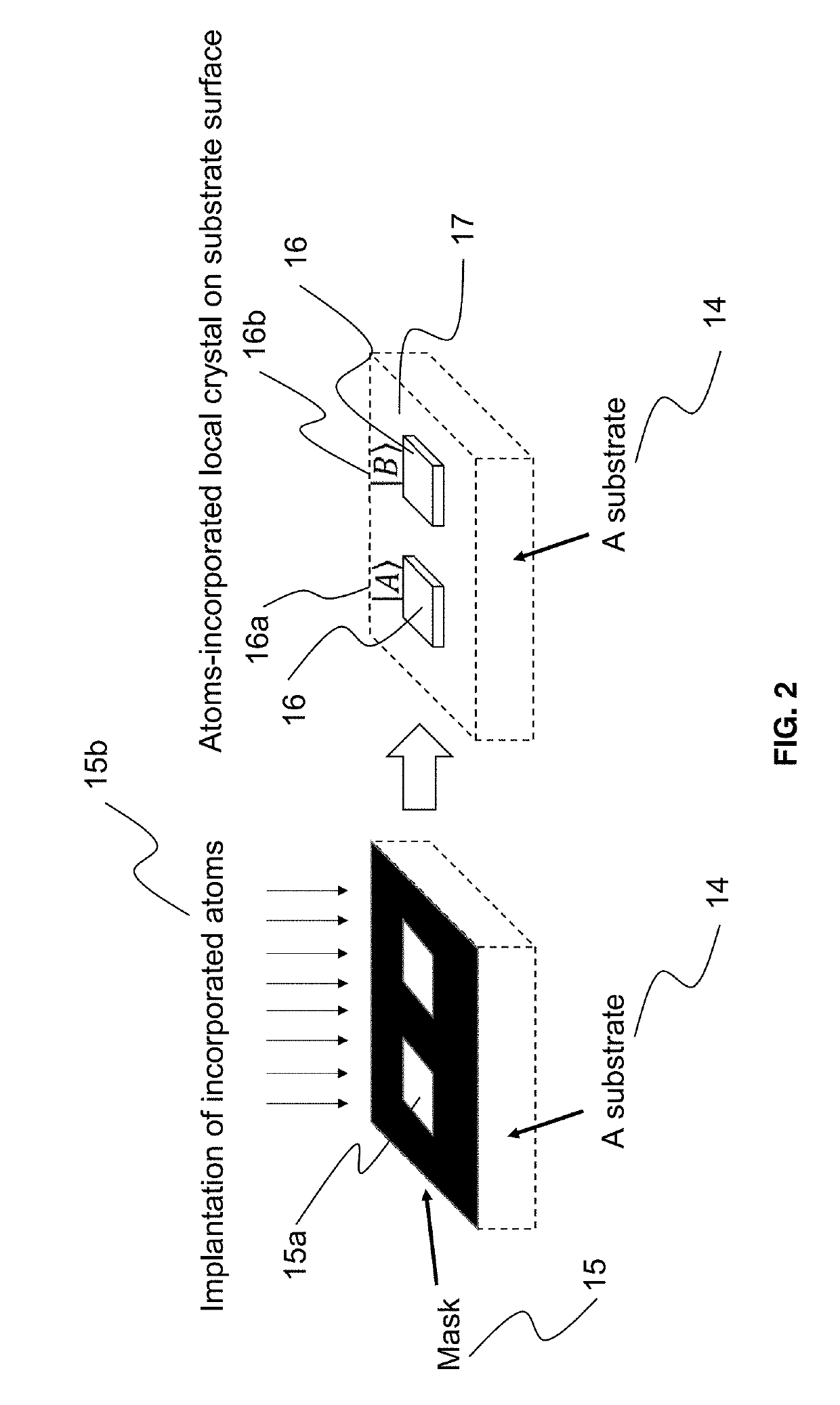

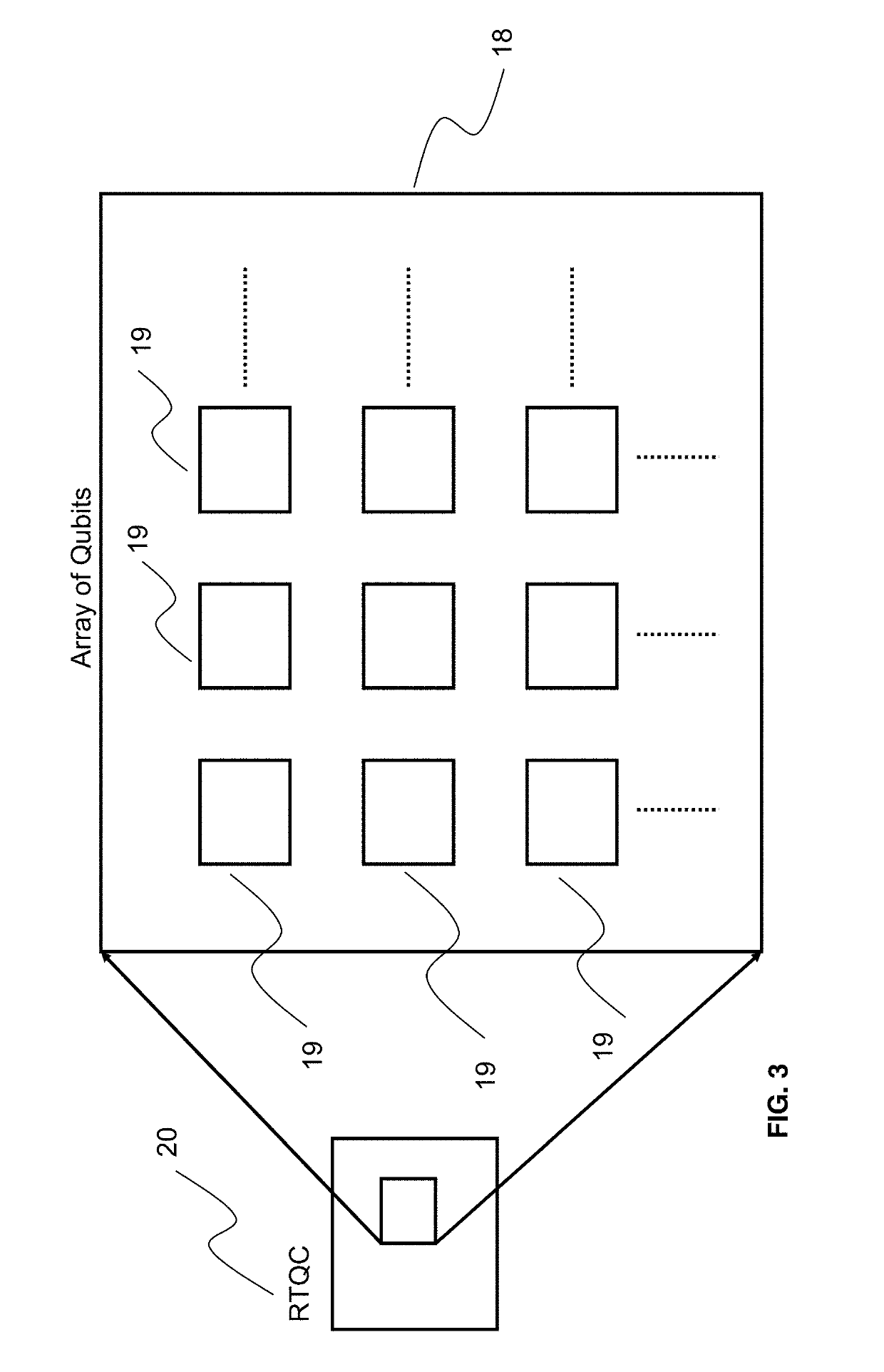

Method of Integrating Qubits for Room-Temperature Quantum Computing

InactiveUS20190311296A1Reduce retention timeReduced freedomQuantum computersKey distribution for secure communicationRetention timeElectronic band structure

A method of qubits, a room temperature quantum computing and a system including a controller, a readout, a resistor and a storage are disclosed. The shape and area of each qubits and the pattern of qubit array may be defined by a pattern on a mask simultaneously to control correlations among qubits. The configuration of qubit correlation may be designed three-dimensionally by stacking layers including arrays of qubits. The external generator may be included in another layer stacked with the layers including the arrays of qubits. The qubit may comprise a band structure having a spin-less ground state and a first excited state with spin. The first excited state may not be split for a retention time even under the external field which can influence a spin. The configuration of qubit correlations may be tuned by considering this retention time and an error correction code in quantum computation.

Owner:FAN HAINING +1

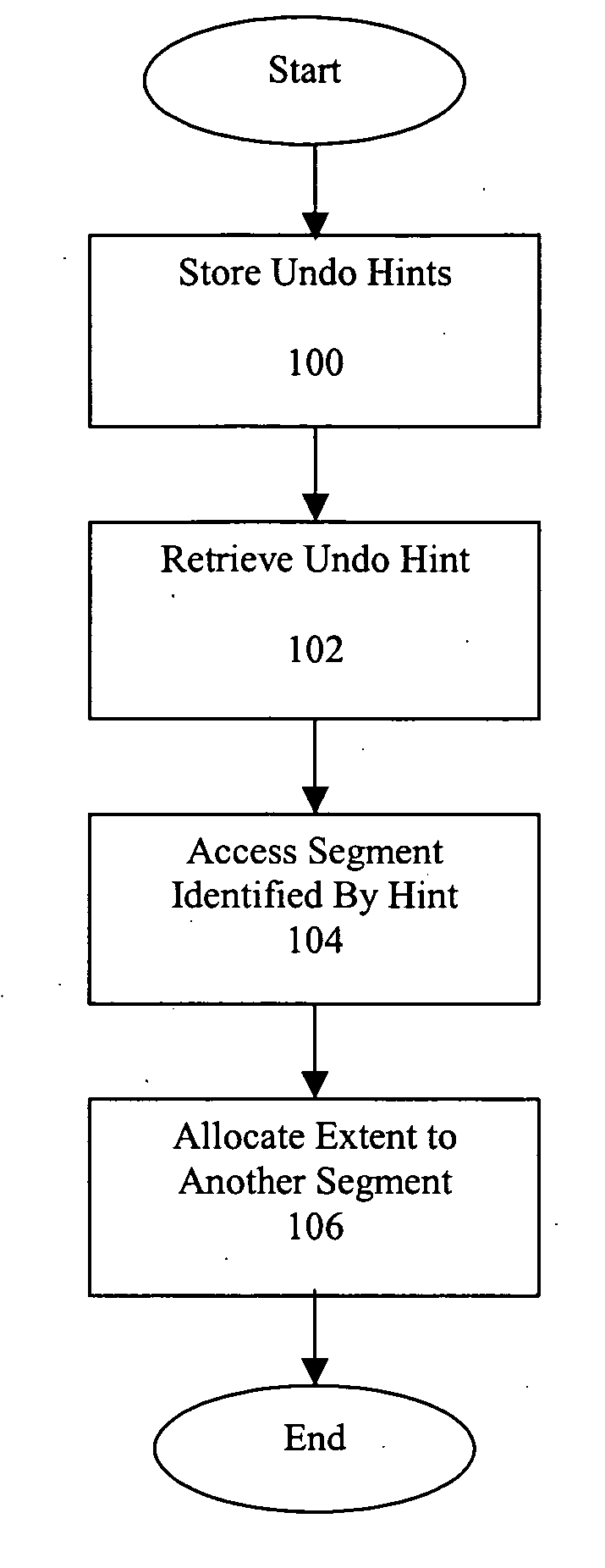

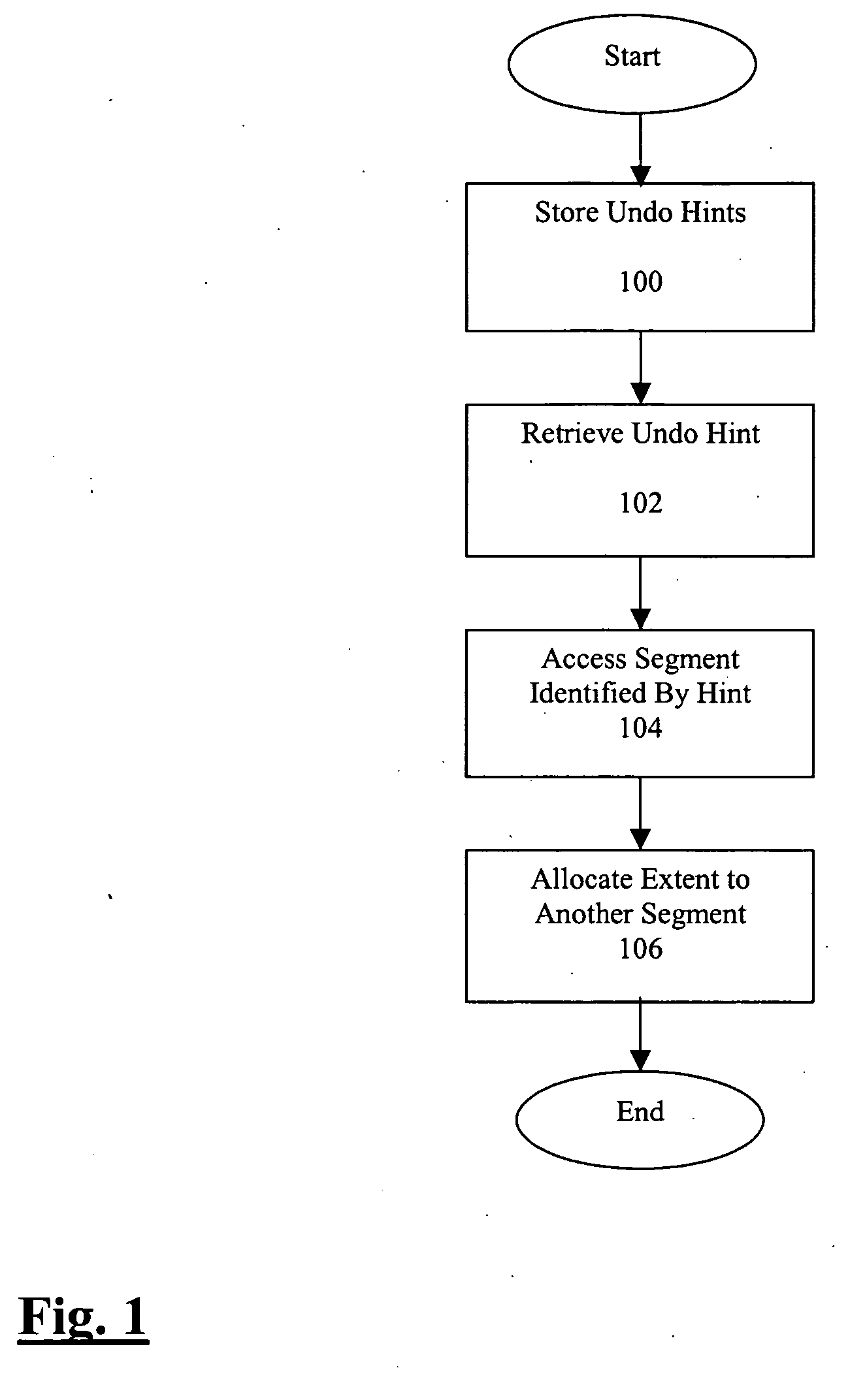

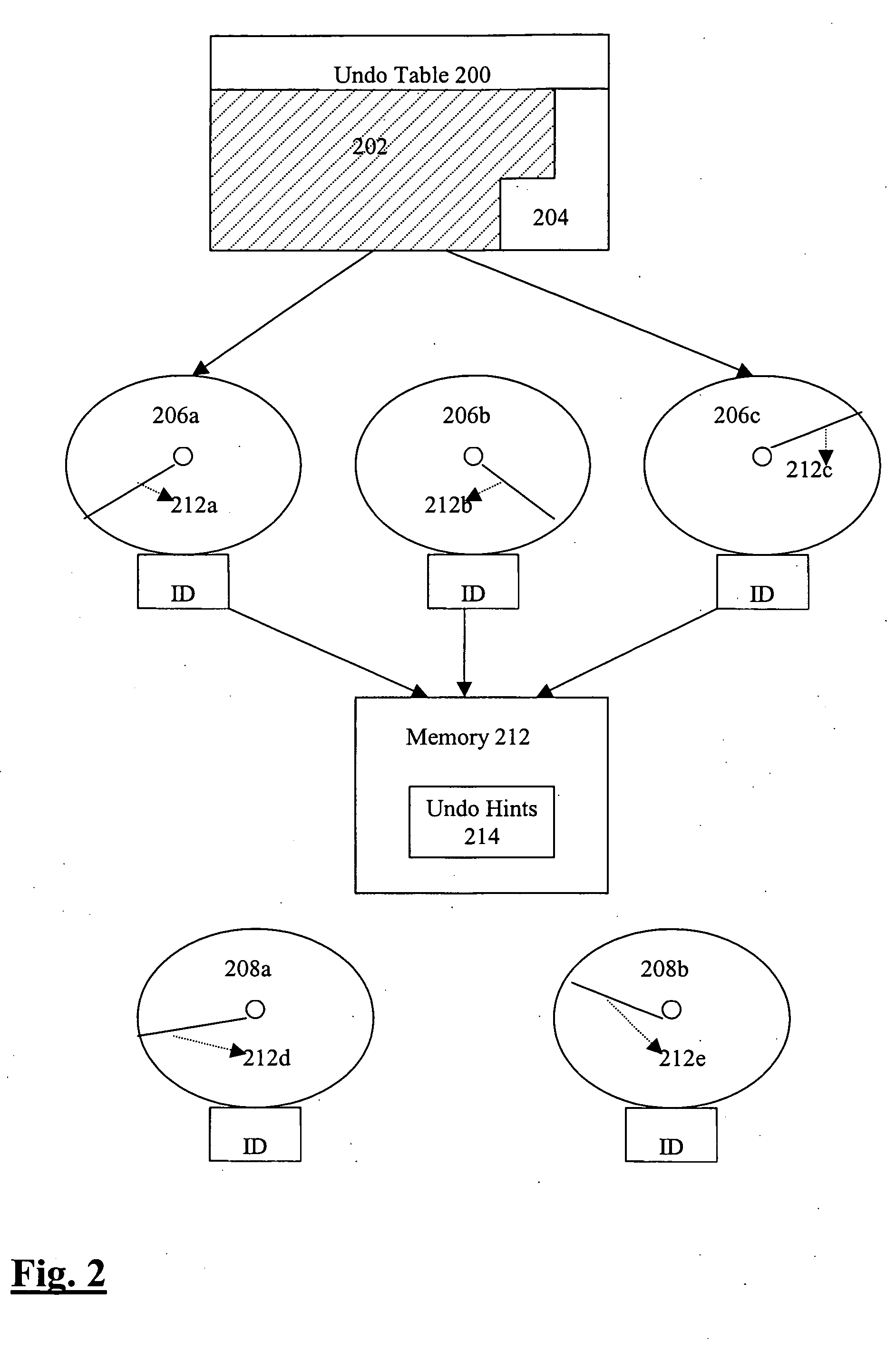

Undo hints to speed up segment extension and tuning of undo retention

ActiveUS20070083488A1Speed up segment extensionReduce retentionData processing applicationsDigital data information retrievalRetention timeArtificial intelligence

Methods and systems for using undo hints to speed up segment extension are disclosed. While a process is searching other segments to find available space, the process collects undo hints that describe when space in a segment might become available. These undo hints are placed in a table of undo hints. When a process is not able to find available space, it may consult the table of undo hints to determine how much to decrease the undo retention. After the undo retention is decreased, the process may again consult the table of undo hints to find a segment that likely contains available space now that the undo retention time has been reduced.

Owner:ORACLE INT CORP

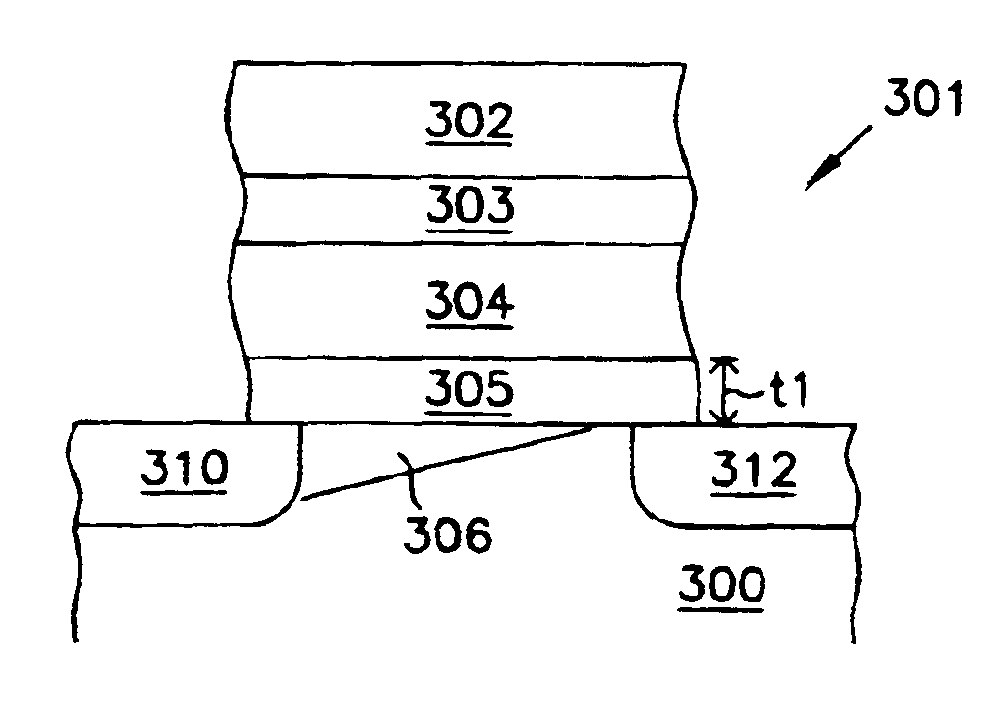

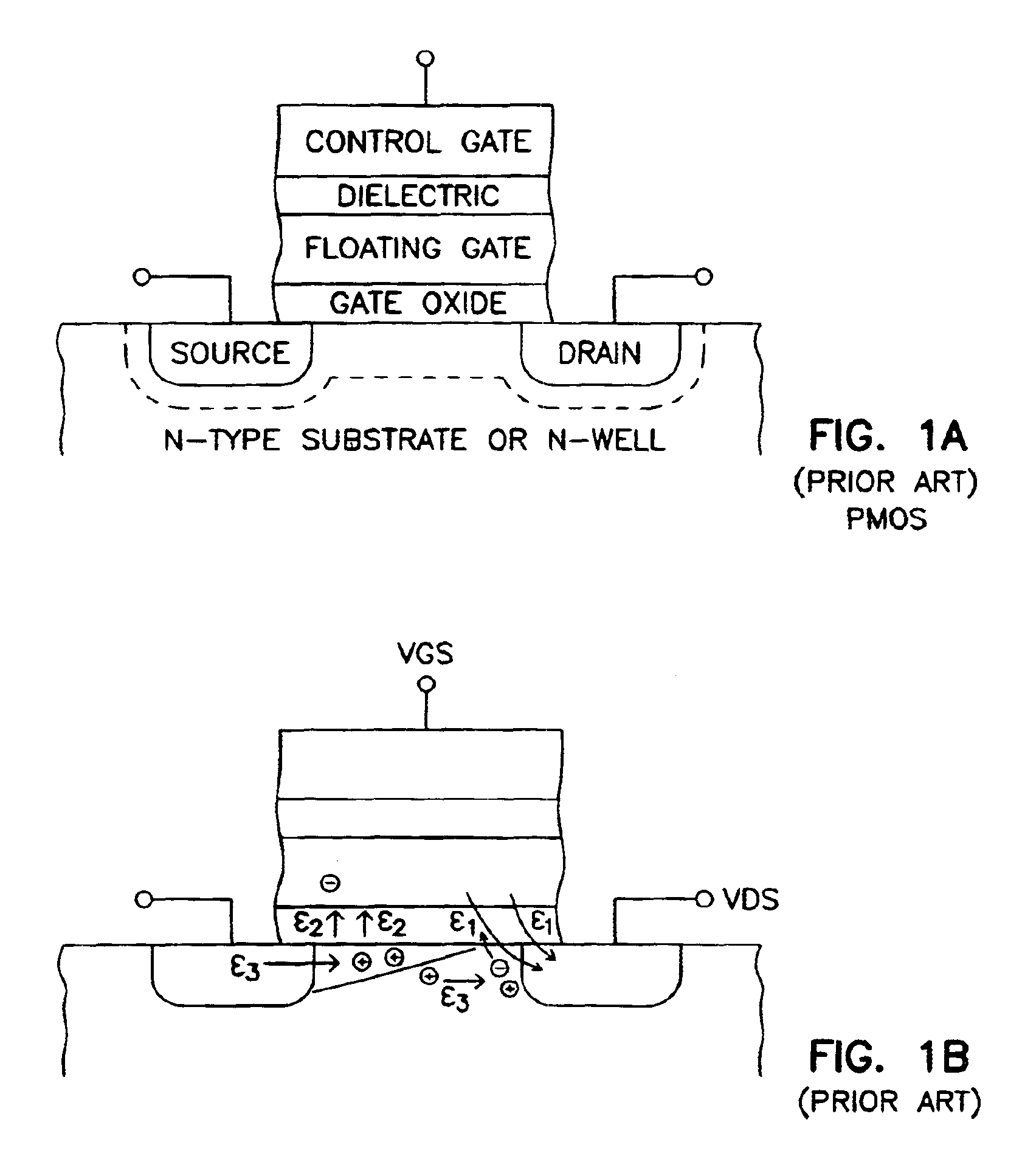

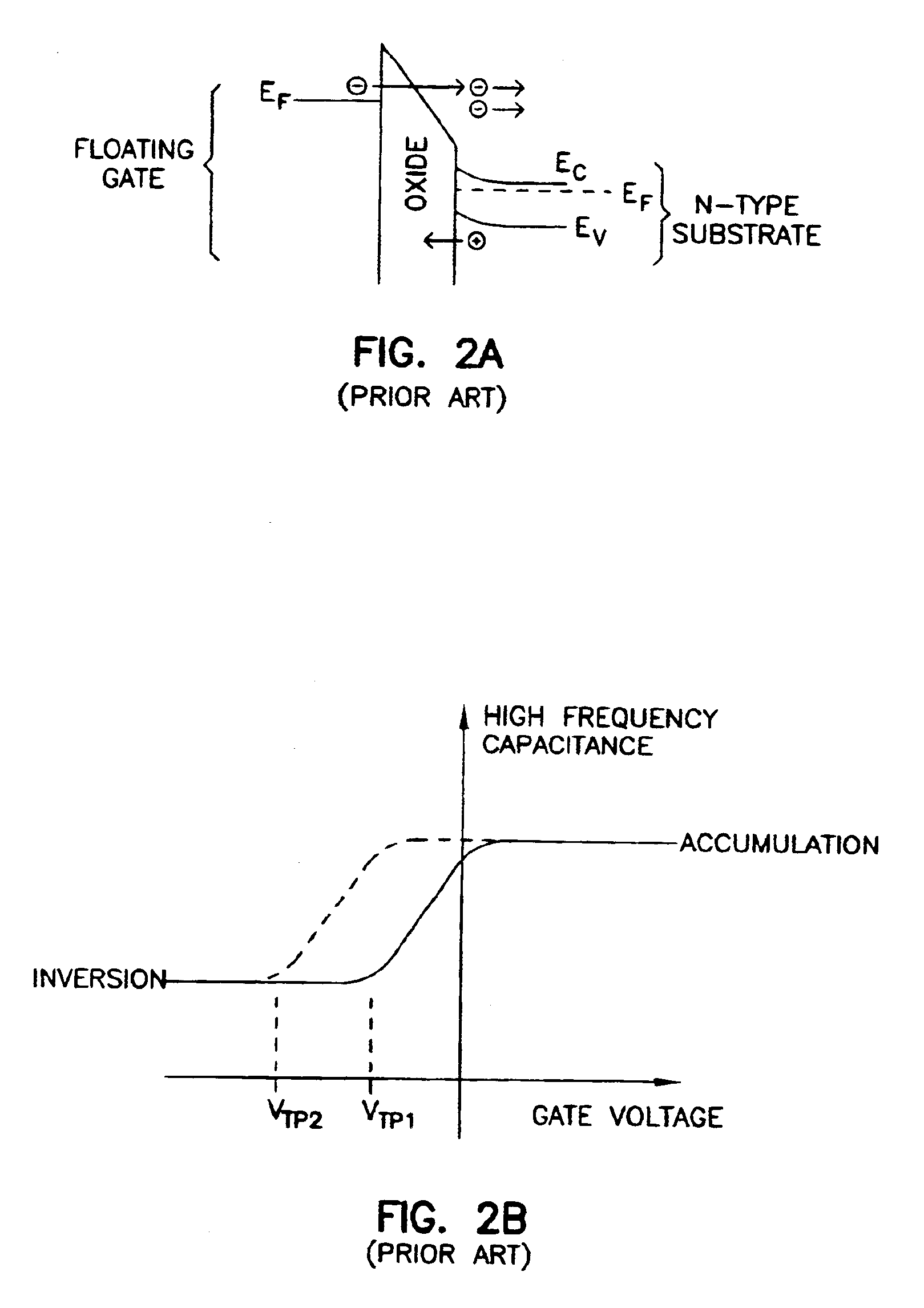

P-channel dynamic flash memory cells with ultrathin tunnel oxides

InactiveUS6909138B2Lower the barrierIncrease currentTransistorRead-only memoriesVoltage shiftP channel

Structures and methods involve dynamic enhancement mode p-channel flash memories with ultrathin tunnel oxide thicknesses. Both write and erase operations are performed by tunneling. The p-channel flash memory cell with thin tunnel oxides will operate on a dynamic basis. The stored data can be refreshed every few seconds as necessary. However, the write and erase operations will now be orders of magnitude faster than traditional p-channel flash memory. Structures and methods for p-channel floating gate transistors are provided that avoid p-channel threshold voltage shifts and achieve source side tunneling erase. The p-channel memory cell structure includes a floating gate separated from a channel region by an oxide layer of less than 50 Angstroms. The methods further include reading the p-channel memory cell by applying a potential to a control gate of the p-channel memory cell of less than 1.0 Volt.

Owner:MICRON TECH INC

Grease with nutritional components being retained and preparation method thereof

ActiveCN104130856AGood dispersionReduce reunionFatty-oils/fats refiningEdible oils/fatsOil and greaseEngineering

The invention provides a processing method of grease. An inert gas is added to the grease before or during the grease being deacidified. By means of the method provided in the invention, neutral grease in the prepared grease has a high recovery ratio and a damage of beneficial components in the grease is little.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

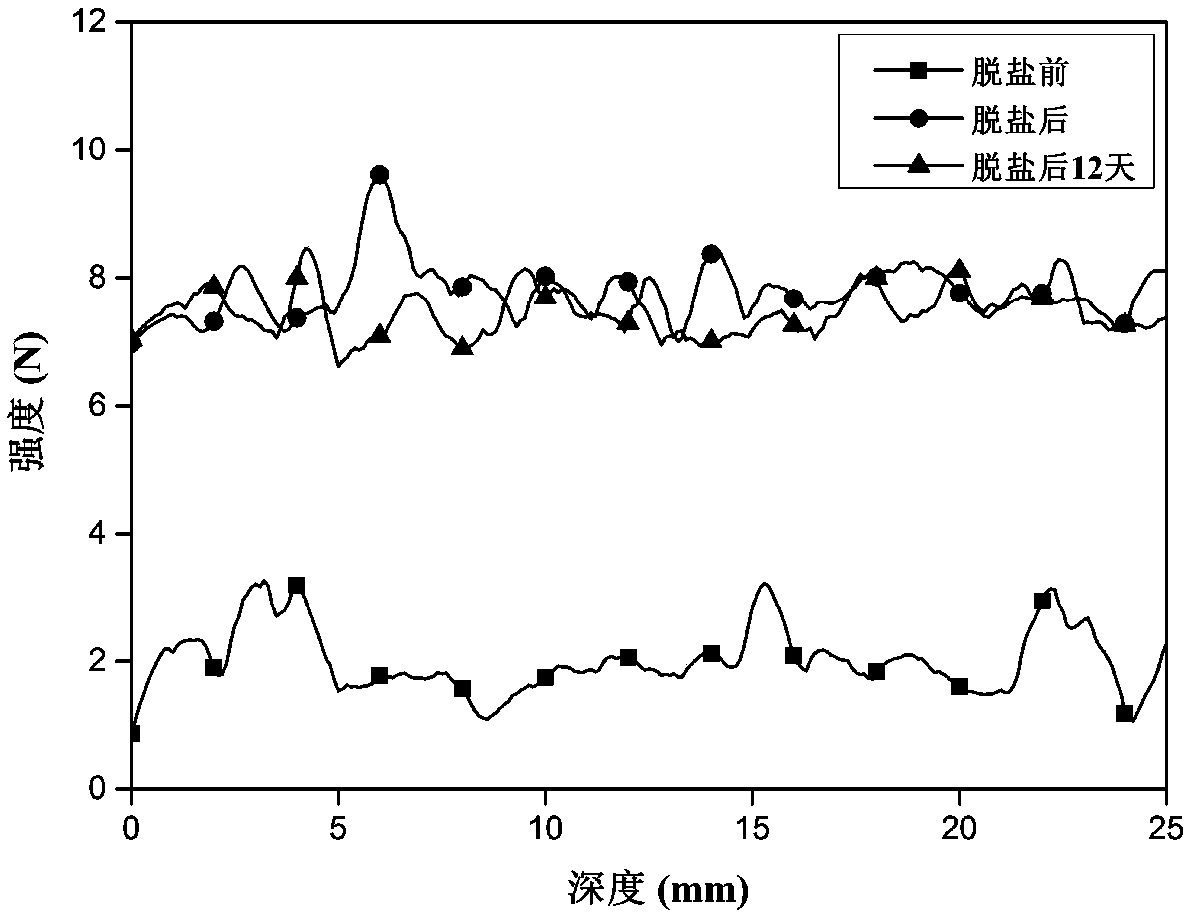

Method for removing sulphate from outdoor crisp brick cultural relic

The invention discloses a method for removing sulphate from an outdoor crisp brick cultural relic. The method is as follows: spraying a salt-damaged crisp part of a brick body with a solution A evenly, then evenly spraying the salt-damaged crisp part of the brick body with a deionized water and solution B mixed liquid with the volume ratio of deionized water to solution B of 1: 6 to 9, and repeating spraying with the solution A and the deionized water and solution B mixed liquid for 3 to 8 times, wherein the solution A is an ethanol solution containing 5 to 15 g / L of phosphoric acid and 10 to25 g / L of dihydrate oxalic acid, and the solution B is a methanol containing 8 to 25 g / L of barium hydroxide octahydrate. According to the method, the outdoor crisp brick cultural relic is desalted for transformation of most destructive Na2SO4 in the brick relic into BaSO4 to deposit in the brick, chlorine salt and sulfate that are not involved in the transformation can be separated from the brickbody in the manner of moving of salts along with water; while desalination, reinforcement function is achieved, the ''fragile'' status of salt-damaged crisp powder of the brick body may not be aggravated, the mechanical strength is significantly increased, the salt penetration increases after the desalination, and the salt retention time in the brick can be reduced.

Owner:SHAANXI NORMAL UNIV

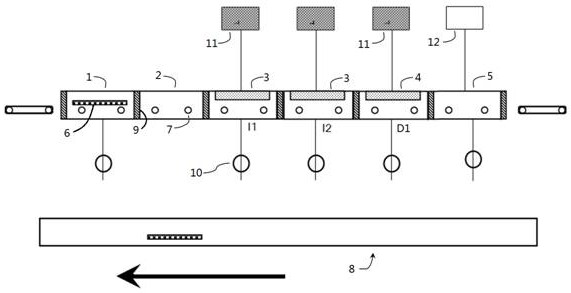

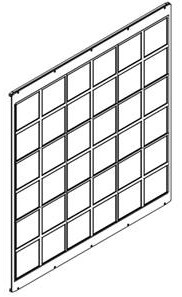

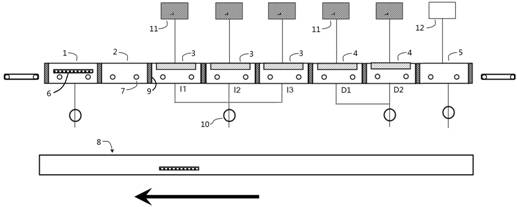

Film coating equipment, method and system, solar cell, assembly and power generation system

ActiveCN111739971AReduce processing waiting timeImprove processing efficiencyFinal product manufactureChemical vapor deposition coatingHeterojunctionEngineering

The invention discloses heterojunction solar cell coating equipment, method and system, a solar cell, an assembly and a power generation system, and belongs to the field of solar cell processing. Theheterojunction solar cell coating equipment is used for depositing a heterojunction solar cell amorphous silicon-based thin film, and comprises a process cavity, wherein the process cavity comprises at least two intrinsic process cavities used for deposition of an intrinsic layer silicon thin film process, and at least one doping process cavity used for deposition of an N-type silicon film or P-type silicon film process, and the cavities in the intrinsic process cavities and the doping process cavity are isolated by isolation valves. By combining the control of gas proportion and pressure, theequipment can process a plurality of solar cells at the same time, so that the overall processing efficiency is greatly improved, and the equipment is suitable for commercial use.

Owner:SUZHOU MAIZHENG TECH CO LTD

Early strengthening agent for hydraulic composition

InactiveUS20110021667A1High early-strengthGood surface textureOrganic chemistryOrganic compound preparationGlycerol DerivativesPhosphate

This invention relates to an early strengthening agent for a hydraulic composition, which contains a compound (A) selected from a specific glycol ether-based compound and a specific glycerin derivate-based compound, as well as an additive composition for a hydraulic composition, which contains the early strengthening agent and a specific phosphate polymer (B).

Owner:KAO CORP

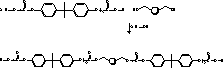

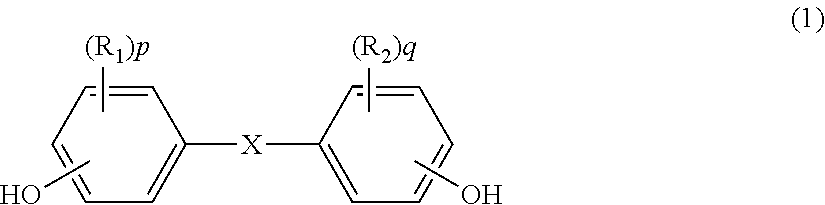

Method for continuous production of high molecular weight polycarbonate resin

A high molecular weight polycarbonate resin is continuously produced by subjecting an aromatic polycarbonate prepolymer and an aliphatic diol compound to a linking and highly polymerizing reaction. Even an aliphatic diol compound having a comparatively low boiling point can be allowed to efficiently contribute to the linking and highly polymerizing reaction. An aromatic polycarbonate prepolymer is produced by a polycondensation reaction between an aromatic dihydroxy compound and a diester carbonate, adding an aliphatic diol compound having an aliphatic group bonding to a terminal hydroxyl group to obtain a prepolymer mixture, and subjecting the resulting prepolymer mixture to a linking and highly polymerizing reaction under reduced pressure. The aliphatic diol compound is added at a pressure exceeding 200 torr, and the prepolymer mixture is subjected to a linking and highly polymerizing reaction before the terminal hydroxyl group concentration of the aromatic polycarbonate prepolymer in the prepolymer mixture reaches 2000 ppm.

Owner:MITSUBISHI GAS CHEM CO INC

Energy efficient process for producing nitrogen oxide

ActiveUS20140127118A1Increase dissociationReduce decomposition rateChemical/physical/physico-chemical processesNitric oxidePower flowDc current

A process for producing NO gas from a feed flow of air or oxygen enriched air, by means of moving an electric arc through the air flow by using a magnetic field and AC or DC currents, in a reactor, wherein a pressure lower than 1 bar is applied, wherein the temperature in the exited arc is adjusted to be within the range of 3000 to 5000 Kelvin, and wherein the air flow is quenched by applying a spray of fine water droplets upstream or just downstream the arc, excess air feed or bypassed air to obtain a stable NO-containing plasma having a temperature below 2000 Kelvin.

Owner:N2 APPLIED

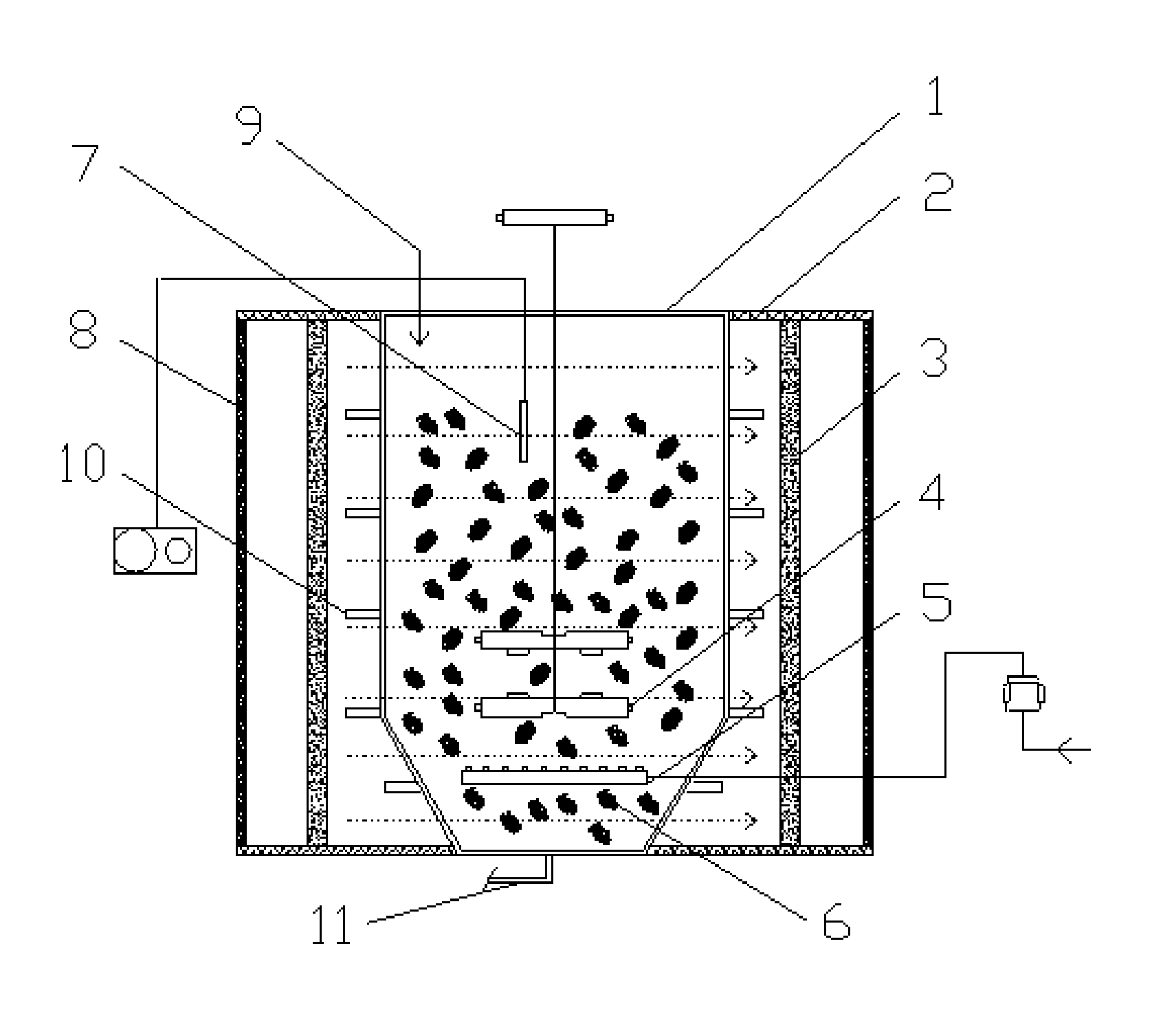

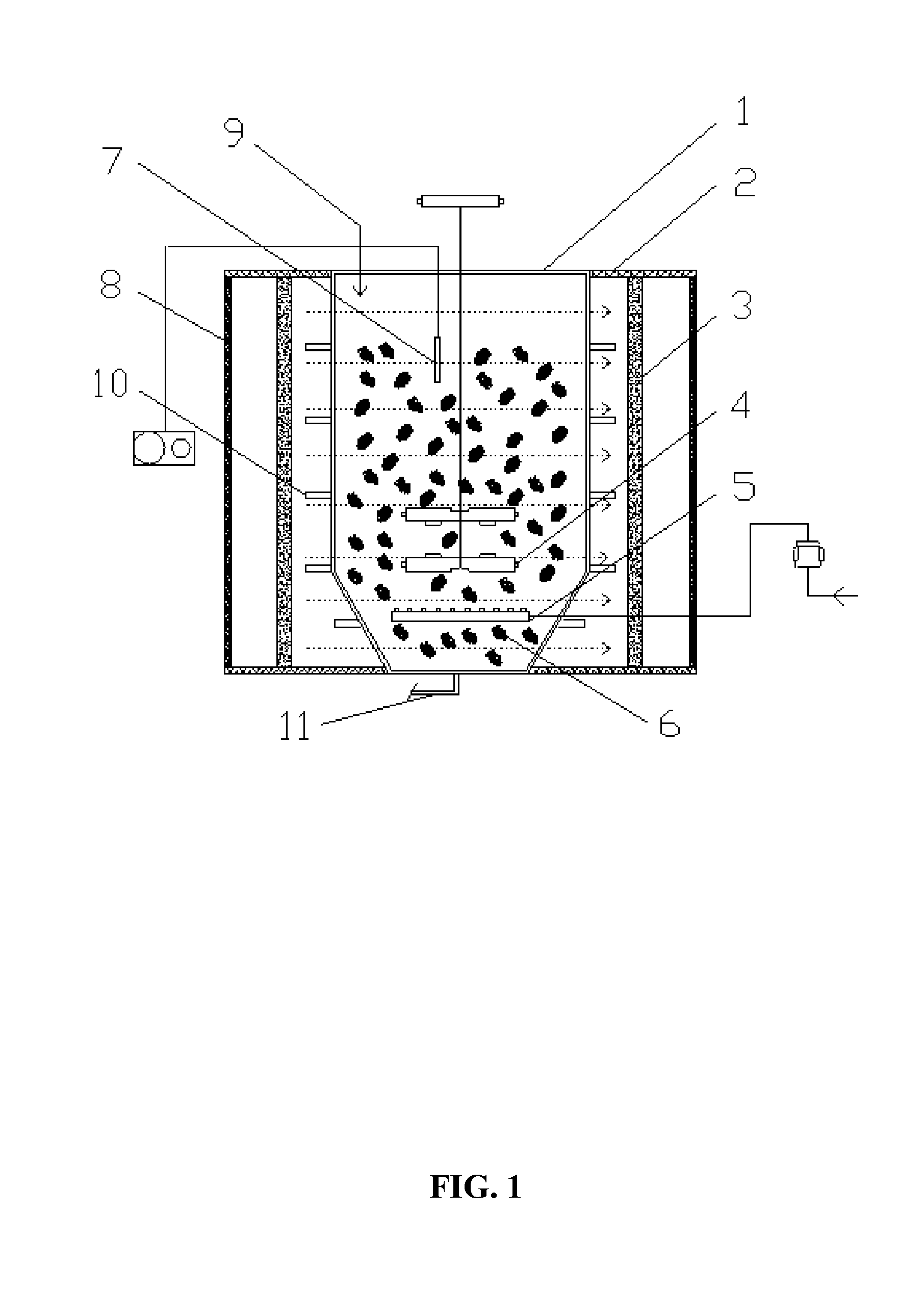

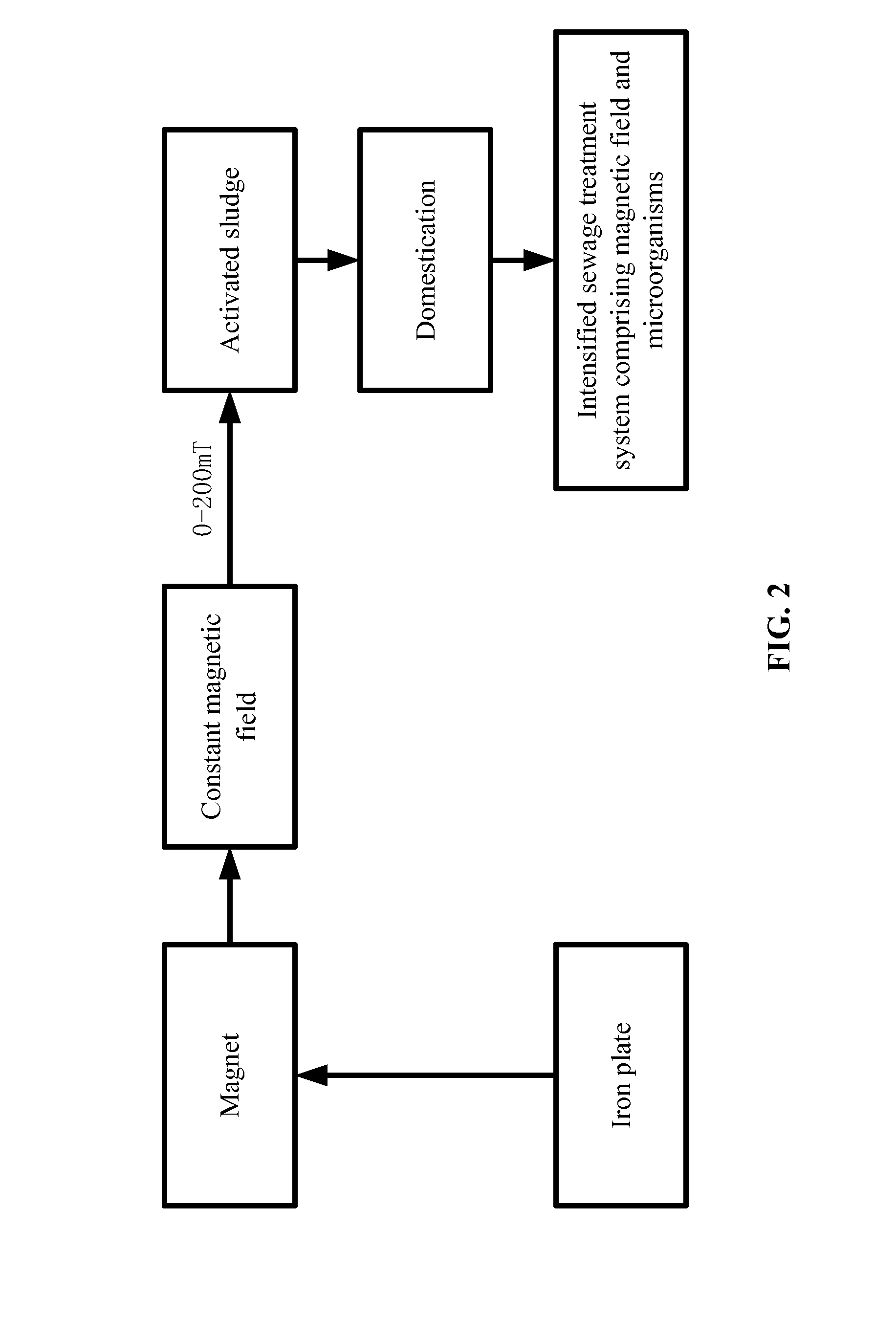

Device and method for sewage treatment using constant magnetic field

ActiveUS20140138309A1High activityEnhanced mass transferWater treatment parameter controlWater/sewage treatmentActivated sludgeNuclear engineering

A device for sewage treatment, including: a reactor and a magnetic field generator. The reactor includes a stirrer, an aerator, an activated sludge zone, an upper end including a water inlet, a side wall including a water outlet, and a bottom including a sludge outlet. The magnetic field includes magnets and iron plates. The activated sludge zone is disposed inside the reactor. The stirrer and the aerator are disposed within the activated sludge zone. The aerator is arranged beneath the stirrer. The magnetic field generator is disposed outside the reactor. The magnets and the iron plates are symmetrically disposed on two sides of the reactor, respectively, and each of the magnets is disposed on the inner side of the corresponding iron plate. The magnets disposed on both sides of the reactor produce magnetic fields having the same direction.

Owner:NANJING UNIV

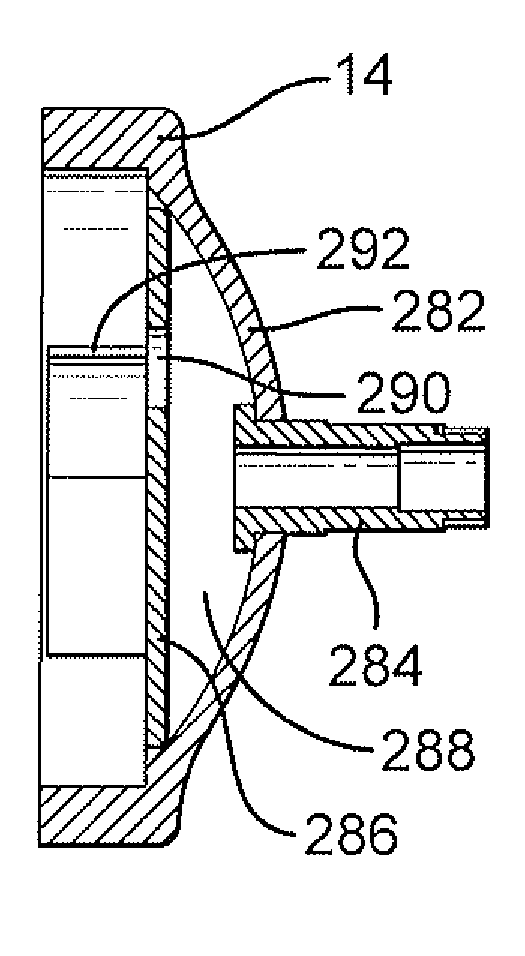

Apparatus and process for treating waste

ActiveUS9156069B2Easy to separateEliminate needBioreactor/fermenter combinationsBiological substance pretreatmentsPlenum chamberWaste management

Solid waste to be treated is introduced into the interior of a rotary autoclave that is downwardly inclined towards its discharge end and has a door at the discharge end. Steam is injected through said door via a plenum chamber in the door so that water and steam pass through a one-way device and then directly into the interior of the autoclave. The one-way device prevents the solid waste from entering the plenum chamber from the interior of the autoclave. The plenum chamber is defined between a region of the door and a plate secured to the door at a small spacing inwardly of the door. The outlet is defined in the plate and the one one-way device is fitted to the outlet.

Owner:AEROTHERMAL GROUP

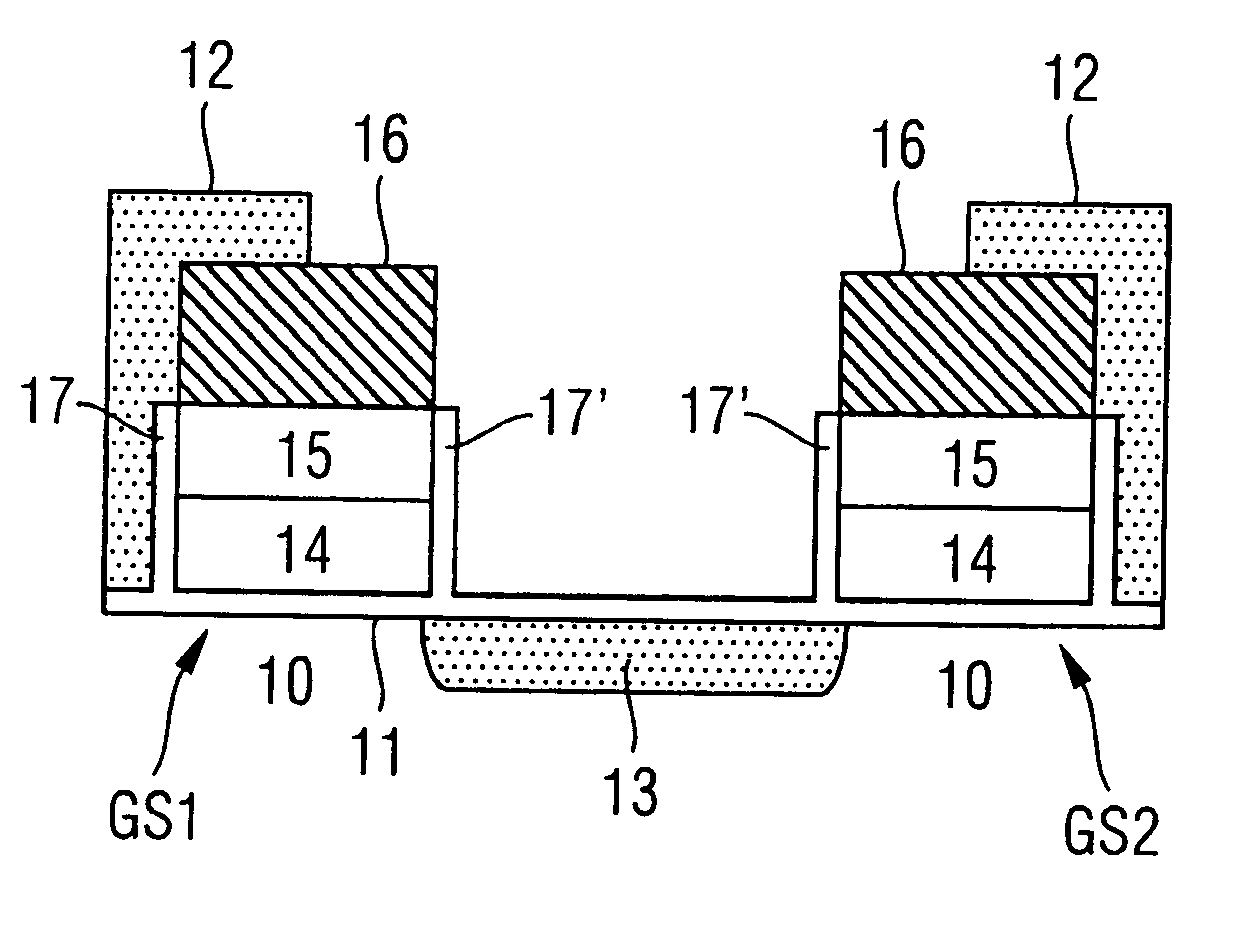

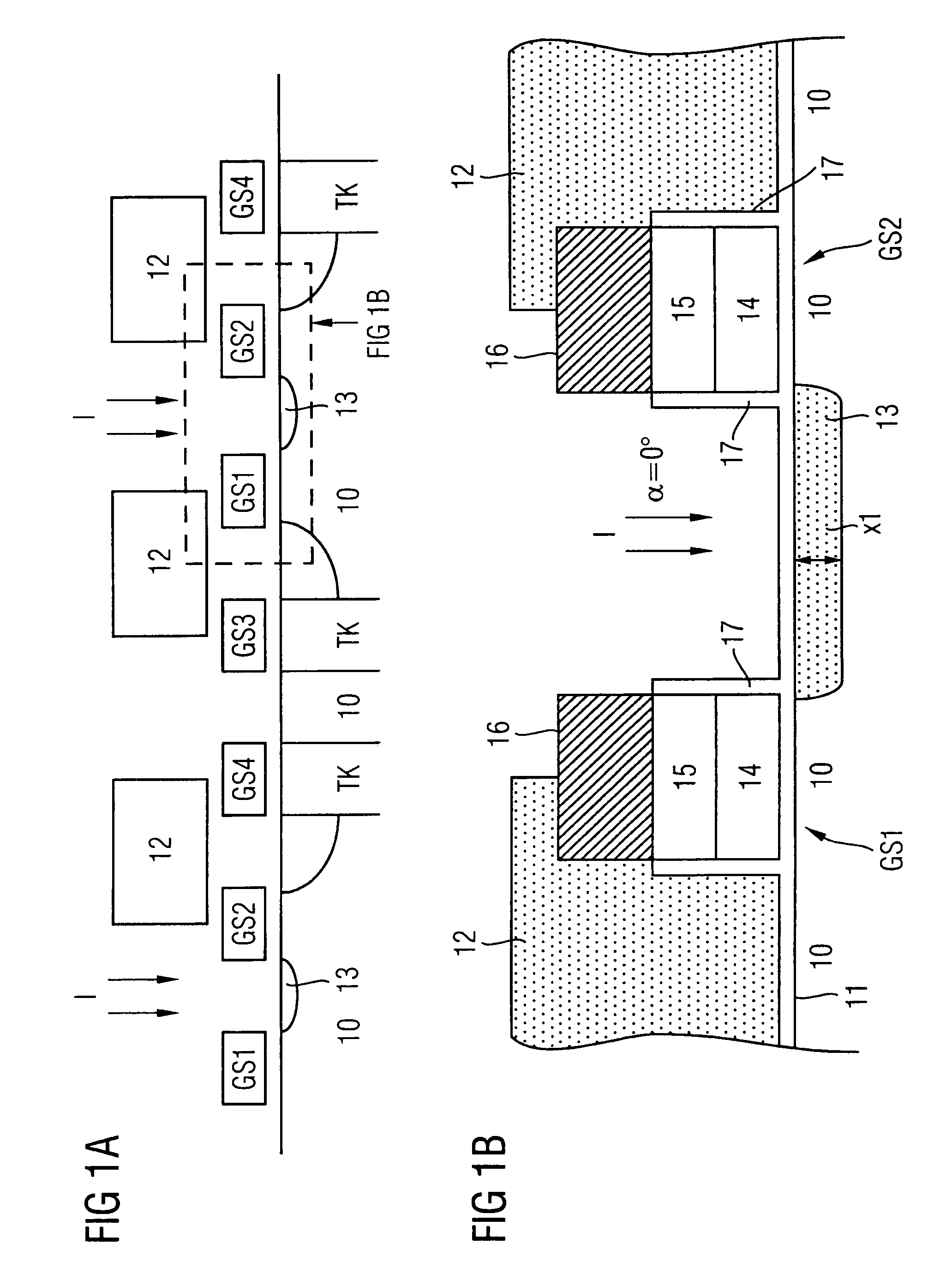

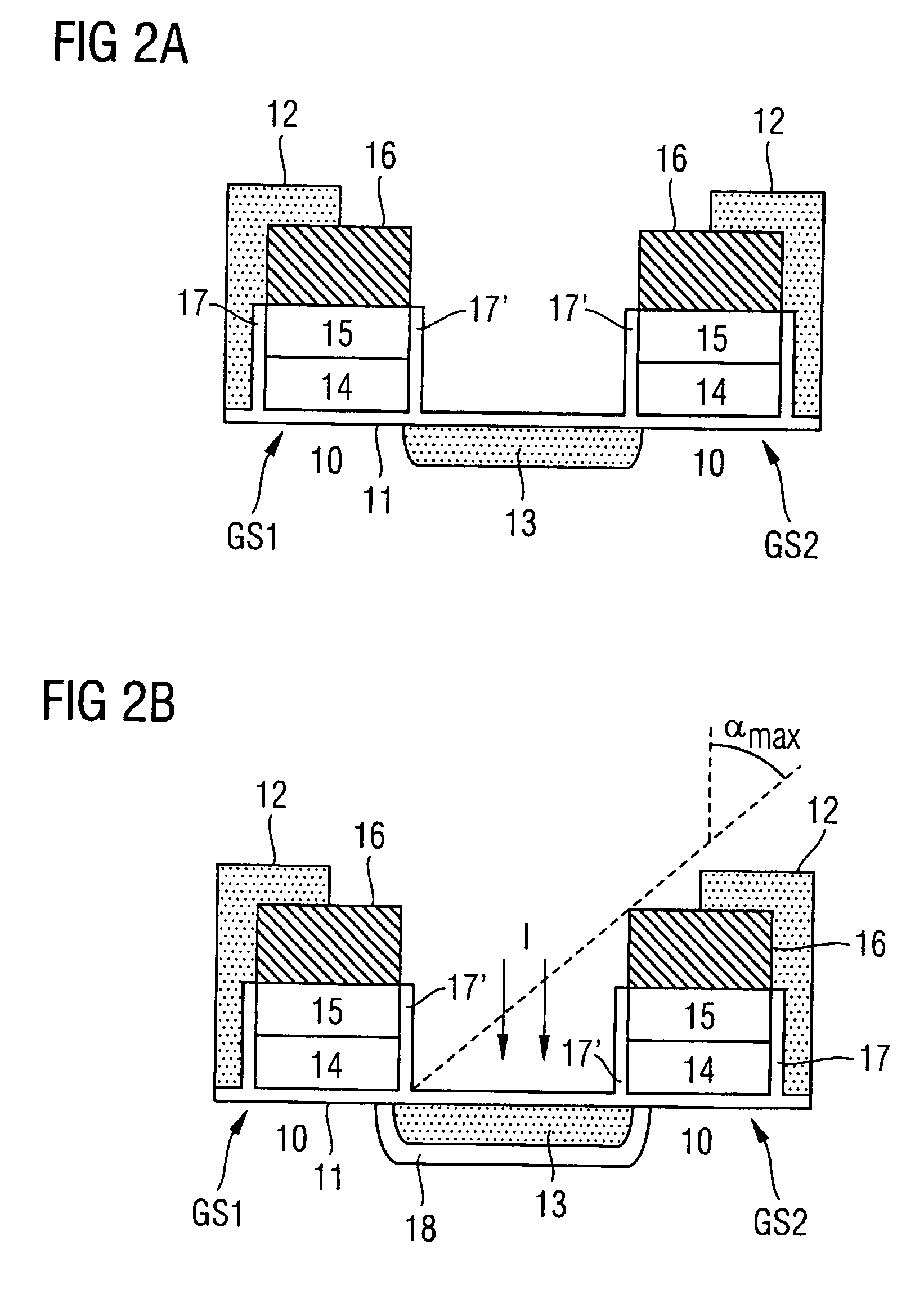

Method for fabricating a semiconductor structure

InactiveUS6967133B2Simplify fabrication processLow connection resistanceTransistorSolid-state devicesGate stackOxide

The present invention provides a method for fabricating a semiconductor structure having a plurality of gate stacks (GS1, GS2, GS3, GS4) on a semiconductor substrate (10), having the following steps: application of the gate stacks (GS1, GS2, GS3, GS4) to a gate dielectric (11) above the semiconductor substrate (10); formation of a sidewall oxide (17) on sidewalls of the gate stacks (GS1, GS2, GS3, GS4); application and patterning of a mask (12) on the semiconductor structure; and implantation of a contact doping (13) in a self-aligned manner with respect to the sidewall oxide (17) of the gate stacks (GS1, GS2) in regions not covered by the mask (12).

Owner:POLARIS INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com