Grease with nutritional components being retained and preparation method thereof

A technology of nutrients and oils, which is applied in the field of oils and fats with retained nutrients and its treatment. It can solve the problems of microwave radiation corrosion on the equipment body, high instantaneous output energy of microwave radiation, intermittent use, etc., and shorten the deacidification treatment time. , Facilitate settlement and avoid the loss of neutral oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] In the present invention, the oil used for deacidification is vegetable oil or animal oil, which can also be called renewable oil, preferably vegetable oil. The oil can be obtained commercially or by conventional oil preparation methods. Specifically, non-limiting examples of vegetable oils include: rice oil, sunflower oil, palm oil, palm kernel oil, peanut oil, rapeseed oil, soybean oil, linseed oil, cottonseed oil, safflower oil, perilla seed oil, tea seed oil, castor oil, palm fruit oil, olive oil, soybean oil, tallow seed oil, almond oil, almond oil, tung oil, rubber seed oil, rice bran oil, corn germ oil, wheat germ Oil, Sesame Seed Oil, Evening Primrose Seed Oil, Hazelnut Oil, Walnut Oil, Grape Seed Oil, Flax Seed Oil, Borage Seed Oil, Sea Buckthorn Seed Oil, Tomato Seed Oil, Pumpkin Seed Oil, Macadamia Nut Oil, Coconut Oil, Cocoa Butter, Algae Oil, etc. Those skilled in the art know that all plant-derived oils contain sterols (also known as phytosterols), and s...

Embodiment 1

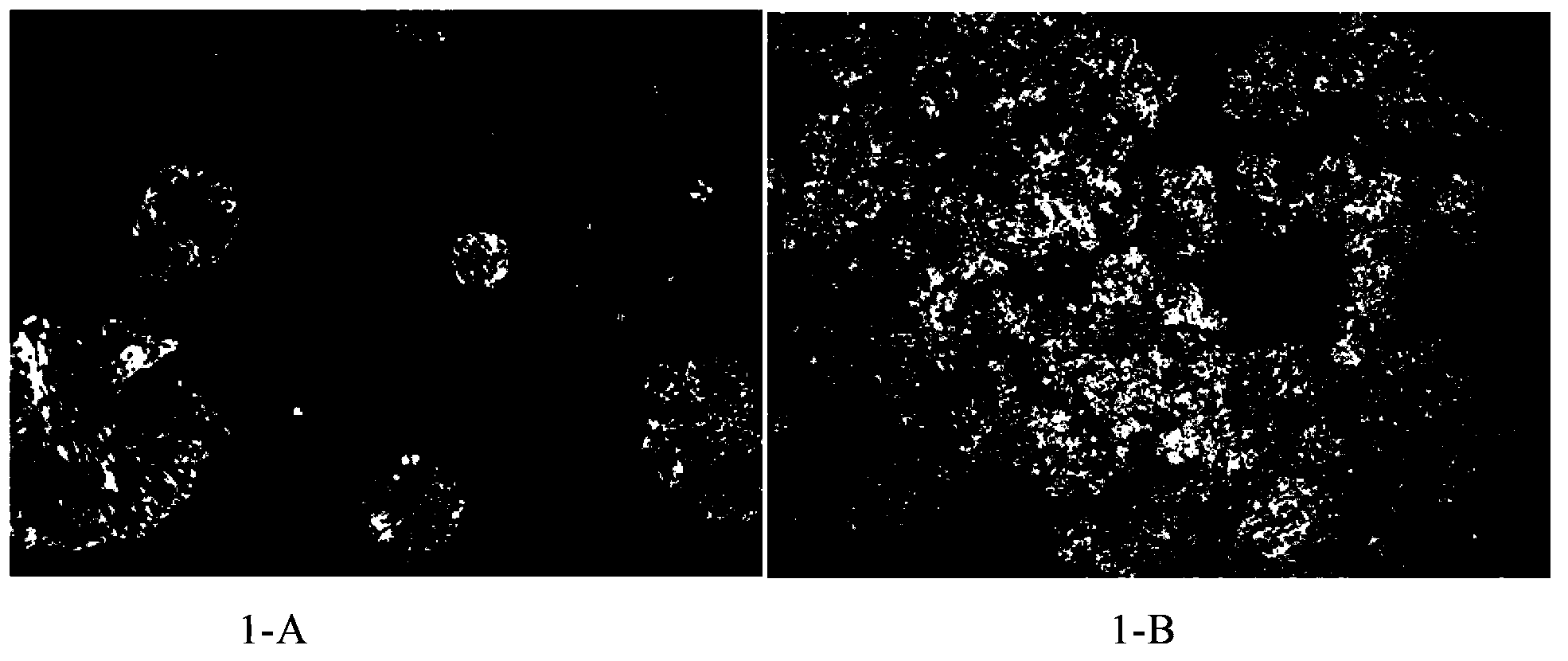

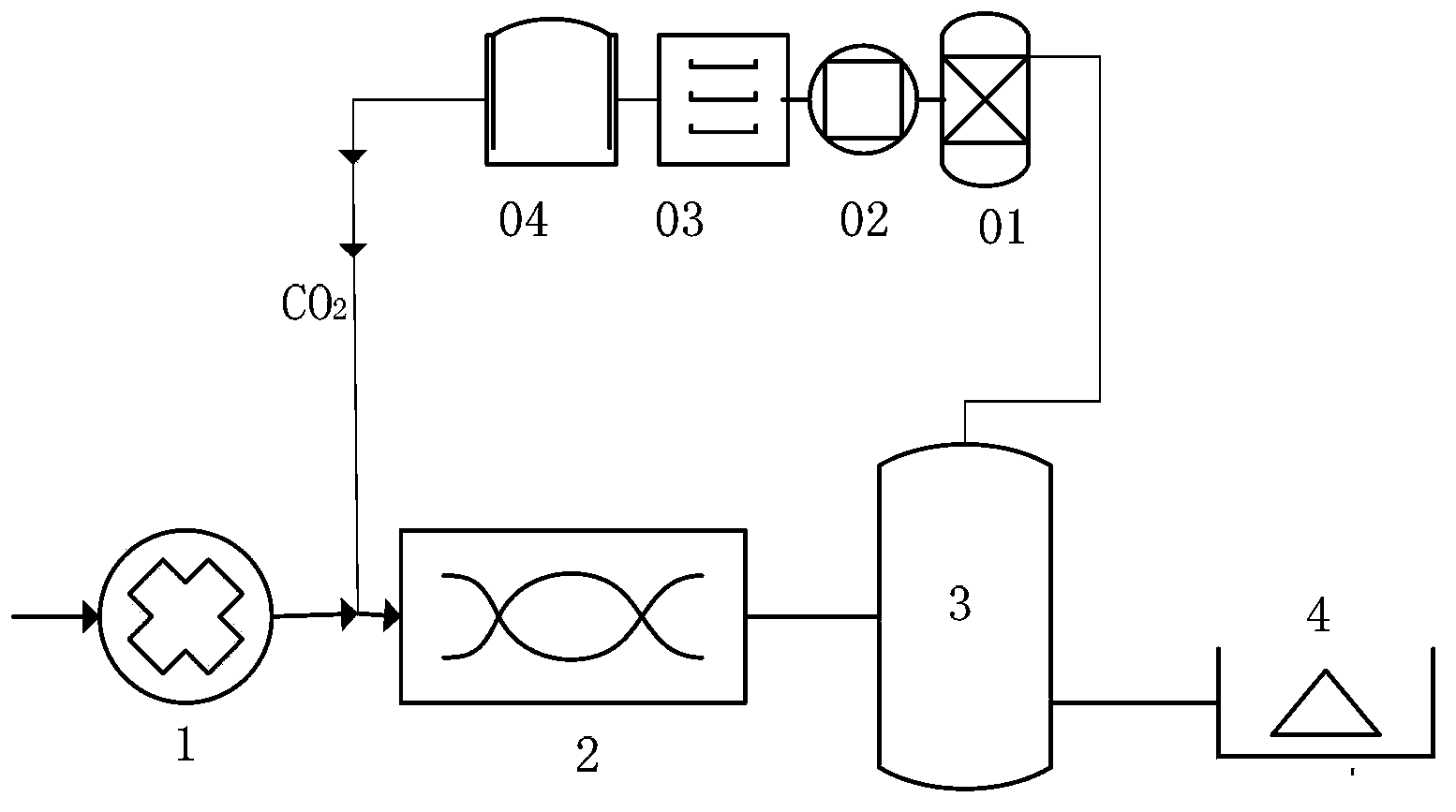

[0194] Example 1: After degumming crude rice oil 1 (acid value 22KOH mg / g, oryzanol content 21750ppm, total sterols 13783ppm, anisidine value 0.55) by acidification and degumming, 15% lye was added. The speed of the dynamic mixer is 2500rpm for mixing, and then the CO is controlled by the pressure regulating valve 2 The gas pressure is 0.5 bar, and enters the static mixer for further stirring. Sampling was carried out, and the particle size was detected by electron microscopy at 400-600 μm. Control the temperature of the rice oil at 25°C, control the stirring speed in the neutralization tank at 30rpm, and the residence time at 20min, then raise the temperature to 80°C for centrifugation. The obtained desoaped rice oil (acid value 0.51KOH mg / g, oryzanol content 7872ppm, total sterols 10067ppm, desoaped rice oil yield = 80.2%) had an anisidine value of 0.47.

Embodiment 2

[0195] Example 2: Crude rice oil 2 (acid value 18KOH mg / g, oryzanol content 20834PPM, total sterols 12974ppm, anisidine value 0.72), after acidification and degumming, 15.5% lye was added. The speed of the dynamic mixer is 2700rpm for mixing, and then the CO is controlled by the pressure regulating valve 2 The gas pressure is 1.5 bar, and enters the static mixer for further stirring. Sampling was carried out, and the particle size was detected by electron microscopy at 350-500 μm. Control the temperature of the rice oil at 35°C, control the stirring speed in the neutralization tank at 28rpm, and the residence time at 18min, then raise the temperature to 85°C for centrifugation. The obtained desoaped rice oil (acid value 0.87KOH mg / g, oryzanol content 14652ppm, total sterols 11312ppm, desoaped rice oil yield = 81.7%) had an anisidine value of 0.66.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com