Method for continuous production of high molecular weight polycarbonate resin

polycarbonate technology, applied in the field of continuous production can solve the problems of difficult to efficiently remove by-product aromatic monohydroxy compounds outside, difficulty in removing impurities such as sodium chloride and residual methylene chloride that have an effect on polymer properties, and short reaction time of high polymerizing step, etc., to achieve the effect of shortening the reaction time, and prolonging the reaction time a high molecular weight polycarbonate resin production method of high molecular weight polycarbonate resin production method of high molecular weight polycarbonate resin production method, high molecular weight polycarbonate resin production method, applied in the field of high molecular weight polycarbonate technology, which is applied in the field of high molecular weight polycarbonate technology, which is applied in the field of high molecular weight polymerization process, and high molecular weight polycarbonate high molecular weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

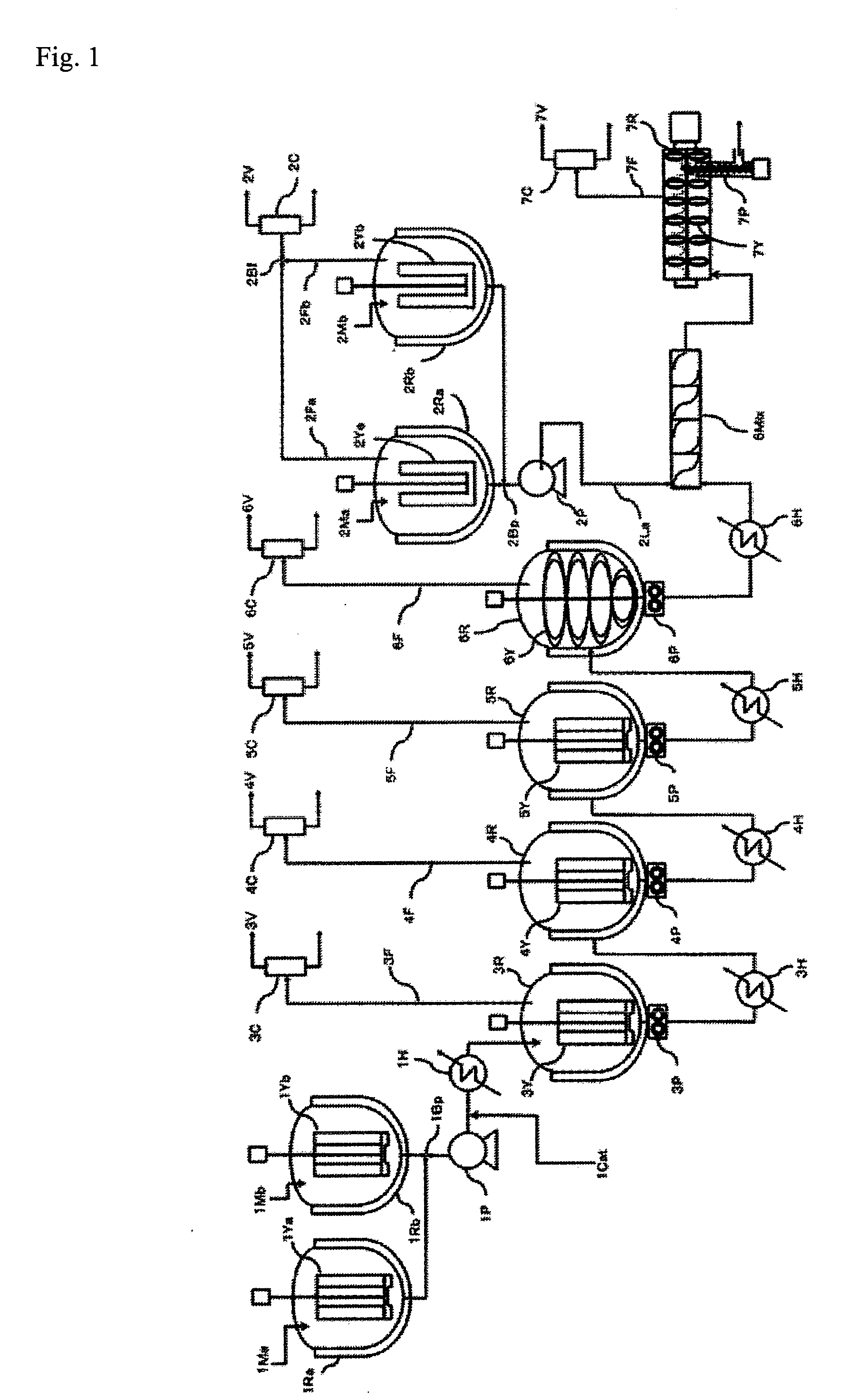

[0337]A polycarbonate resin was produced under the following conditions with the continuous production apparatus shown in FIG. 1 having two primary raw material preparation tanks (1Ra, 1Rb), two linking agent preparation tanks (2Ra, 2Rb), four vertical stirred reaction vessels (3R to 6R) and one horizontal stirred reaction vessel (7R).

[0338]First, each reaction vessel and preheater was preliminarily set to an internal temperature and pressure corresponding to the reaction conditions indicated in Table 1.

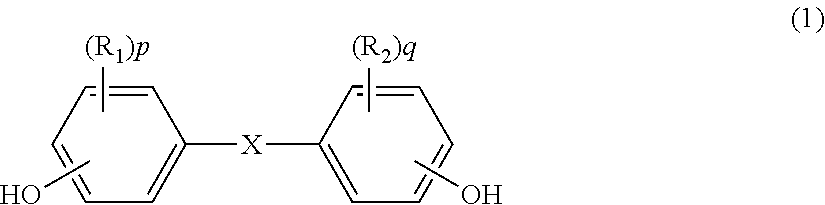

[0339]A melt mixture prepared by suitably mixing diphenyl carbonate and bisphenol A (BPA) so that the raw material molar ratio (diphenyl carbonate / BPA) in the primary raw material preparation tanks 1Ra and 1Rb was 1.12 was continuously supplied to the first vertical stirred reaction vessel 3R (reaction conditions: 100 torr (13 kPa), 180° C., stirring speed: 160 rpm, volume: 130 L) in a nitrogen gas atmosphere at a flow rate of 46.8 kg / hr, and the liquid level was maintained at a cons...

example 2

[0372]A polycarbonate resin was produced under the following conditions with the continuous production apparatus shown in FIG. 1 having two primary raw material preparation tanks, two linking agent preparation tanks, four vertical stirred reaction vessels and one horizontal stirred reaction vessel.

[0373]First, each reaction vessel and preheater was preliminarily set to an internal temperature and pressure corresponding to the reaction conditions indicated in Table 1.

[0374]A melt mixture prepared by suitably mixing diphenyl carbonate and bisphenol A (BPA) so that the raw material molar ratio (diphenyl carbonate / BPA) in the primary raw material preparation tanks 1Ra and 1Rb was 1.15 was continuously supplied to the first vertical stirred reaction vessel 3R (reaction conditions: 100 torr (13 kPa), 180° C., stirring speed: 160 rpm, volume: 130 L) in a nitrogen gas atmosphere at a flow rate of 46.9 kg / hr, and the liquid level was maintained at a constant level while controlling the openi...

example 3

[0407]A polycarbonate resin was produced under the following conditions with the continuous production apparatus shown in FIG. 1 having two primary raw material preparation tanks, two linking agent preparation tanks, four vertical stirred reaction vessels and one horizontal stirred reaction vessel.

[0408]First, each reaction vessel and preheater was preliminarily set to an internal temperature and pressure corresponding to the reaction conditions indicated in Table 1.

[0409]A melt mixture prepared by suitably mixing diphenyl carbonate and bisphenol A (BPA) so that the raw material molar ratio (diphenyl carbonate / BPA) in the primary raw material preparation tanks 1Ra and 1Rb was 1.12 was continuously supplied to the first vertical stirred reaction vessel 3R (reaction conditions: 100 torr (13 kPa), 180° C., stirring speed: 160 rpm, volume: 130 L) in a nitrogen gas atmosphere at a flow rate of 46.6 kg / hr, and the liquid level was maintained at a constant level while controlling the openi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com