Patents

Literature

64results about How to "Increase cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Banana fiber and its production and its blending wires and fabrics

InactiveCN1472372ALight materialGood hygroscopicityVegetable fibres from other vegetable matterYarnYarnFiber bundle

Provided is a banana fiber using a banana stem which is an industrial waste as a raw material, a method for producing the banana fiber, a union yarn composed of a staple fiber of the banana fiber and other fiber and a fiber structure prepared from the union yarn. The banana fiber is obtained by drying peeled temporary stem of banana and opening the fiber so as to have 10-50 mm average fiber length and 0.5-80 dtex average fineness. The method for producing the banana fiber comprises a step (a) for cutting stems of banana, a step (b) for peeling and removing colored epidermis of stems, a step (c) for peeling much bark constituting stems to provide a unit bark, a step (d) for taking out a fiber bundle by pressing the unit bark by a press, a step (e) for drying the fiber bundle, a step (f) for obtaining a monofilament from the dried fiber bundle and a step (g) cutting the monofilament into a definite length and obtaining the staple fiber.

Owner:NISSHINBO IND INC

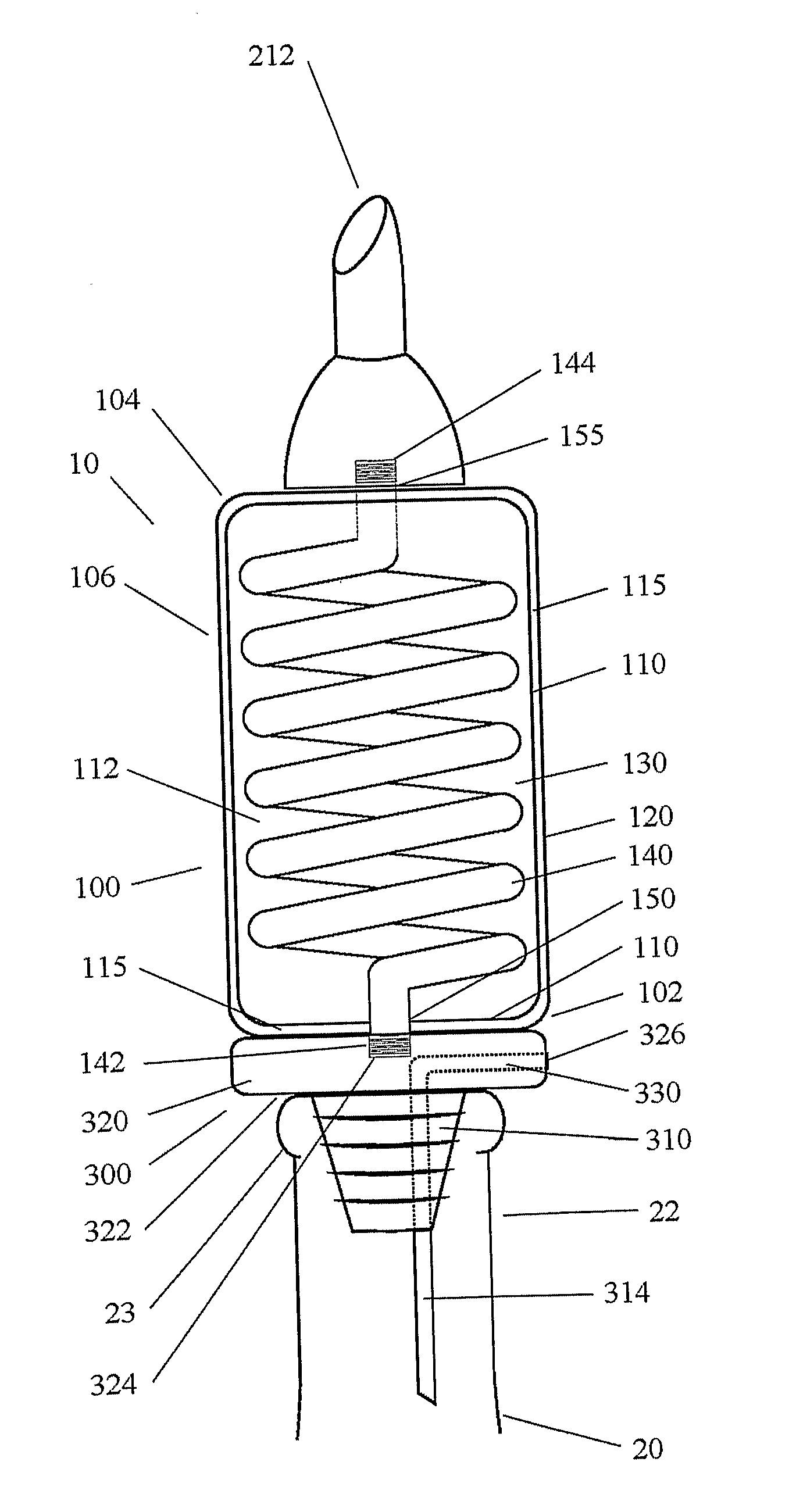

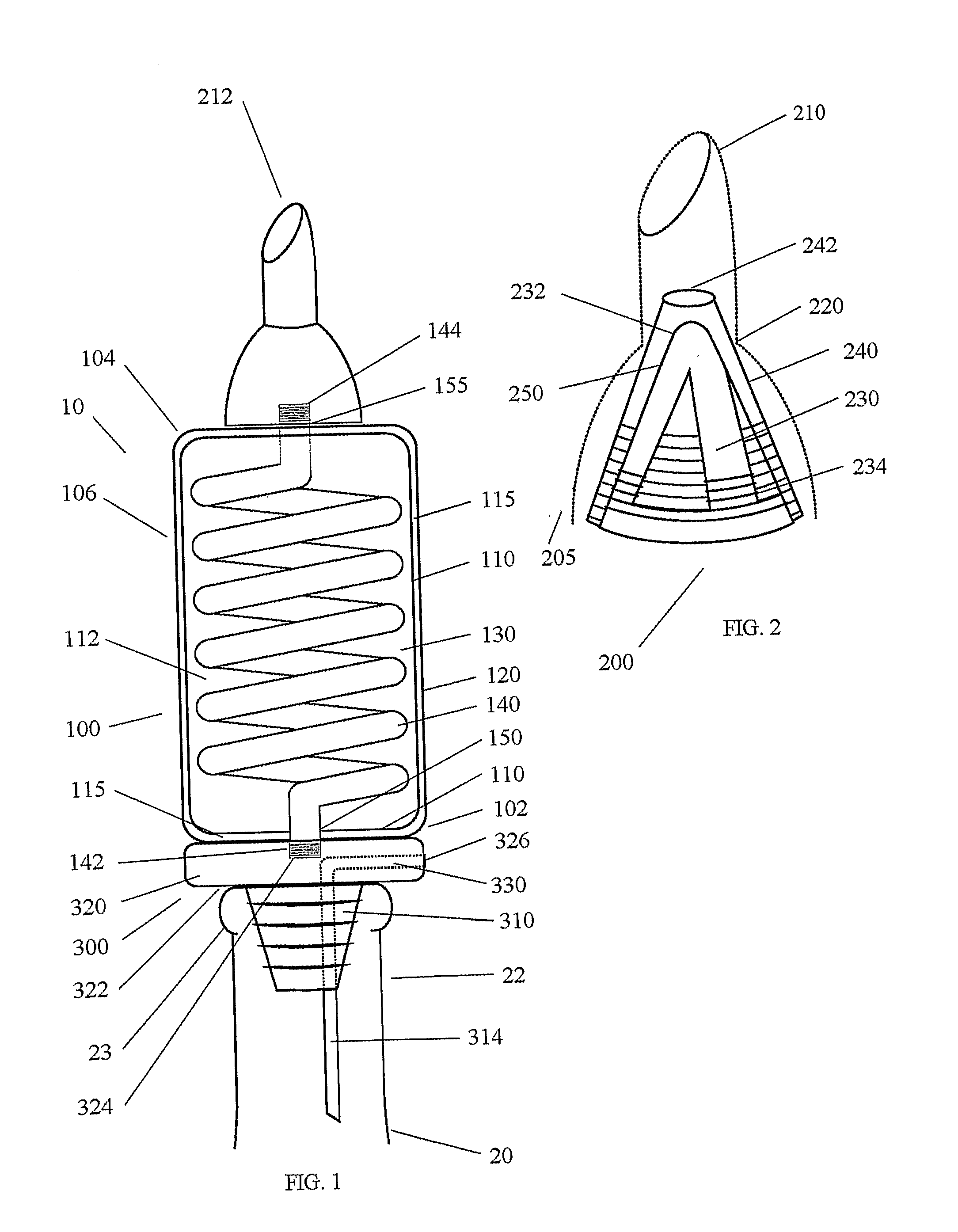

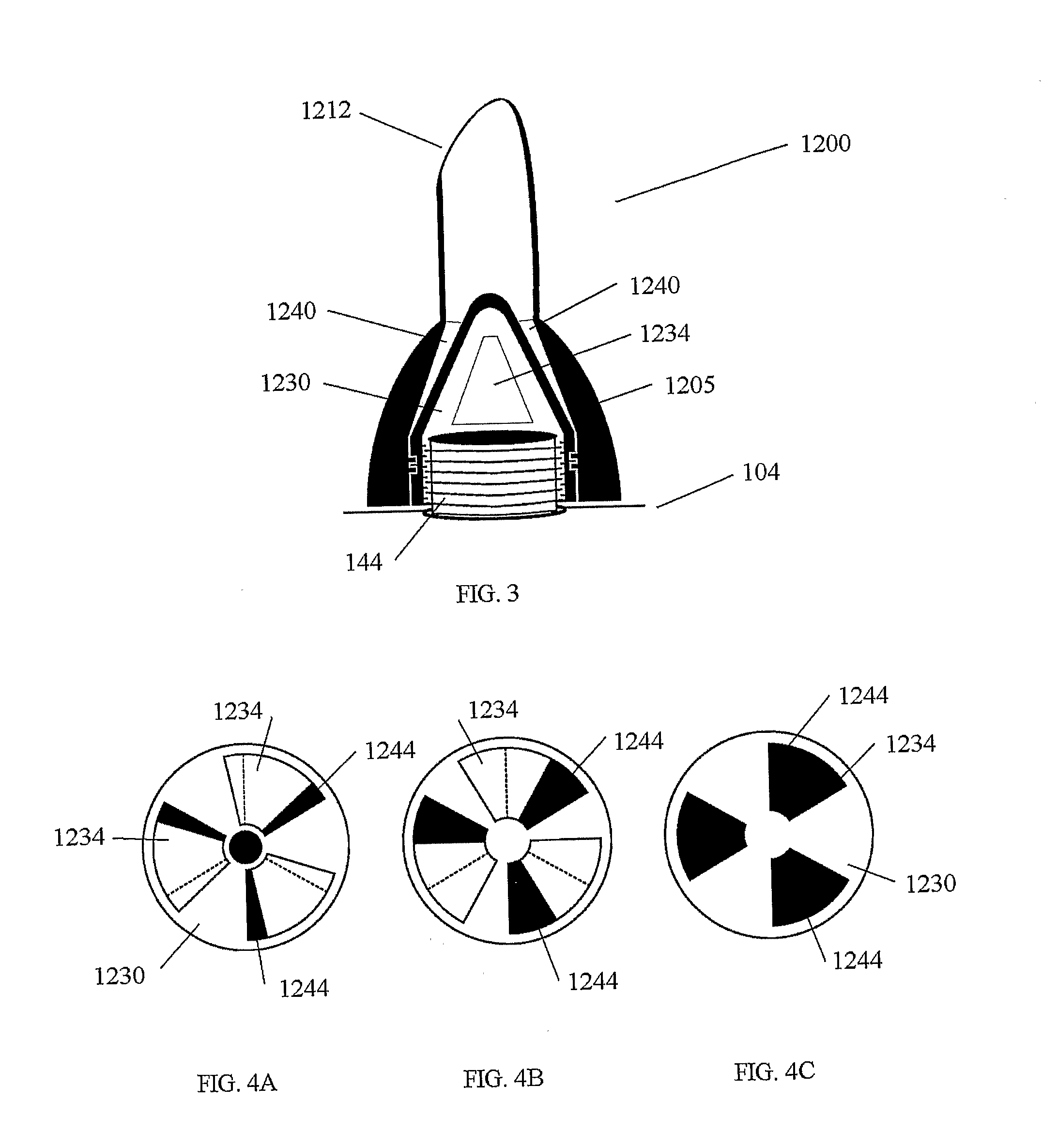

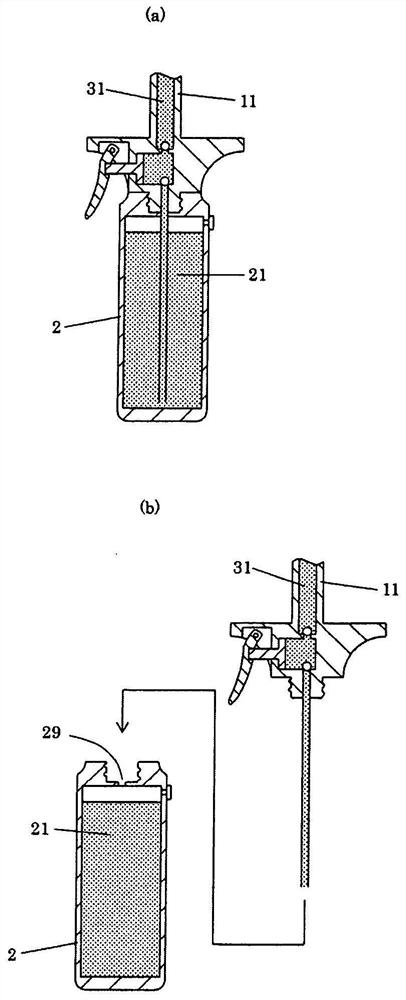

Liquid Cooling and Dispensing Device

InactiveUS20080302822A1Stable flow of liquidIncrease coolingDomestic refrigeratorsLiquid flow controllersEngineeringClose contact

A device to cool a liquid during the pouring procedure is provided. The device comprises an enclosure having a top portion and a bottom portion. Generally mounted to the bottom portion is a base for mounting the device to the neck of a bottle. Optionally mounted to the top portion is a spout which generally comprises a valve adapted to control the temperature of the poured liquid by controlling the flow thereof. The bottom portion and the top portion respectively comprise a first and a second openings between which extends a preferably metallic coil conduit. Within the enclosure, the conduit is surrounded by a low freezing cooling material. The device further comprises a vent passage extending in the base portion. Upon pouring the liquid from a bottle, the liquid circulates through the conduit which is in close contact with the cold cooling material, effectively cooling the liquid.

Owner:RAVI SOLUTION INC (CA)

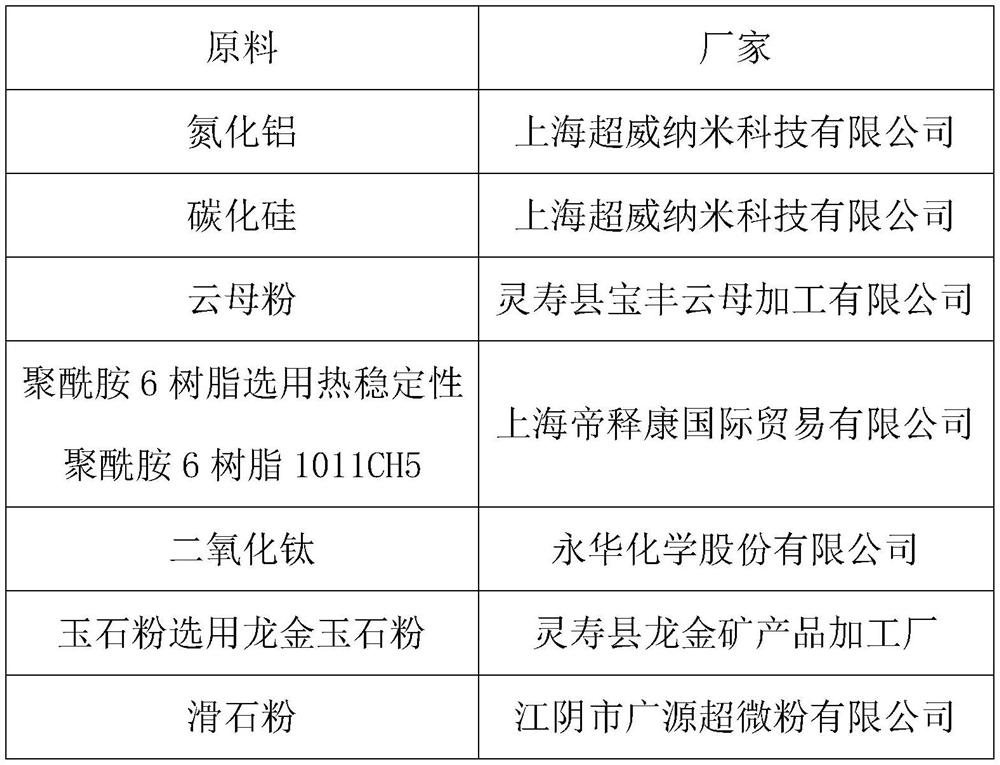

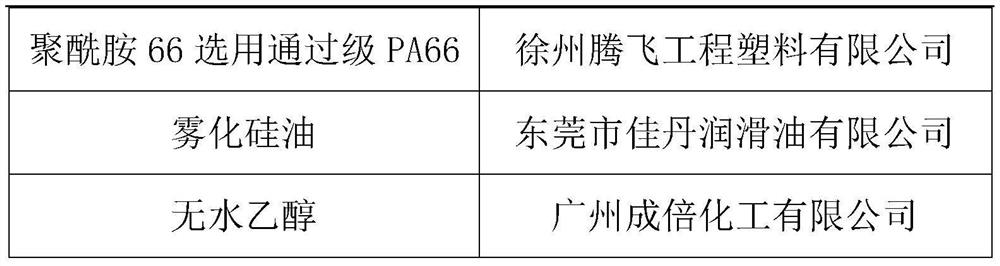

Production process for jade fiber and nylon filament knitware

The invention relates to the technical field of production of functional knitted fabrics, in particular to a production process for jade fiber and nylon filament knitware, which comprises the following steps of: weaving jade fibers and nylon filaments into knitted pieces with related textures such as weft plain and 1+1 rib; sewing into ready-made clothes; and performing refining, dyeing, after finishing and shaping in turn. The produced knitware has the advantages of comfortableness and attractive appearance, and well shows the performance such as health care, temperature reduction and the like, so the produced knitware can better meet the requirements of people on comfortableness, health care and coolness of the knitware.

Owner:SANFLAG FASHION DONGGUAN +1

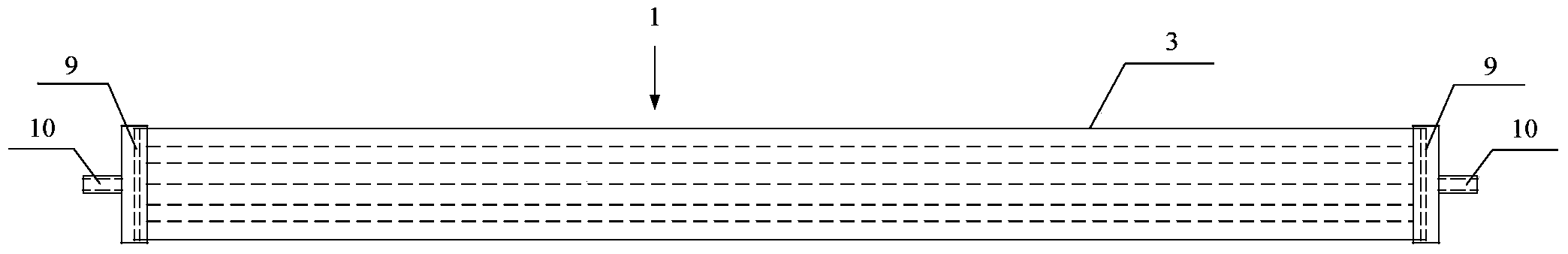

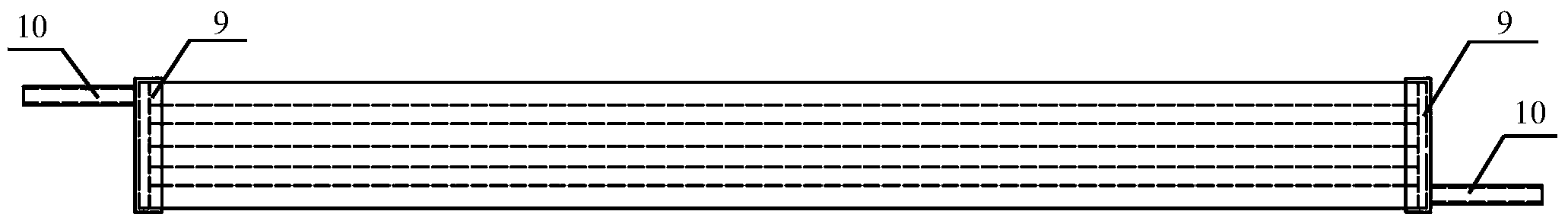

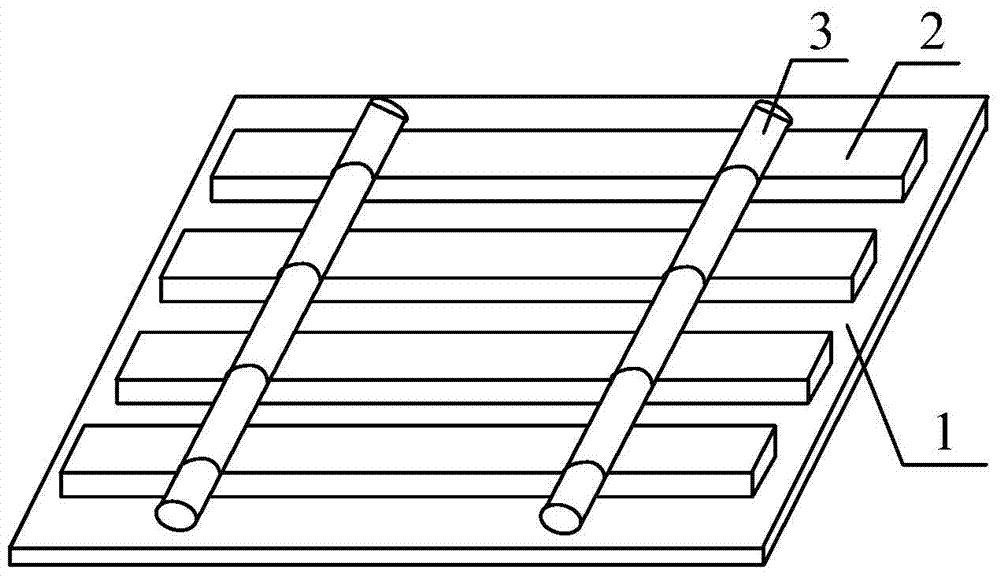

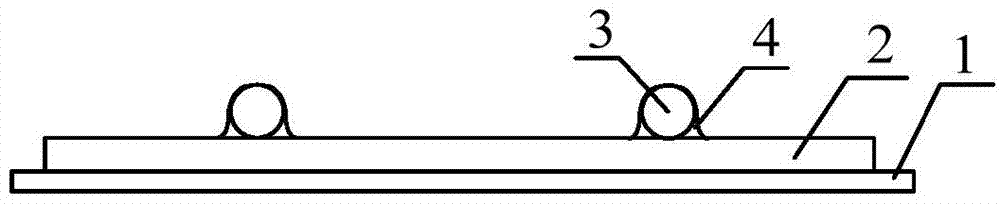

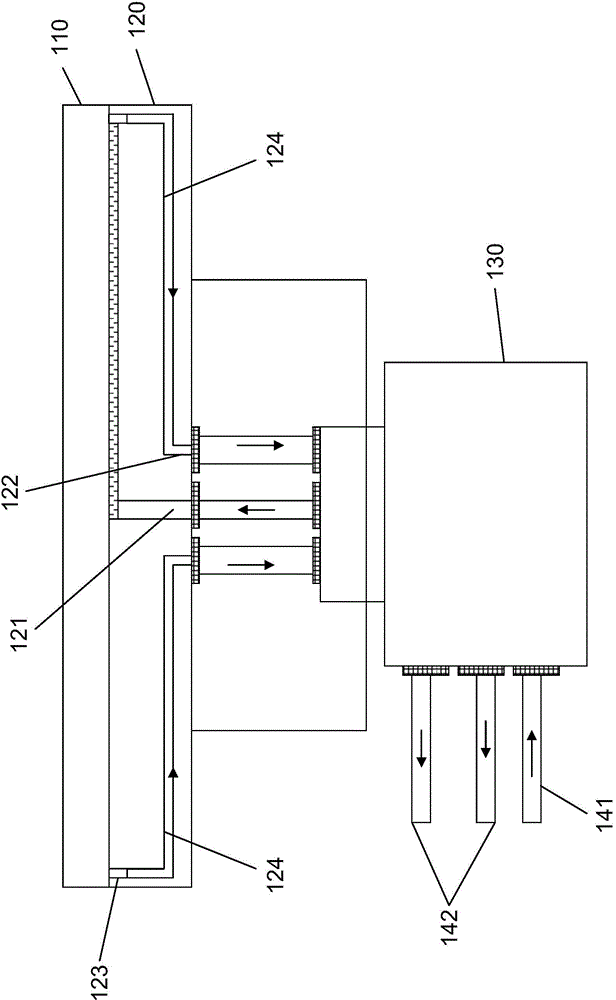

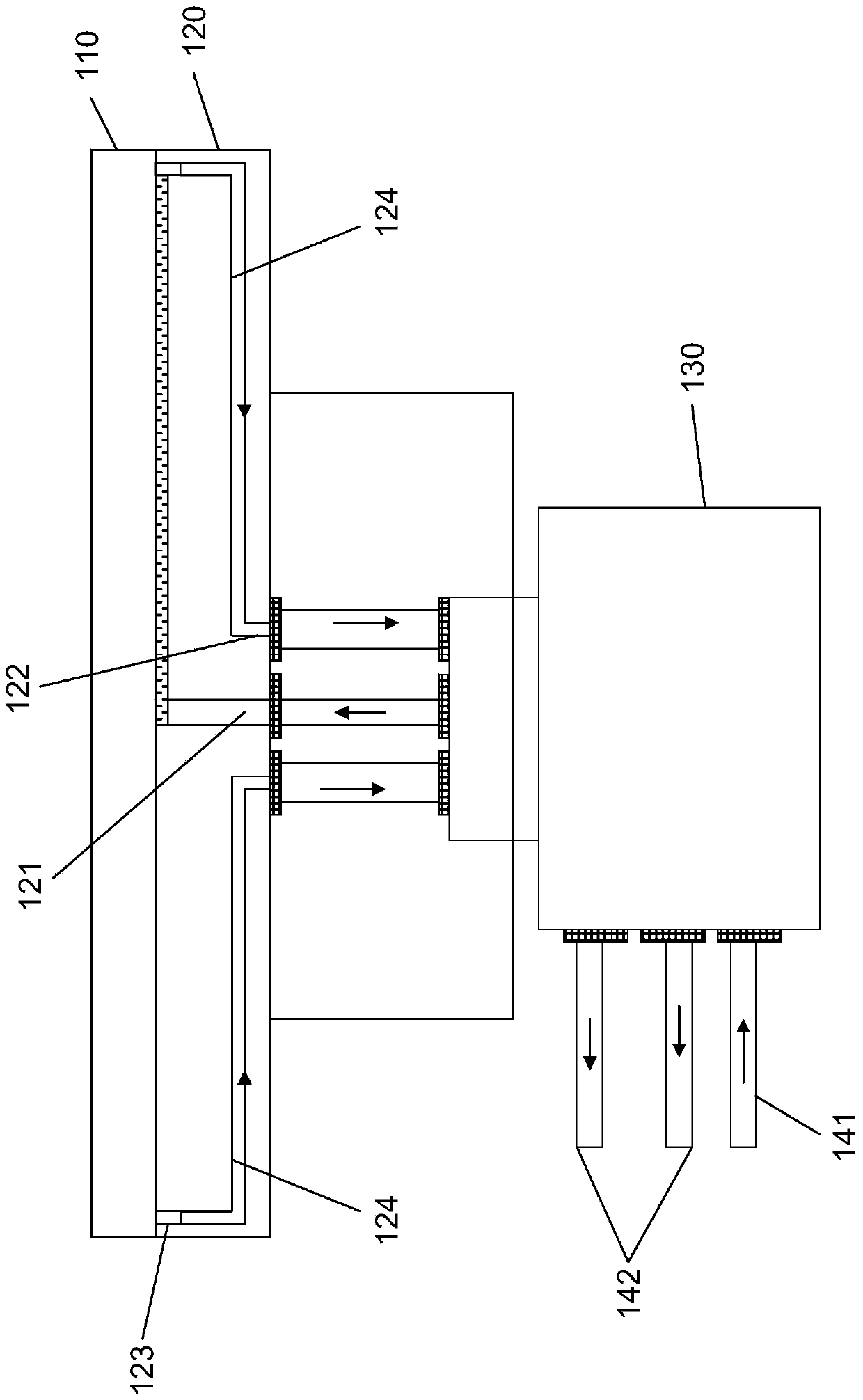

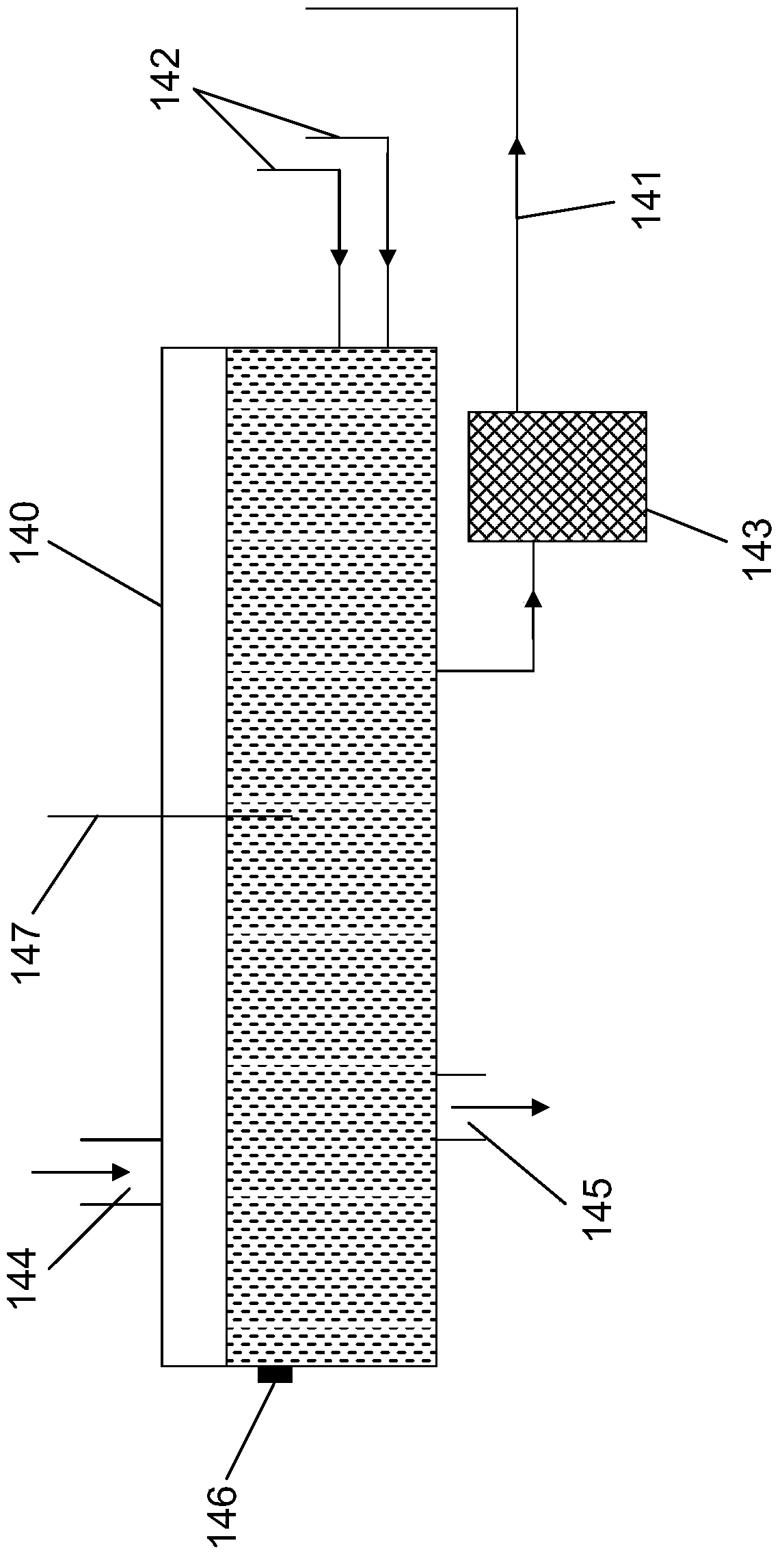

Efficient heat exchange water pipe and heat pipe radiant heating/refrigerating system

ActiveCN103968700AReduce pressure capacity requirementsImprove work efficiencyIndirect heat exchangersHeating and refrigeration combinationsWater sourceMetallic materials

The invention relates to an efficient heat exchange water pipe and a heat pipe radiant heating / refrigerating system. The efficient heat exchange water pipe and a flat heat pipe are arranged in an intersecting mode so as to conduct heat exchange. The efficient heat exchange water pipe is made of metal materials through extrusion or stamping forming, and an array structure composed of two or more small-caliber pipes arranged side by side in the length direction of the water pipe is arranged in the water pipe. The efficient heat exchange water pipe is provided with a flat surface attached to the flat heat pipe. The side walls of the small-caliber pipes are connected with one another. The internal equivalent diameter of each small-caliber pipe ranges from 1 mm to 15 mm. One end of the efficient heat exchange water pipe is provided with a connector which is communicated with an external water source. The small-caliber pipes are communicated with the water source through the connector. The efficient heat exchange water pipe has the advantages of being high in heat exchange efficiency. According to the heat pipe radiant heating / refrigerating system with the efficient heat exchange water pipe, indoor heating and refrigeration are completed through the heat pipe radiation technology and dehumidification can also be achieved; the heat pipe radiant heating / refrigerating system with the efficient heat exchange water pipe has the advantages of being simple in technology, safe in operation and high in efficiency.

Owner:CHANGZHOU HETONG PURUN ENERGY TECH CO LTD

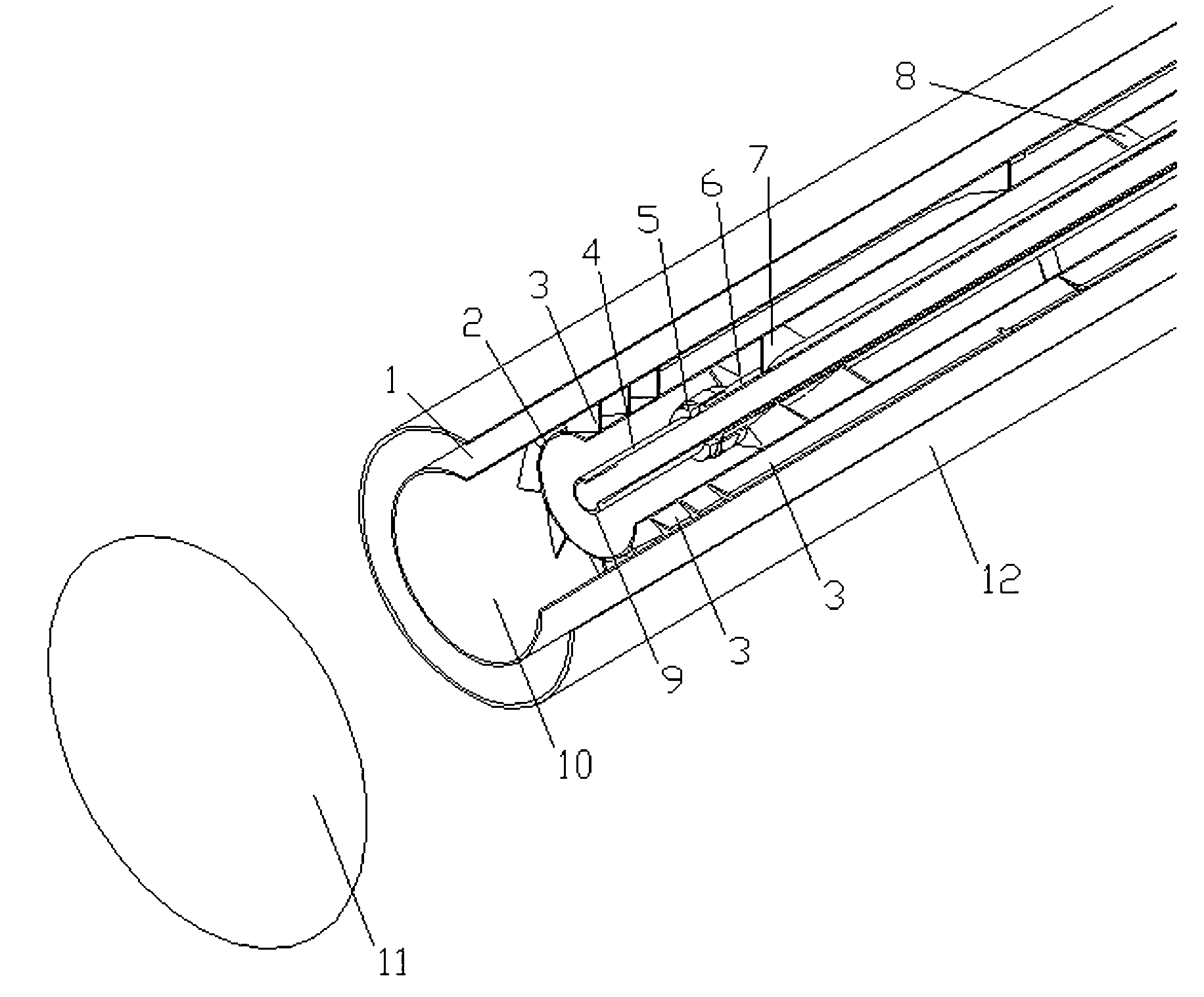

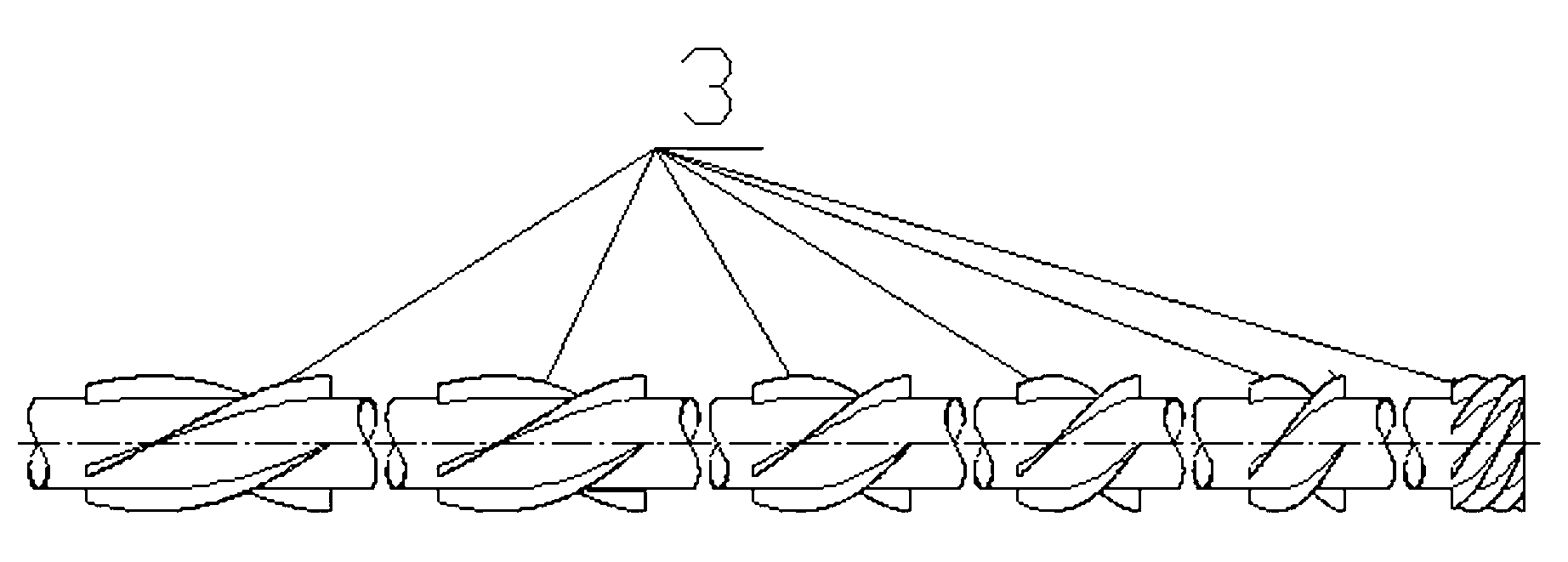

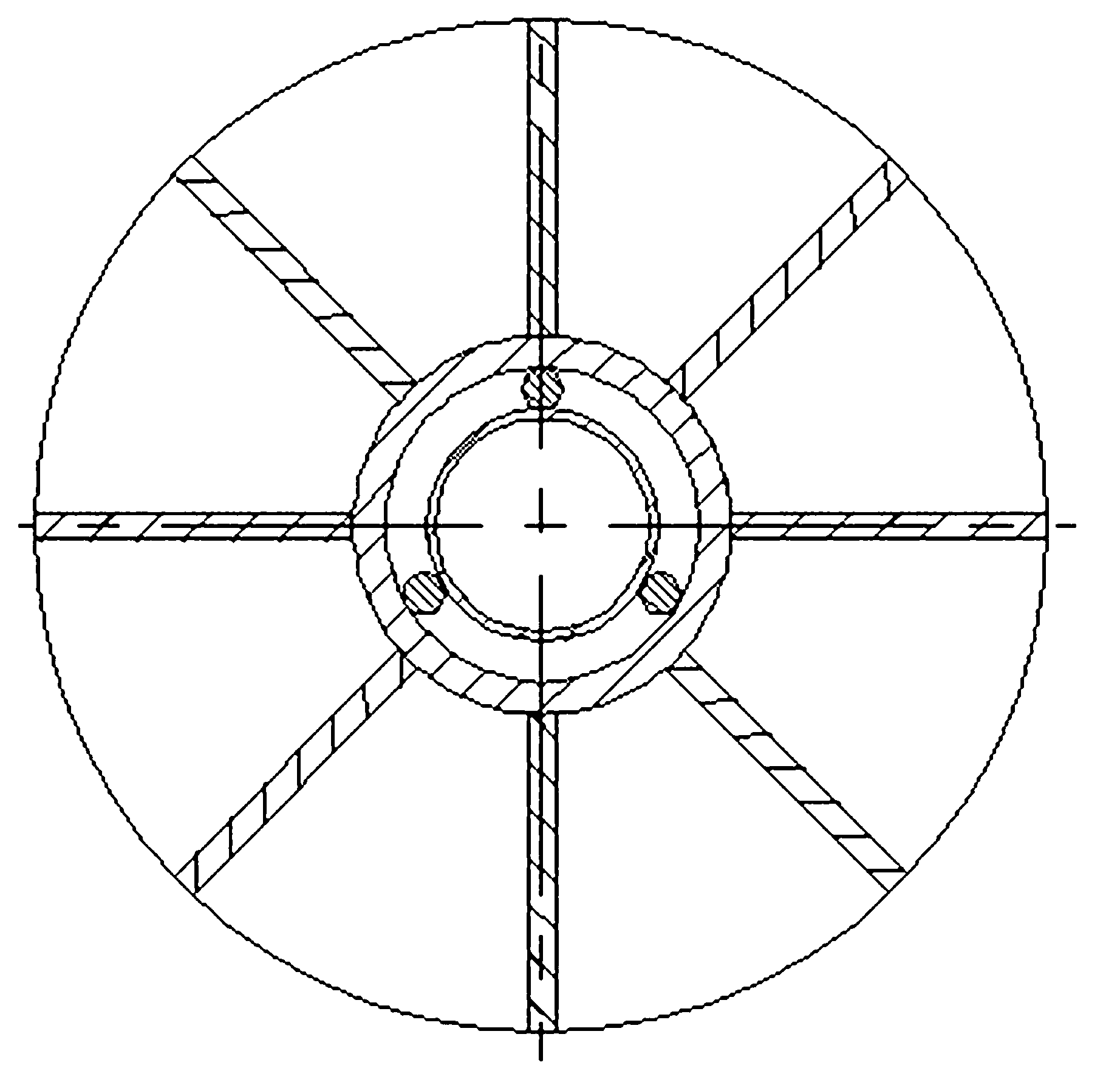

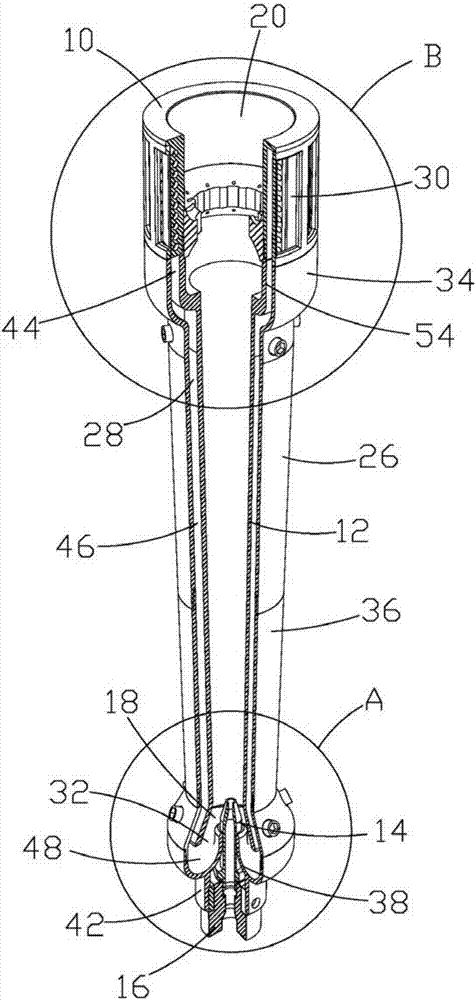

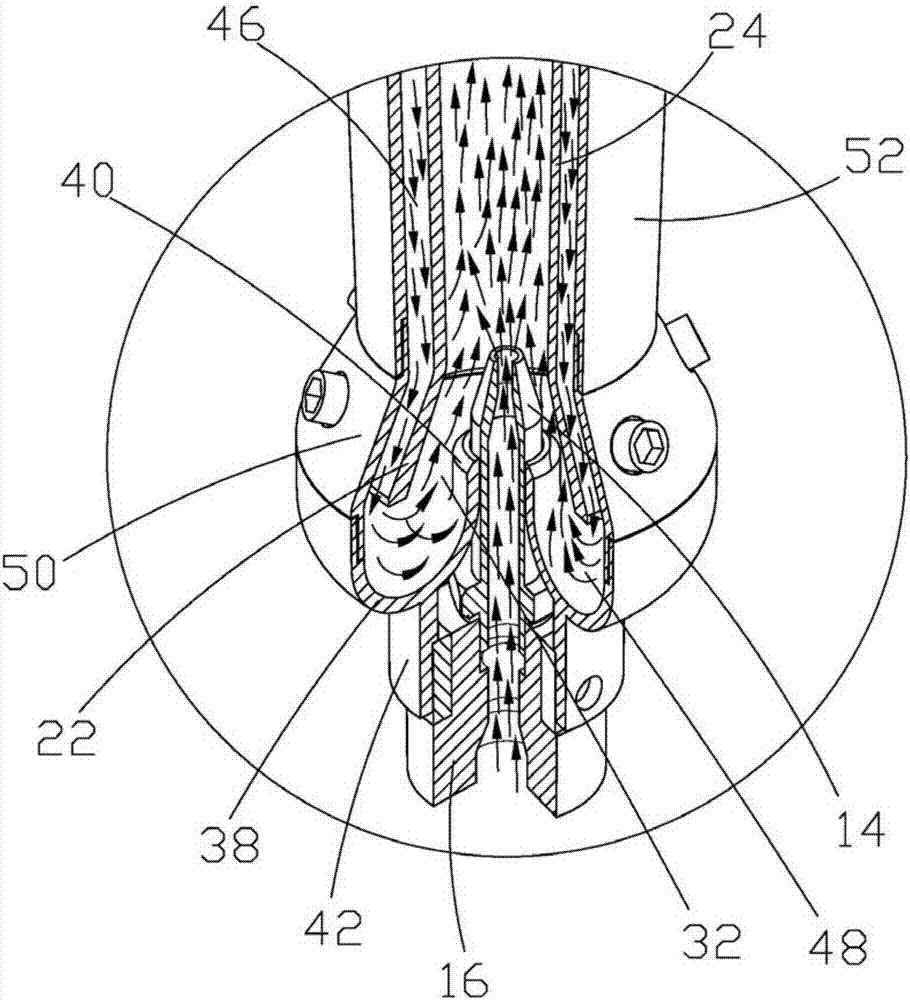

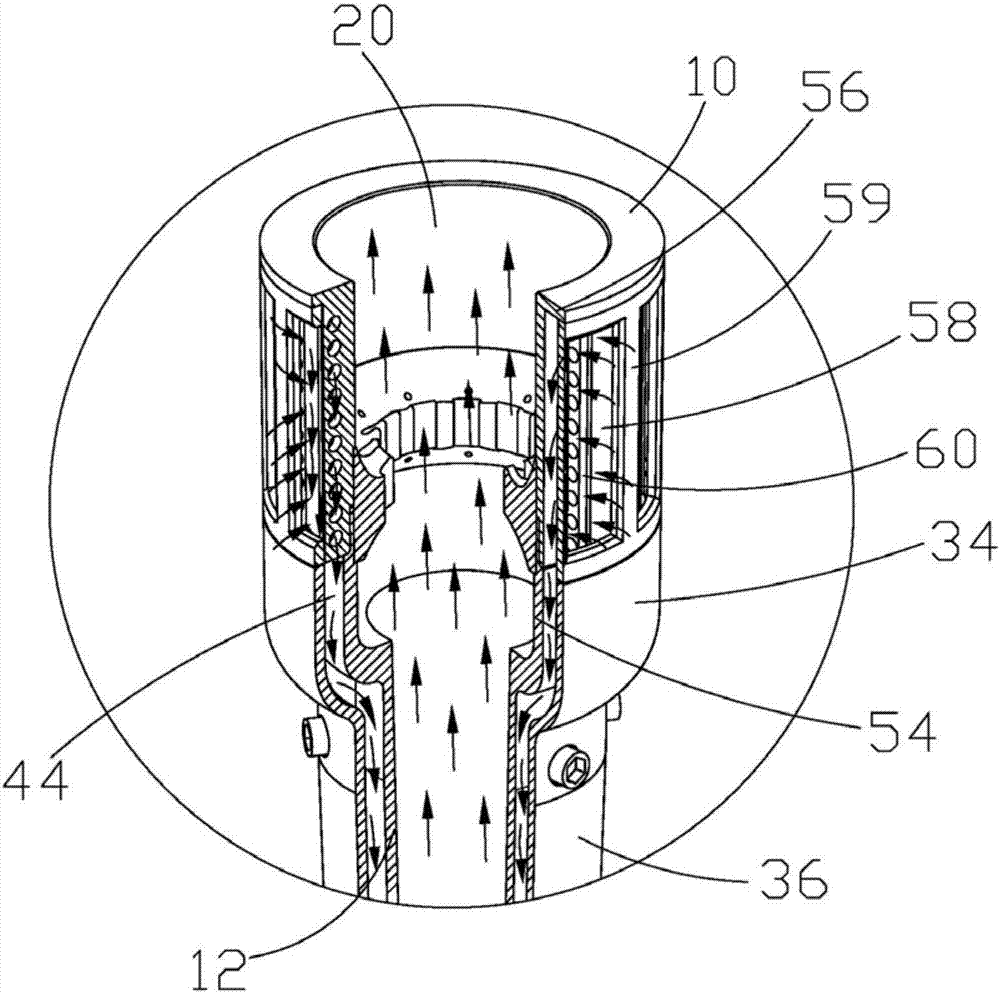

Nickel-making oxygen-enriching top-blowing immersion spray gun with longer service life

The invention relates to a nickel-making oxygen-enriching top-blowing immersion spray gun with longer service life. The diameters of a cover cylinder, an air pipe and an oxygen pipe of the spray gun successively decrease gradually, and the cover cylinder, the air pipe and the oxygen pipe of the spray gun are arranged coaxially; a mixing chamber is arranged on the outlet end of the spray gun; a multi-stage swirler is arranged between the air pipe and the oxygen pipe of the spray gun; a single-stage swirler is arranged between the oxygen pipe and the fuel pipe of the spray gun; the single-stage swirler is a blade type swirler; and the multi-stage swirler is a six-stage blade type swirler. Due to the arrangement and improvement of the swirlers, the cooling degree is strengthened. Due to the arrangement of a fin, the bending degree of the spray gun is reduced effectively, oxygen and the air of the spray gun are mixed in advance, higher combustion efficiency is achieved, and the fuel is prevented from being adhered to the inner wall of the mixing chamber to burn down the inner wall of the mixing chamber. Because an air stop ring plate is arranged near a sleeve air outlet, the secondary combustion of carbon monoxide on the upper part of the furnace is realized, and the generation of elemental sulfur is inhibited effectively. The immersion depth of the spray gun can be controlled stably, the service life can be prolonged, and the change frequency can be reduced. In addition, the production operation rate can be reduced, and the production cost can be saved.

Owner:JINCHUAN GROUP LIMITED

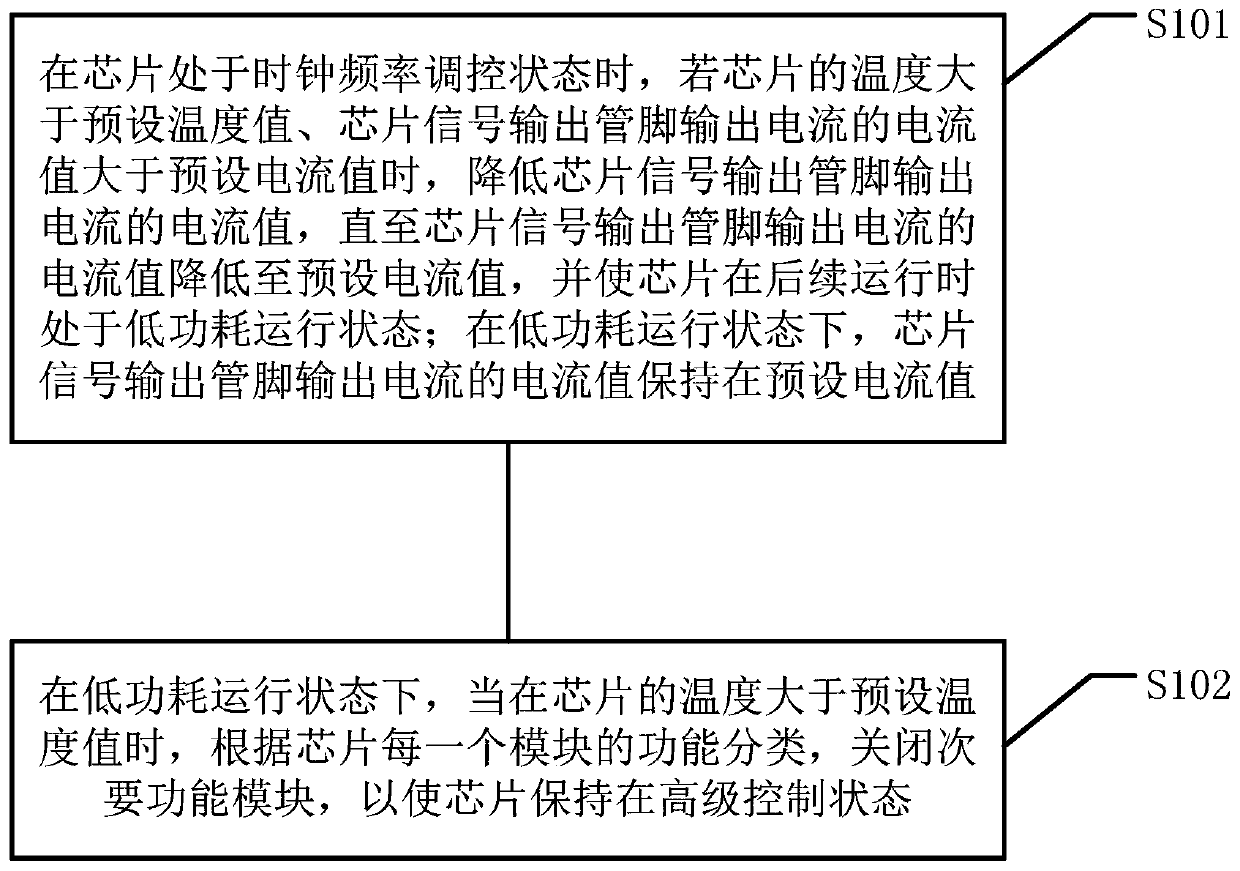

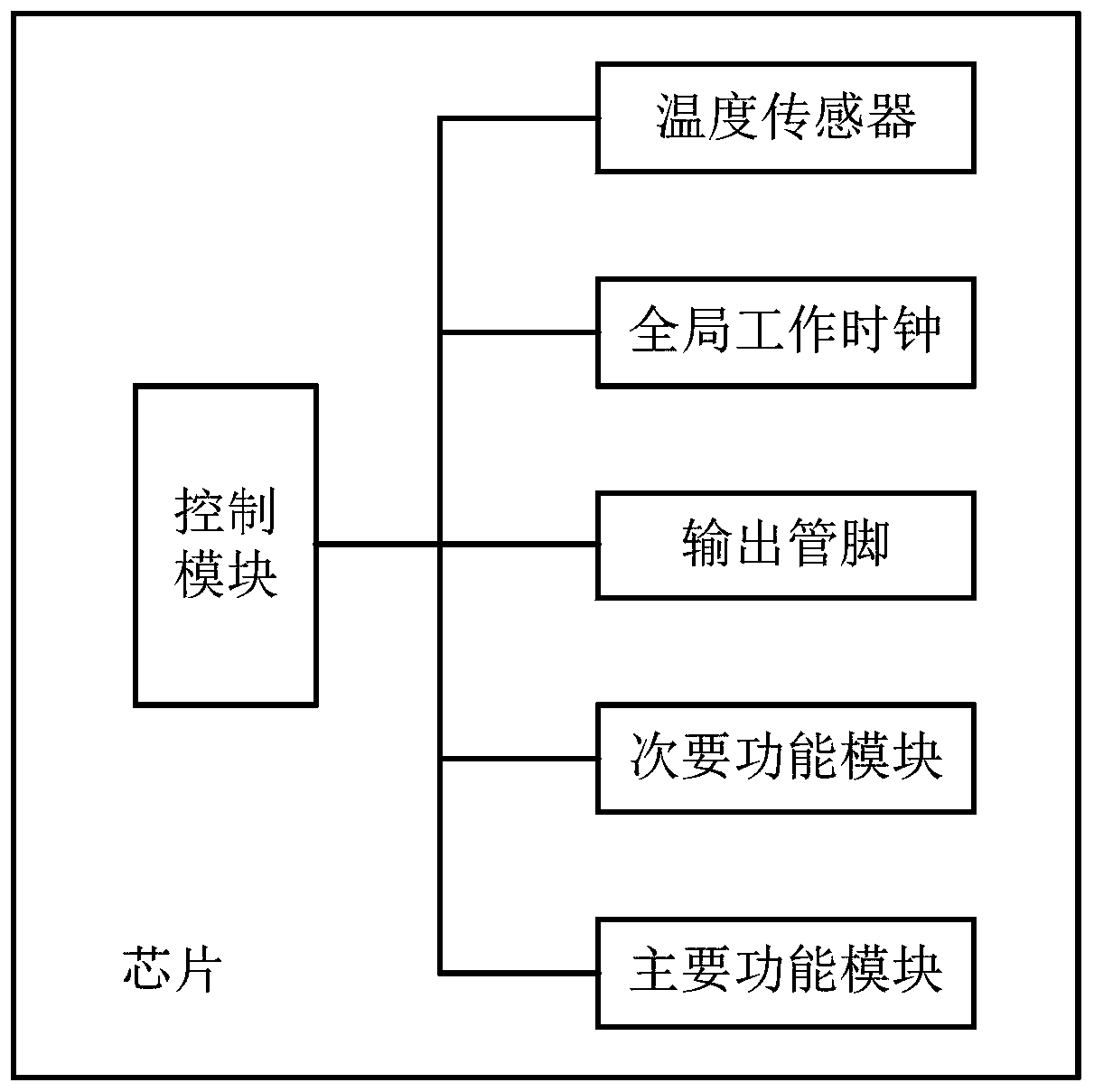

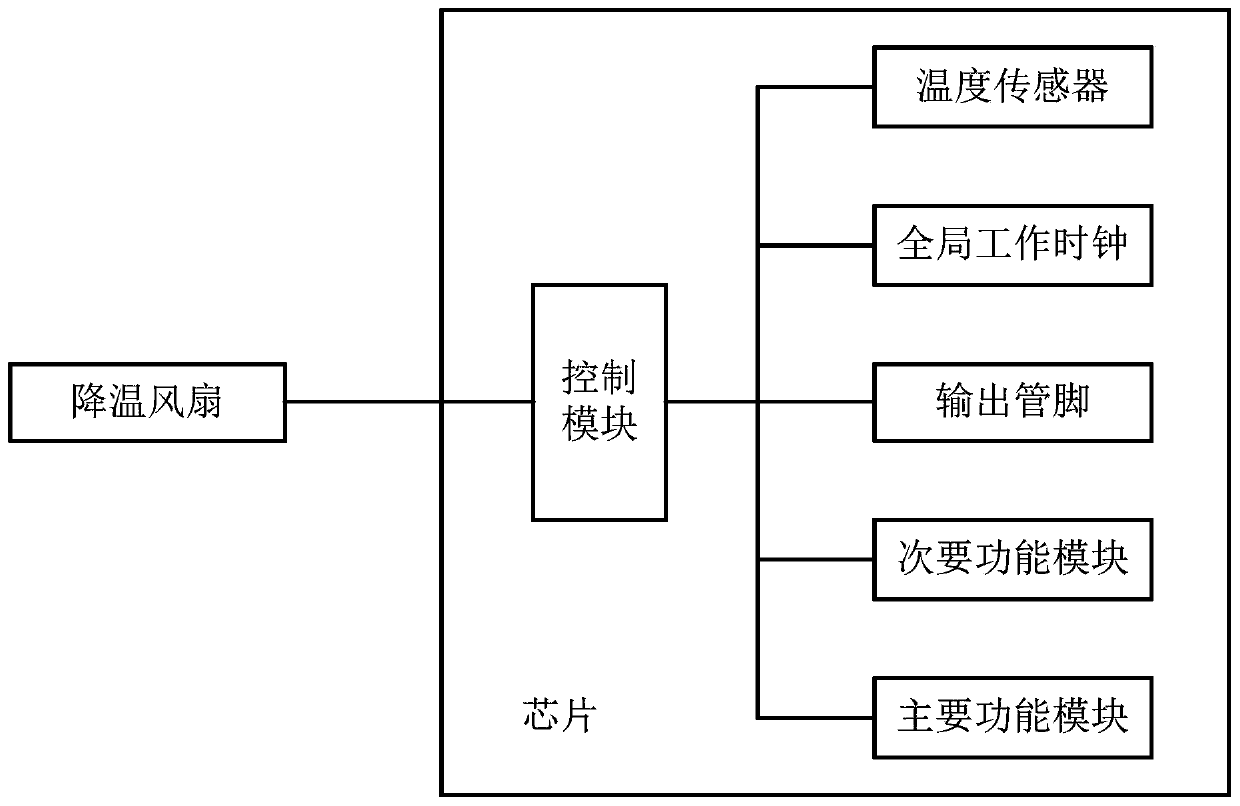

Chip control method, device and equipment and medium

The invention discloses a chip control method, device and equipment and a medium. The method comprises the following steps: when a chip is in a clock frequency regulation and control state, reducing the value of an output current of a signal output pin of the chip until the current value of the output current of the signal output pin of the chip is reduced to a preset current value if the temperature of the chip is greater than a preset temperature value and the current value of the output current of the signal output pin of the chip is greater than the preset current value; enabling the chip to be in a low-power-consumption operation state during subsequent operation; wherein, in the low-power-consumption operation state, the current value of the output current of the signal output pin of the chip is kept at the preset current value; and in the low-power-consumption operation state, when the temperature of the chip is greater than the preset temperature value, a secondary function module is turned off according to the function classification of each module of the chip, so that the chip is kept in an advanced control state.

Owner:BEIJING TRICOLOR TECH

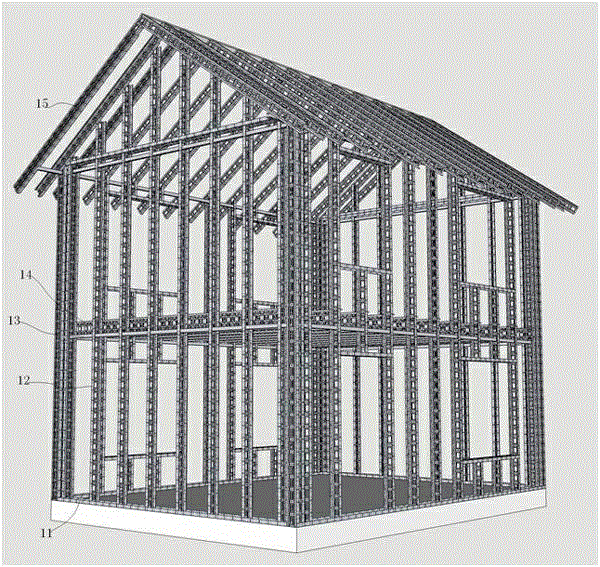

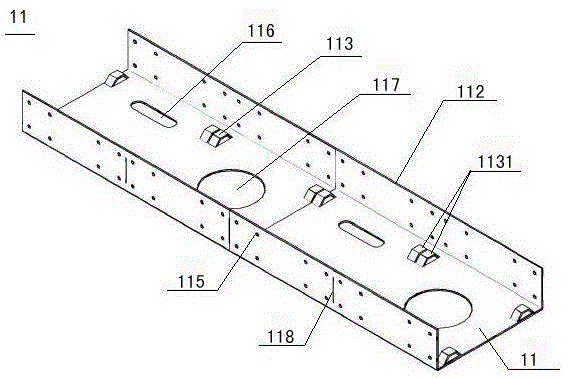

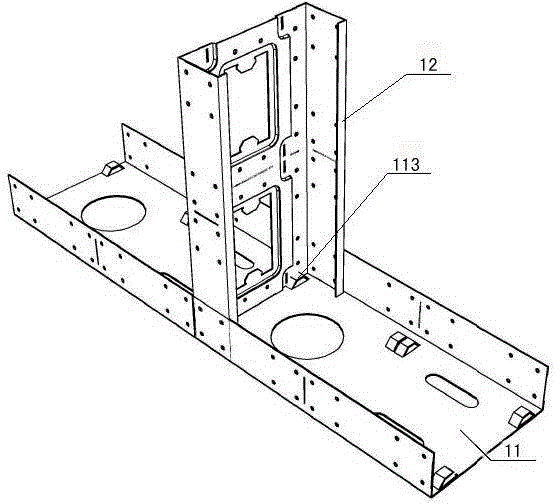

Lightweight steel structure building frame system

ActiveCN105297886AQuickly locate and fixReduce distance measurement and positioning processBuilding constructionsMaterials scienceBeam column

The invention discloses a lightweight steel structure building frame system. The lightweight steel structure building frame system comprises steel ground beams, steel beam columns, transverse ring beams, steel floor beams and roof beams, wherein the steel beam columns are vertically arranged on the steel ground beams; the transverse ring beams are fixedly connected with the steel beam columns; the steel floor beams are placed on the ring beams and are fixedly connected with the steel beam columns; the roof beams are arranged on a roof and are fixedly connected with the steel beam columns; and respective connection portions of the steel ground beams, the steel beam columns, the ring beams and the steel floor beams are subjected to punch forming at one step according to certain modulus spacing. Various lightweight steel members which are produced in a standardizing and modularizing mode can be connected to one another together quickly and conveniently, during mounting, the lightweight steel structure building frame system can be positioned and fixed rapidly, ranging and location procedures of the steel beam columns and the like of an existing steel structure building are greatly reduced during mounting, construction materials are saved, construction efficiency is greatly improved, and construction cost is reduced obviously.

Owner:SUMAKE ARCHIT TECH LTD

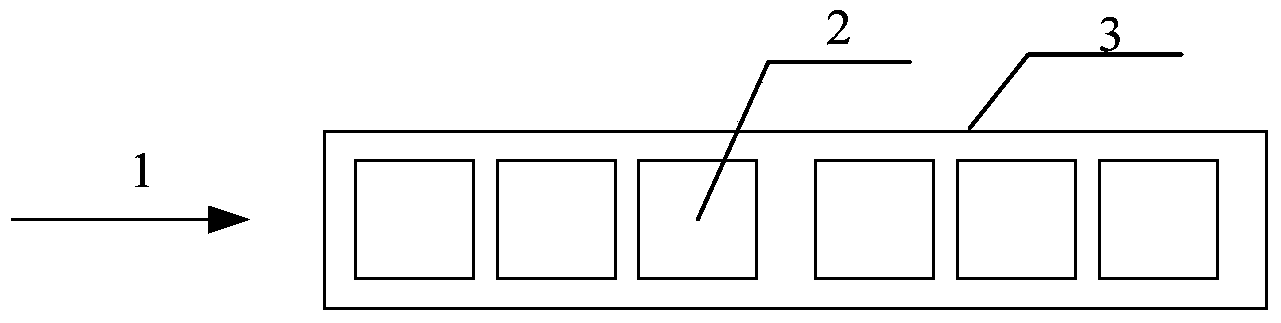

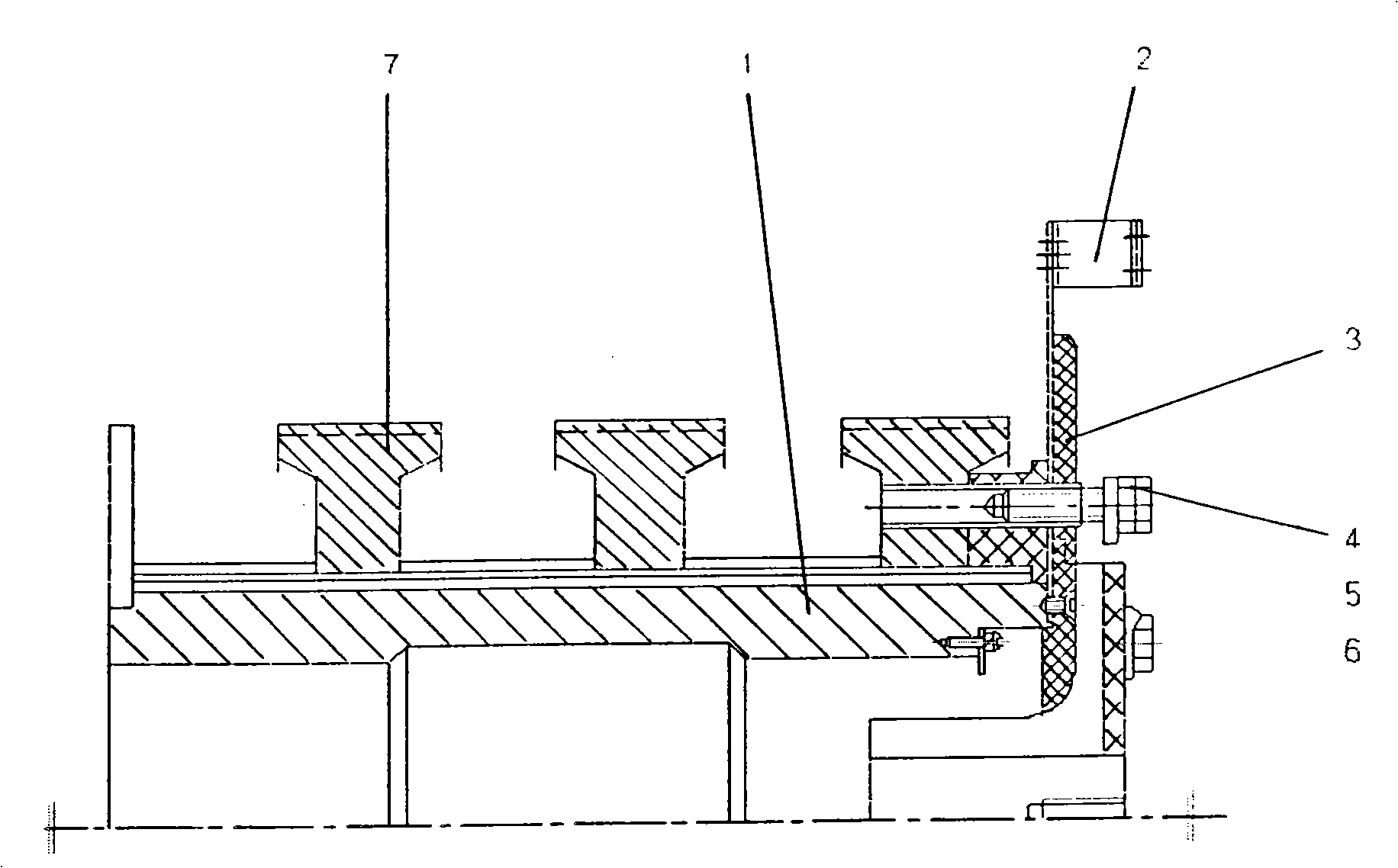

System and method for heat pipe radiation type top board heating/refrigeration

ActiveCN103940147AReduce the laying areaUniform room heatingCentral heating with accumulated heatHeating and refrigeration combinationsLiquid mediumEvaporation

The invention relates to a system and method for heat pipe radiation type top board heating / refrigeration. The system and method are used for indoor heating or refrigeration. The system comprises a heat conduction substrate, one or more flat heat pipes arranged side by side and one or more water pipes. The flat heat pipes are laid above the heat conduction substrate. The water pipes are laid above the flat heat pipes. The water pipes and the flat heat pipes are arranged in an intersecting mode. The water pipes in the system for heat pipe radiation type top board heating are communicated with a heat source through liquid media. The water pipes are arranged on evaporation sections of the flat heat pipes. Heat is exchanged between condensation sections of the flat heat pipes and the heat conduction substrate. The water pipes in the system for heat pipe radiation type top board refrigeration are communicated with a cold source through liquid media. The water pipes are arranged on the condensation sections of the flat heat pipes. Heat is exchanged between the evaporation sections of the flat heat pipes and the heat conduction substrate. According to the system, indoor heating or refrigeration is achieved according to the heat pipe radiation technology and the system has the advantages of being simple in process, safe in operation, high in efficiency and capable of saving energy.

Owner:禾丰科技股份有限公司

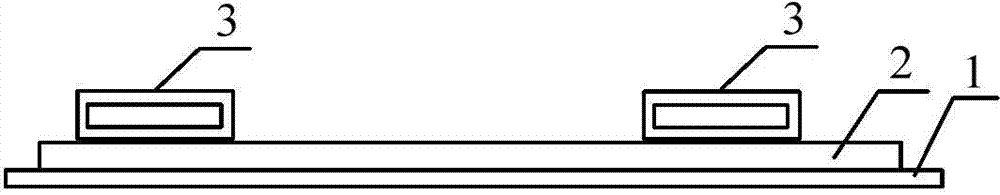

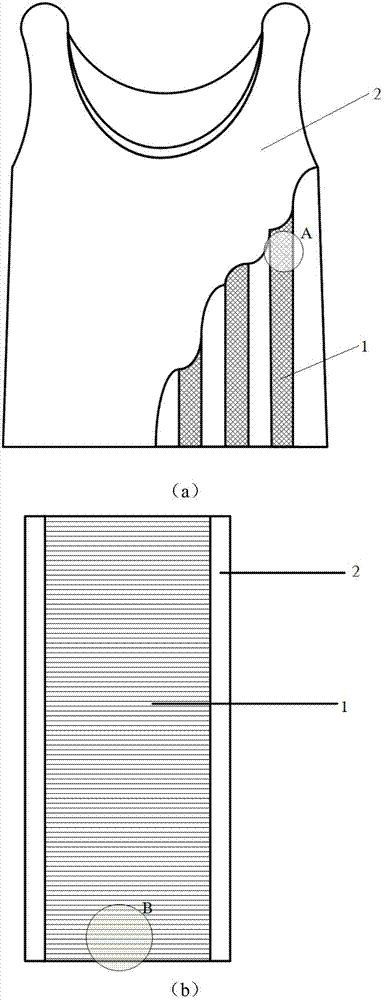

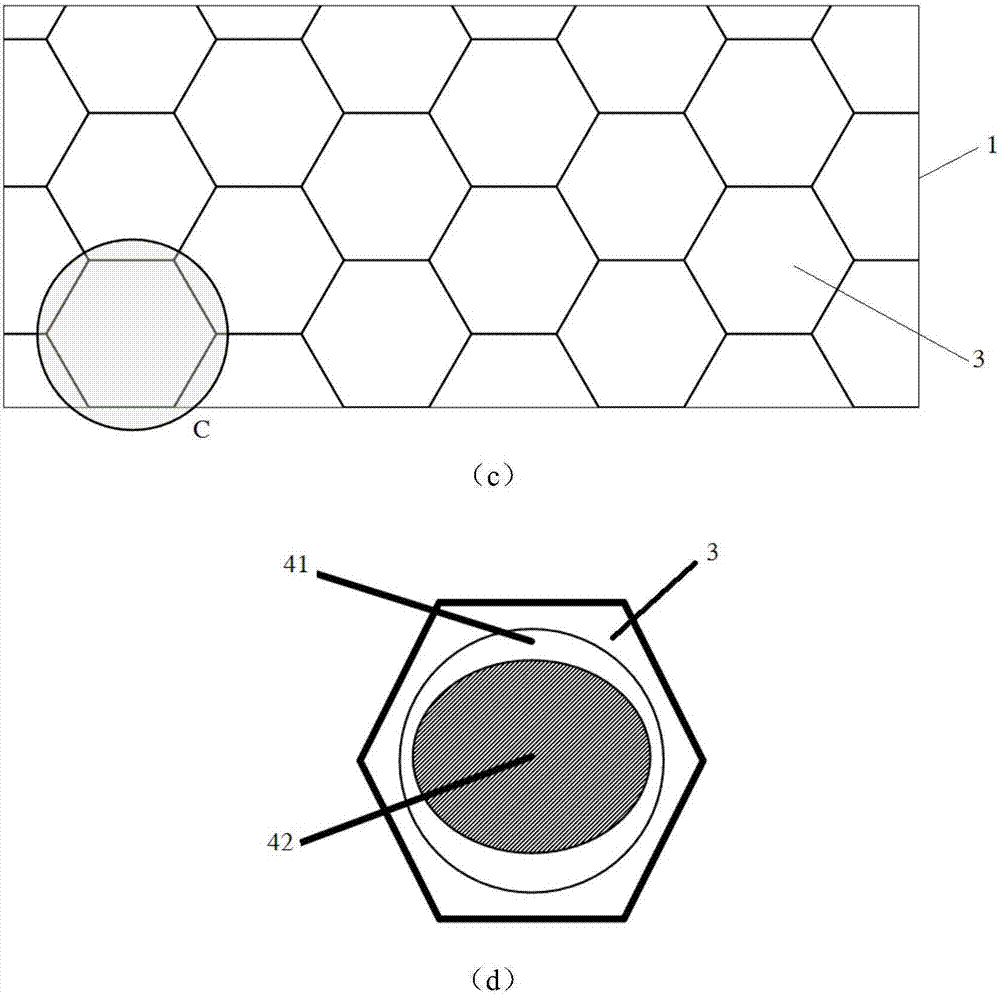

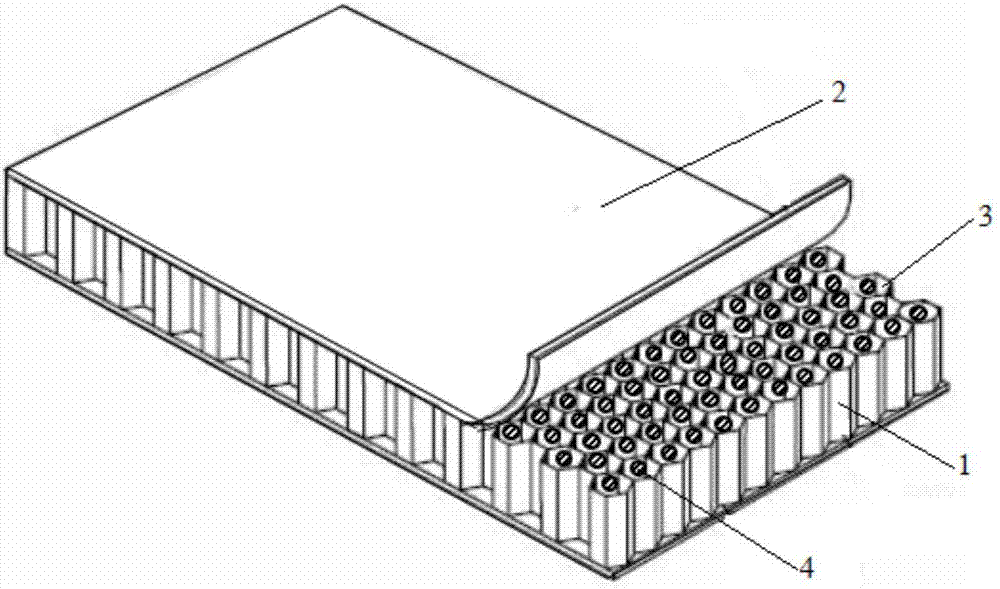

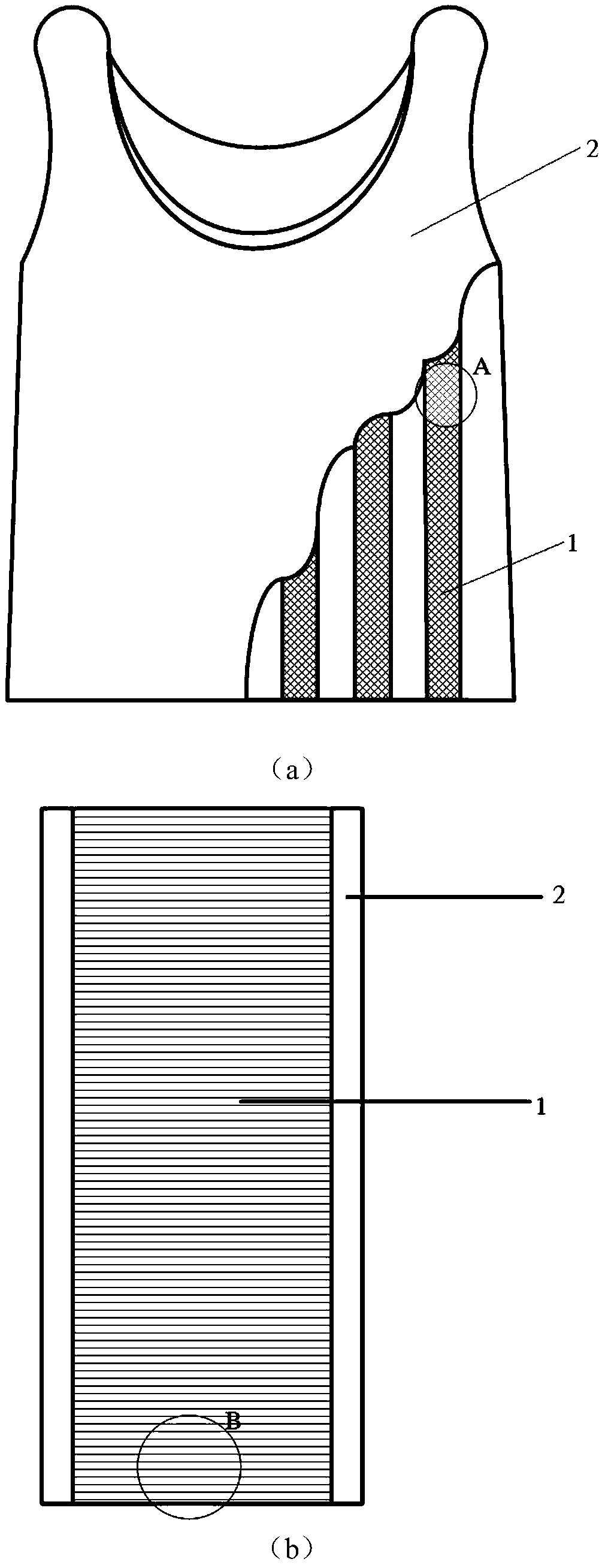

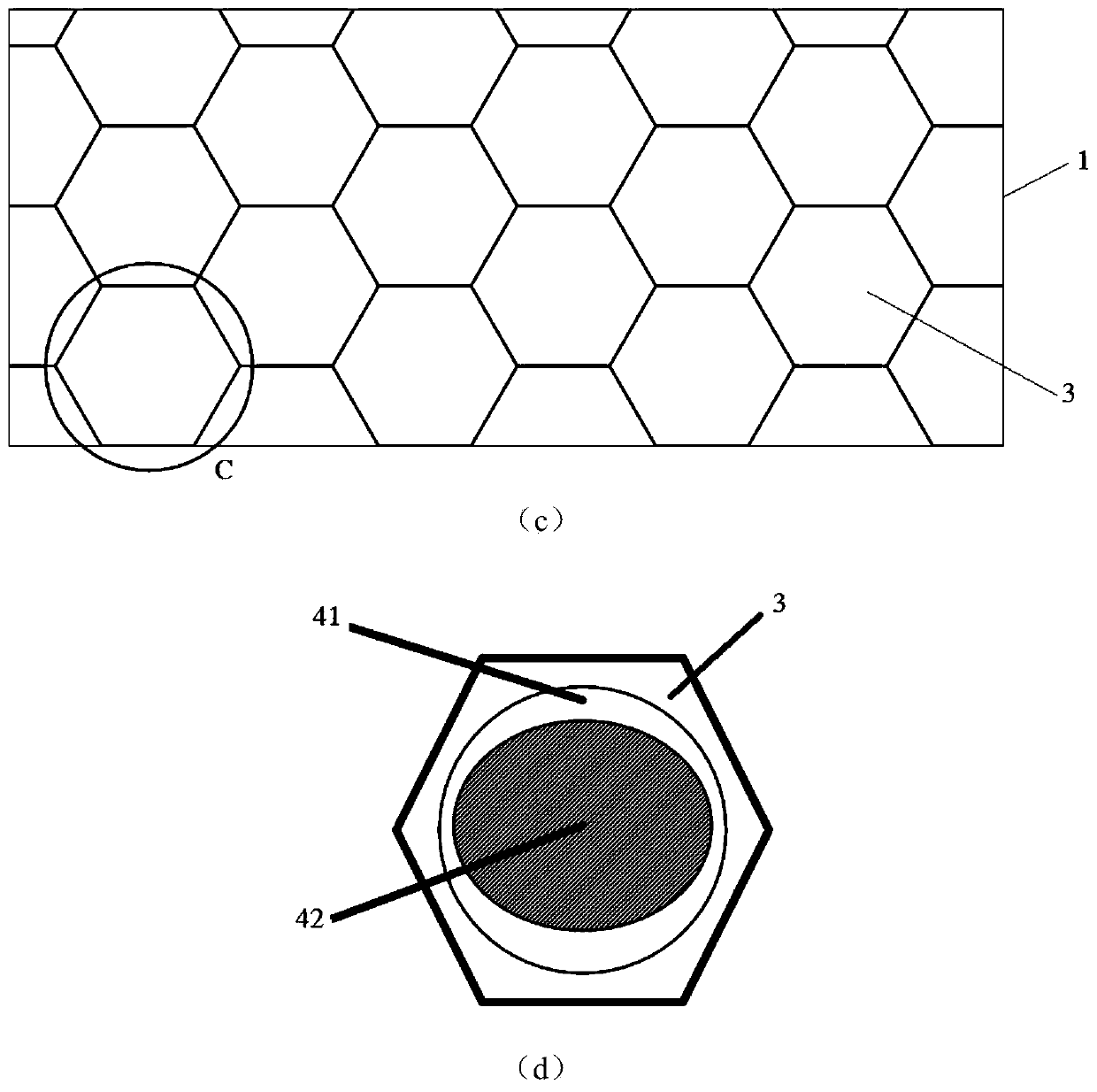

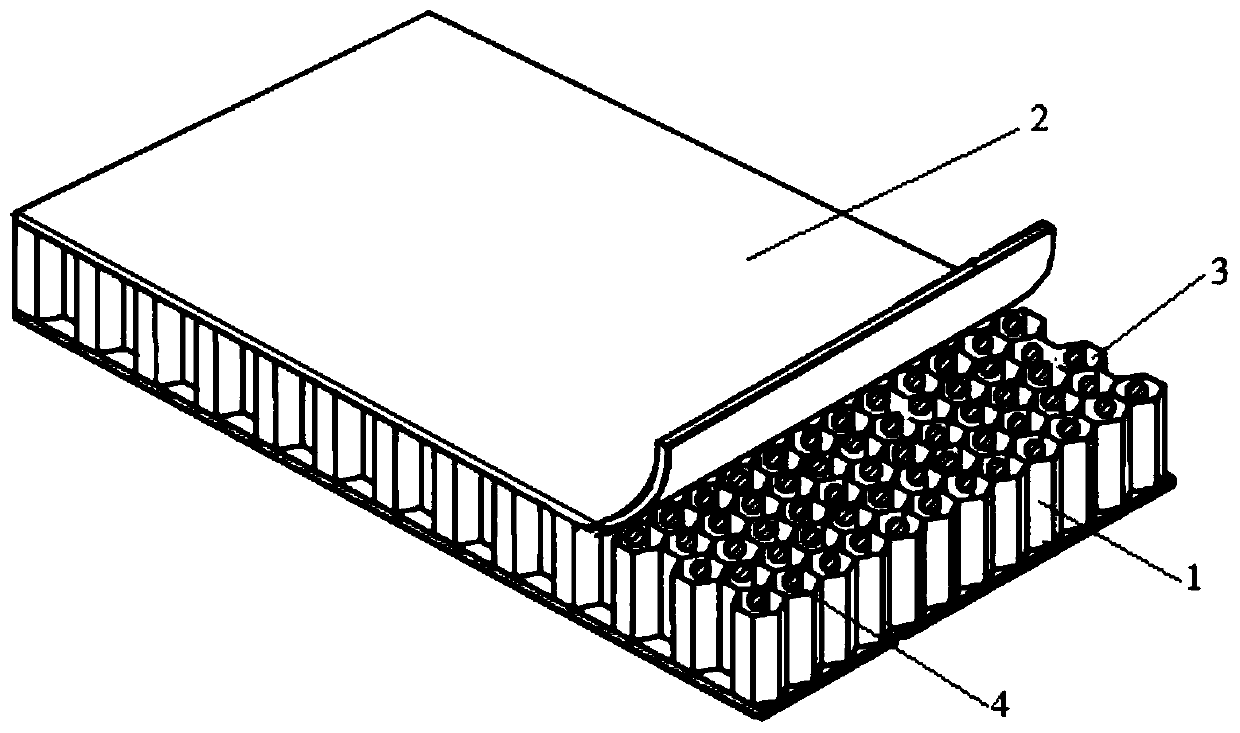

Wearable equipment based on composite phase change material and production method of wearable equipment

ActiveCN107011872AImprove stress resistanceHigh latent heat of phase changeHeat-exchange elementsProtective garmentPolyesterFiber

The invention discloses wearable equipment based on a composite phase change material and a production method of the wearable equipment. The production method incudes: preparing the composite phase change material, performing microencapsulation on the composite phase change material, performing microcapsule formaldehyde removing, performing cellular board encapsulation and performing fiber cloth and silk encapsulation. The production method has the advantages that the composite phase change material prepared by the eutectic mixture of two organic phase change materials as the core material, melamine-formaldehyde prepolymer is allowed to have polymerization reaction with an emulsion so as to perform microcapsule wrapping on the core material, microcapsules are loaded into a polyester fiber cellular board to increase the pressure resistance of the microcapsules so as to prevent the deformation and leakage of the microcapsules, the finally obtained wearable equipment is a polyester fiber cellular board sleeved with fiber cloth and silk, the phase-change-material microcapsules are loaded into the holes of the cellular board, and the microcapsules use melamine resin generated by melamine and formaldehyde as the wall material and the composite phase change material as the core material and is high in phase change latent heat, stable in chemical performance, non-corrosive and capable of achieving zero energy consumption when being used in a high-temperature environments in summer.

Owner:SOUTHEAST UNIV

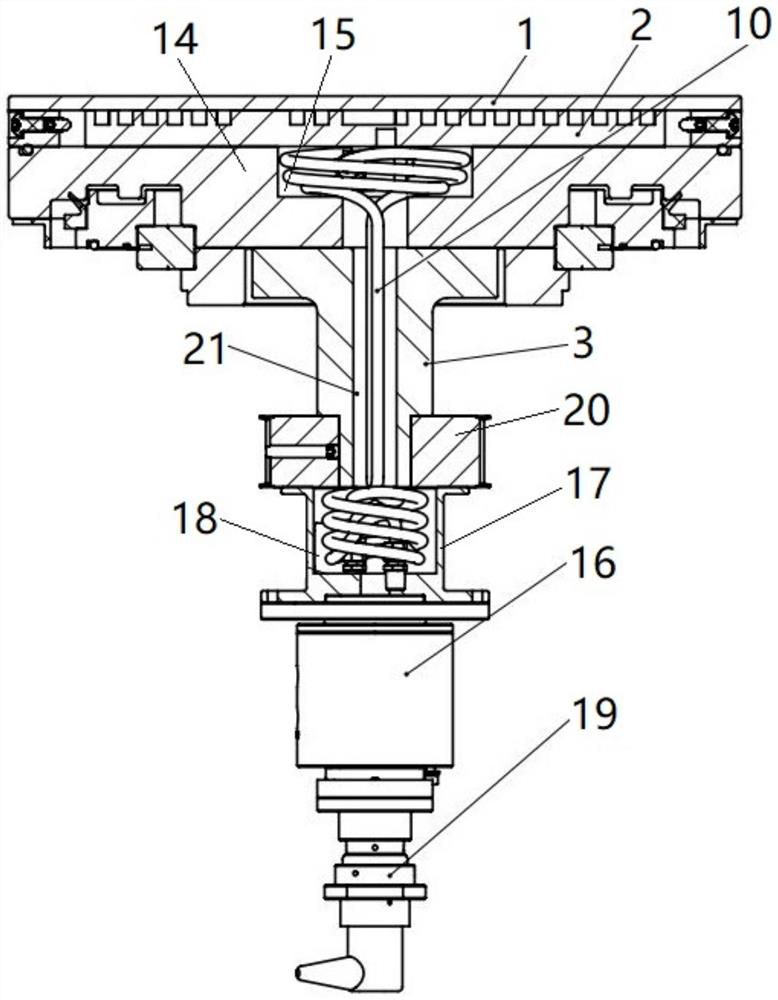

Self-cooling injection burner

PendingCN107062225AIncrease coolingReduce radiationCombustion technology mitigationGaseous fuel burnerEngineeringNozzle

The invention provides a self-cooling injection burner. The self-cooling injection burner comprises a mixing tube, a combustion head and a nozzle. The mixing tube is provided with an air inlet end and an air outlet end. The nozzle is arranged at the air inlet end and used for spraying fuel into the mixing tube and further sucking external air into the mixing tube under the injection action. The combustion head is arranged at the air outlet end and used for combusting a mixture of the fuel and the air. The injection burner further comprises an air flow channel guiding the sucked-in air to flow. The air flow channel extends to the air inlet end of the mixing tube from the periphery of the combustion head, so that the combustion head is cooled before the sucked-in air arrives at the air inlet end of the mixing tube. Due to the fact that the air used for combustion supporting is led into the combustion head to be used for combustion supporting again after cooling, the advantages of the injection burner are reserved, and meanwhile the cooling effect of the combustion head is improved; and combustion stability is improved, the service life of the combustion head is prolonged, and radiation to the environment by the combustion head is reduced.

Owner:SHENZHEN WISDOM ENERGY TECH CO

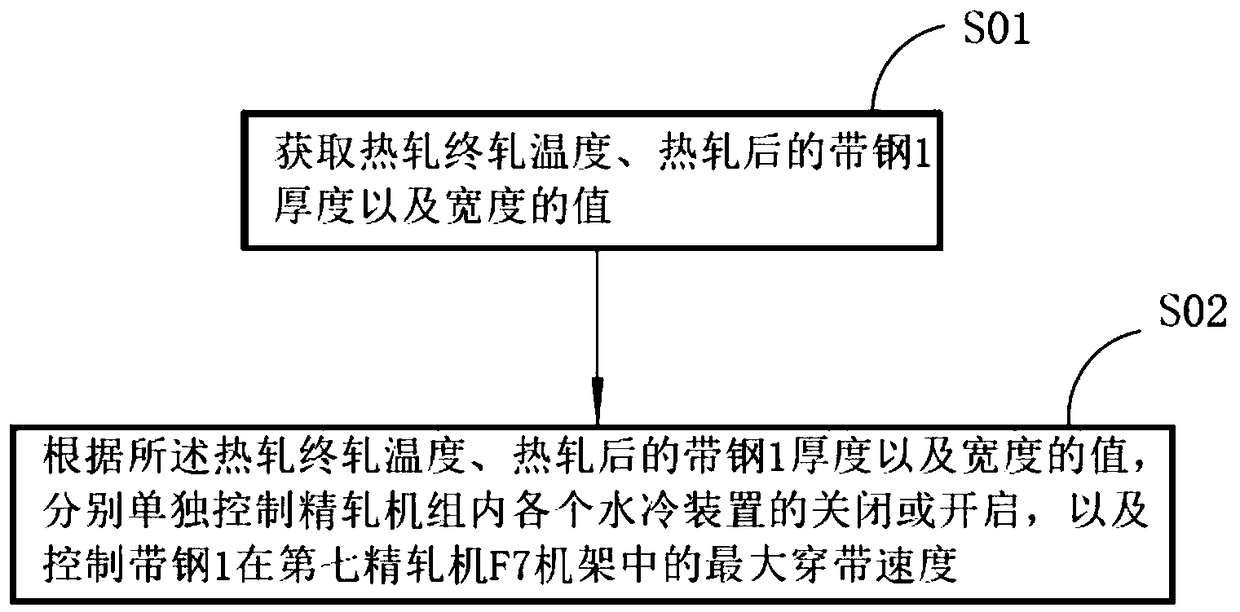

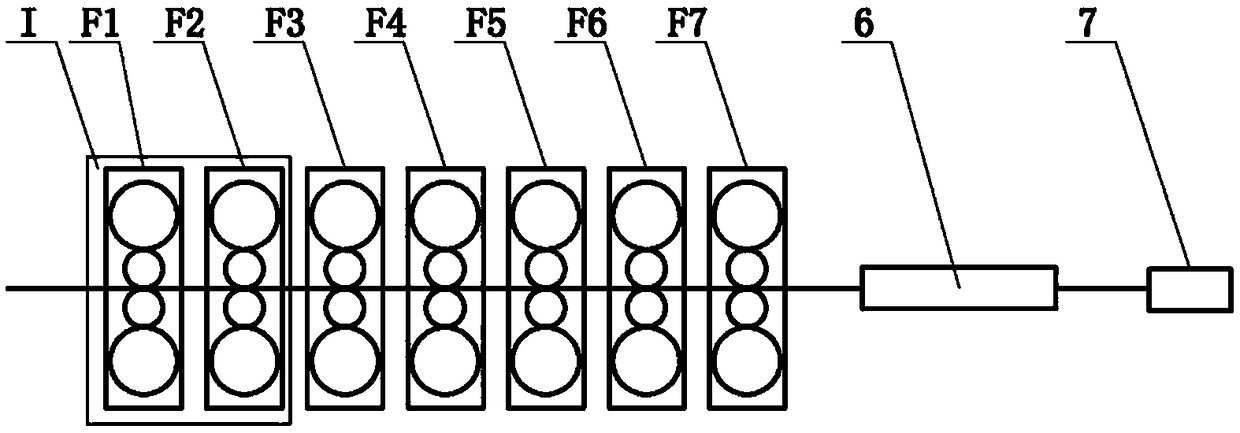

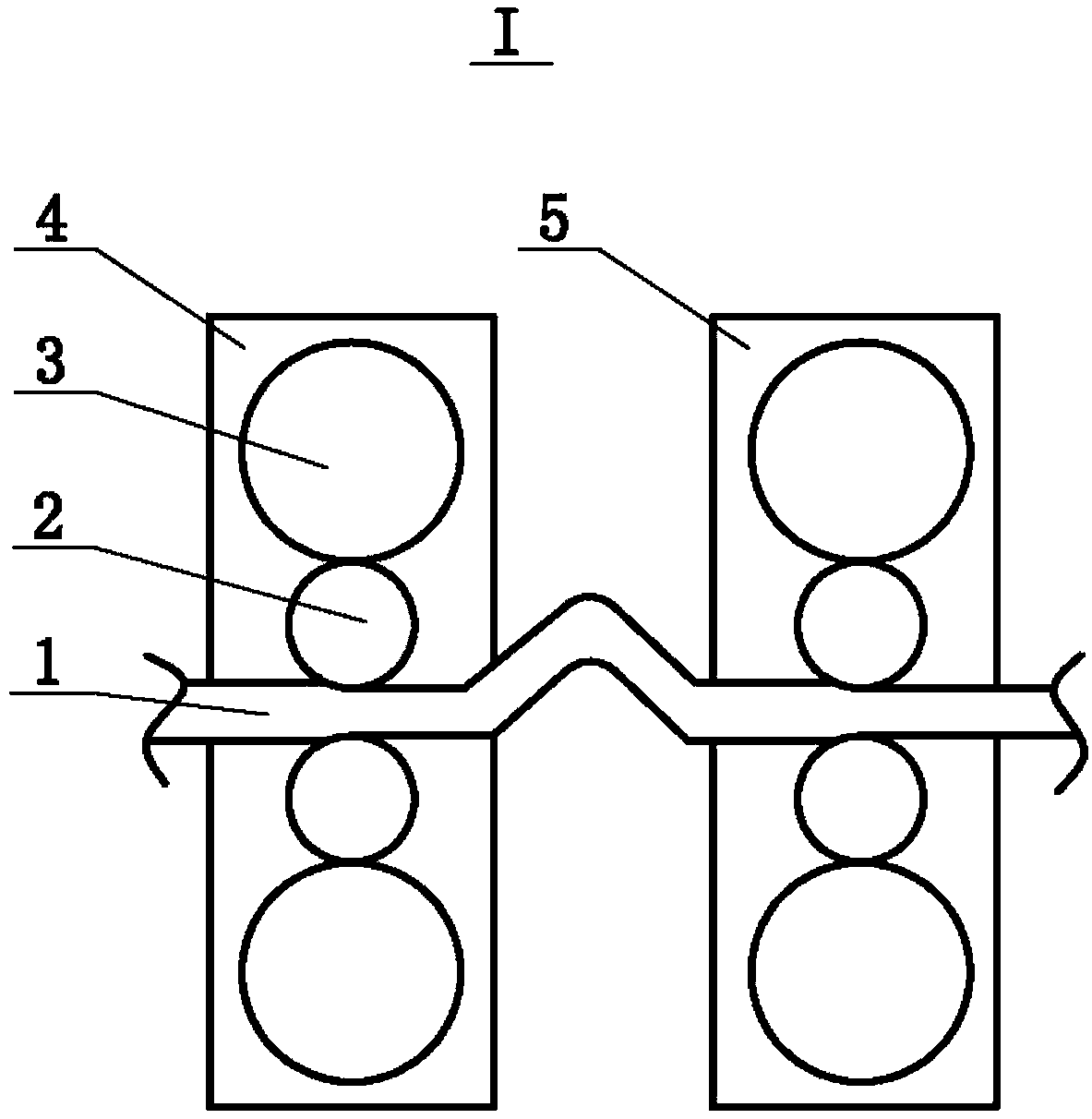

Method for preventing generation of roll marks on hot rolled steel strips with medium and high content of carbon

ActiveCN109226258AControl the threading speedAvoid damageTemperature control deviceMetal rolling stand detailsStrip steelWater cooling

The invention belongs to the technical field of manufacturing of steel and discloses a method for preventing generation of roll marks of hot rolled steel strips with a medium and high content of carbon. The method comprises the steps of obtaining hot rolling final rolling temperature and values of the thickness and width of the steel strips after hot rolling; according to the hot rolling final rolling temperature and the values of the thickness and width of the steel strips after hot rolling, separately controlling closing or opening of each water cooling device in a finishing rolling unit alone and controlling the maximum strip passing speed of the steel strips in a rack of a seventh finishing rolling machine. By comprehensively controlling closing or opening of each water cooling devicein the finishing rolling unit, controlling the strip passing speed of the rack of the seventh finishing rolling machine and controlling the diameter of a working roller of the rack of the seventh finishing rolling machine, the generation of the roll marks on the steel strips can be effectively controlled.

Owner:湖南华菱涟源钢铁有限公司

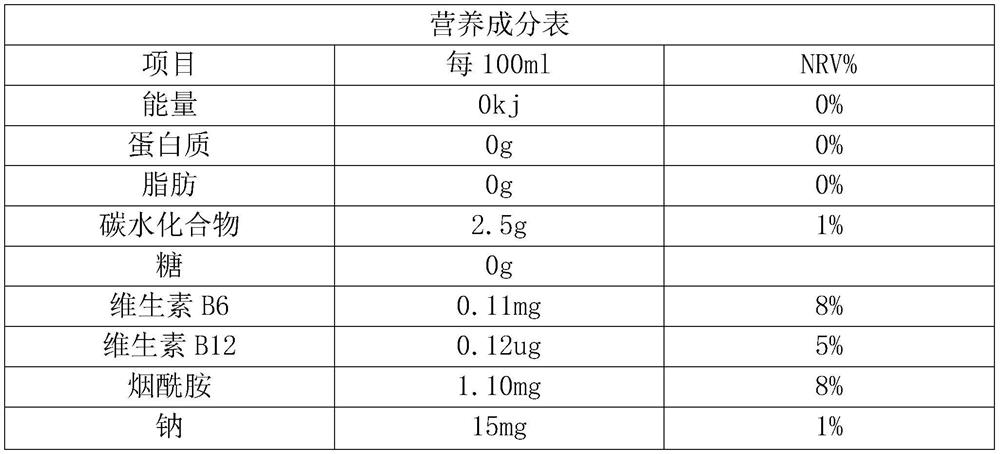

Flavored sparkling water

PendingCN113367259AGreat tasteImprove mouthfeelGaseous food ingredientsFood ingredient functionsBiotechnologyTheanine

The invention discloses flavored sparkling water. The sparkling water is prepared from the following raw materials in parts by mass: 15 to 25 g of erythritol, 0.1 to 0.3 g of L-theanine, 4 to 8 g of carbon dioxide, 0.2 to 0.3 g of AK sugar, 0.4 to 0.6 g of malic acid, 0.2 to 0.4 g of citric acid, 0.2 to 0.4 g of sodium citrate, 0.05 to 0.15 g of vitamin B complex, 0.1 to 0.2 g of sodium benzoate, 0.5 to 0.7 g of opacifier, an additive and 1000 g of water. The super-strong bubble carbon dioxide is added to conventional bubble water, the taste degree of the flavored beverage and the bubble degree in the beverage are improved, L-theanine is added, the beverage can reduce blood pressure, soothe the nerves, improve sleep, promote brain functions and contribute to insomnia, and the beverage is suitable for being drunk by various people with zero sugar, zero fat and zero calorie, is good in taste, and keeps good flavor and taste. The beverage with different tastes can be prepared according to the addition of different additives, and the beverage can be stored for a long time and is convenient to transport and store.

Owner:安徽迎驾山泉股份有限公司

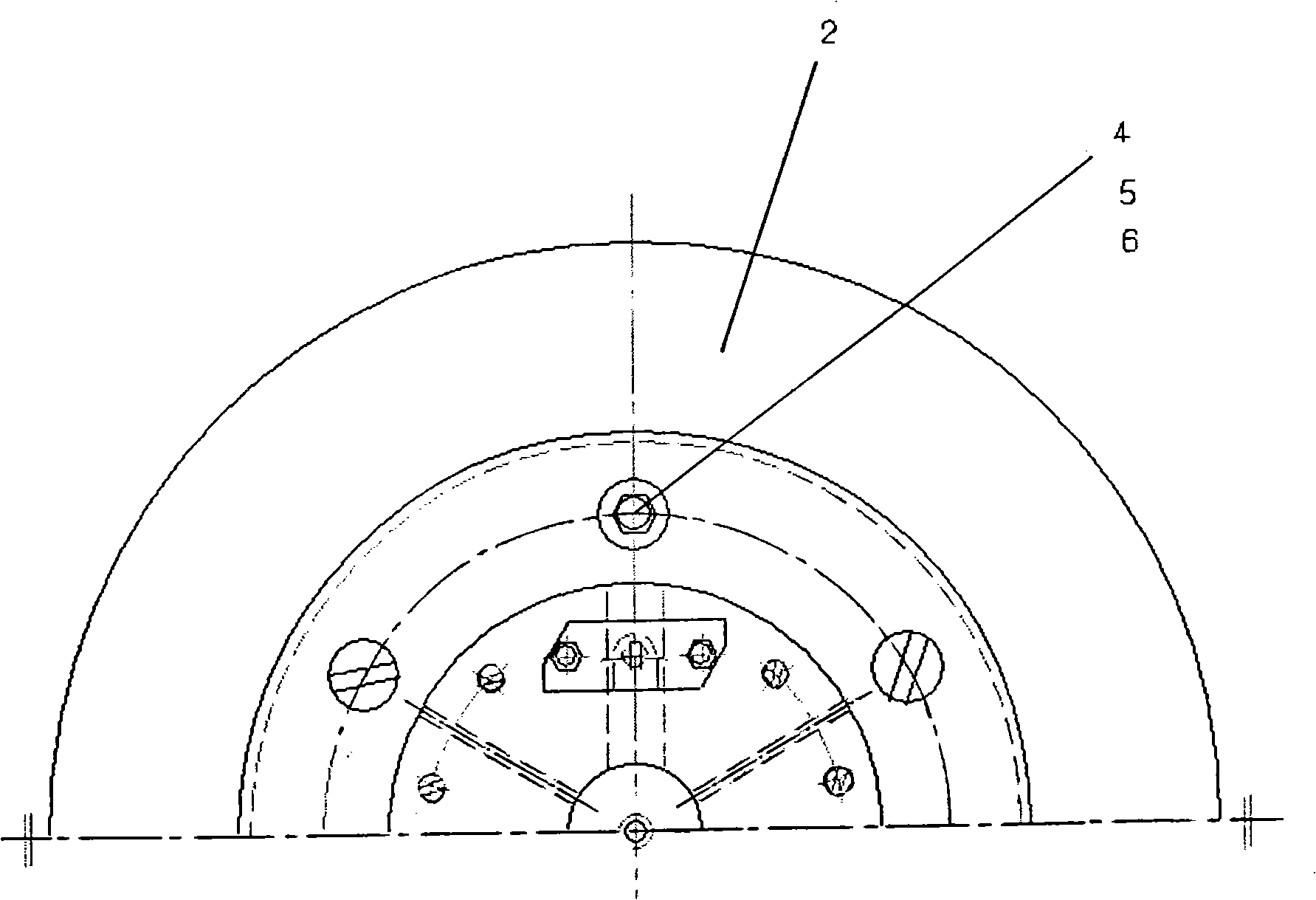

Slip ring novel structure of large medium-size coiling motor

InactiveCN101304147AIncrease coolingReduce toner depositionRotary current collectorCooling/ventillation arrangementEngineeringSlip ring

The invention discloses a new structure of a large and middle scale wound motor slip ring, which relates to the improvement of the structure of the wound motor, wherein, a fan is arranged at the outer end of the slip ring at the outermost side and is specially used for cooling the slip ring. The fan is fixed on the slip ring by a plug, a bolt, a nut and a washer. The new structure of the large and middle scale wound motor slip ring has the beneficial effects that: the cooling at the position of the slip ring is improved by installing the fan of the slip ring; both the attachment amounts of carbon powder and the temperature rise of the slip ring are reduced; the stability of the slip ring in operational process is greatly improved.

Owner:上海电机成套联合有限公司

High efficiency and low cost thermoelectric module and making process thereof

InactiveCN101202323AIncrease heat transfer areaImprove heat transfer efficiencyThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentSemiconductor materialsThermal insulation

The invention relates to a thermoelectric component with high efficiency and low cost and the producing technique thereof, which comprises P-type and N-type semiconductor components, an upper baffle and a lower baffle, an upper electrical insulation and heat conducting layer and a lower electrical insulation and heat conducting layer and electrical and thermal insulation materials which are filled in the spare space; wherein, the upper and lower electrical insulation and heat conducting layer is the Al2O3 plating film which is plated on the baffle, and the upper baffle and the lower baffle adopt the block aluminum plate or the copper plate and are made through the etching technology. The invention has the advantages of greatly decreasing the consumption of the semiconductor material, adopting the aluminum plate to substitute the copper plate, lowering cost, simplifying making technology, being suitable for industrialized mass production, and greatly improving the refrigeration and induced thermal efficiency of the semiconductor thermoelectric component.

Owner:邓贤金

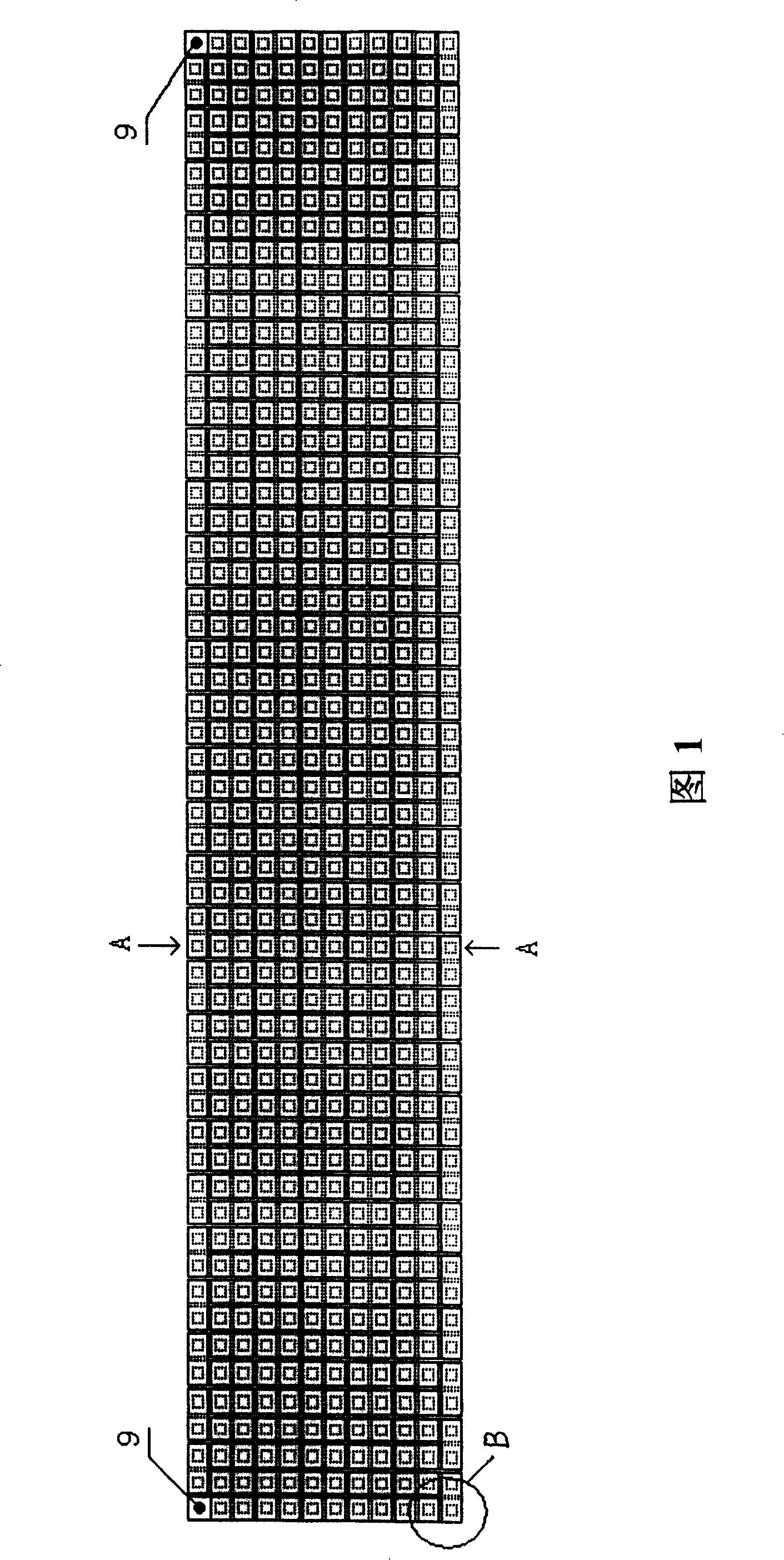

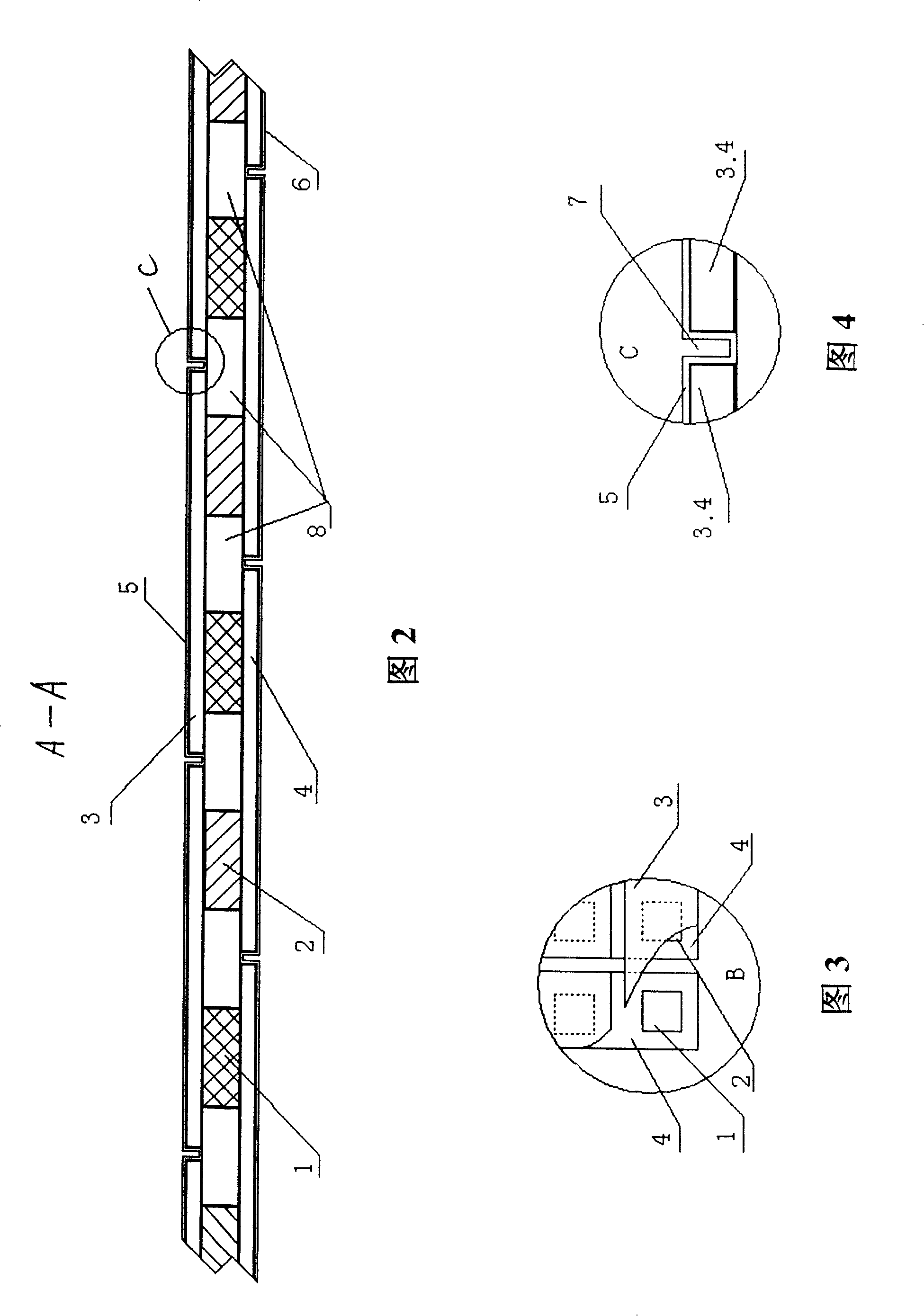

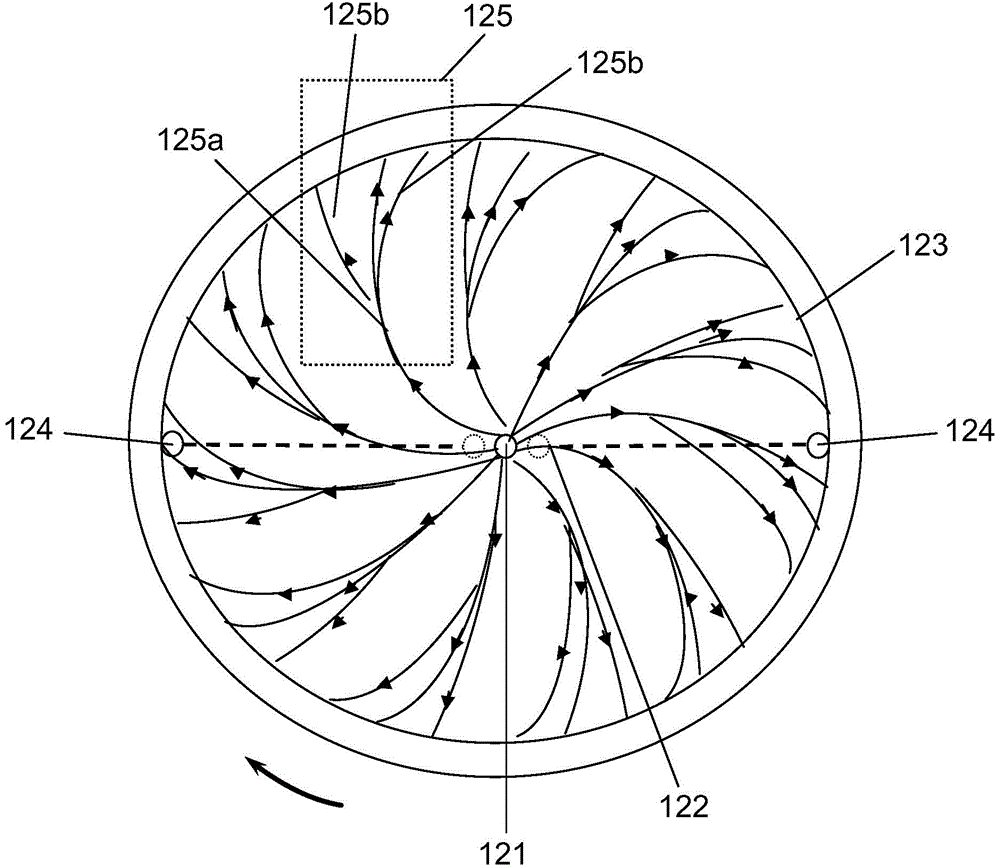

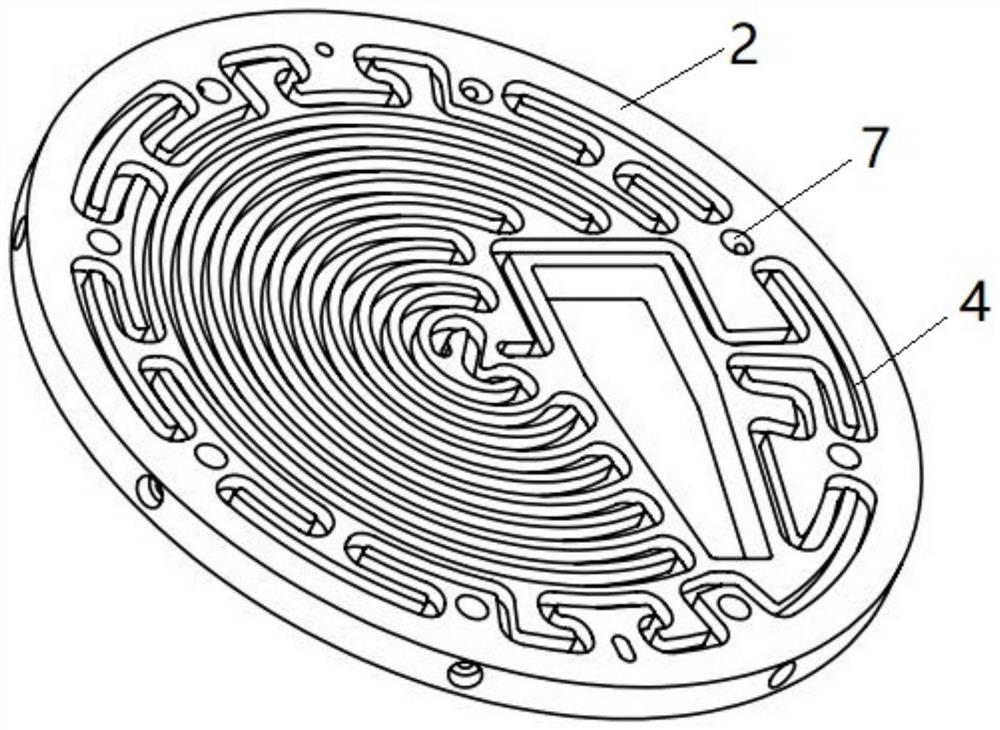

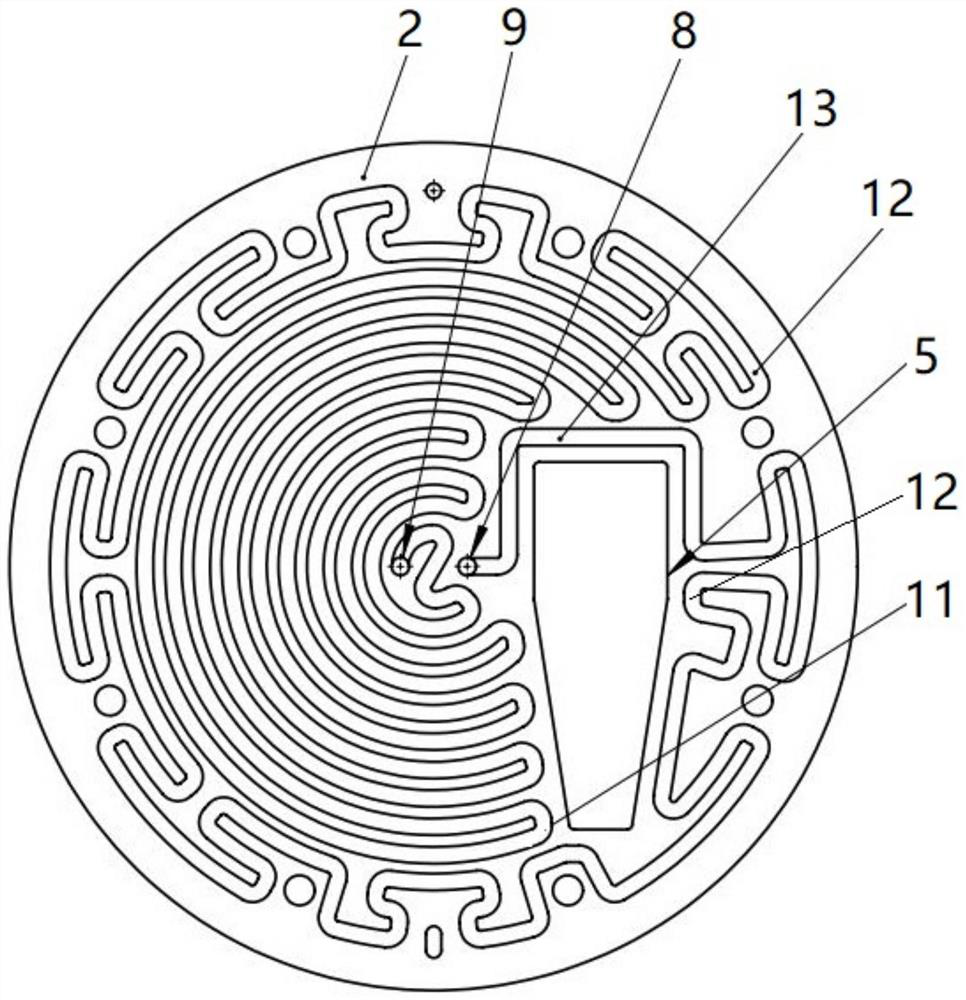

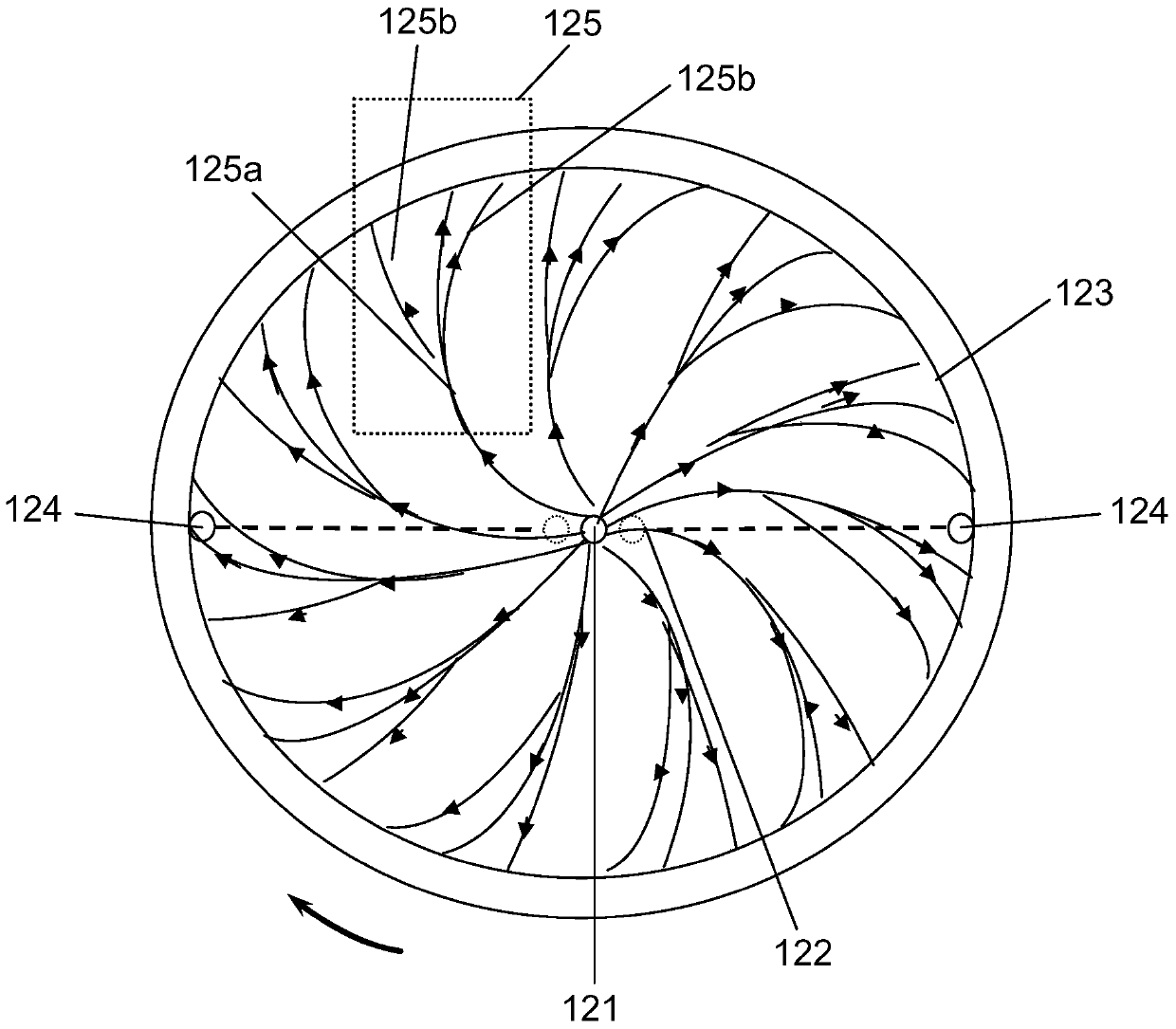

Polishing disk and cooling device thereof

ActiveCN105290956AReduce the temperatureImprove temperature distribution uniformityLapping toolsReturn channelWaste management

The invention discloses a cooling device of the polishing disk. The cooling device is applied to the polishing disk and comprises a cooling water inlet, cooling water outlets, an annular liquid return tank, liquid return channels and cooling water grooves. The cooling water inlet and the cooling water outlets are formed in the polishing disk. The annular liquid return tank and the liquid return channels are formed in the polishing disk, one end of each liquid return channel is communicated with the liquid return tank, and the other ends of the liquid return channels are communicated with the cooling water outlets. The cooling water grooves are formed in the polishing disk and located in the area, wrapped by the liquid return tank, of the polishing disk, and the cooling water grooves are evenly distributed in a branch shape. Each cooling water groove comprises a main groove body and side groove bodies, wherein one end of the main groove body is communicated with the cooling water inlet, the other end of the main groove body is communicated with the liquid return tank, one ends of the side groove bodies are communicated with the main groove body, and the other ends of the side groove bodies are communicated with the liquid return tank. The invention further discloses the polishing disk with the cooling device.

Owner:ACM RES SHANGHAI

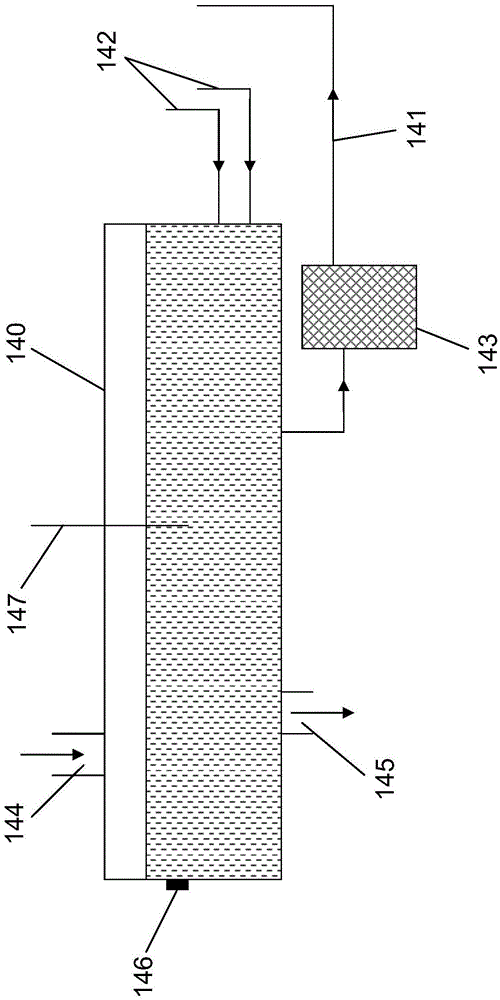

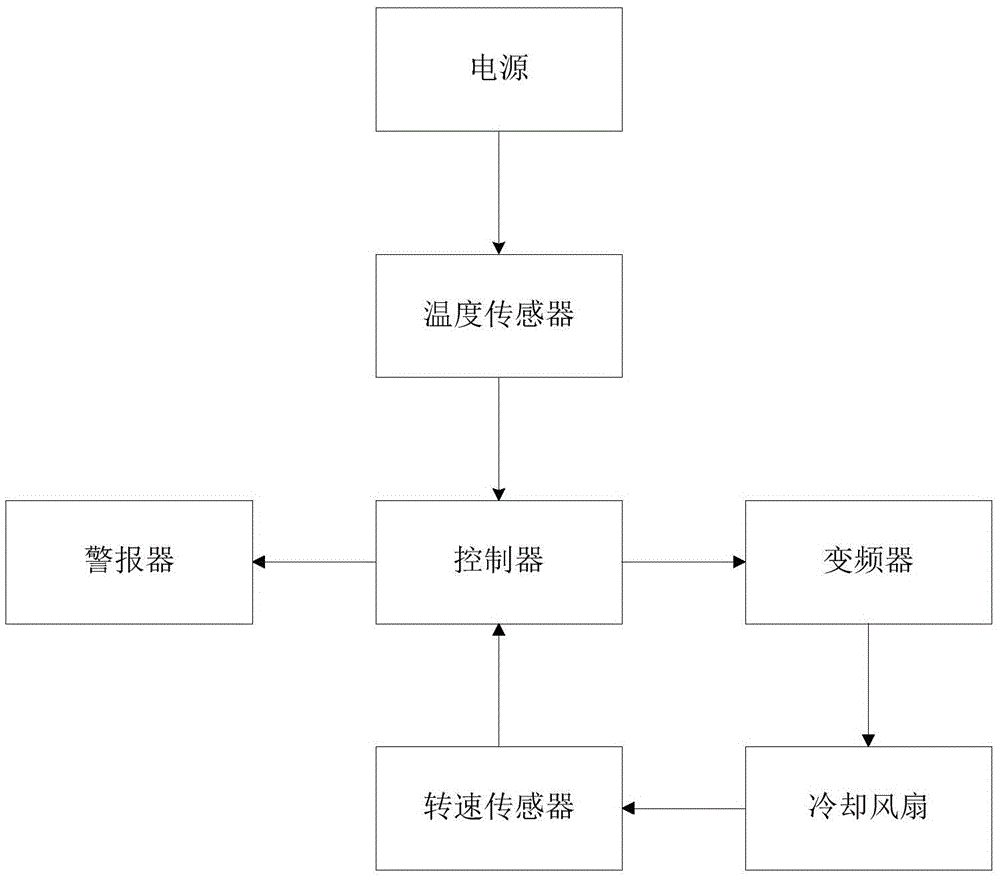

Heat radiation method of power supply

InactiveCN105682433AStable jobRealize cooling treatmentAlarmsModifications using gaseous coolantsRoom temperatureEngineering

The invention provides a heat radiation method of a power supply. The method comprises a heat radiation device, including a temperature sensor, a controller, a cooling fan and a rotating speed sensor, of the power supply is provided; the temperature sensor is used to measure the room temperature and the temperature of the power supply, and measured temperature information is sent to the controller; and the rotating speed sensor measures the rotating speed of the cooling fan, measured rotating speed information is sent to the controller, the controller adjusts the rotating speed of the cooling fan according to the temperature information and the rotating speed information, and thus, the temperature of the power supply is effectively controlled. The method of the invention can be used to control the temperature of the power supply more effectively, and ensure stable work of the power supply.

Owner:刘梦真

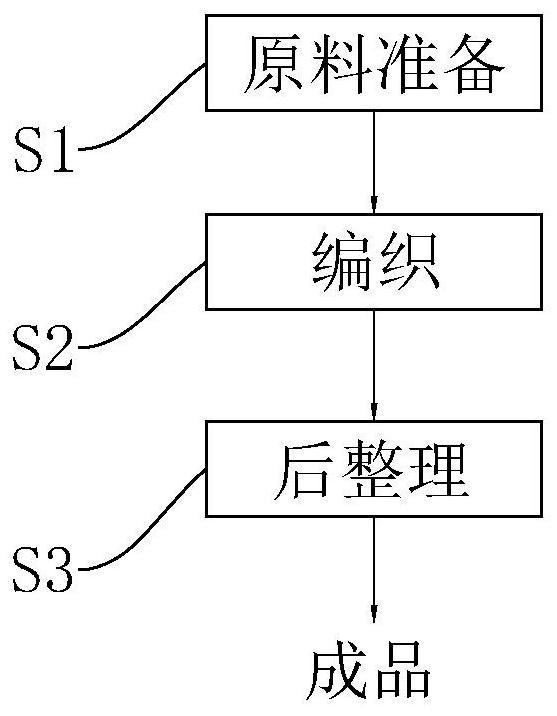

Preparation process of polyamide-polyester blended fabric with ice-cold feeling

InactiveCN112760784AGood drapeImprove comfortHeating/cooling textile fabricsWoven fabricsPolyesterYarn

The invention relates to the technical field of fabric spinning, and particularly discloses a preparation process of a polyamide-polyester blended fabric with an ice-cold feeling. The preparation process comprises the following steps of S1, preparing raw materials, specifically, preparing cool nylon yarns, and preparing polyester yarns at the same time; S2, weaving, specifically, mutually interweaving the cool nylon yarns and the polyester yarns prepared in the step S1 to form a fabric, and enabling the cool nylon yarns and the polyester yarns to be respectively positioned on two sides of the fabric; and S3, after treatment specifically, after finishing in the step S3, obtaining the polyamide-polyester blended fabric with the ice-cold feeling. The cool nylon yarns and the polyester yarns are used for mixed spinning, and the cool nylon yarns and the polyester yarns are located on the two sides of the woven fabric respectively when the two kinds of fiber yarns are used for spinning the fabric, so that when the fabric is used as clothes, the cool nylon yarns make contact with the surface of the human body, and the cool feeling can be brought to people; meanwhile, the polyester yarns face outwards, so that the draping feeling of the clothes is better, and the anti-wrinkle performance is excellent.

Owner:绍兴天普纺织有限公司 +1

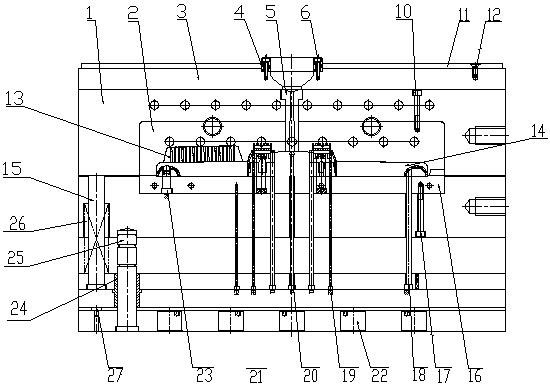

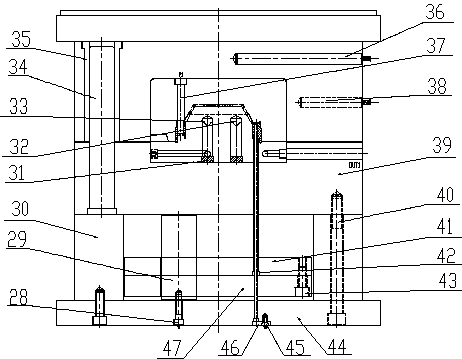

Injection mold for thin-walled deep-cavity electromechanical shell

PendingCN108262921ASimple and reasonable structural designHigh precisionThin walledMaterials science

The invention discloses an injection mold for a thin-walled deep-cavity electromechanical shell. The injection mold comprises a fixed mold side, a movable mold side and a cooling system of the injection mold. The fixed mold side is provided with a fixed plate and a fixed mold plate, and the movable mold side is provided with a movable mold plate, a supporting plate, a base plate and a movable moldseat plate. The injection mold has a one-mold two-cavity structural mode, and the cooling system of the injection mold is provided with a well at the position of a deep cavity of the electromechanical shell so as to ensure balanced cooling. The mold adopts a side pouring mode, cool material wells are arranged at the tail ends of a main runner and a sub-runner, and the circumstance that cool materials enter a cavity to affect the quality of plastic parts is prevented. By the injection mold, according to the structural characteristics of thin-walled deep-cavity plastic parts and on the basis ofa traditional structural mode of a mold, the dimensional stability of an injection parts is ensured effectively, moreover, shrinkage and warping influences are controlled in a specified range, and the quality of products is improved.

Owner:SHANDONG UNIV OF SCI & TECH

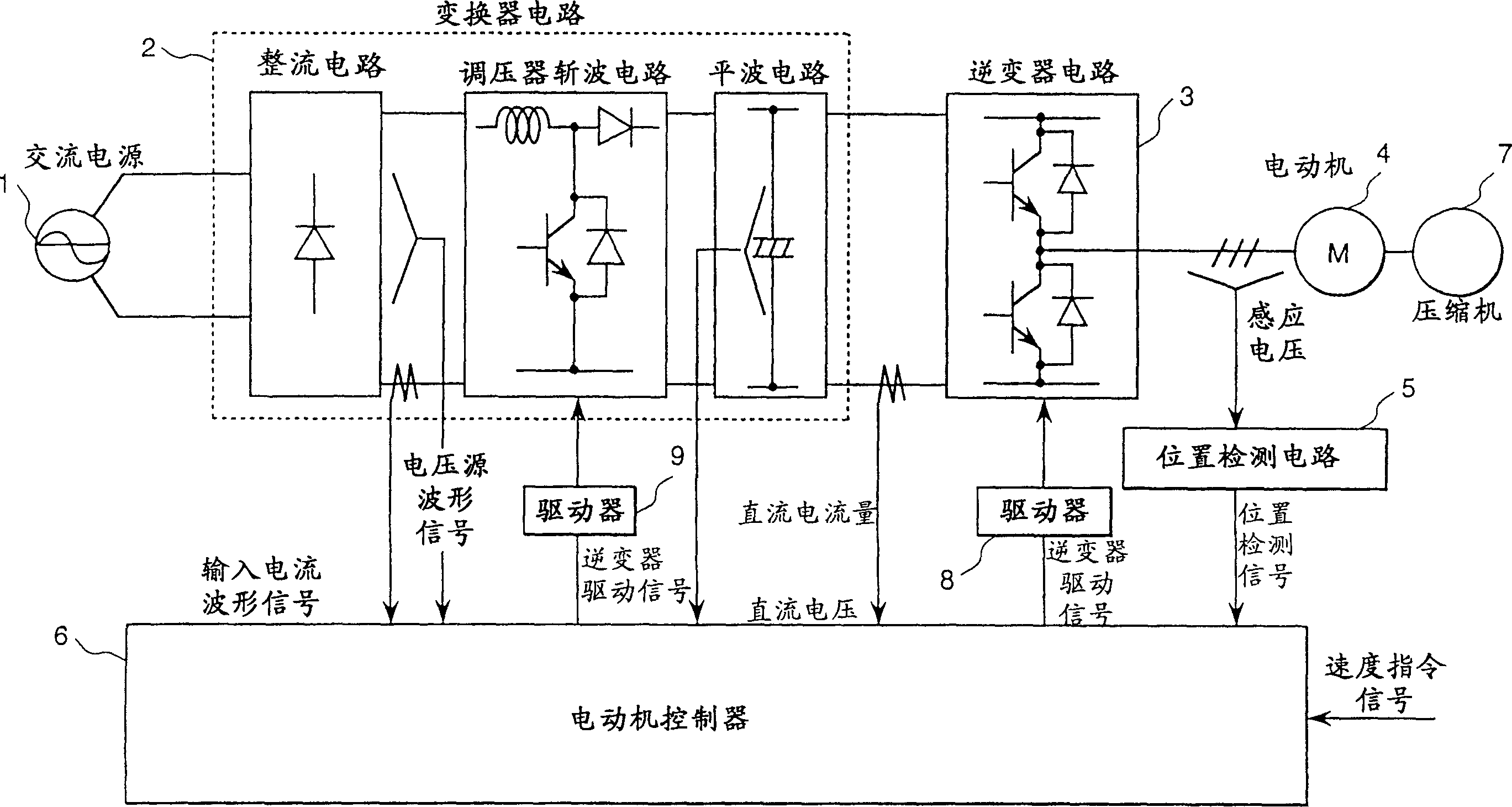

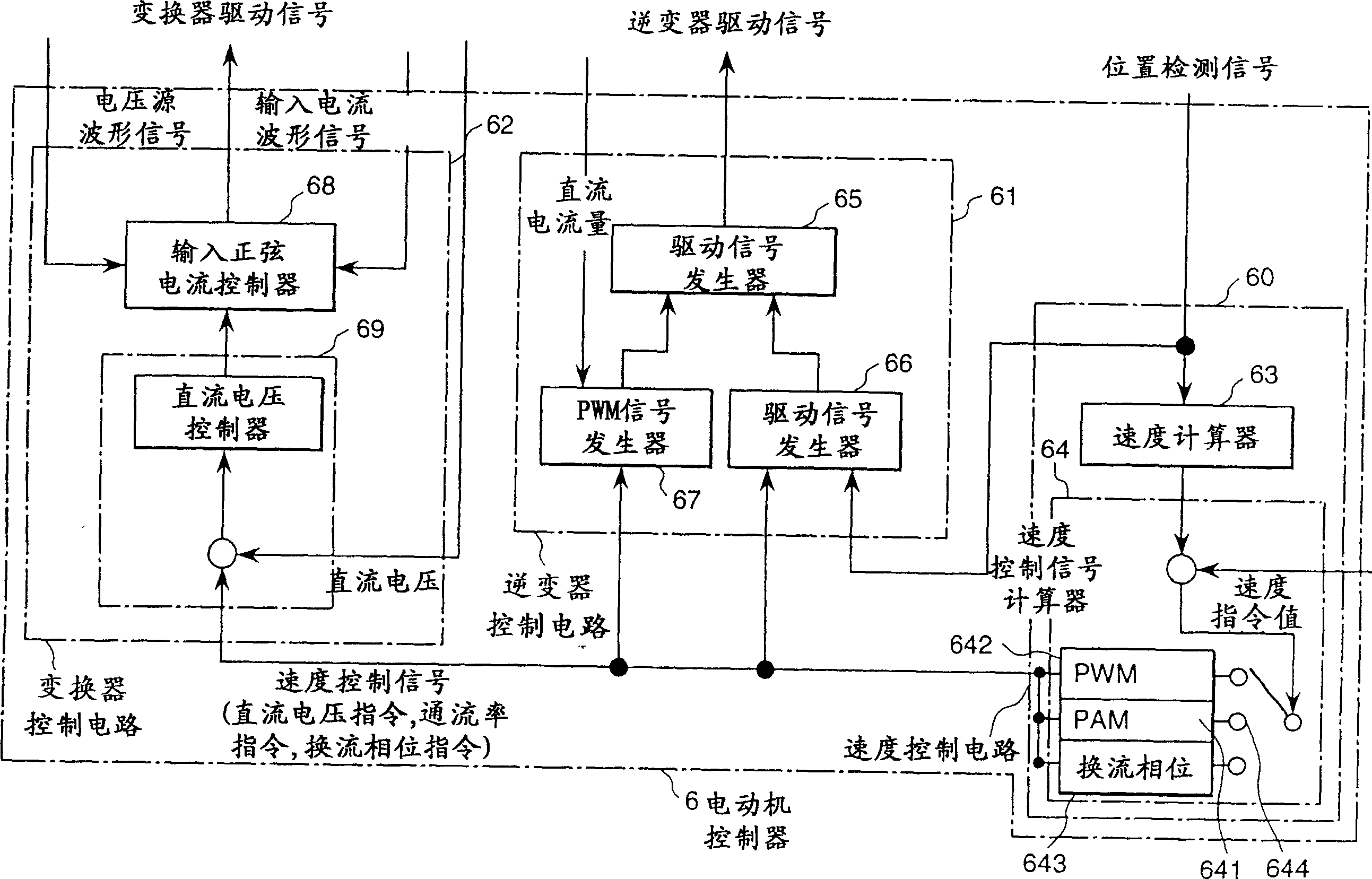

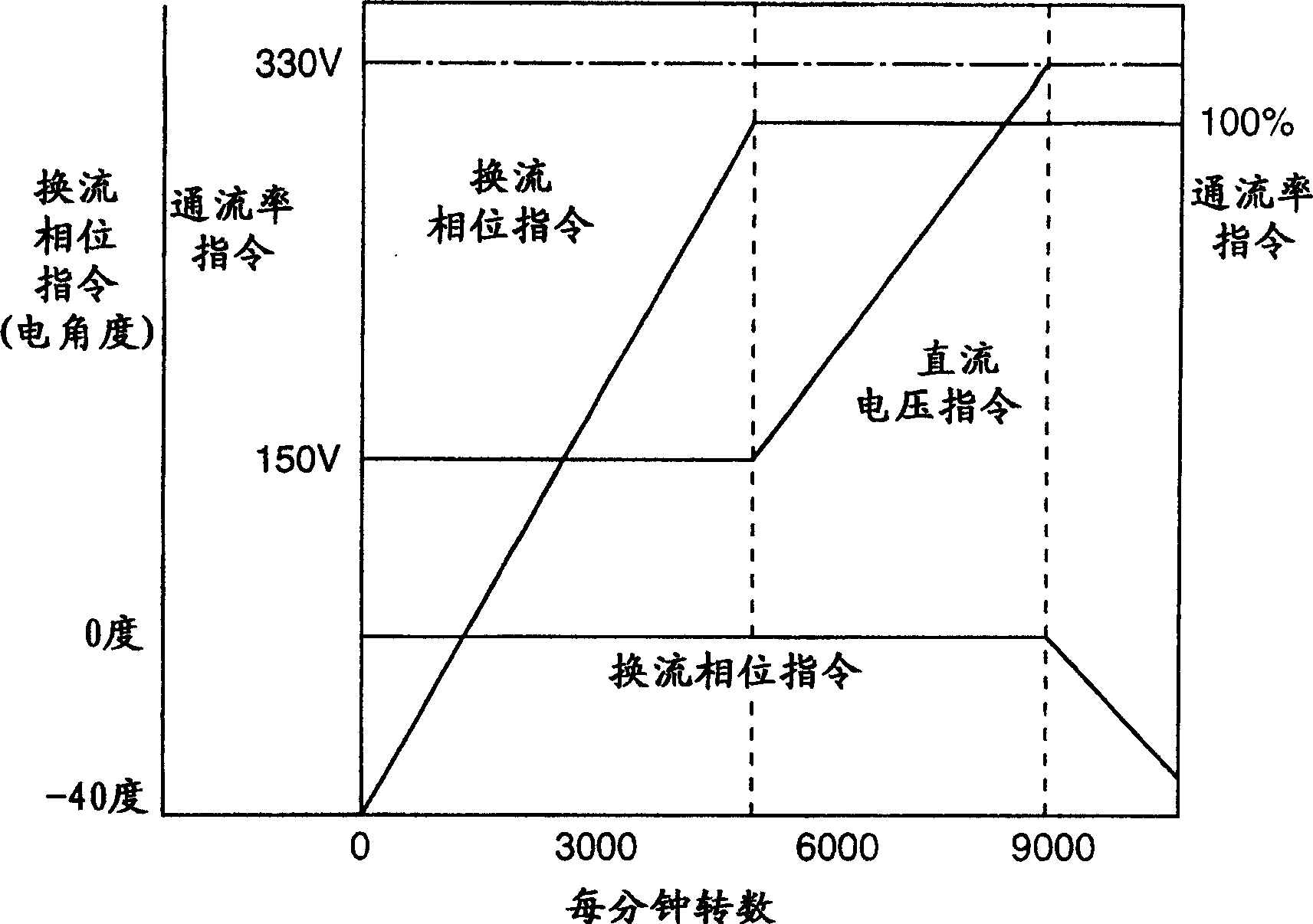

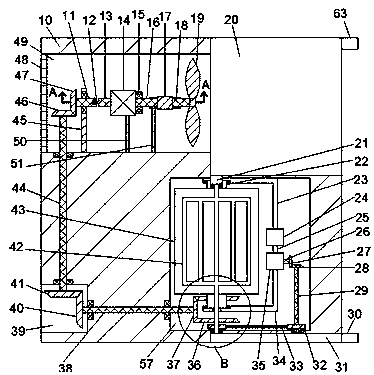

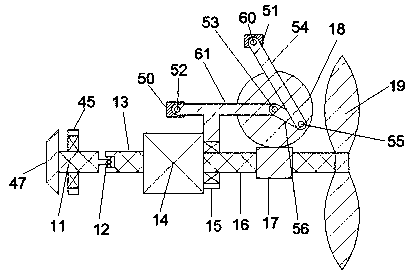

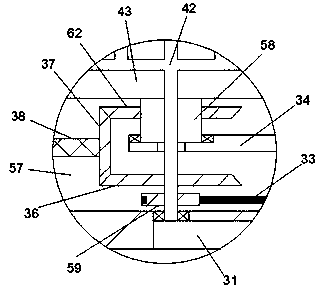

Controller for PWM/PAM motor

InactiveCN1276575CImprove efficiencyGuaranteed uptimeMotor control for low load efficiencyMotor control for very low speedsStable stateControl signal

It has been a subject to be able to control a motor driving unit which is controlled by switching to / from PWM control from / to PAM control so that the maximum limit of the revolution per minute can be increased and, at the same time, the unit can be operated at the maximum efficiency in a steady-state operation. The above problem can be solved by a control means for a motor which comprises a converter circuit, an inverter circuit connected to the output of the converter circuit, amotor connected to the inverter circuit, and a speed control signal computing means that outputs a DC voltage command and a conduction ratio command to the converter control circuit and the inverter control circuit; wherein the speed of the motor is controlled by maintaining the DC voltage command to the converter control circuit constant but altering the conduction ratio command value to the inverter control circuit when the load to the motor is low, and by maintaining the conduction ratio command to the inverter control circuit constant but altering the DC voltage command to the converter control circuit; and said control means comprises a commutating phase control means that alters the commutating timing of the coil of the motor, and the motor is so controlled that the efficiency becomes the maximum limit in a steady-state operation and the revolution per minute becomes the maximum limit in a high-speed operation.

Owner:HITACHI LTD

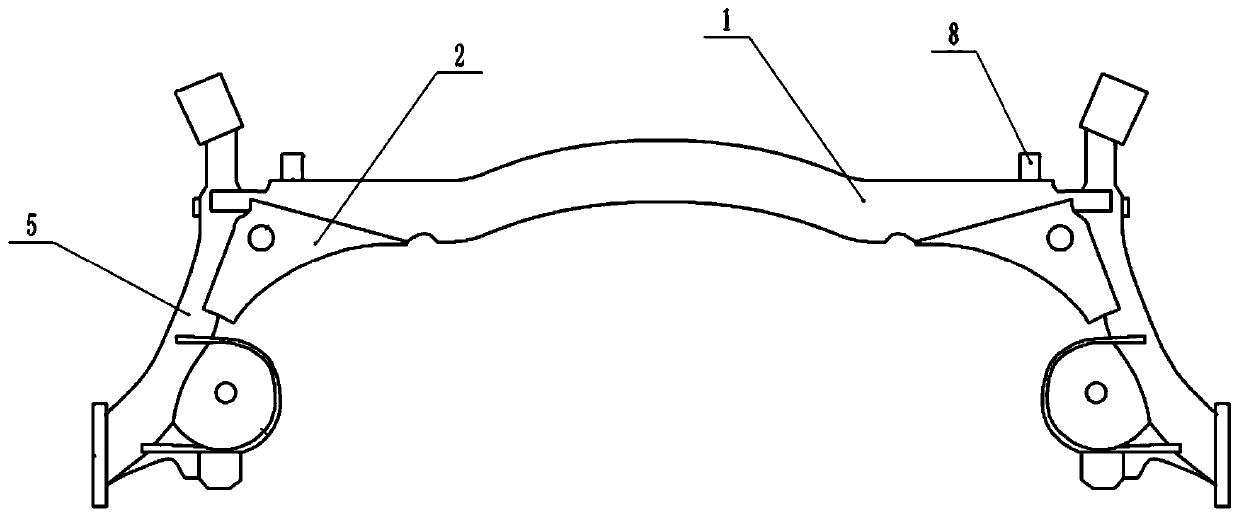

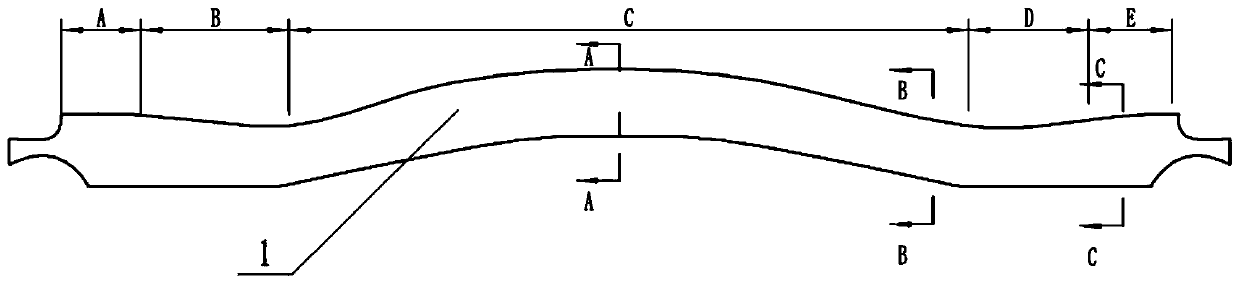

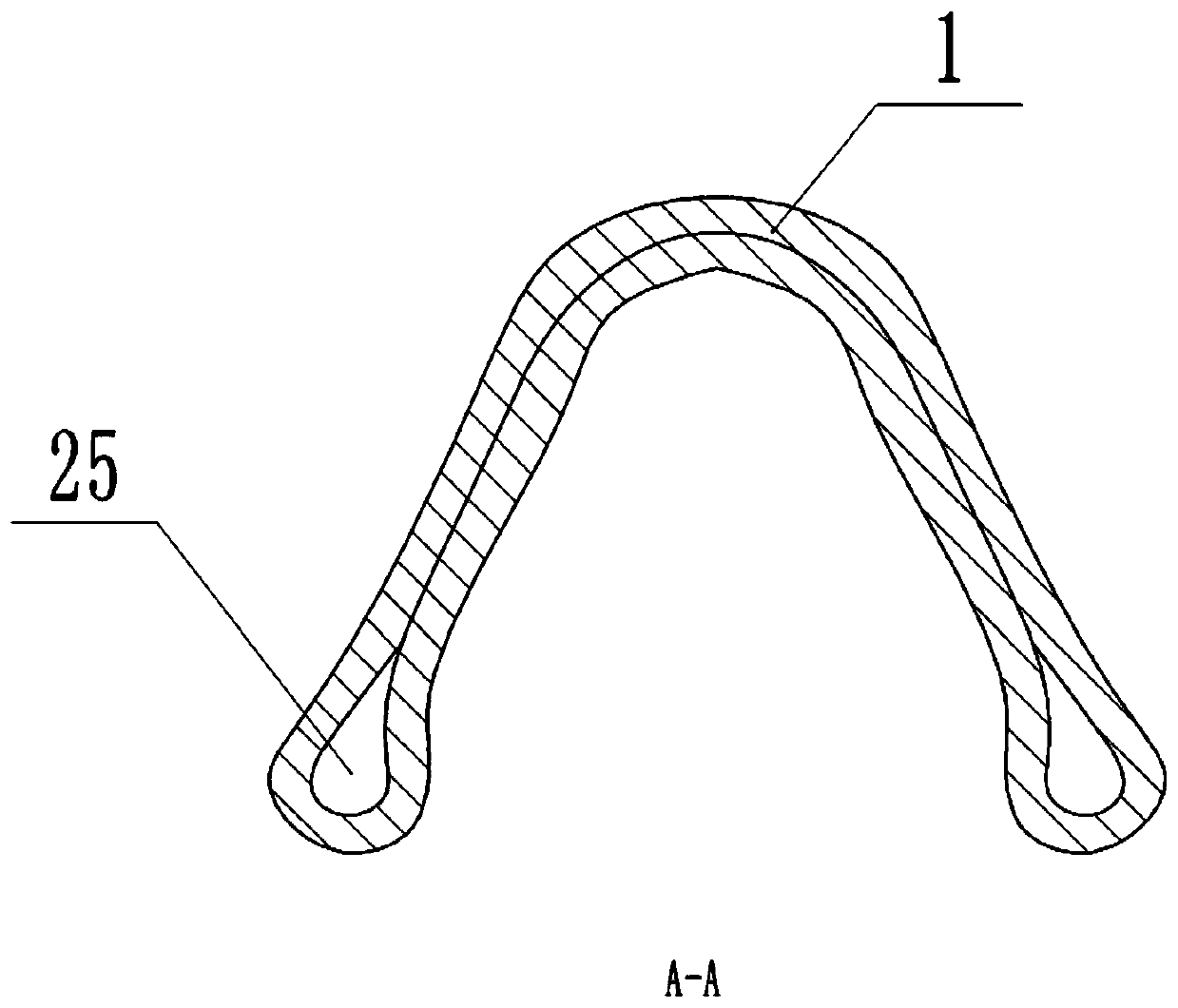

Antifatigue torsion beam formed through pipe punching

PendingCN110385954AImprove operational stabilityImprove securityInterconnection systemsTrailing armPunching

The invention relates to the field of vehicle parts, in particular to an antifatigue torsion beam formed through pipe punching. The antifatigue torsion beam comprises a cross beam and trailing arms, the trailing arms are fixedly connected to the two ends of the cross beam, and the cross beam is formed through punching of a pipe. Before the pipe is punched, the pipe is filled with wax, and the waxis in a honeycomb shape. According to the scheme, the antifatigue capability of the torsion beam is improved.

Owner:天人汽车底盘(芜湖)股份有限公司

Chinlon cool demin shirt cloth

InactiveCN108774754AIncrease coolingImprove cooling effectFilament/thread formingWoven fabricsFiberCombing

The invention relates to chinlon cool demin shirt cloth. The chinlon cool demin shirt cloth is formed by weaving Dacron nylon chilled fibers with specifications of warp and weft- density of 133*86, ayarn count of 32S combing*140D / 136F chinlon, a structure of 3 / 1 right inclination, fabric width of 53 / 54, fabric weight of 4.8 oz, constituents of 60% of cotton and 40% of chinlon, warp-wise shrinkageof -3%, and weft-wise shrinkage of -3%, and the fabric weight of 4.9 oz after washing. Through adoption of the Dacron nylon chilled fibers with the component proportion of 60% of cotton and 40% of chinlon, the cost proportion is appropriate; and the fabric is thin and comfortable, permeates air, is good on the heat dissipation effect, has capabilities of air permeability, moisture absorption andmoisture permeability, is suitable for summer clothes, and is strong in practicability.

Owner:佛山市顺德区港纺联纺织有限公司

Banana fiber and its production and its blending wires and fabrics

InactiveCN100424237CGood earth environmentNo need to increase the cultivation areaVegetable fibres from other vegetable matterYarnYarnFiber bundle

Provided is a banana fiber using a banana stem which is an industrial waste as a raw material, a method for producing the banana fiber, a union yarn composed of a staple fiber of the banana fiber and other fiber and a fiber structure prepared from the union yarn. The banana fiber is obtained by drying peeled temporary stem of banana and opening the fiber so as to have 10-50 mm average fiber length and 0.5-80 dtex average fineness. The method for producing the banana fiber comprises a step (a) for cutting stems of banana, a step (b) for peeling and removing colored epidermis of stems, a step (c) for peeling much bark constituting stems to provide a unit bark, a step (d) for taking out a fiber bundle by pressing the unit bark by a press, a step (e) for drying the fiber bundle, a step (f) for obtaining a monofilament from the dried fiber bundle and a step (g) cutting the monofilament into a definite length and obtaining the staple fiber.

Owner:NISSHINBO IND INC

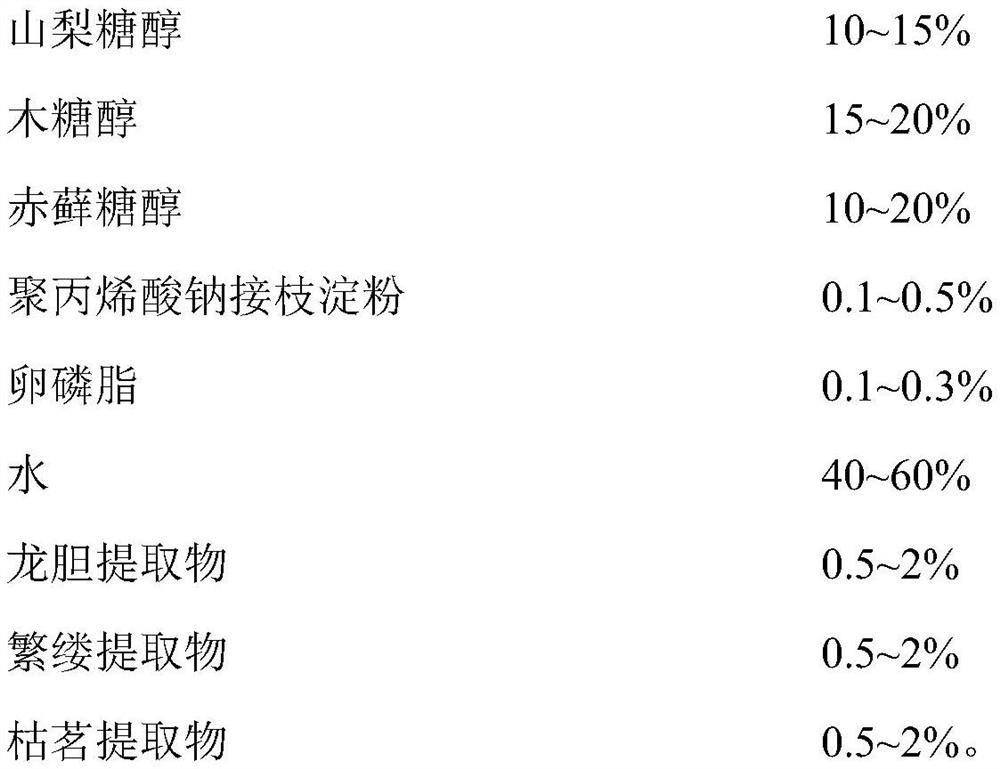

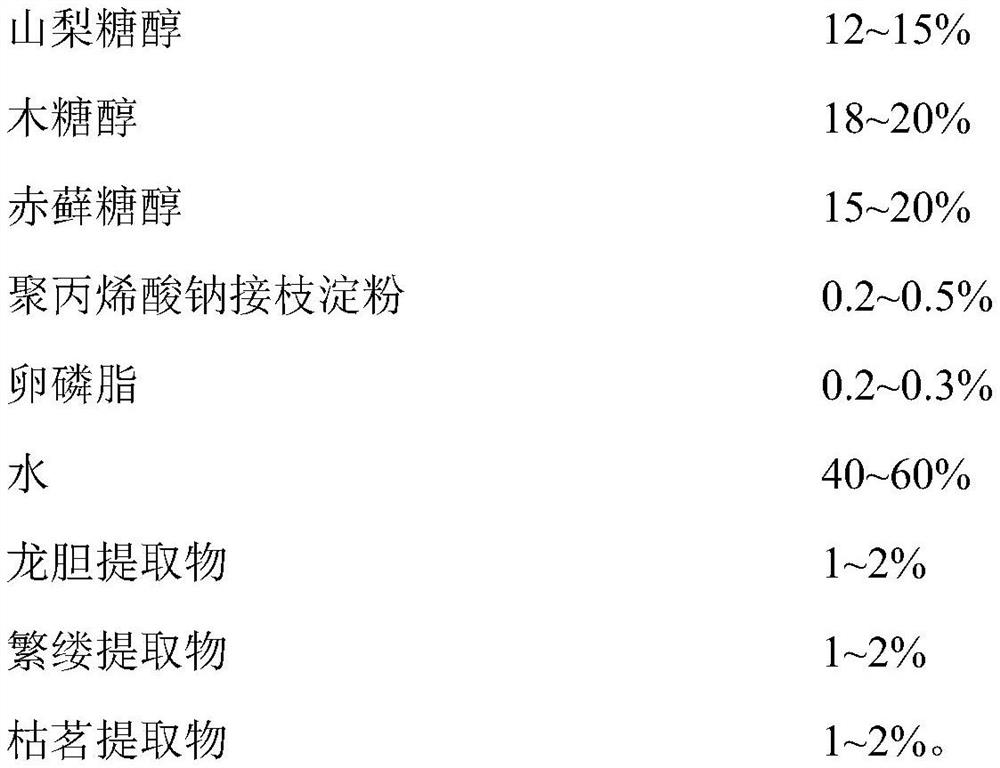

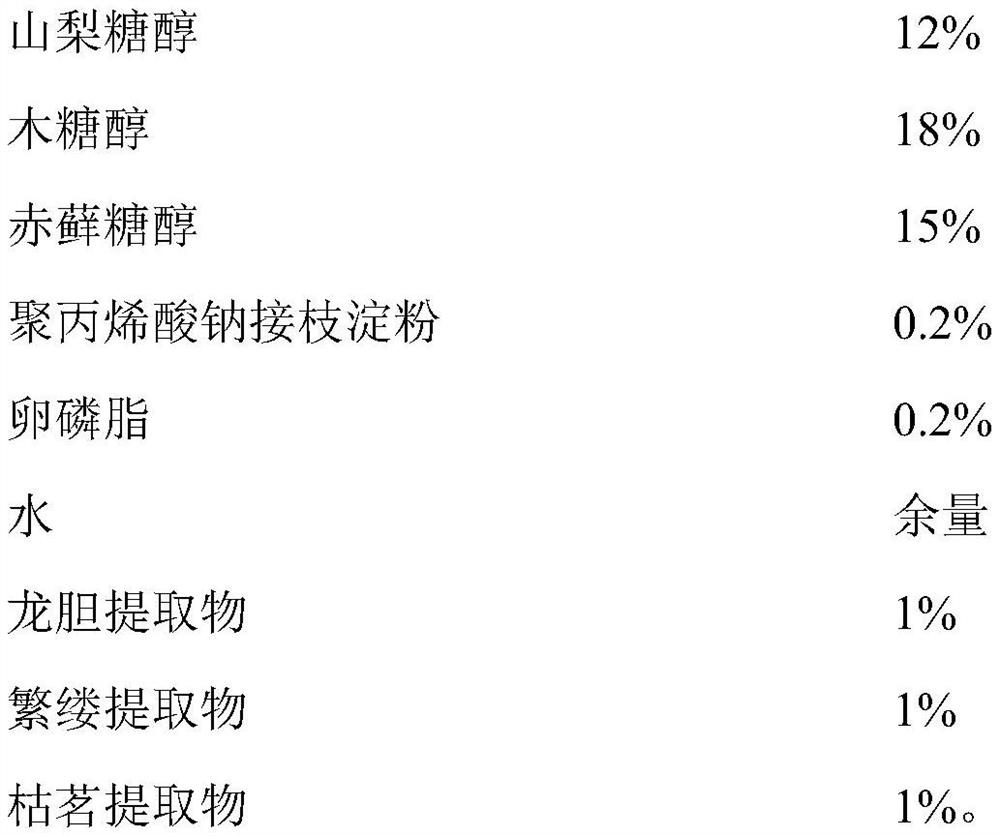

Cooling and soothing liquid dressing and application thereof

InactiveCN114306727AEvenly dispersedIncrease coolingTherapeutic coolingTherapeutic heatingChickweed ExtractBiology

The invention discloses a cooling and soothing liquid dressing and application thereof, the cooling and soothing liquid dressing comprises a powder item and a water item, and the powder item comprises sorbitol, xylitol, erythritol, sodium polyacrylate grafted starch and lecithin; the water item comprises water, a radix gentianae extract, a chickweed extract and a cumin extract. According to the cooling and soothing liquid dressing provided by the invention, by utilizing the characteristic that the powder and the water can absorb heat when being mixed, the skin surface is cooled by coating the mixture with reduced temperature.

Owner:宁波久瑞生物工程有限公司

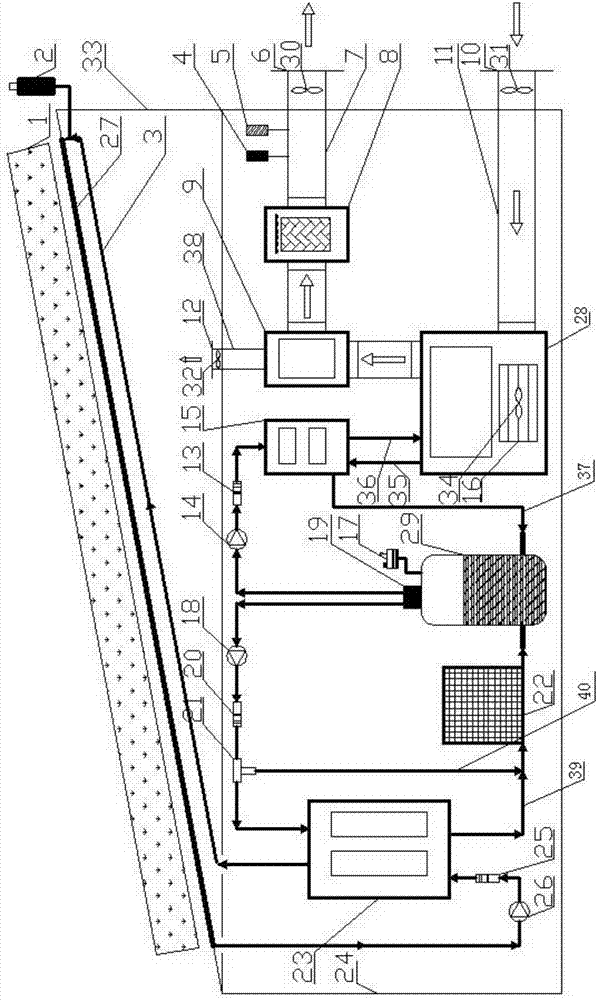

Evaporative cooling air conditioning unit based on solar refrigeration and solution dehumidification

InactiveCN107036207AStrong environmental protectionStrong energy savingMechanical apparatusSpace heating and ventilation safety systemsPlate heat exchangerCombined use

The invention discloses an evaporative cooling air conditioning unit based on solar refrigeration and solution dehumidification. The evaporative cooling air conditioning unit comprises a housing; a PV heat collector and a polyethene heat exchanger are erected at the upper part of the housing through a bracket; the polyethene heat exchanger is connected with a plate heat exchanger through a water circulation pipe a for forming a closed circulation loop; the plate heat exchanger communicates with a solution dehumidification unit and an evaporative cooling unit through pipelines sequentially; and the plate heat exchanger, the solution dehumidification unit and the evaporative cooling unit are located in the housing. Through combined use of an evaporative cooling technology, a solution dehumidification technology and a solar refrigeration technology, different refrigeration and heating modes are selected under different environmental conditions, the evaporative cooling air conditioning unit is applicable to a humid area and a low-humidity area, an energy source is saved, and the efficiency is improved. In addition, a dehumidification solution can kill bacteria like staphylococcocci, streptococci, kebsiella pneumoniae and mycetozoan, so that the quality of air is further improved, and the evaporative cooling air conditioning unit has very good practical value.

Owner:XI'AN POLYTECHNIC UNIVERSITY

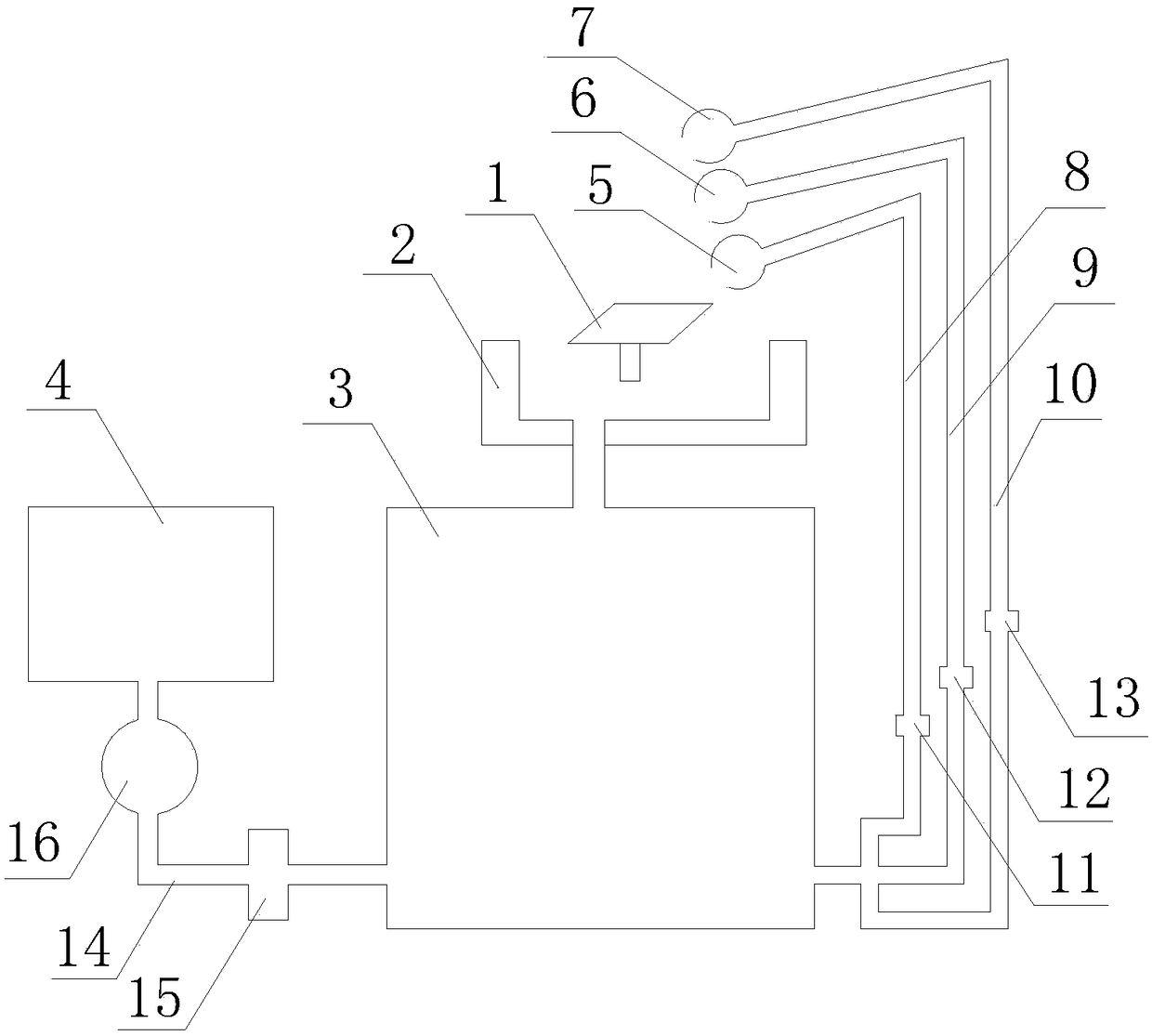

A machine tool temperature control system

ActiveCN106514431BImprove cooling effectHigh trafficMaintainance and safety accessoriesTemperature controlLiquid temperature

The invention discloses a machine tool temperature control system. The machine tool temperature control system comprises a worktable, a liquid collecting box, a cooling box, a temperature sensor, a cooling liquid box and a controller; a machining station is arranged on the worktable, and is provided with a first nozzle, a second nozzle and a third nozzle; the liquid collecting box is arranged below the worktable; the liquid collecting box is opened at the top, and is provided with a first liquid outlet at the bottom; a liquid inlet, a second liquid outlet and a third liquid outlet are formed in the cooling box; the liquid inlet is communicated with the first liquid outlet by a pipeline; the temperature sensor is arranged in the liquid inlet of the cooling box for detecting the temperature of liquid flowing in the cooling box; the cooling liquid box is in pipeline communication with the third liquid outlet through a fourth pipe; an electromagnetic valve and an electronic pump are arranged on the fourth pipe; the controller is communicated with the temperature sensor, the electromagnetic valve and the electronic pump; multiple cooling modes are preset in the controller; and the controller selects the cooling modes according to detecting values of the temperature sensor and / or the change tendency of the detecting values.

Owner:张武昌

Polishing device with cooling function

ActiveCN114473848AImprove cooling effectCool evenlyLapping machinesGrinding feed controlRotational axisChemical reaction

According to the polishing device with the cooling function, a polishing disc is provided with a first disc body and a second disc body which are connected in an up-down attached mode, and an avoiding hole for a sensor to penetrate through is formed in the second disc body; the rotating shaft is connected to the second disc body and used for driving the polishing disc to rotate. The cooling loop is spirally coiled between the first disc body and the second disc body, and cooling liquid can circulate in the cooling loop; a liquid inlet / return port of the cooling loop is communicated with a hose, and the hose penetrates through the shaft penetrating hole of the rotating shaft and then is suitable for being communicated with a cooling liquid tank; the avoiding hole is lapped by the cooling loop, and cooling liquid firstly flows through the cooling loop lapped in the circumferential direction of the avoiding hole; the driving assembly is at least partially arranged on the rotating shaft and used for driving the rotating shaft to rotate. According to the cooling loop, the polishing disc can be circularly cooled, and the influence of heat on the chemical reaction of the polishing liquid is reduced; and the avoiding hole is wrapped by the cooling loop, so that the sensor can be fully cooled, and the problem of non-uniform heat dissipation caused by installation of the sensor is reduced.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

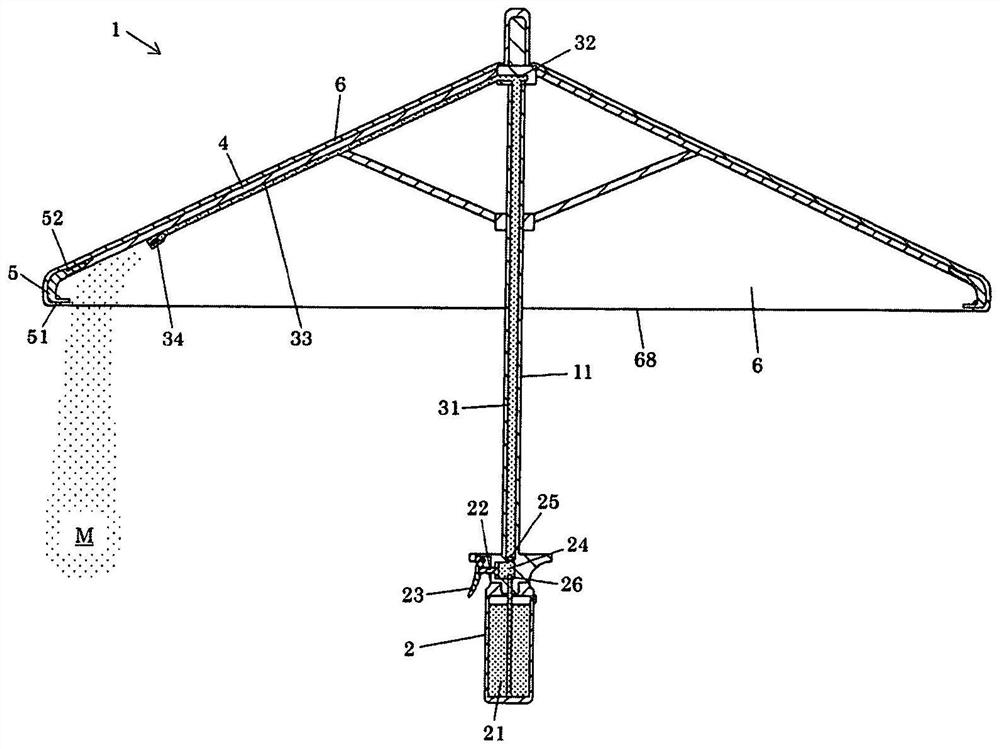

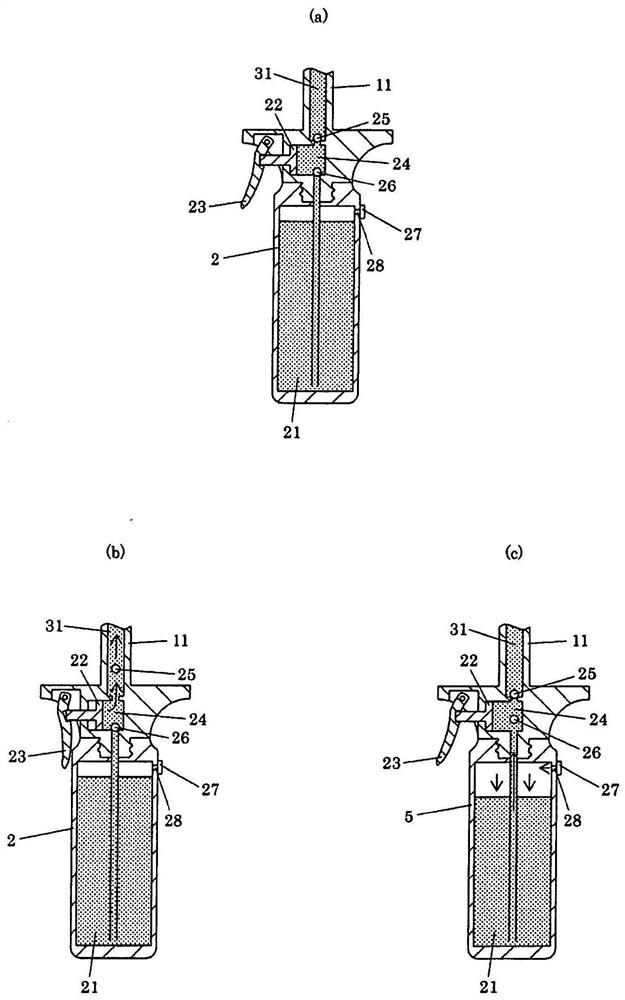

Umbrella suitable as parasol with spray device

ActiveCN110897284BReduce riskBending stabilityWalking sticksUmbrellasThermodynamicsWater storage tank

The present invention provides an umbrella suitable as a parasol equipped with a spraying device which can effectively and stably obtain the cooling sensation generated by the heat of vaporization of water directly and stably even when there is wind, not to mention when there is no wind. An umbrella suitable as a sun umbrella with a spray device has a handle, a middle rod and an umbrella stand, and is suitable for a sun umbrella that can be opened and closed. The spray device includes: a water storage tank installed on the handle and a manual or electric pump; the first water supply pipe arranged along the middle rod; and the second water supply pipe arranged along one or more than two umbrella stands and the nozzle arranged at the front end of the second water supply pipe, the spray An umbrella suitable as a sun umbrella of the device is characterized in that by operating the pump, the water in the water storage tank passes through the first water supply pipe and the second water supply pipe, and becomes The nozzle is sprayed in the form of mist, and the nozzle is located in front of the umbrella buckle member attached to the front end of the umbrella frame.

Owner:土佐企业株式会社

Engine and engine oil cooling device

InactiveCN111140333ASimple structureEasy to operateLubricant conduit arrangementsMachines/enginesElectric machineryWater cooling

The invention discloses and relates to the field of engine cooling, and particularly relates to an engine and engine oil cooling device. The engine and engine oil cooling device comprises a body, andan engine is arranged in the body. An oil inlet is formed in the upper end of the engine, and a cooling cavity is formed in the left end of the engine. A first fixed rod and a second fixed rod are fixedly mounted on the lower end wall of the cooling cavity, and a first connecting rod is hinged to the upper end of the first fixed rod through a first fixed point. A connecting block is fixedly mounted at the front end of the first connecting rod, and a first driving shaft is rotationally mounted in the connecting block. A motor in power connection with the first driving shaft is arranged at the left end of the first driving shaft, and a worm is fixedly mounted on the first driving shaft. A first rotary shaft is hinged to the other end of the first connecting rod, and a worm wheel engaged withthe worm is fixedly mounted at the lower end of the first rotary shaft. An engine cooling assembly and an engine oil cooling assembly of the device are controlled by the same motor, engine cooling isachieved through air cooling, and engine oil cooling is achieved through water cooling.

Owner:广州扬坪机电科技有限公司

A kind of wearable equipment based on composite phase change material and its preparation method

ActiveCN107011872BImprove stress resistanceHigh latent heat of phase changeHeat-exchange elementsProtective garmentPolyesterFiber

The invention discloses wearable equipment based on a composite phase change material and a production method of the wearable equipment. The production method incudes: preparing the composite phase change material, performing microencapsulation on the composite phase change material, performing microcapsule formaldehyde removing, performing cellular board encapsulation and performing fiber cloth and silk encapsulation. The production method has the advantages that the composite phase change material prepared by the eutectic mixture of two organic phase change materials as the core material, melamine-formaldehyde prepolymer is allowed to have polymerization reaction with an emulsion so as to perform microcapsule wrapping on the core material, microcapsules are loaded into a polyester fiber cellular board to increase the pressure resistance of the microcapsules so as to prevent the deformation and leakage of the microcapsules, the finally obtained wearable equipment is a polyester fiber cellular board sleeved with fiber cloth and silk, the phase-change-material microcapsules are loaded into the holes of the cellular board, and the microcapsules use melamine resin generated by melamine and formaldehyde as the wall material and the composite phase change material as the core material and is high in phase change latent heat, stable in chemical performance, non-corrosive and capable of achieving zero energy consumption when being used in a high-temperature environments in summer.

Owner:SOUTHEAST UNIV

Polishing disc and its cooling device

ActiveCN105290956BReduce the temperatureImprove temperature distribution uniformityLapping toolsReturn channelMechanical engineering

The invention discloses a cooling device of the polishing disk. The cooling device is applied to the polishing disk and comprises a cooling water inlet, cooling water outlets, an annular liquid return tank, liquid return channels and cooling water grooves. The cooling water inlet and the cooling water outlets are formed in the polishing disk. The annular liquid return tank and the liquid return channels are formed in the polishing disk, one end of each liquid return channel is communicated with the liquid return tank, and the other ends of the liquid return channels are communicated with the cooling water outlets. The cooling water grooves are formed in the polishing disk and located in the area, wrapped by the liquid return tank, of the polishing disk, and the cooling water grooves are evenly distributed in a branch shape. Each cooling water groove comprises a main groove body and side groove bodies, wherein one end of the main groove body is communicated with the cooling water inlet, the other end of the main groove body is communicated with the liquid return tank, one ends of the side groove bodies are communicated with the main groove body, and the other ends of the side groove bodies are communicated with the liquid return tank. The invention further discloses the polishing disk with the cooling device.

Owner:ACM RES SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com