Heat radiation method of power supply

A heat dissipation method and power supply technology, applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problems of complicated installation, labor cost, high price, increase cooling strength and ensure stability running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments.

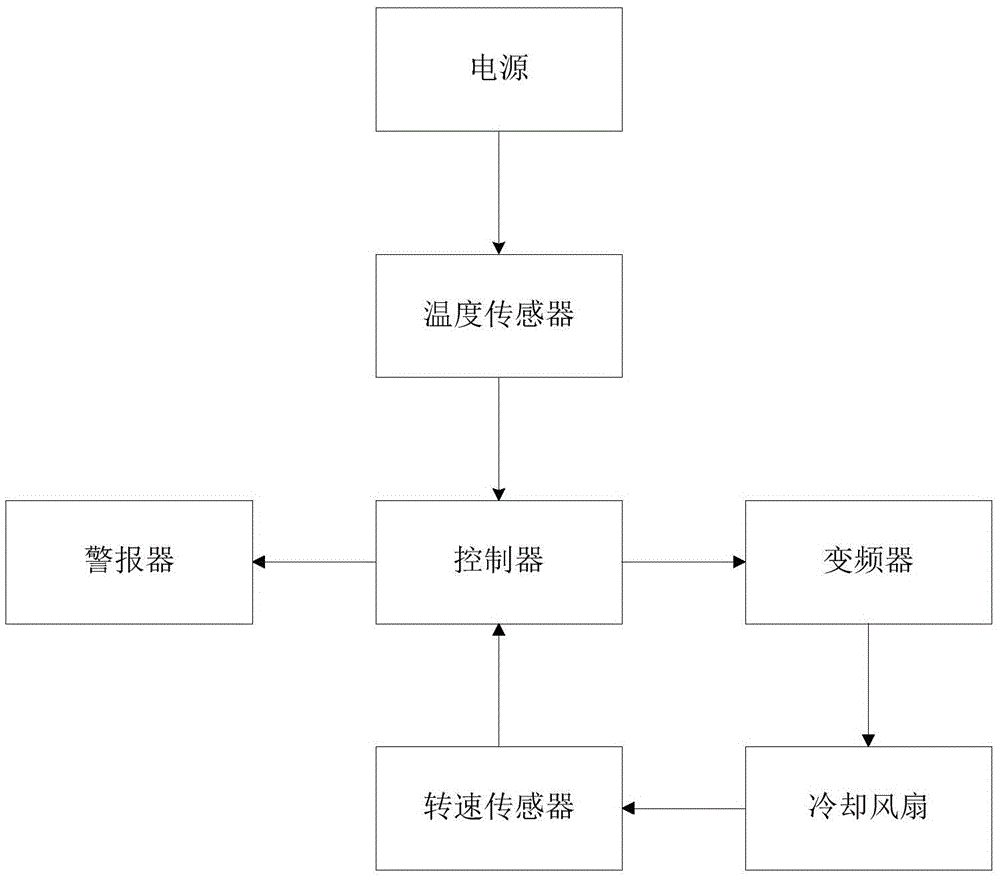

[0028] In one embodiment of the present invention, as figure 1 As shown, the power cooling device provided includes: temperature sensor, controller, cooling fan, speed sensor;

[0029] The heat dissipation device of the power supply uses a temperature sensor to measure the room temperature and the temperature of the power supply, and sends the measured temperature information to the controller; at the same time, it uses the speed sensor to measure the speed of the cooling fan, and sends the measured speed information to the controller; and the The controller can judge and adjust the rotating speed of the cooling fan in time according to the temperature information and the rotating speed information.

[0030] Among them, the temperature sensor is used to measure the actual working temperature of the power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com