High efficiency and low cost thermoelectric module and making process thereof

A thermoelectric component, low-cost technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices using only the Peltier or Seebeck effect, etc. Difficulty and other problems, to achieve the effect of increasing current, heat transfer area and heat transfer efficiency, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

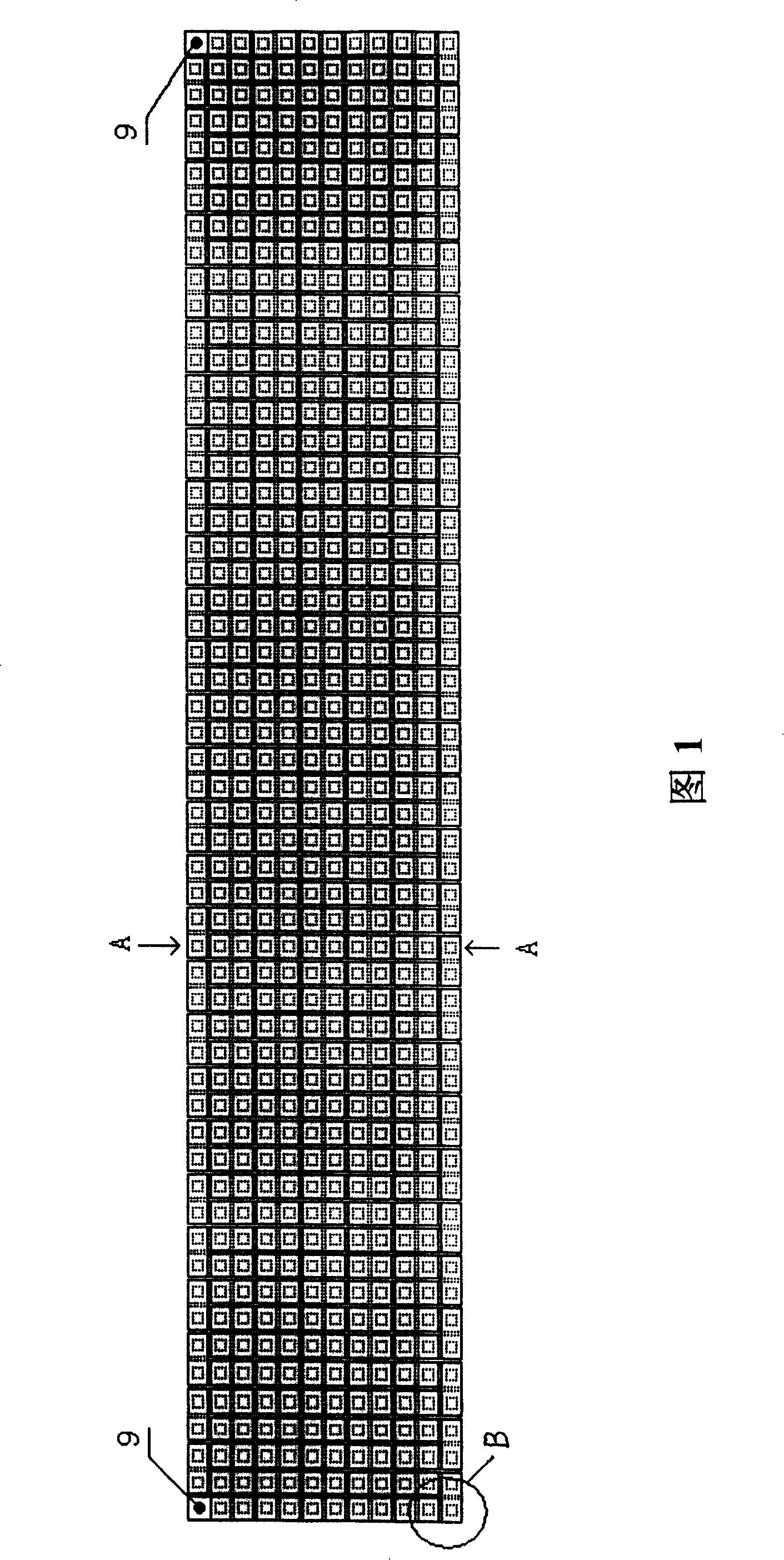

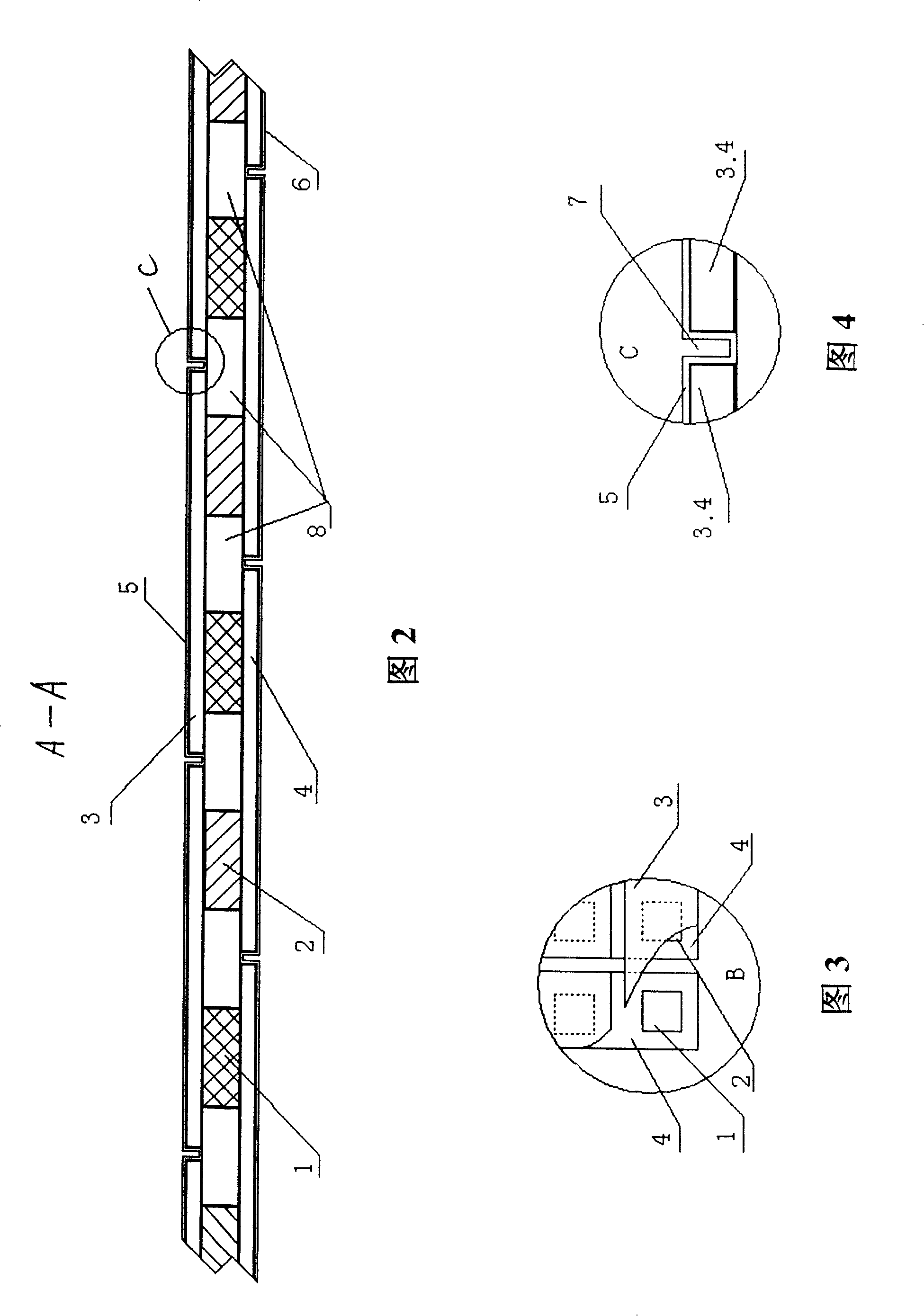

[0024] Referring to the drawings, the high-efficiency, low-consumption, low-cost thermoelectric component of the present invention is composed of a P-type semiconductor thermoelectric element 1, an N-type semiconductor thermoelectric element 2, an upper deflector 3, a lower deflector 4, an upper insulating and heat conducting layer 5, and a lower insulating layer. The heat-conducting layer 6 and the insulating material 8 filled in the remaining space between the upper and lower insulating and heat-conducting layers are composed of the two ends of the P and N semiconductor thermoelectric elements in close contact with one side of the deflector, and the deflector The other side is in close contact with the insulating and heat-conducting layer, and is connected and fixed. The P-type semiconductor thermoelectric element 1 and N-type semiconductor thermoelectric element 2 of the present invention are of sheet type, and the ratio of the cross-sectional area to the thickness is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com