Nickel-making oxygen-enriching top-blowing immersion spray gun with longer service life

An oxygen-enriched top-blowing and immersion technology, applied in furnaces, lighting and heating equipment, furnace components, etc., can solve problems such as insufficient coal mixing, burning of mixing chamber, boiler explosion, etc., to improve production efficiency, Enhanced cooling and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

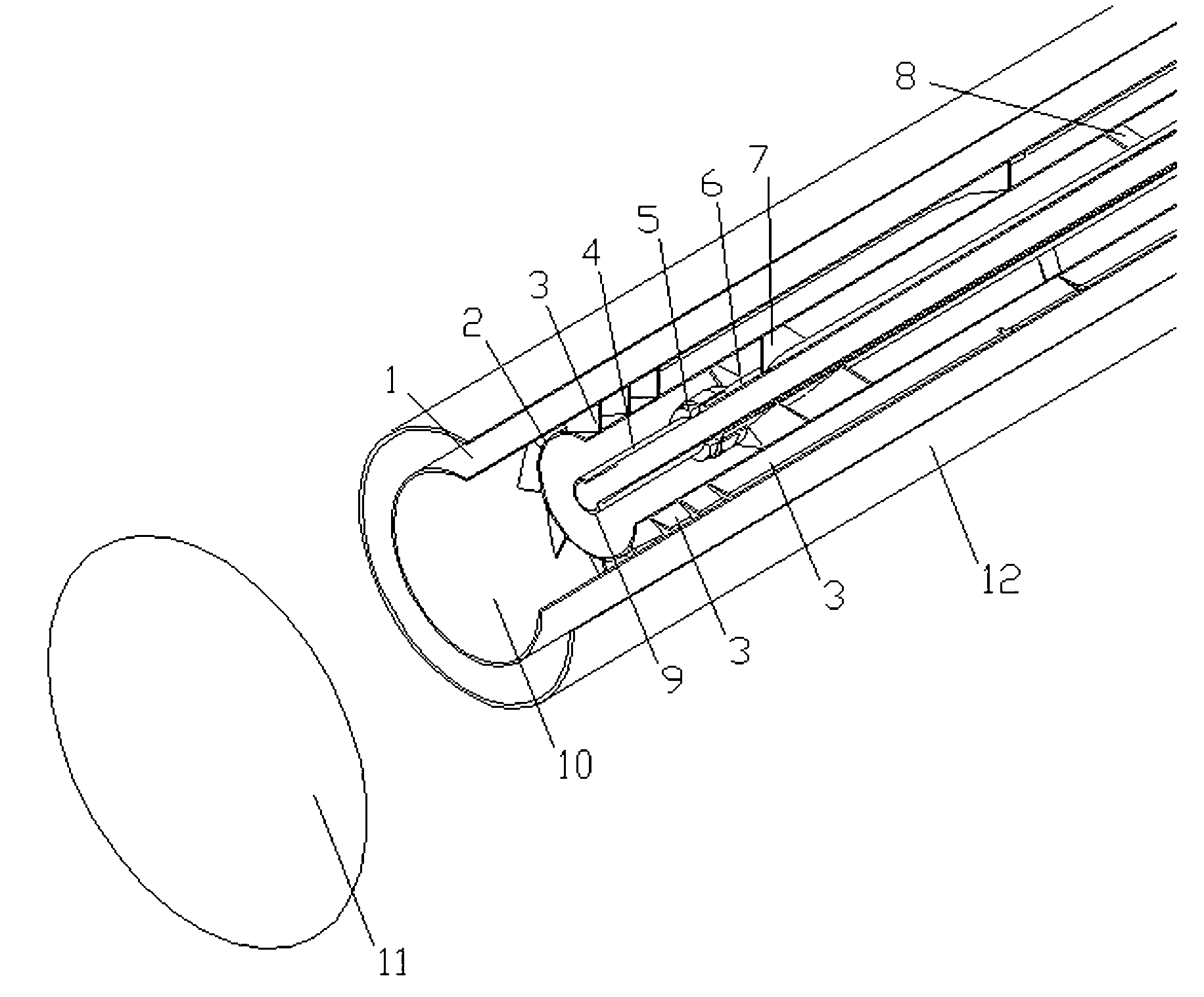

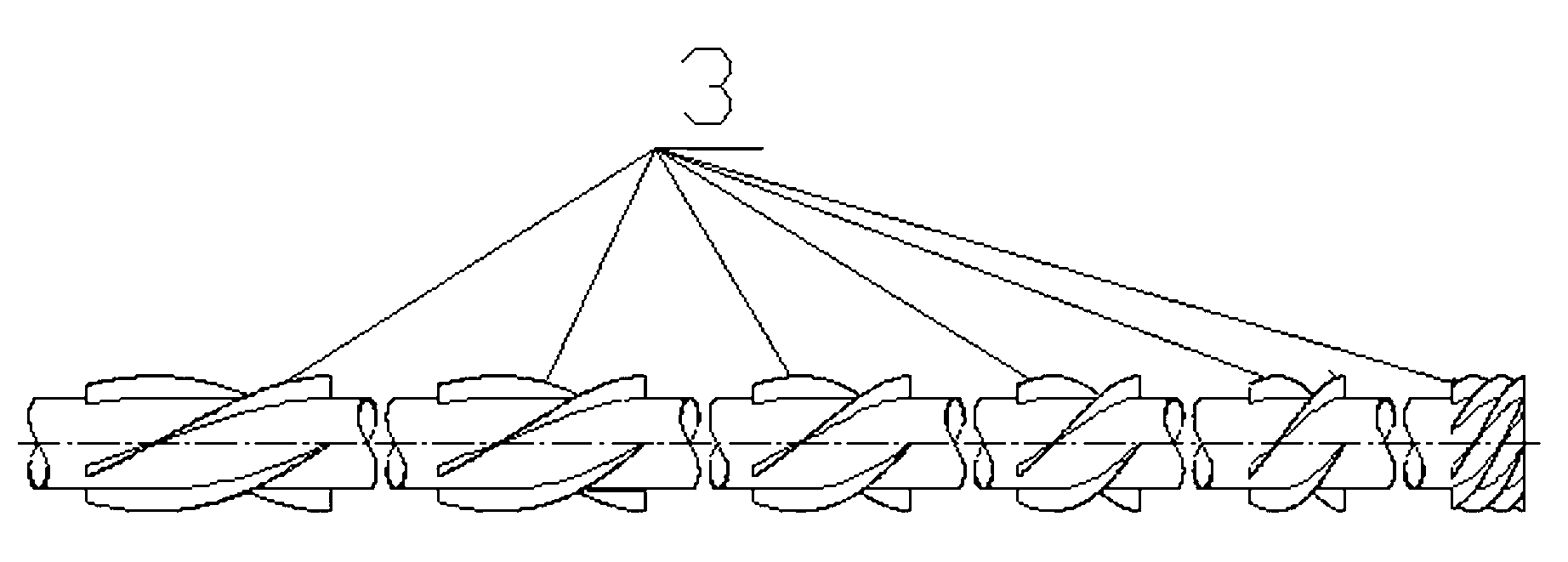

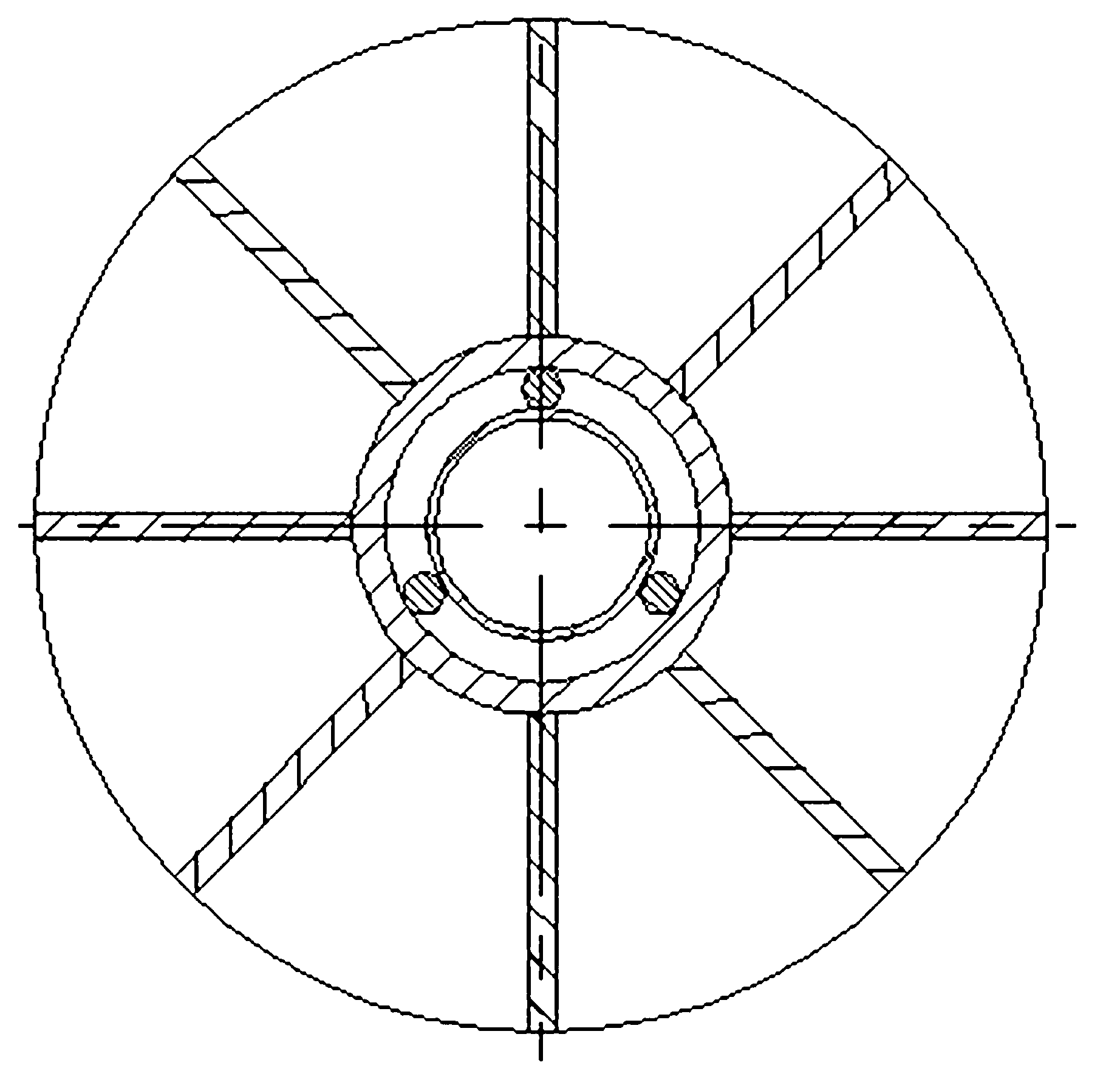

[0021] according to figure 1 Shown is a nickel-oxygen-enriched top-blown submerged spray gun with improved service life, including a spray gun cover tube 12, a spray gun air duct 1, a spray gun oxygen tube 2, a fuel tube 4 and a mixing chamber 10, a spray gun cover tube 12, and a spray gun air duct 1. The diameters of the oxygen pipes 2 of the spray gun are arranged coaxially with successively reduced diameters, the mixing chamber 10 is arranged at the outlet end of the spray gun, and a multi-stage cyclone 3 is provided between the air pipe 1 of the spray gun and the oxygen pipe 2 of the spray gun, such as Figure 2 to Figure 3 Shown: multi-stage swirl flow, 3 is a vane swirler with six stages in total, stages 1-5 have four blades, stage 6 has eight blades, and the inlet angles of the six-stage blades are 18.7°, 20.5°, and 26.6° respectively . The single-stage swirler 7 is a blade-type swirler with four blades, the blade inlet angle is 10.5°, and the outlet angle is 43.3°. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com