A machine tool temperature control system

A technology of temperature control system and machine tool, applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve problems such as hierarchical control, selection of cooling mode, tool damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

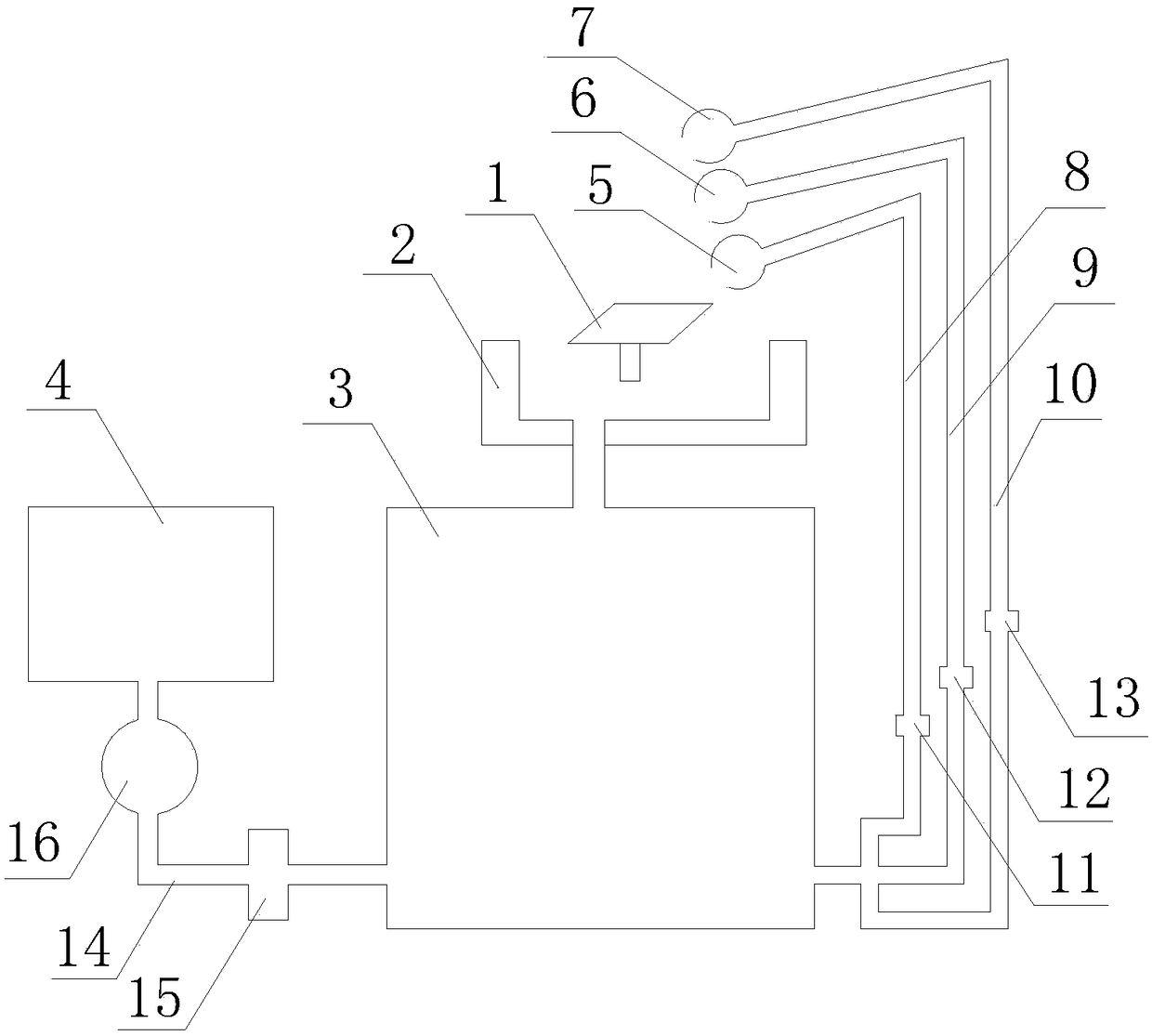

[0024] Such as figure 1 as shown, figure 1 It is a machine tool temperature control system proposed by the present invention.

[0025] refer to figure 1 , the machine tool temperature control system that the present invention proposes, comprises: workbench 1, effluent tank 2, cooling tank 3, temperature sensor, coolant tank 4 and controller;

[0026] A processing station is provided on the workbench 1, and a first nozzle 5, a second nozzle 6 and a third nozzle 7 are arranged at the processing station;

[0027] The liquid accumulation tank 2 is arranged under the workbench 1, and is used to collect the liquid produced during the cooling process of the processing station. The liquid accumulation tank 2 has an opening at the top and a first liquid outlet at the bottom; a filter is provided at the first liquid outlet. The net is used to filter the waste in the liquid to prevent the waste in the liquid from flowing to the processing station again, which will affect the machining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com