Counterweight telescopic oil-containing waste gas filtering equipment

A waste gas filtration and telescopic technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high cleaning difficulty, easy to be blocked, difficult to handle, etc., to ensure service life and ensure transparency performance, improve the effect of filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

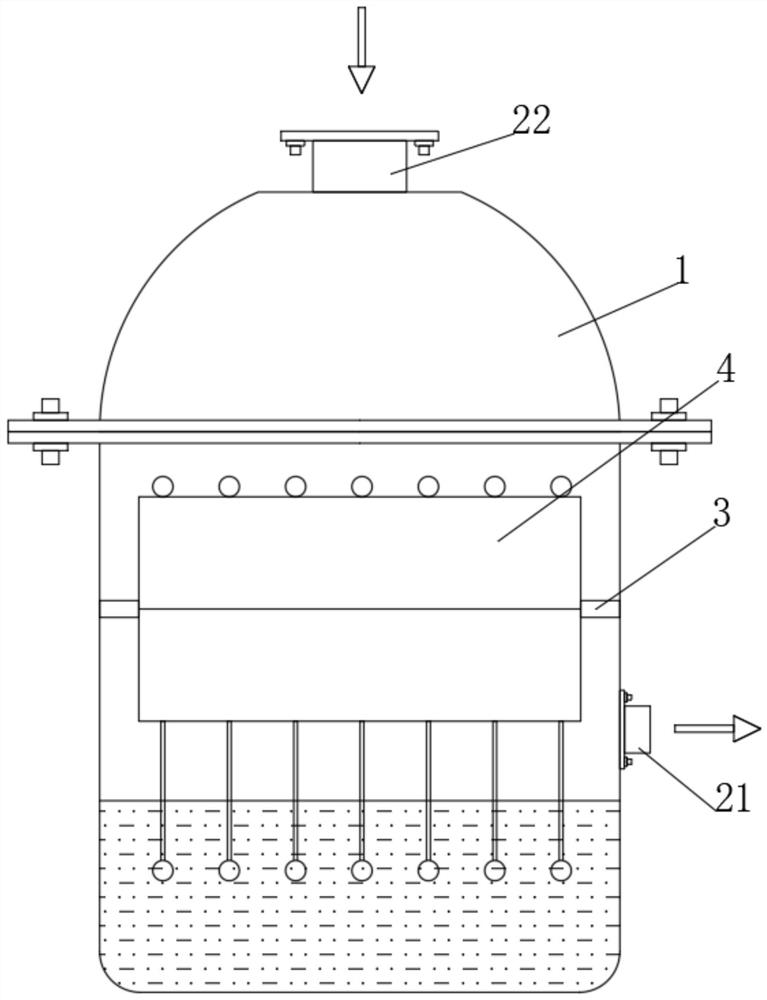

[0041] see figure 1 , a counterweight telescopic oily waste gas filtering device, comprising a device body 1, an air outlet 21 is fixedly connected to the right end of the device body 1, an air inlet 22 is fixedly connected to the upper end of the device body 1, and the air outlet 21 and the air inlet 22 are connected to each other. The equipment body 1 is connected, and the bottom end of the equipment body 1 is filled with an oil decomposing agent, and the air outlet 21 is higher than the liquid level of the oil decomposing agent. The middle parts of the left and right ends of the equipment body 1 are equipped with an electric rotating shaft 3, two electric rotating shafts 3 A plurality of interlayer self-cleaning filter plates 4 are fixedly connected between them.

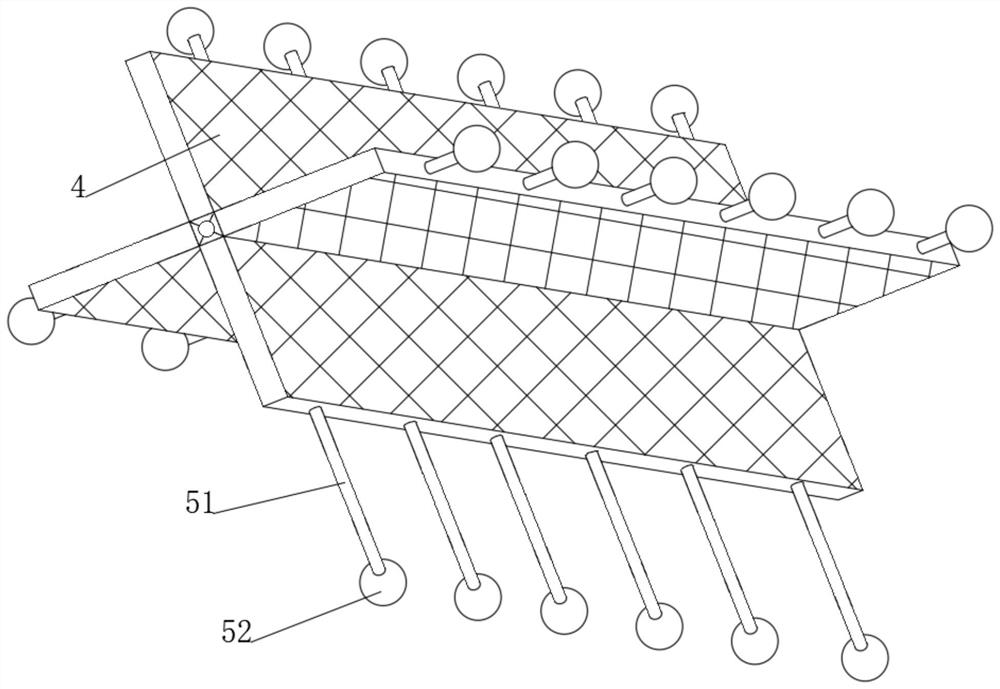

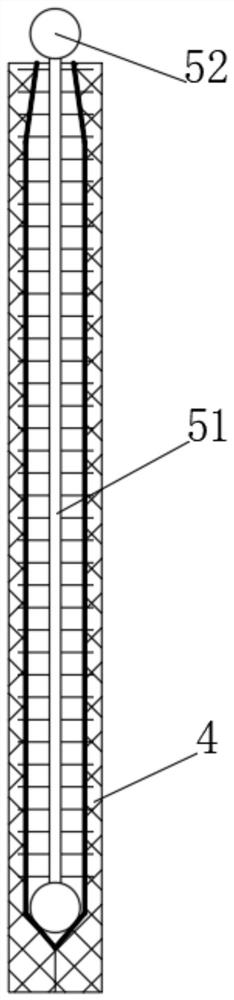

[0042] see Figure 2-3 , the interlayer self-cleaning filter plate 4 is excavated with a narrow-mouth inlay groove inside, and a counterweight telescopic brush is inserted movable inside the narrow-mouth inlay g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com