Patents

Literature

45results about How to "Improve premix effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

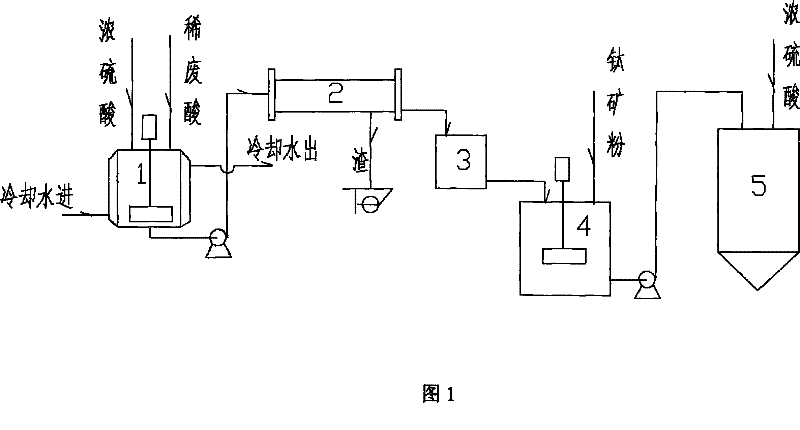

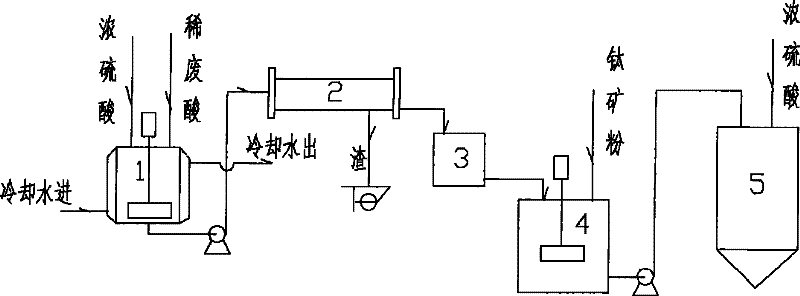

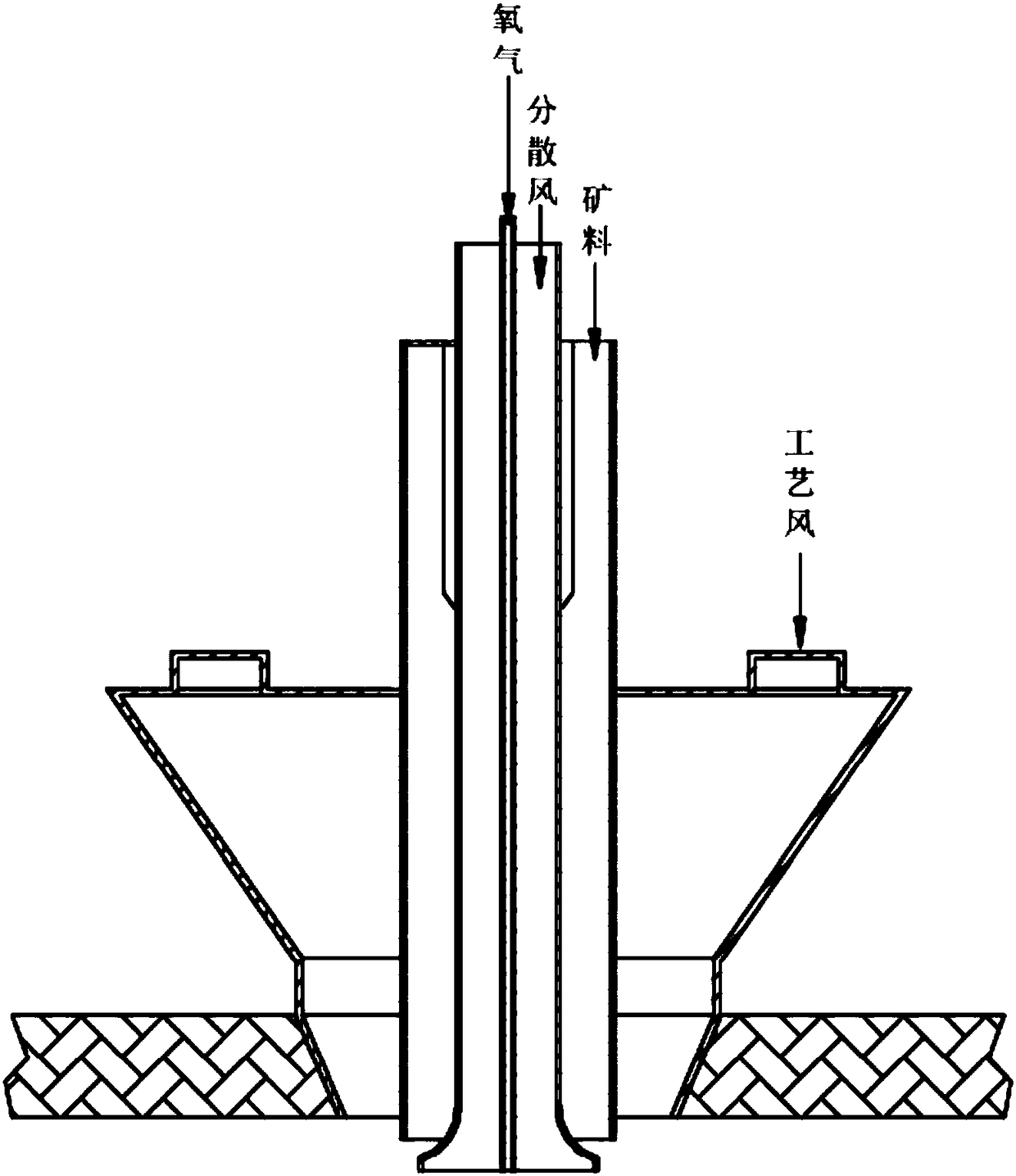

Titanium ore acidolysis method through sulfuric acid process

The invention relates to an improved method for the titanium ore acidolysis through sulfuric acid in the process of producing titanium white through a sulfuric acid process. The method is characterized in that: the method comprises the following steps: firstly premixing dilute waste acid produced by titanium white production after concentration and trash extraction with the titanium ore; and then adding the premixed ore slurry into an acidolysis pot, and then adding concentrated sulfuric acid so as to initiate a main reaction through the dilution heat produced by the added concentrated acid. The method has the advantages of: 1) improving the reutilization amount of titanium white waste acid and reducing the cost of concentrated waste acid; 2) removing a sulfuric acid cooling link so as to simplify the operation; 3) improving the operational conditions of premixing and acidolysis so as to reduce the risk of technical accidents; and 4) strengthening the premixing intensity, improving the premixing effect, so that the acidolysis reaction is sufficient and the acidolysis rate is remarkably improved.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

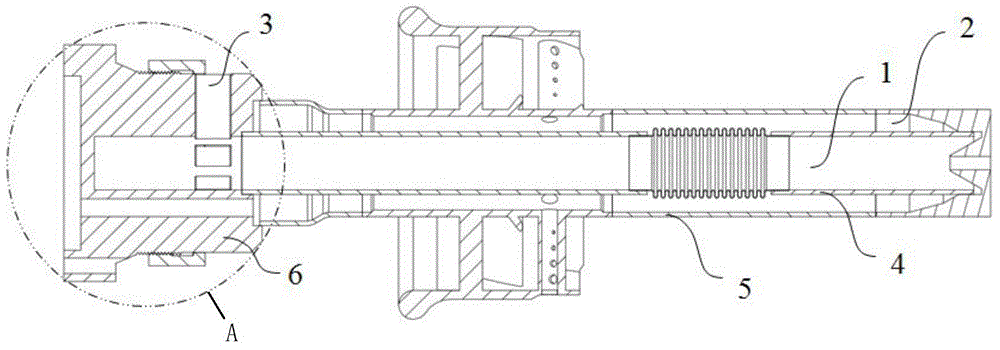

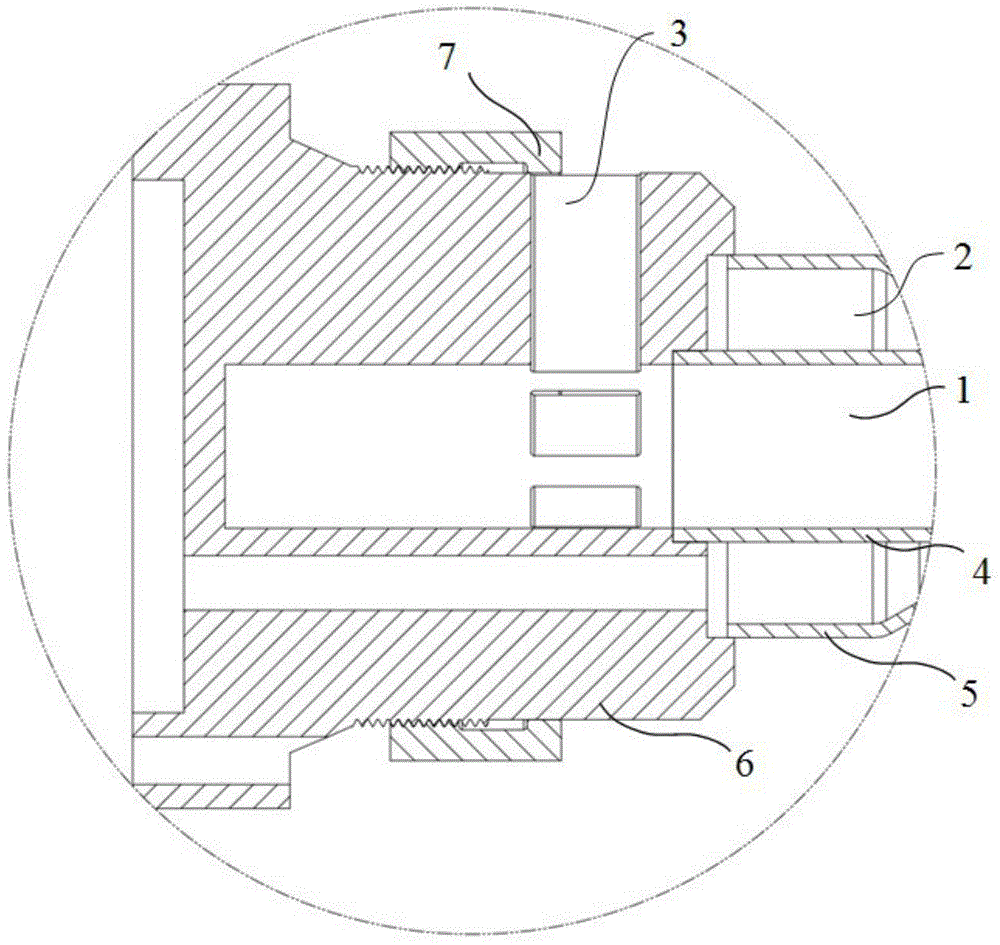

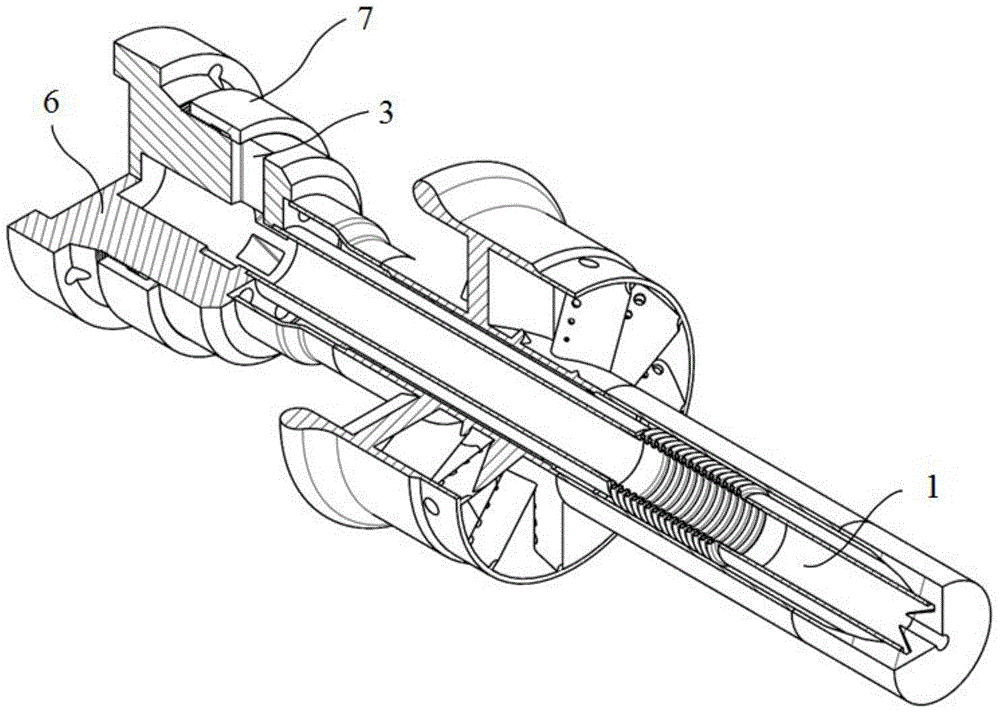

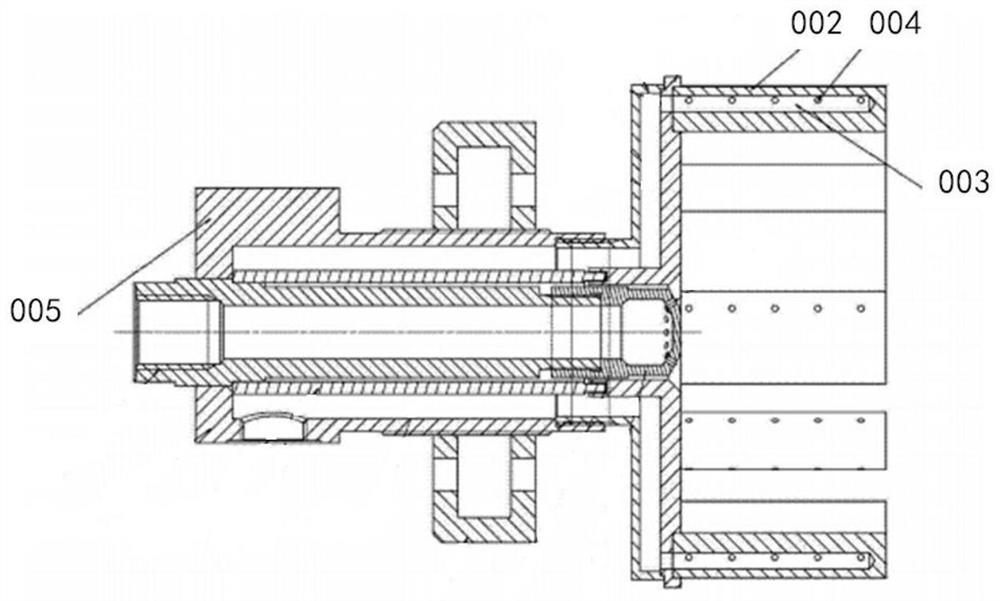

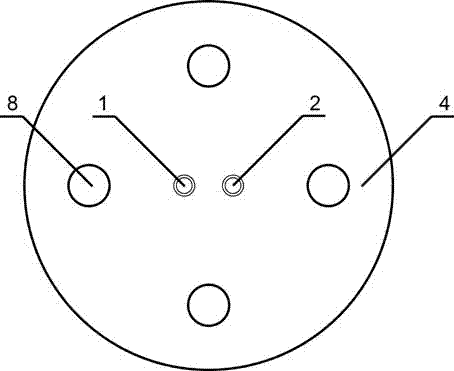

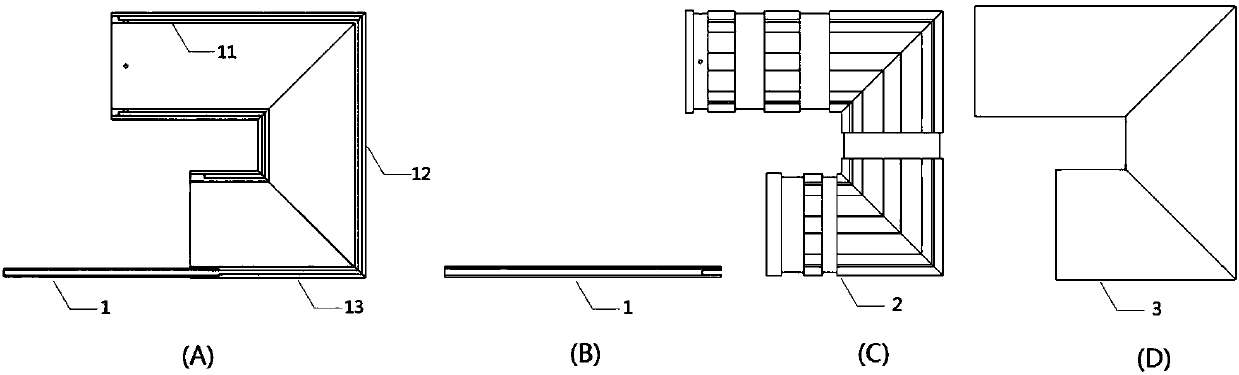

Air inlet structure for fuel nozzle of gas turbine

ActiveCN104456624ARealize stepless speed changeImprove reliabilityContinuous combustion chamberInlet channelMixing effect

The invention relates to the technical field of gas turbines, and provides an air inlet structure for a fuel nozzle of a gas turbine. The fuel nozzle comprises a center air channel and a fuel cavity which are communicated with each other, and the center air channel is used for connecting the air into the fuel cavity. A nozzle hanging flange is arranged at one end of the center air channel, and the nozzle hanging flange is provided with air inlet channels used for connecting the air into the center air channel. The nozzle hanging flange is movably sleeved with an adjusting sleeve, and the adjusting sleeve is used for limiting the sizes of openings of the air inlet channels through axial movement. By axially adjusting the adjusting sleeve, the flow of the air entering the center air channel can be adjusted, hence, it is guaranteed that fuel and air have a good pre-mixing effect, tempering can be prevented from happening to a nozzle outlet, and the reliability of the nozzle is improved; in addition, stepless speed change of the gas turbine can be achieved through the adjusting sleeve.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

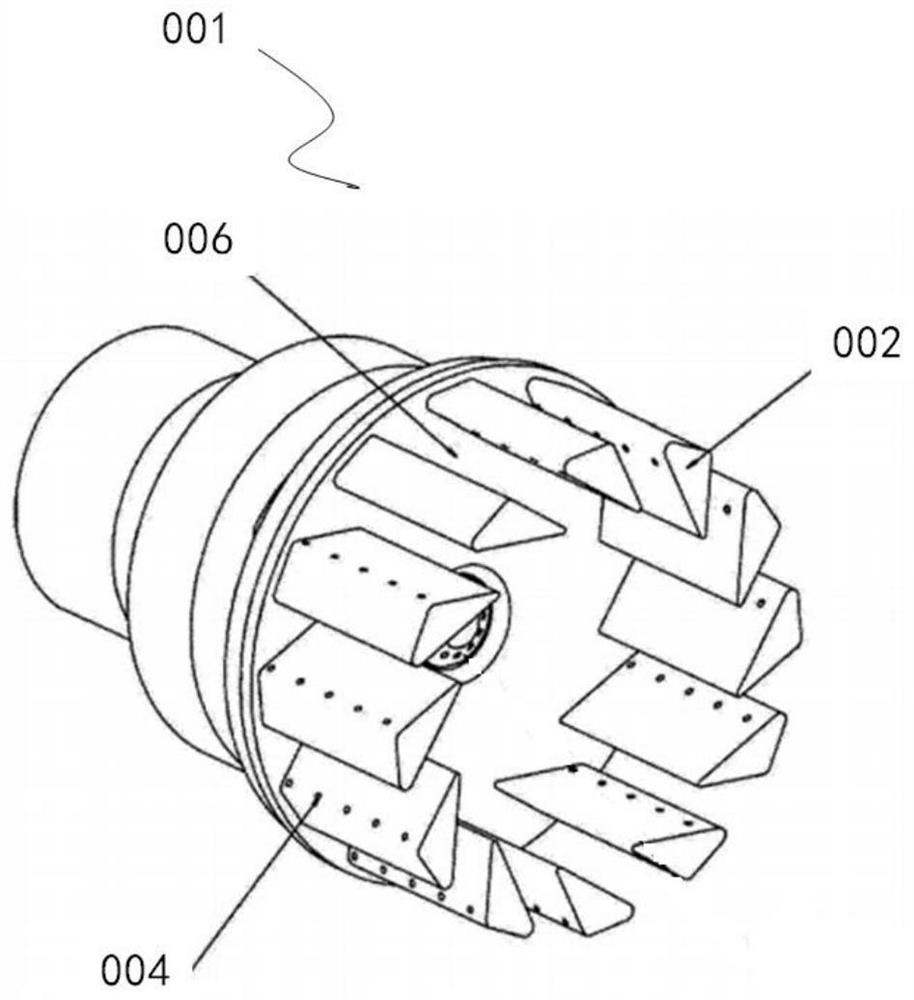

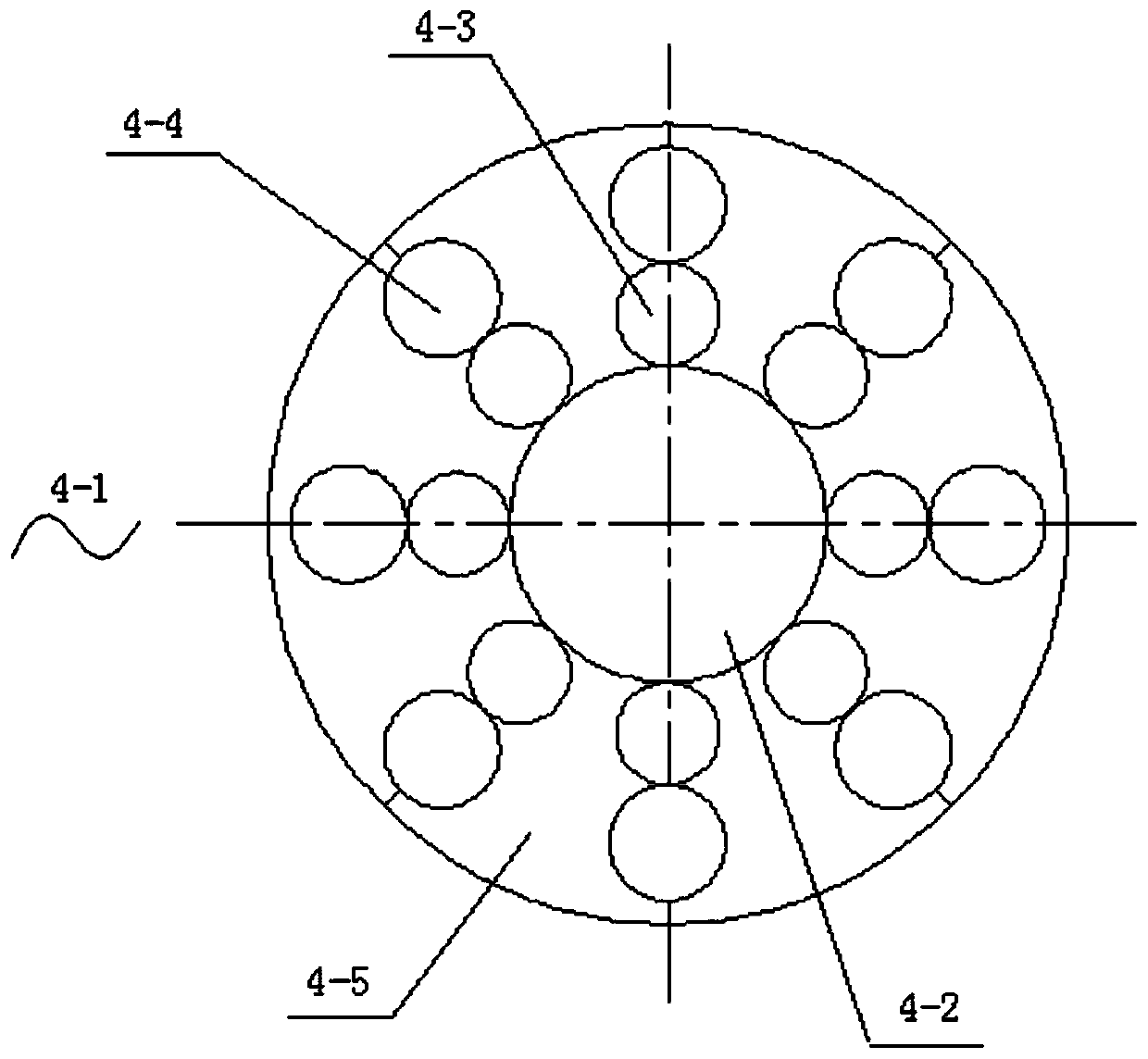

Gas turbine combustor nozzle and method for premixing fuel and air in nozzle

ActiveCN113091094AControl Premix UniformityPrecise adjustment of air volumeContinuous combustion chamberCombustorMechanics

The invention provides a gas turbine combustor nozzle and a method for premixing fuel and air in the nozzle. The gas turbine combustor nozzle comprises a fuel conveying header pipe, fuel flow channels and fuel and air premixing pipes. The fuel conveying header pipe is provided with a plurality of fuel outlet holes, and each fuel outlet hole corresponds to at least one fuel flow channel. The multiple fuel and air premixing pipes are arranged and provided with fuel spray holes. Fuel enters the fuel conveying header pipe, enters the fuel flow channels through the fuel outlet holes, enters the fuel and air premixing pipes through the fuel spray holes and is mixed with air entering the fuel and air premixing pipes in advance to form a mixture, and the mixture is sprayed out of the fuel and air premixing pipes. According to the gas turbine combustor nozzle and the method for premixing the fuel and the air in the nozzle, the whole nozzle has good fuel and air premixing uniformity.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

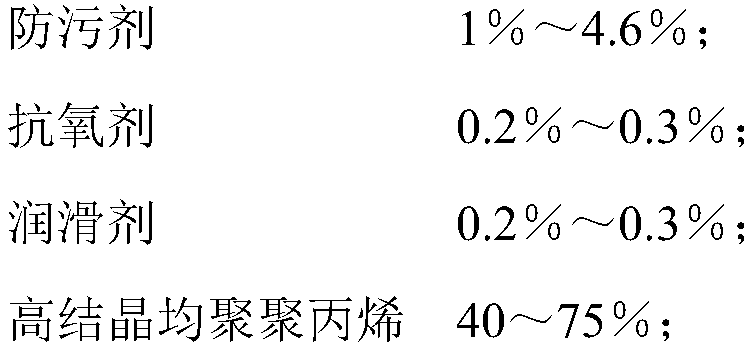

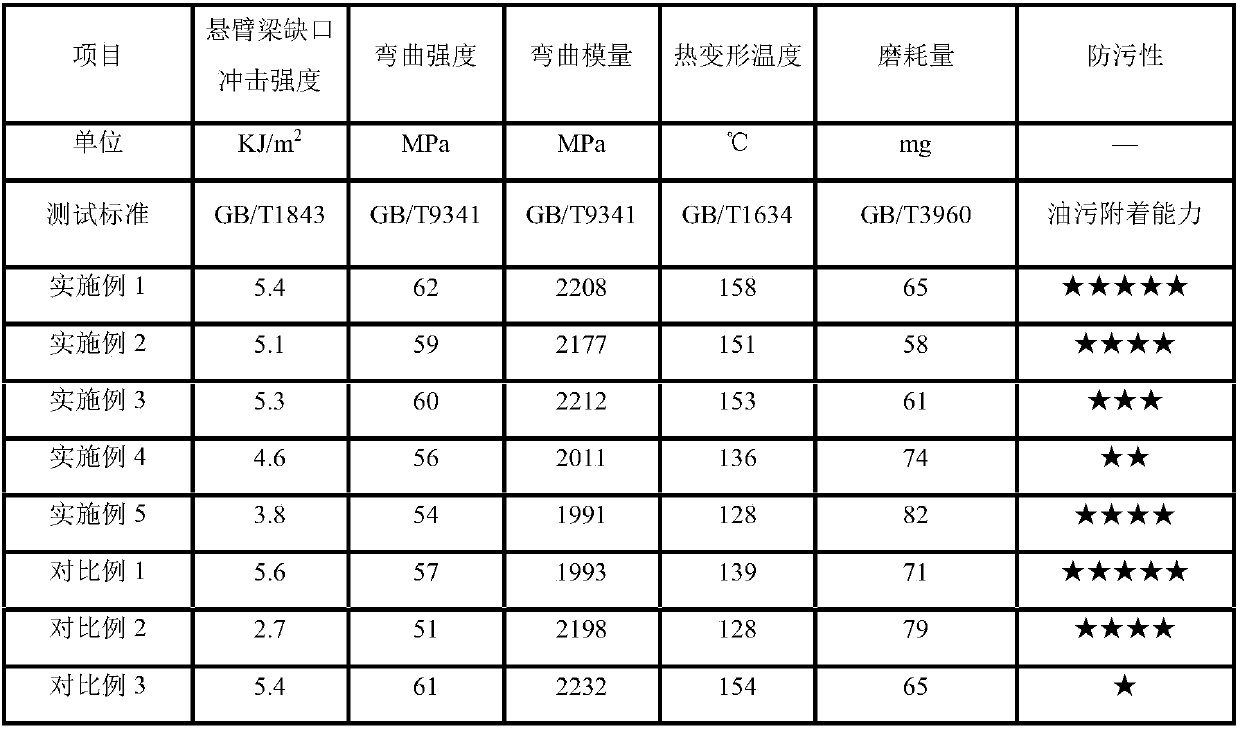

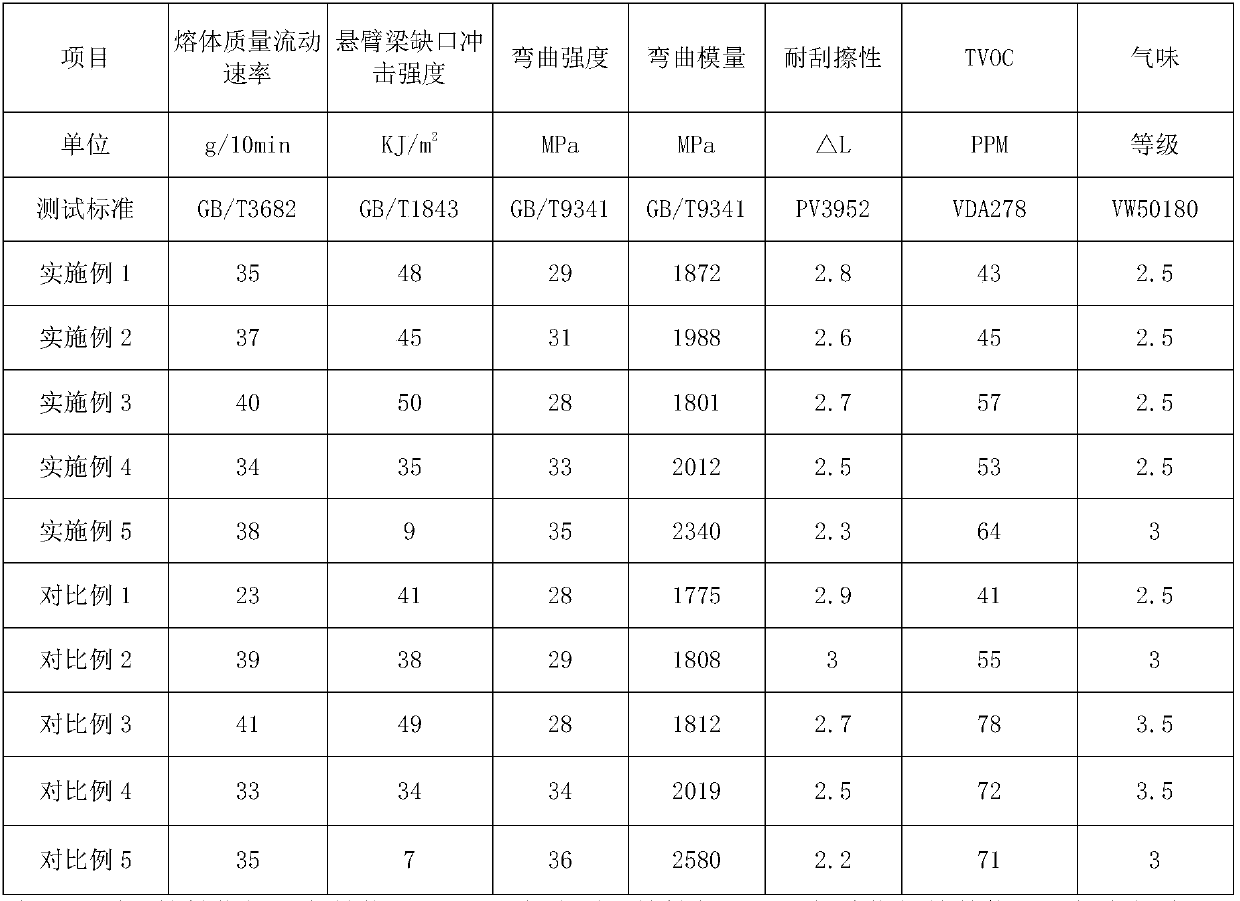

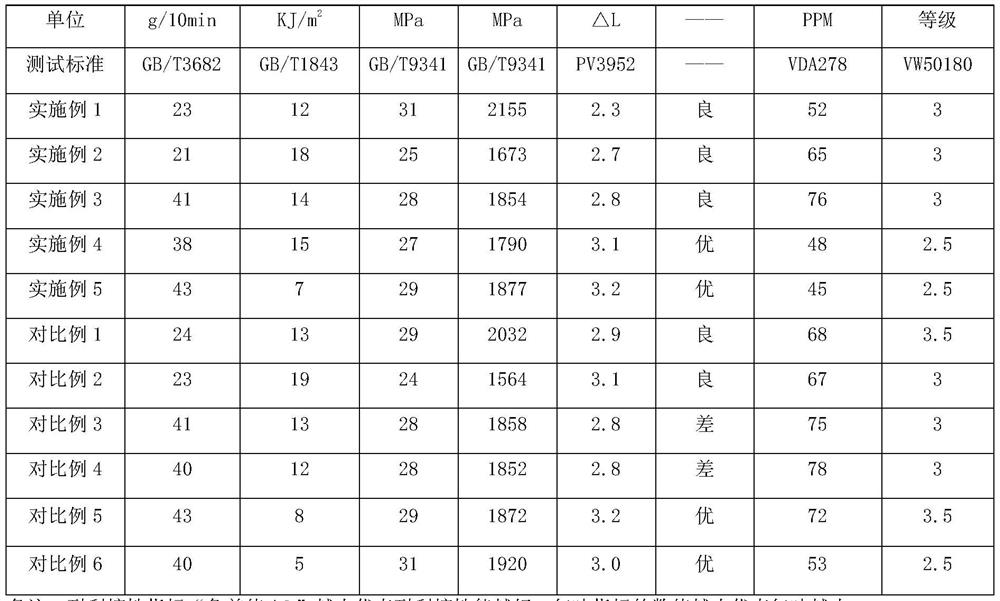

Pollution-resistance high-temperature-resistance polypropylene material and preparation method thereof

The invention belongs to the technical field of polymer composite material modification, and particularly relates to a pollution-resistance high-temperature-resistance polypropylene material and a preparation method thereof. The polypropylene material is characterized in that high-crystallization homopolymer polypropylene is taken as a basic component, polyketone resin is added to improve the wearresistance and mechanical performance of the material, barium sulfate masterbatch is taken as a filling agent to reduce dust pollution, a compatibilizer is added to improve the bonding force betweenraw materials to improve the mechanical performance of the material, organic group modified ultrahigh molecular weight polyorganosiloxane is taken as an antifouling agent to improve the water and oilresistance and the wear resistance of the material, and the anti-ageing performance of the material is improved by adopting an antioxidant. The material has the advantages of easy processing, high glossiness, high wearing resistance, pollution resistance, easy dyeing, excellent physical mechanical performance and the like, the demands by household electrical appliance products and kitchen electrical appliances on housing materials thereof in severe environments can be completely met, and the material can be widely applied to the production of plastic spare parts which need to slide or rotate in the fields of machinery, building materials, sports and the like.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

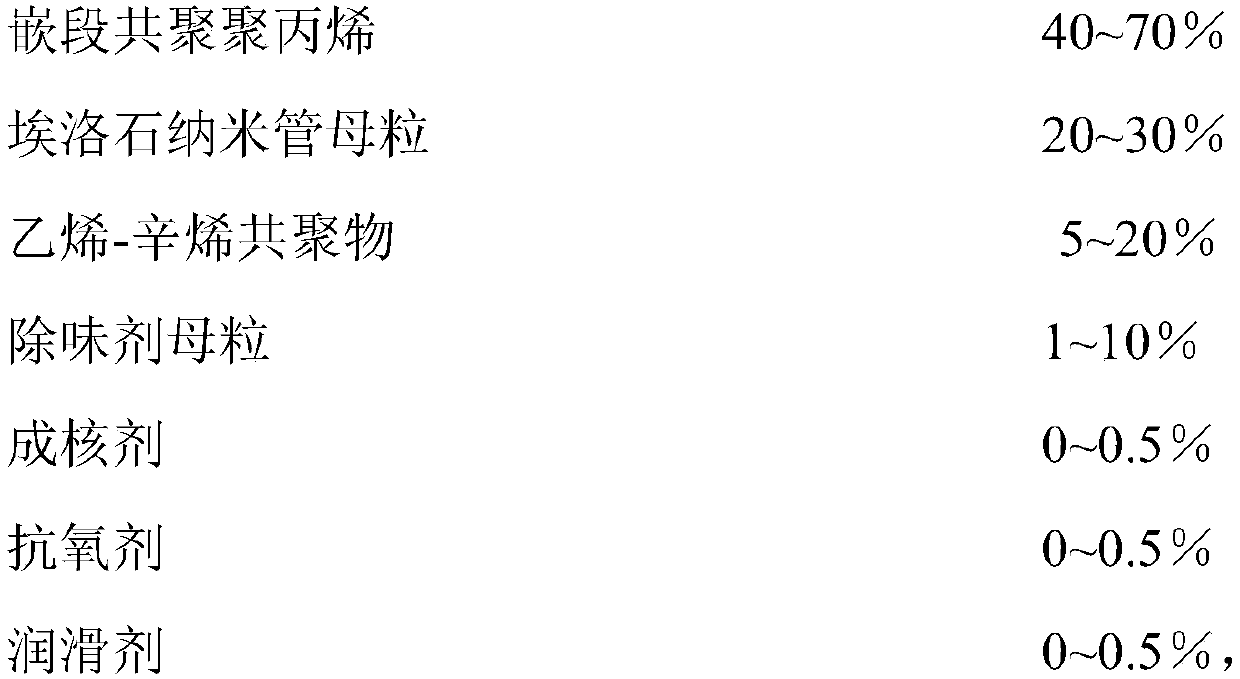

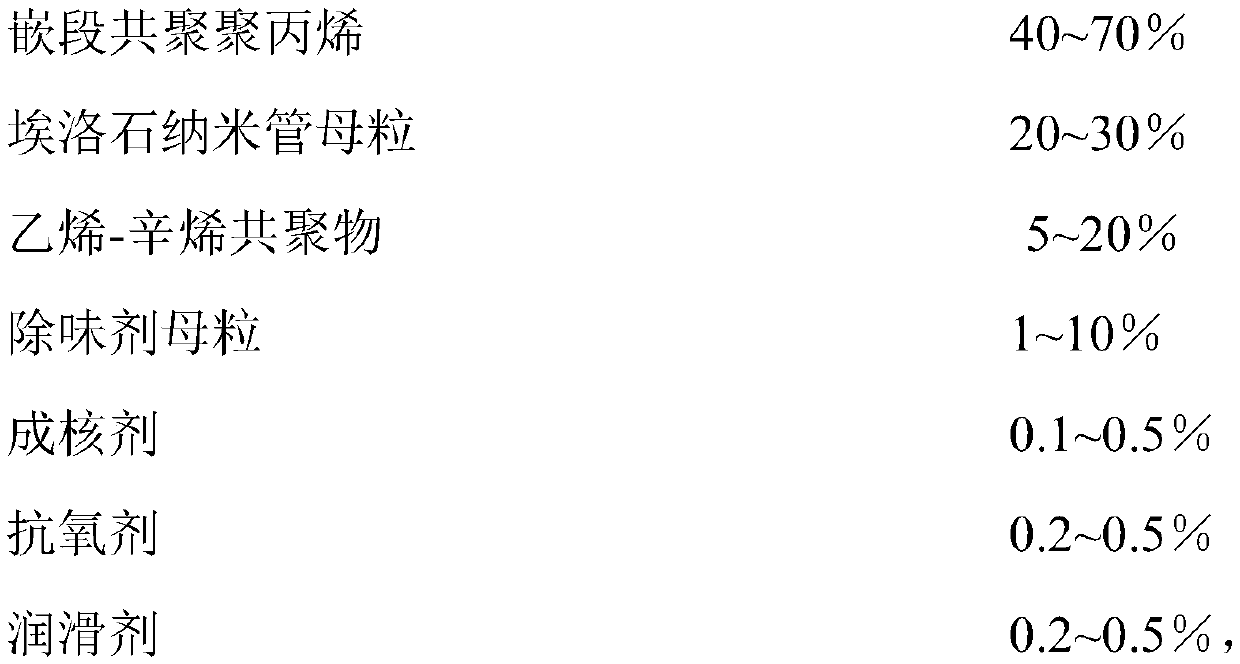

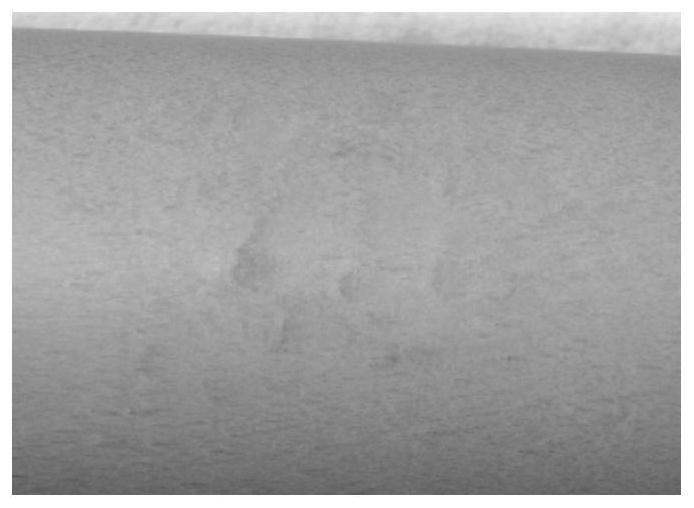

Low-odor polypropylene material for automobile interior decoration and preparation method and application thereof

The invention discloses a low-odor polypropylene material for automobile interior decoration and a preparation method and application thereof. The low-odor polypropylene material for automobile interior decoration is prepared from the following components in percentage by mass: 40 to 70 percent of block copolymer polypropylene, 20 to 30 percent of halloysite nanotube masterbatch, 5 to 20 percent of an ethylene octene copolymer, 1 to 10 percent of deodorant masterbatch, 0 to 0.5 percent of a nucleating agent, 0 to 0.5 percent of an antioxidant and 0 to 0.5 percent of a lubricant. According to the low-odor polypropylene material for automobile interior decoration, block copolymerized polypropylene is used as a resin base material, and is modified by adding the halloysite nanotube masterbatchand the deodorant masterbatch, thereby improving the scratch resistance of the polypropylene material and reducing the volatility and odor. The low-odor polypropylene produced by the invention can bewidely used in the automobile field.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

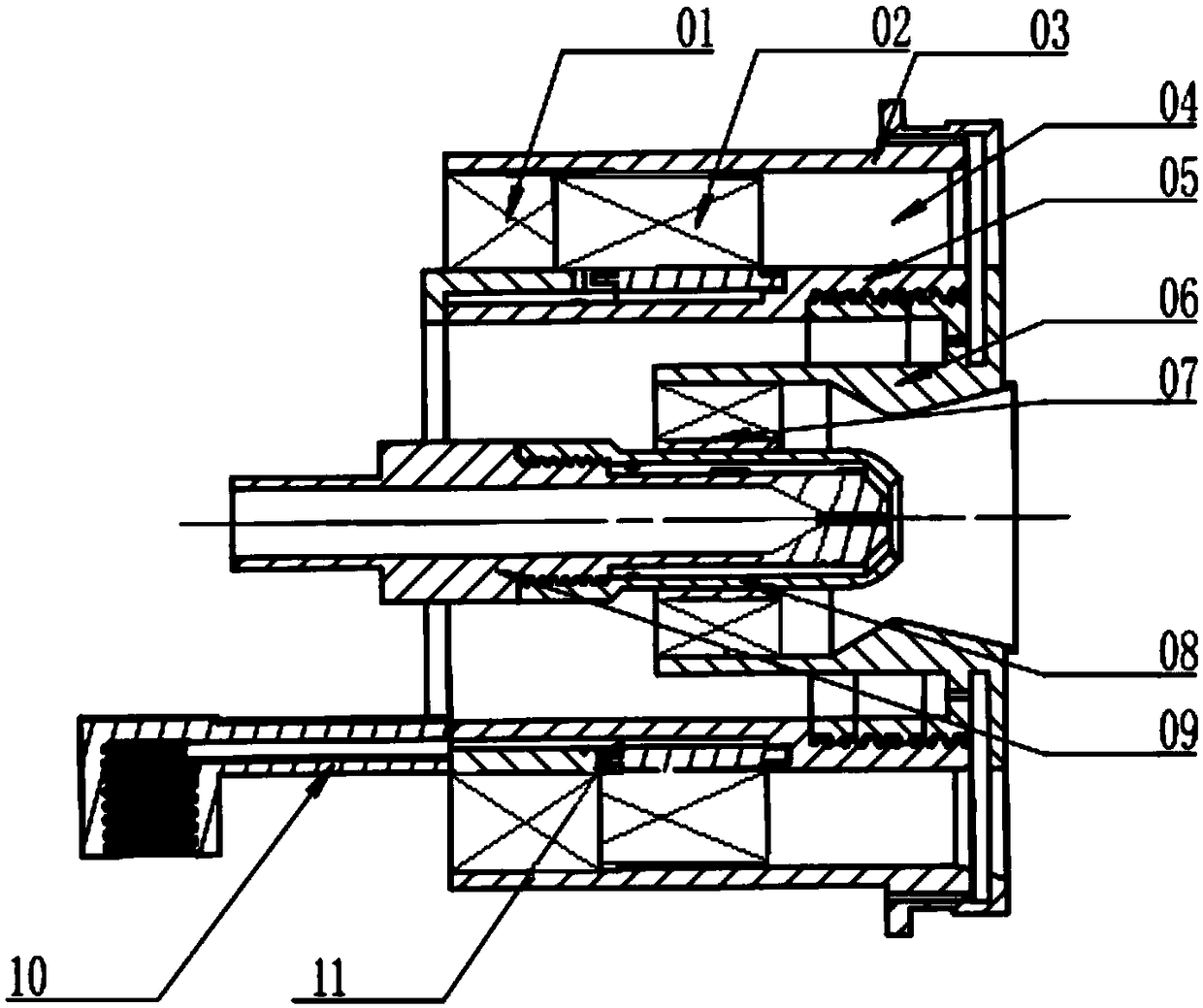

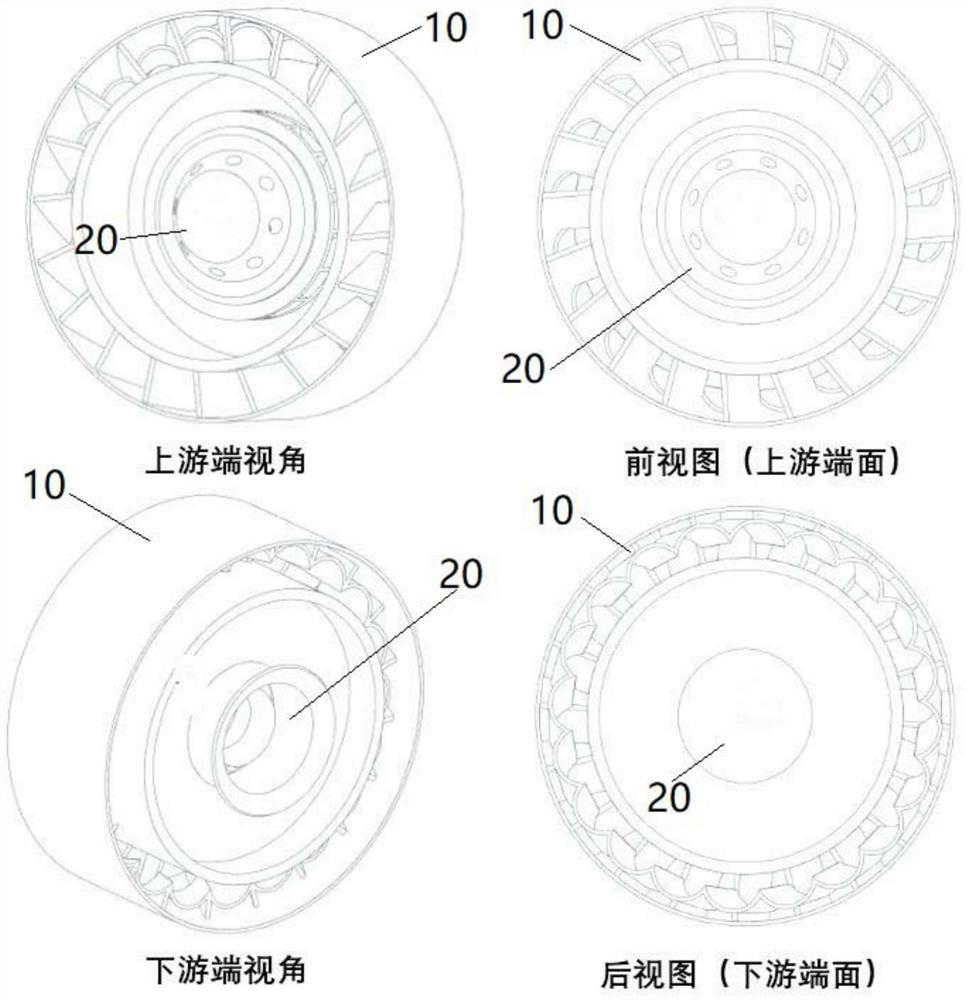

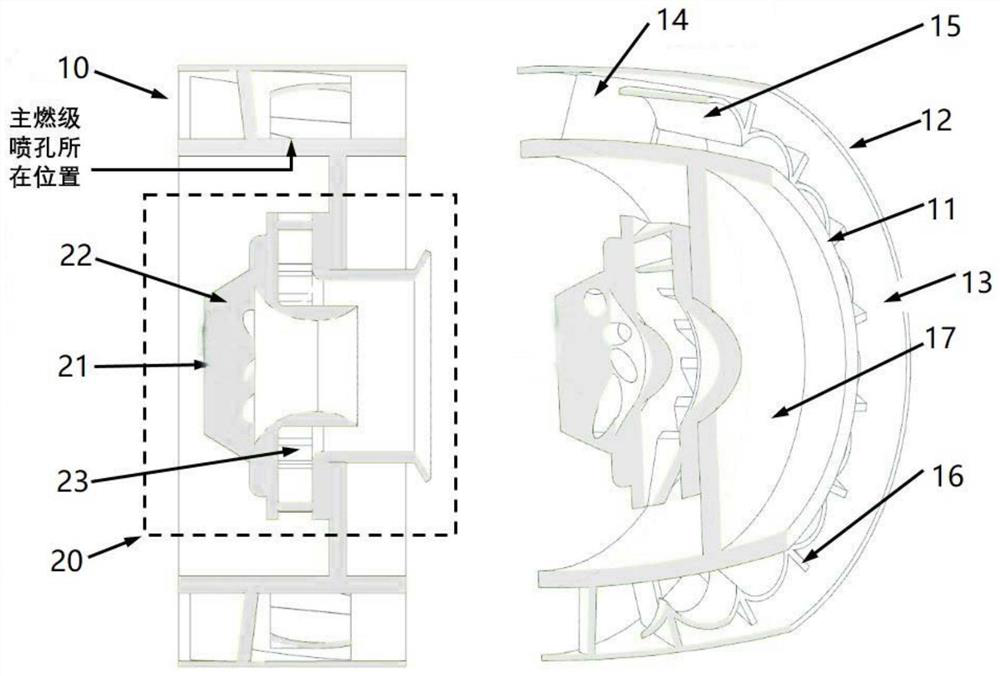

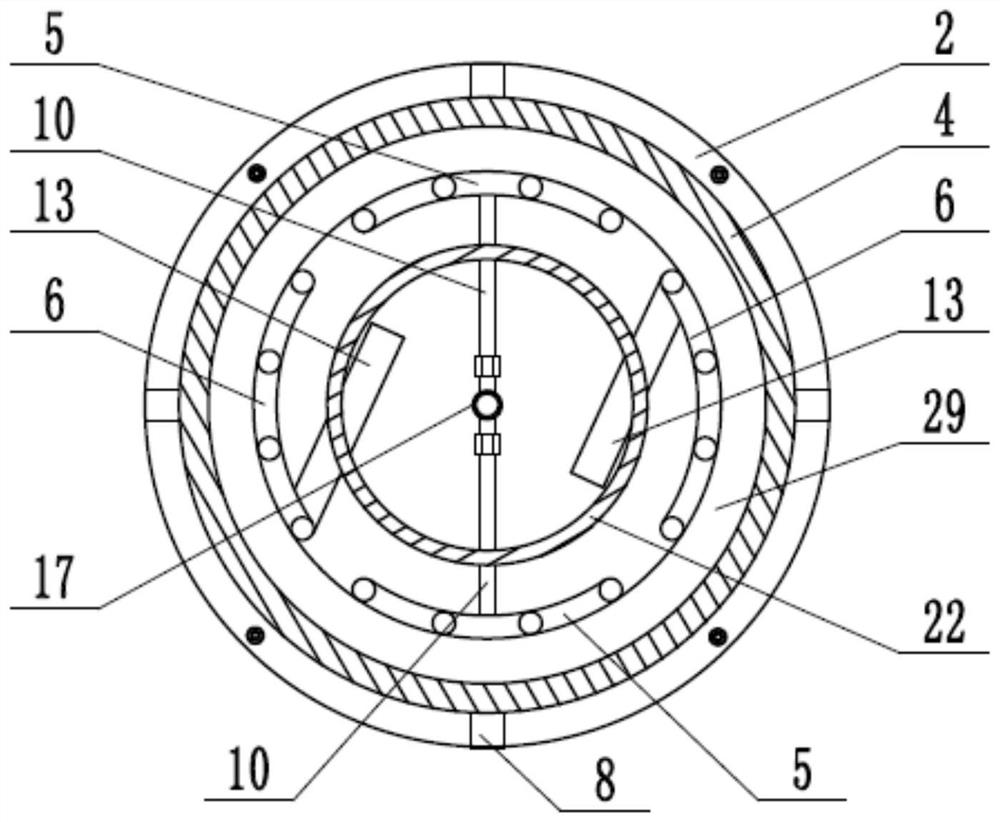

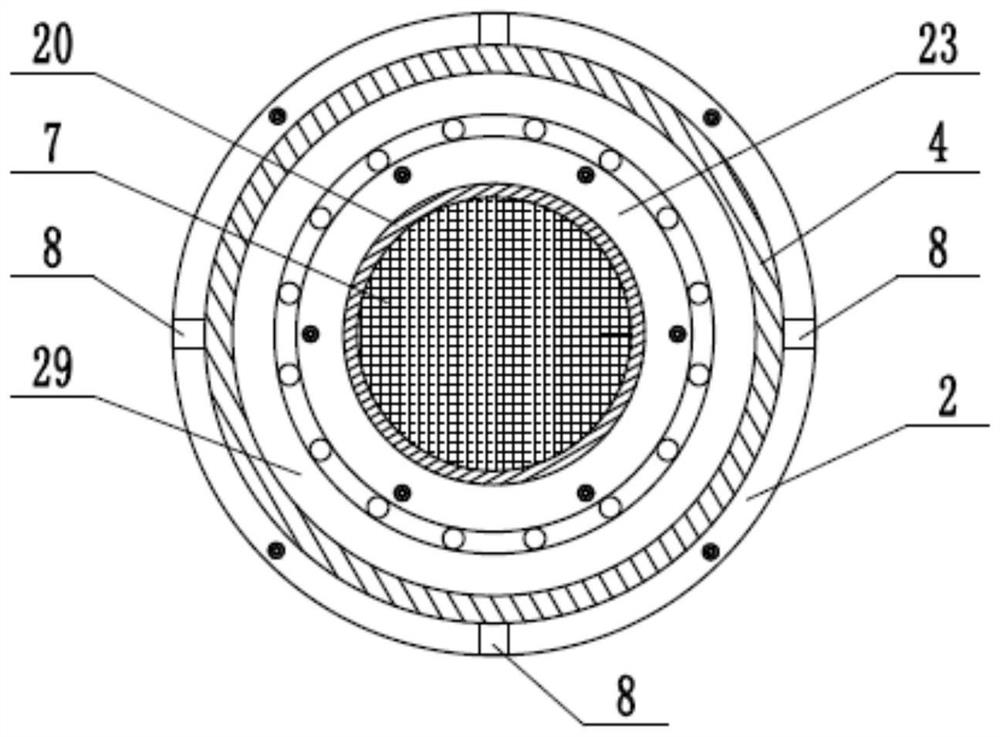

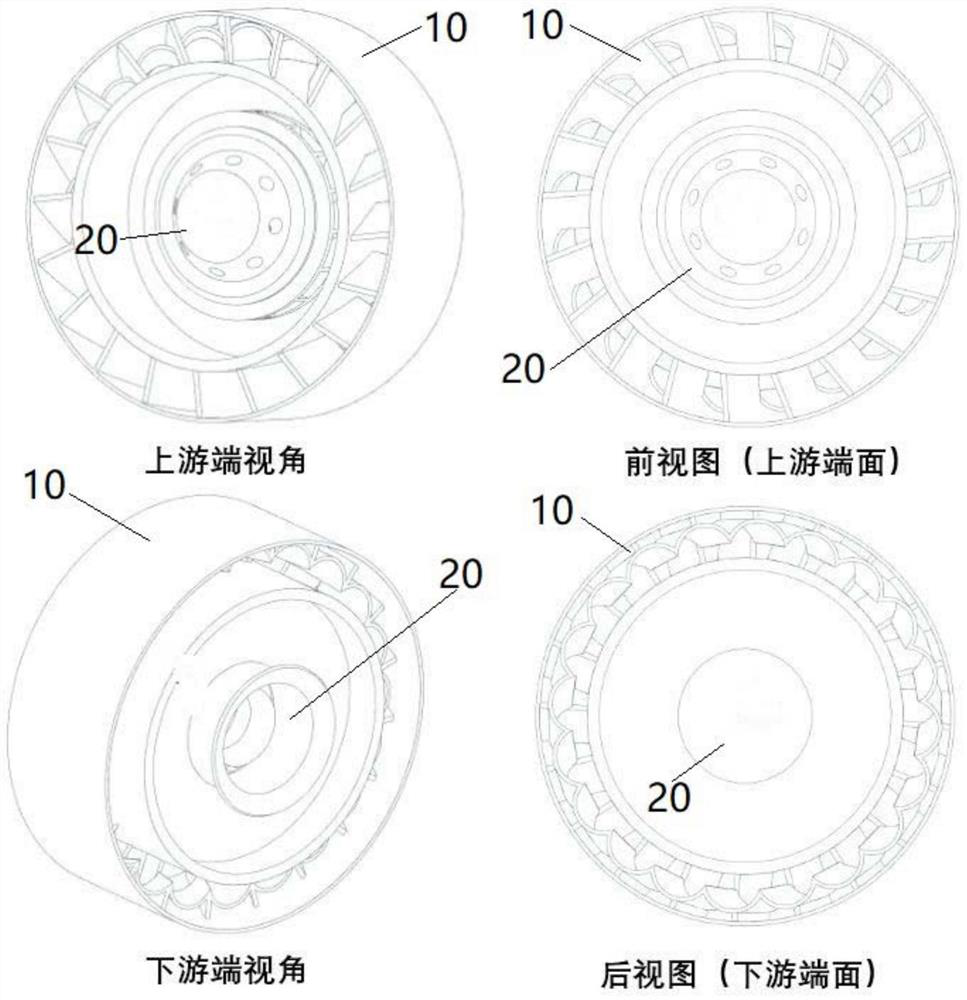

Low-emission combustion chamber head with main combustion stage adopting axial rotational flow pre-membrane plate matching with blade injection structure

ActiveCN108592084AGood premix effectGuaranteed ignition performanceContinuous combustion chamberDiffusion flameCombustion chamber

The invention discloses a low-emission combustion chamber head with a main combustion stage adopting an axial rotational flow pre-membrane plate matching with blade injection structure. According to the combustion chamber head, the head adopts a center grading design and consists of a main combustion stage and a pre-combustion stage; the main combustion stage is provided an axial rotational flow pre-membrane structure, the main functions of a main combustion stage swirler is that air is enable to generate rotational flow, moreover, fuel oil is injected into the air through small holes in blades, and the fuel oil is atomized and mixed in the swirling air; axial rotational flow pre-membrane blades are aligned with fuel oil injection holes in the swirler blades, and are used for carrying outpre-membrane atomization on the fuel oil, the atomization effect of main combustion stage fuel oil is improved, and therefore the relatively high low-emission performance is achieved; and the pre-combustion stage adopts diffusion flame to stabilized the flame, the main combustion stage adopts the structure in the chamber head to perform fuel oil atomization premixed combustion, so that the low-emission performance of the combustion chamber is further improved.

Owner:BEIHANG UNIV

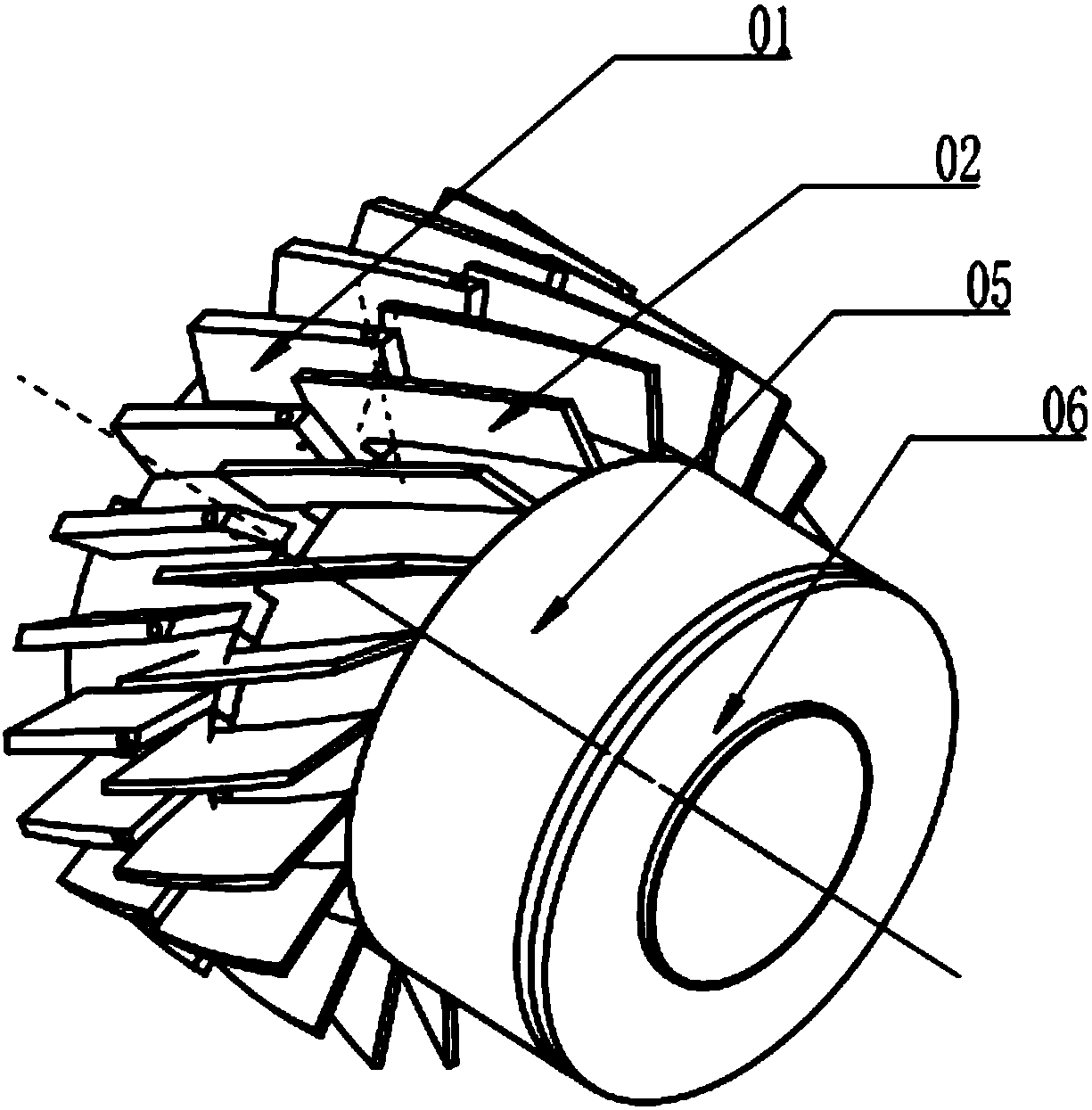

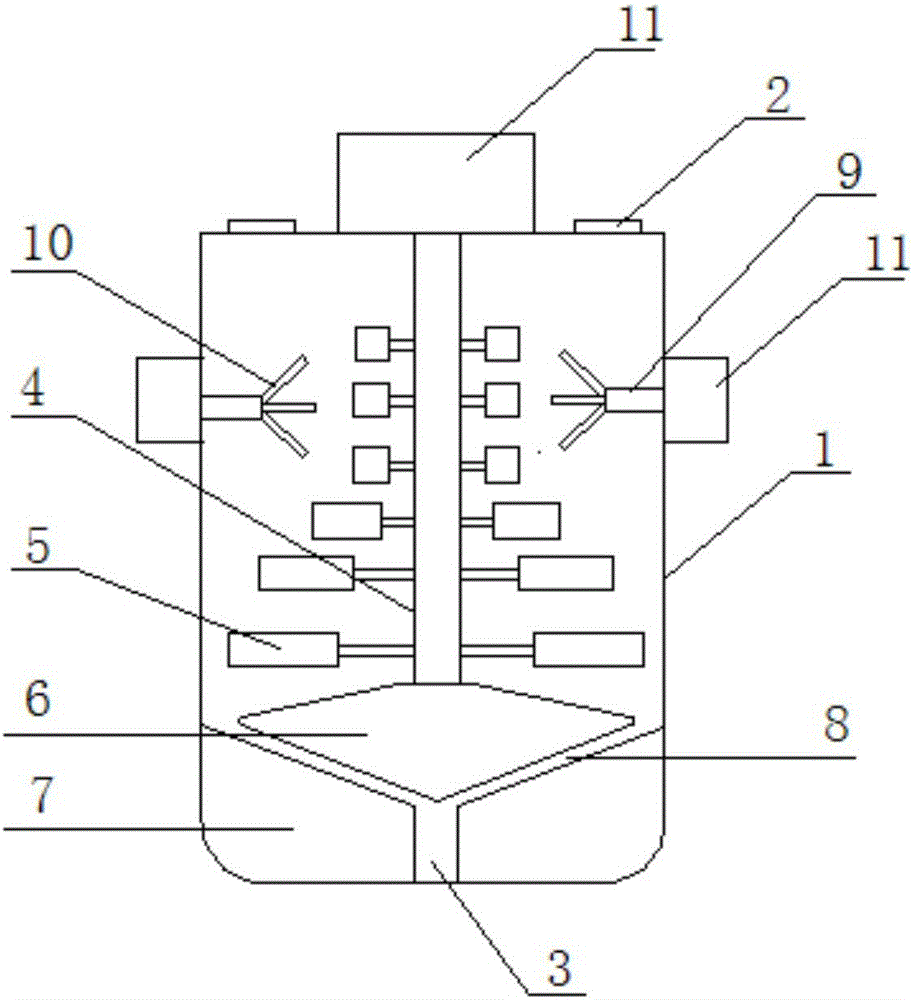

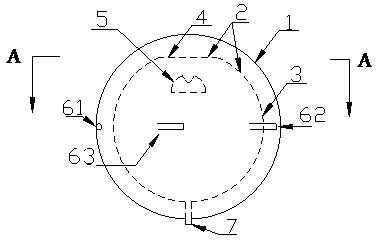

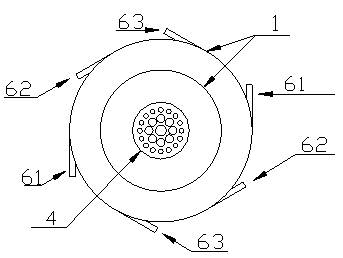

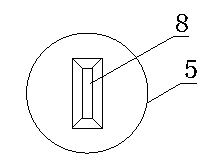

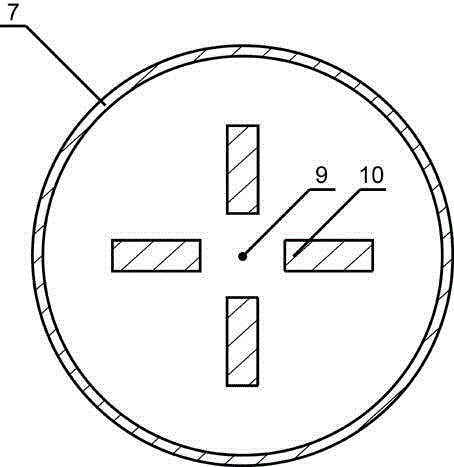

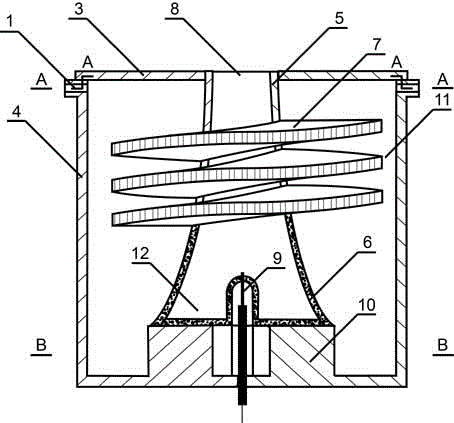

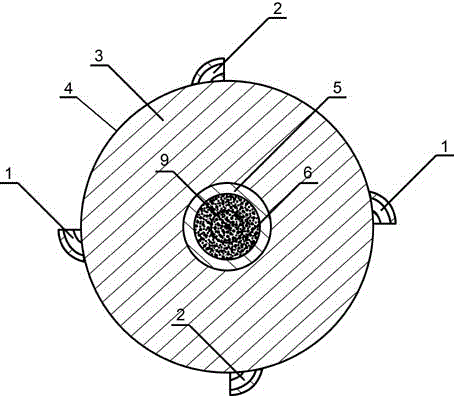

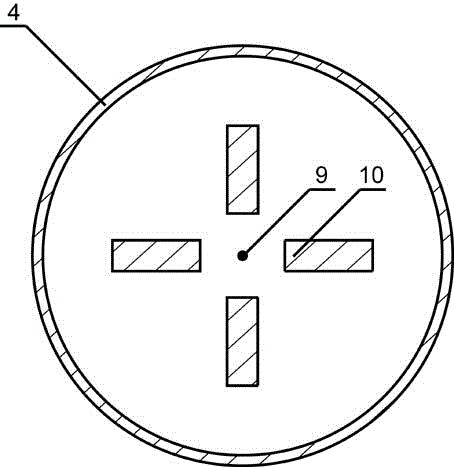

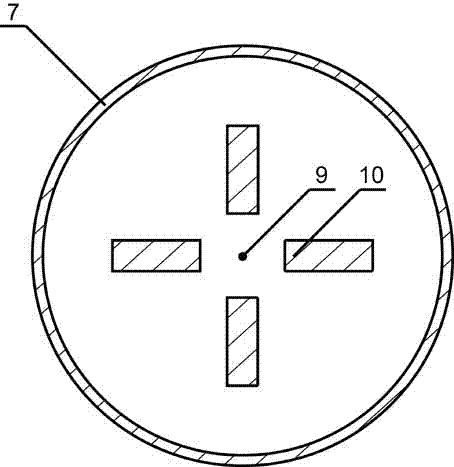

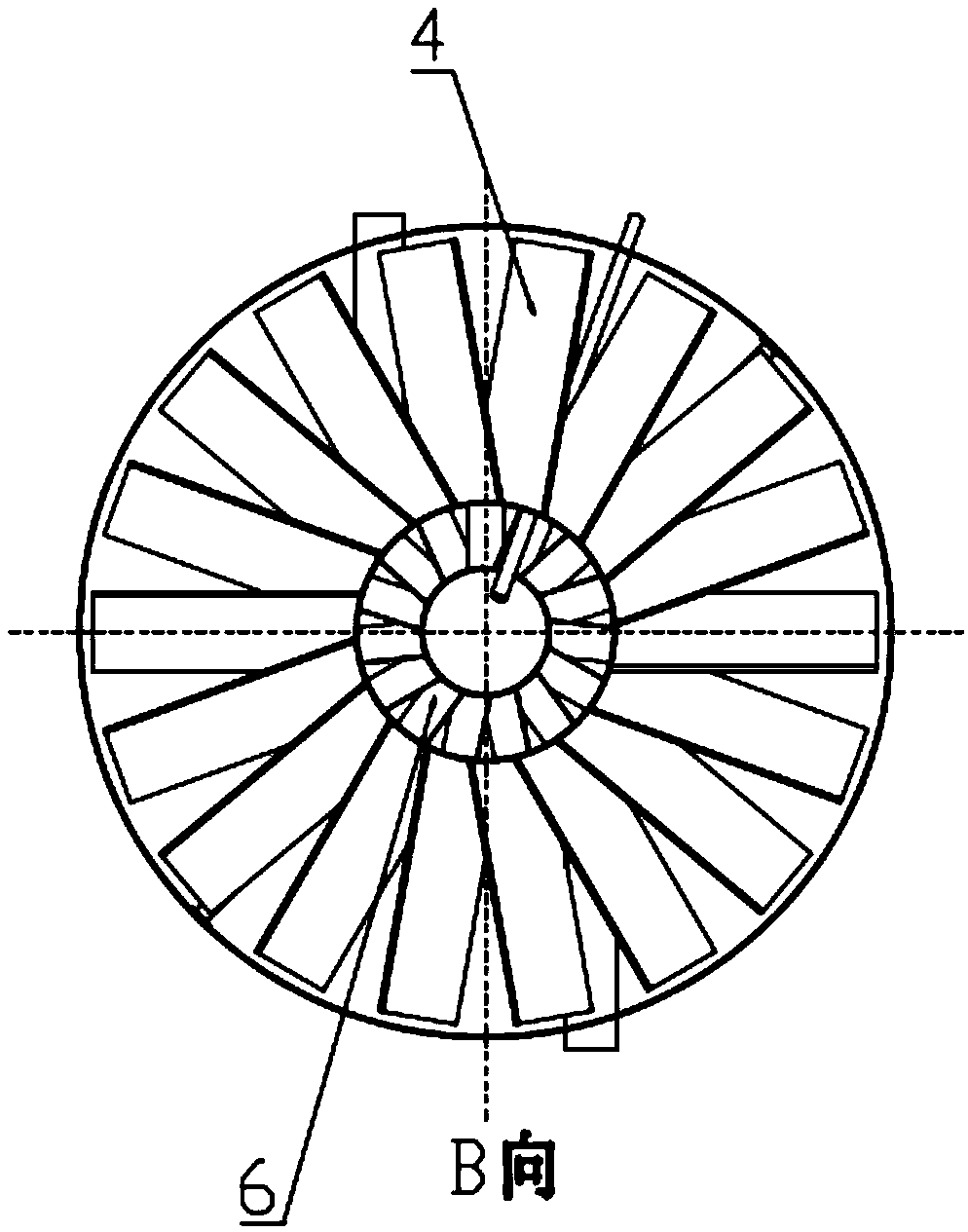

Pre-mixing and rough grinding tank for powder paint

InactiveCN106076482AUniform particle sizeQuality improvementRotary stirring mixersTransportation and packagingCross-linkEngineering

This invention provides a pre-mixing and rough grinding tank for powder paint. The pre-mixing and rough grinding tank for the powder paint comprises a tank body; the top of the tank body is provided with a feeding port and a speed reducing motor; a discharging port is formed in the bottom of the tank body; the speed reducing motor is connected with a first rotating shaft which stretches into the tank body; a plurality of horizontal rectangular blades are arranged on the surface of the first rotating shaft; a rough grinding part is arranged at the bottom of the tank body and comprises an upper abrasive disk arranged at the bottom of the first rotating shaft and a lower abrasive disk arranged at the bottom in the tank body and matched with the upper abrasive disk; and a material channel is formed between the upper abrasive disk and the lower abrasive disk and communicates with the discharging port formed in the bottom of the tank body. The pre-mixing and rough grinding tank for the powder paint is created and makes the grain sizes of premixed raw materials consistent and uniform by arranging a rough grinding device to further grind the crushed raw materials, the fusing and cross-linking quality of materials in an extruding machine is improved, and the product quality is improved.

Owner:天津嘉明新材料科技有限公司

V-shaped gap type hemispherical blunt body micro-combustor with hydrogen permeation and combustion stabilization functions

The invention discloses a V-shaped gap type hemispherical blunt body micro-combustor with the hydrogen permeation and combustion stabilization functions. The micro-combustor comprises an outer spherical body, an inner spherical body and a blunt body. At least one set of gas inlet channels are formed in the peripheral direction of the middle of the outer spherical body. Each gas inlet channel of each set is composed of a fuel gas inlet, an air inlet and a hydrogen inlet. A gas outlet channel is formed in the bottom of the outer spherical body, and another gas outlet channel is formed in the bottom of the inner spherical body. The inner spherical body is composed of a segment and a round multi-hole panel. The segment is made of a hydrogen permeation material. The round multi-hole panel is provided with a plurality of round holes. The blunt body is a hollow hemispherical body and is arranged on the upper portion in the inner spherical body. The top of the blunt body is provided with a V-shaped gap. The micro-combustor enables gas of micro flow to generate catalytic combustion reaction fast and efficiently. Due to the blunt body, the premixed gas forms a return flow zone in the back of the blunt body; according to the characteristics of low speed and high temperature of the rear return flow zone of the blunt body, near fuel is lighted so that the purpose of combustion stabilization can be achieved, the blow-off limit of the fuel can be improved greatly, and the combustion efficiency is improved.

Owner:CHONGQING UNIV

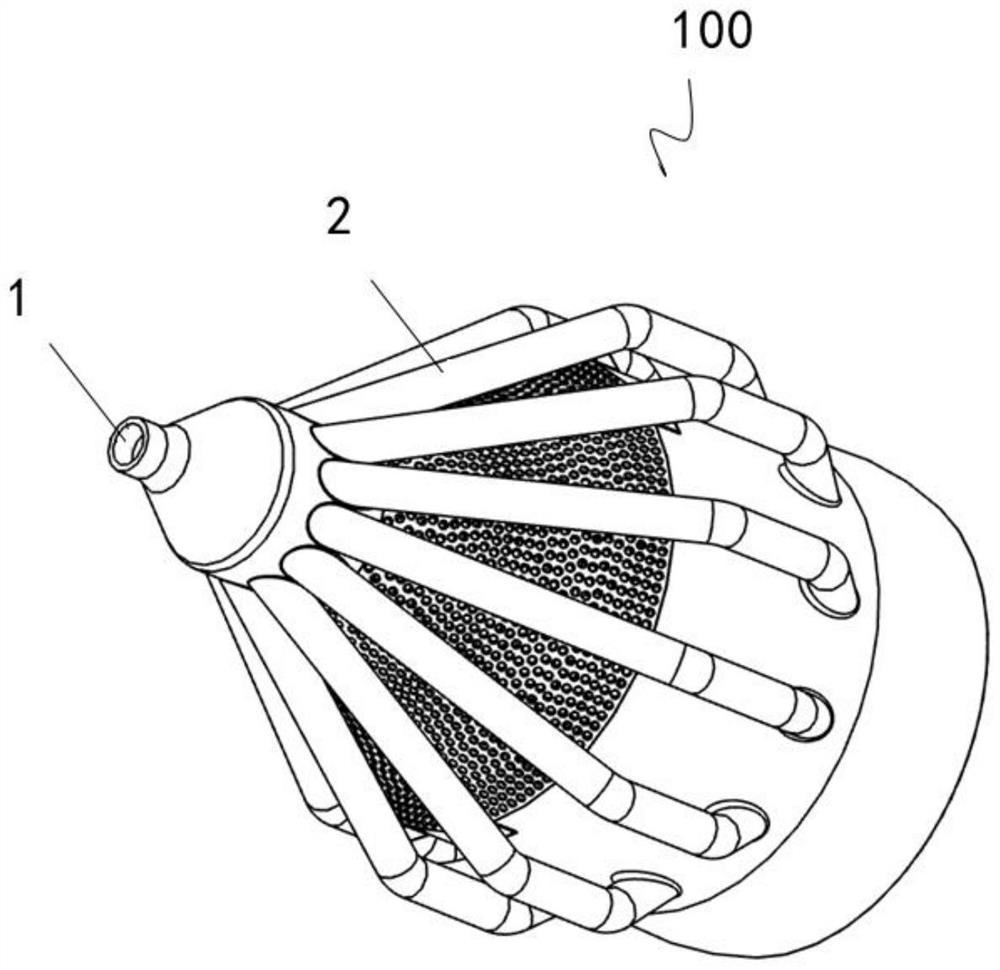

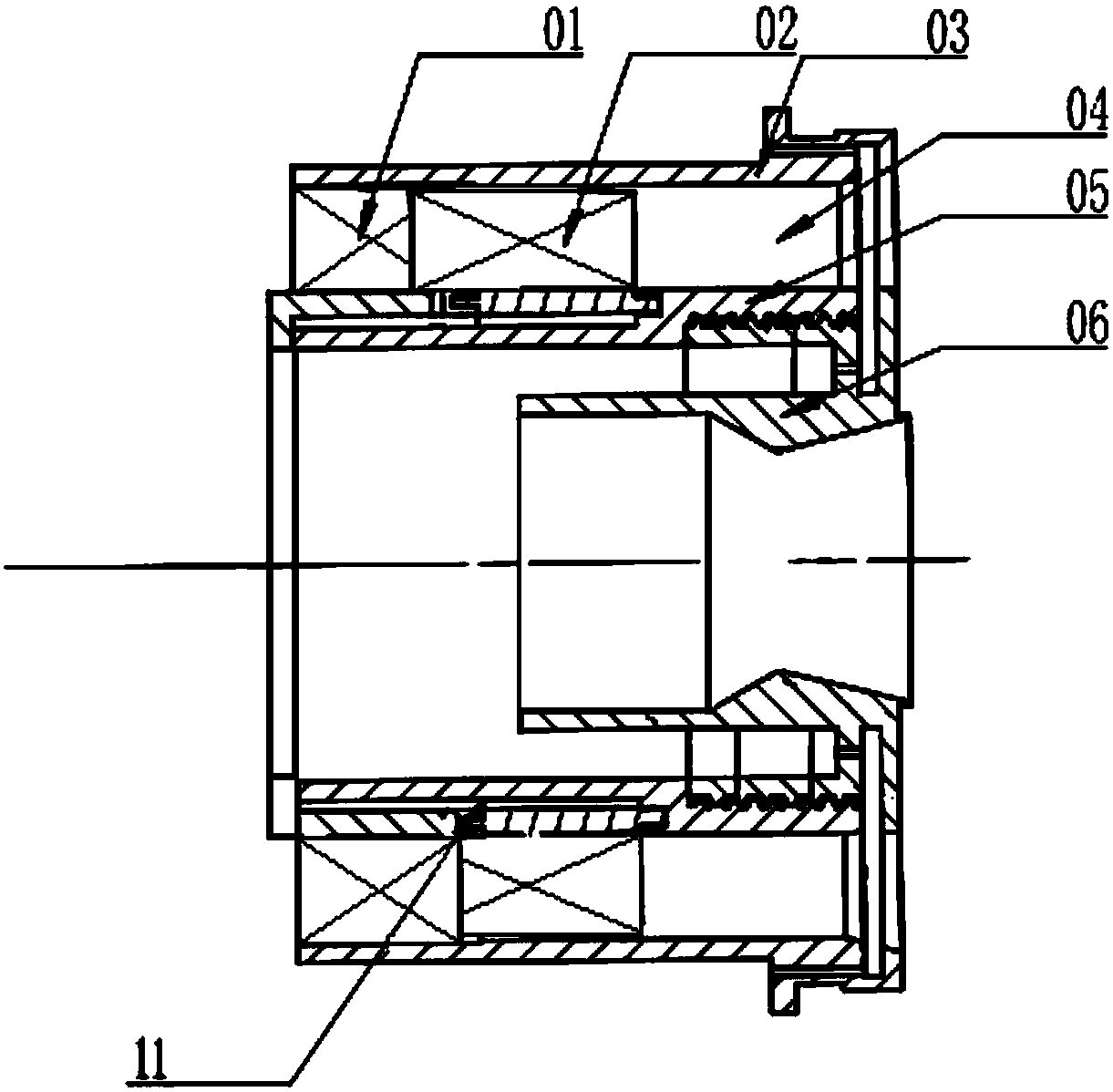

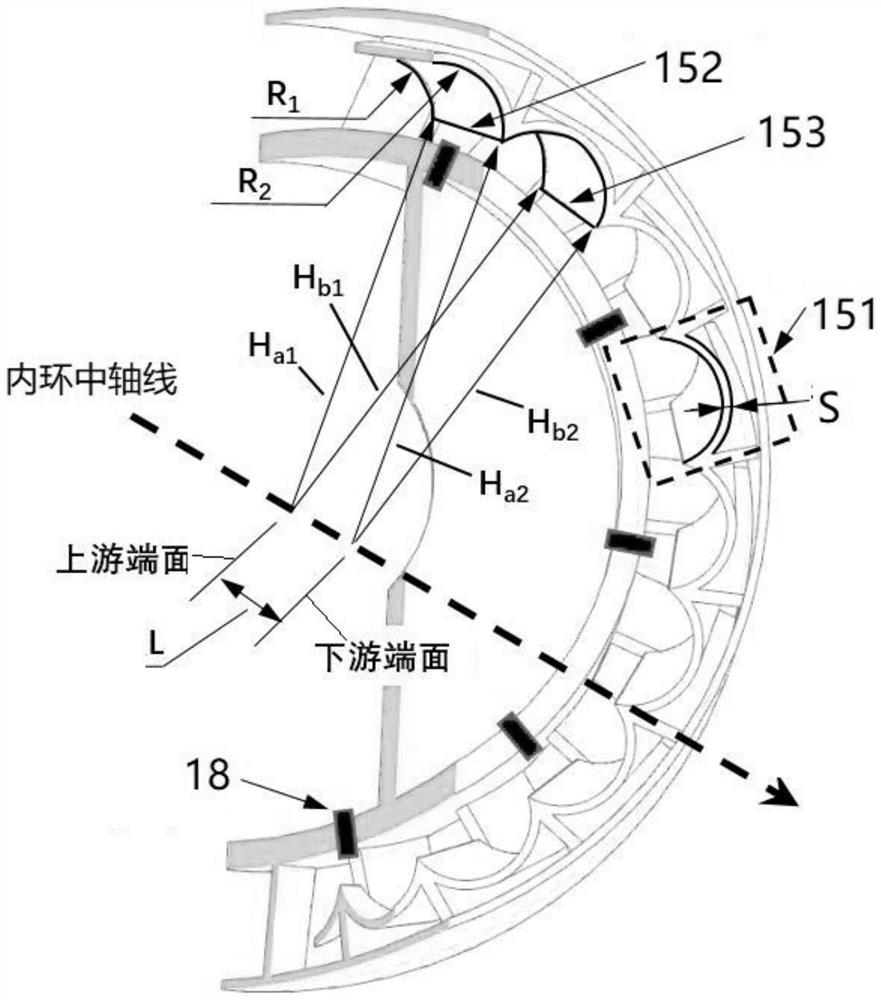

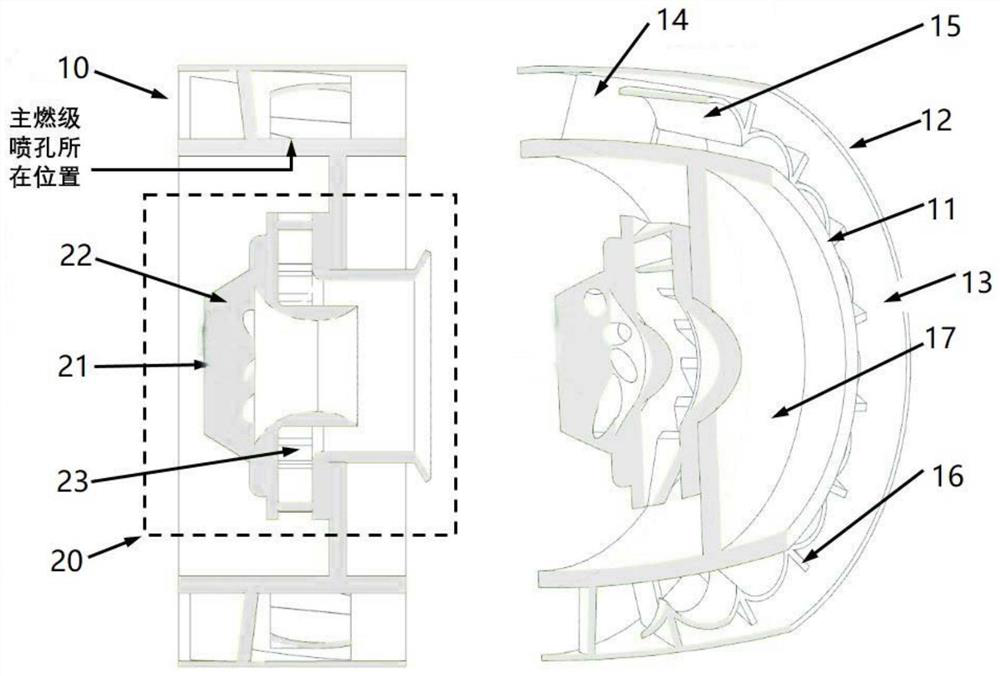

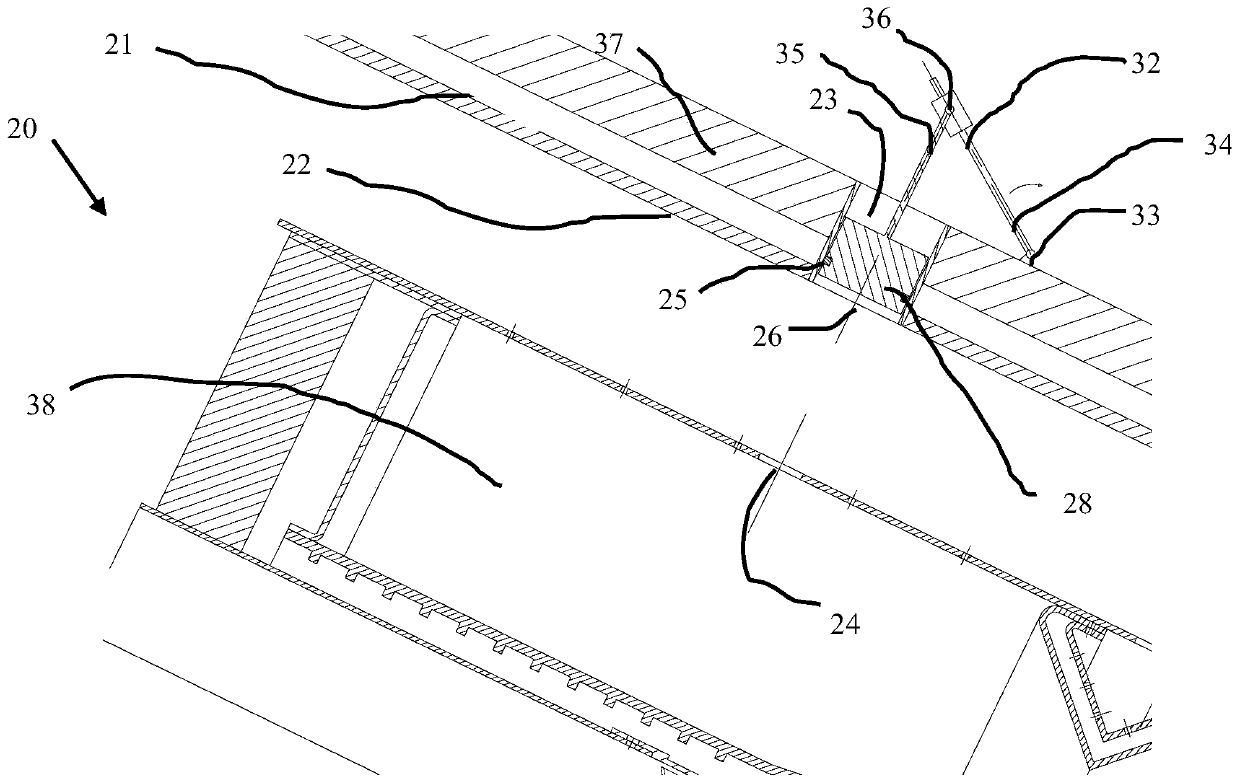

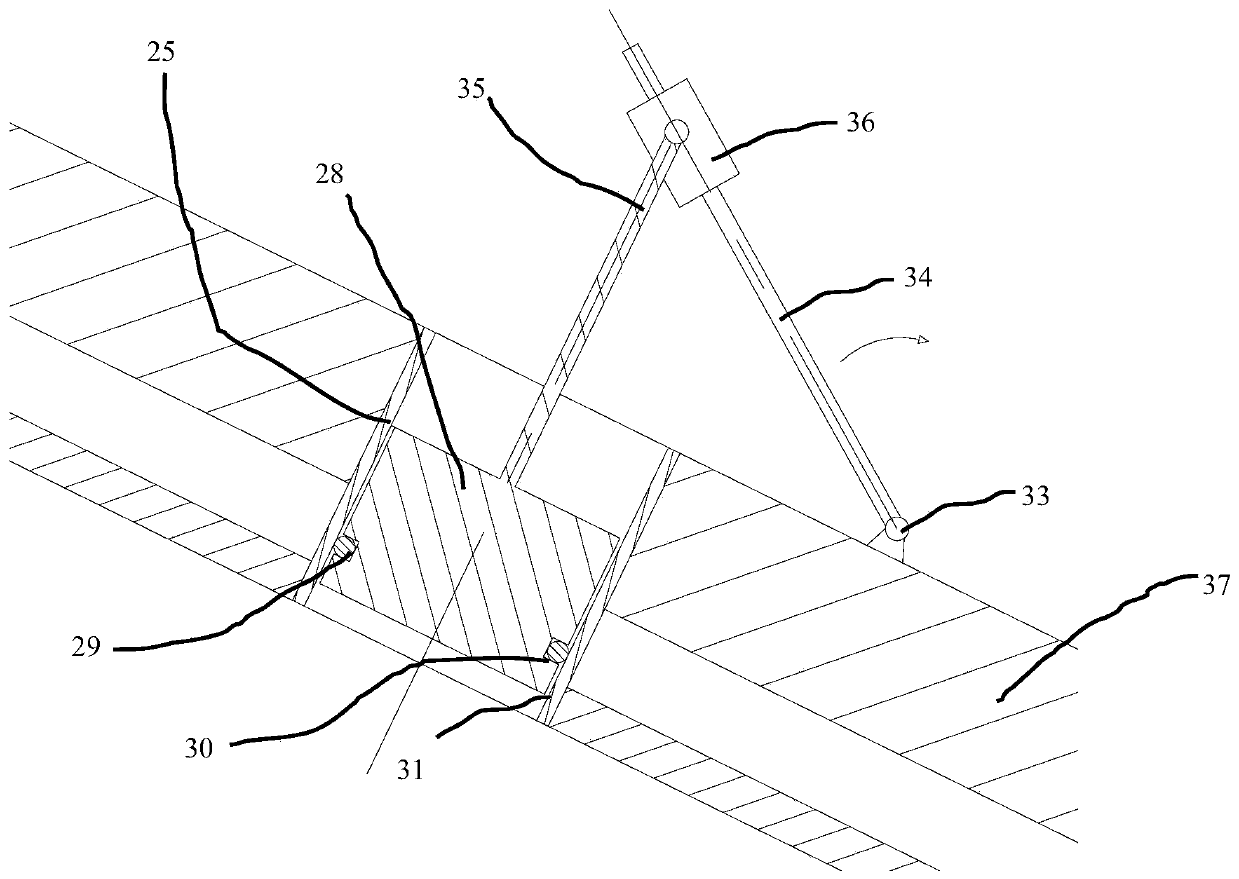

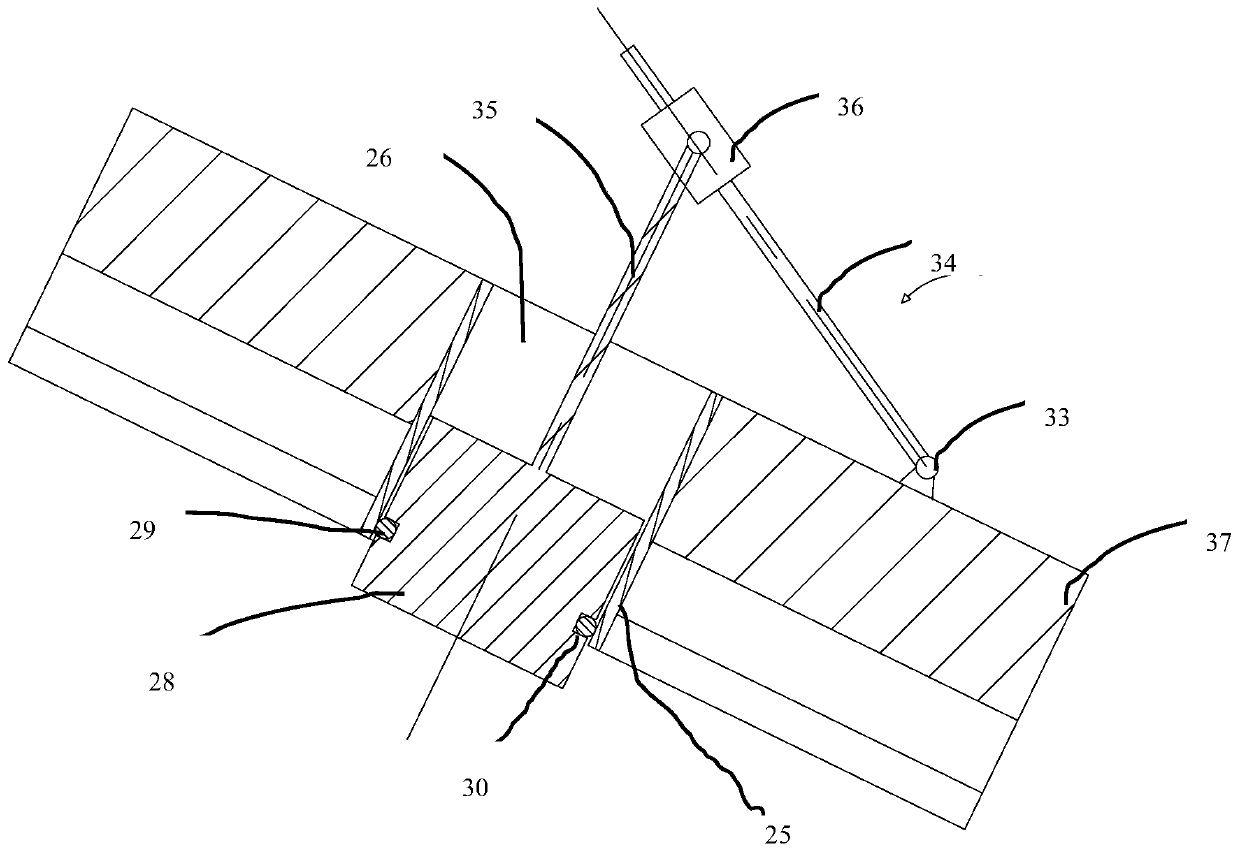

Staged combustion chamber head with entrainment pre-filming plate structure

ActiveCN113280367AOptimize spatial distributionImprove combustion effectContinuous combustion chamberCombustion chamberStaged combustion

The invention provides a staged combustion chamber head with an entrainment pre-film plate structure. The staged combustion chamber head comprises a pre-combustion stage and a main combustion stage arranged outside the pre-combustion stage in a sleeving mode. The main combustion stage comprises an inner ring and a sleeve arranged outside the inner ring in a sleeving mode. The inner ring is provided with a plurality of spray holes distributed in the circumferential direction. An annular air channel is formed between the inner ring and the sleeve. Axial rotational flow blades and an entrainment pre-filming plate are sequentially arranged in the air channel from front to back. The multiple axial rotational flow blades are arranged, and the multiple axial rotational flow blades are arranged in the circumferential direction. The entrainment pre-filming plate is annular and is formed by arranging a plurality of segmented arcs in the circumferential direction. The spray holes are arranged right opposite to the arc ridge of the entrainment pre-filming plate, and two segmented arcs are arranged between any two adjacent spray holes. The radial heights of the front end and the rear end of the arc ridge are both larger than the radius of the outer surface of the inner ring and smaller than the radius of the inner surface of the sleeve.

Owner:AERO ENGINE ACAD OF CHINA

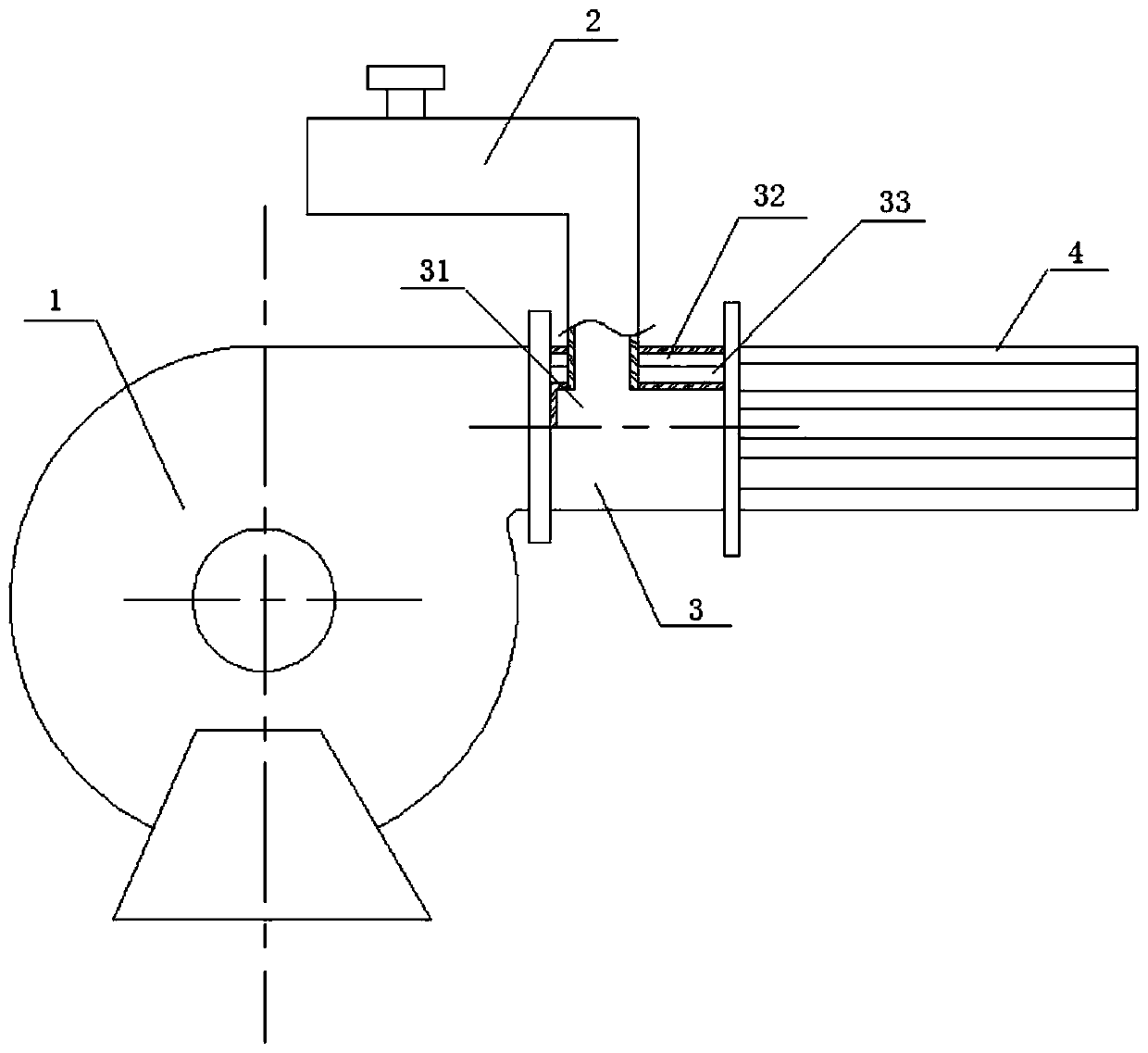

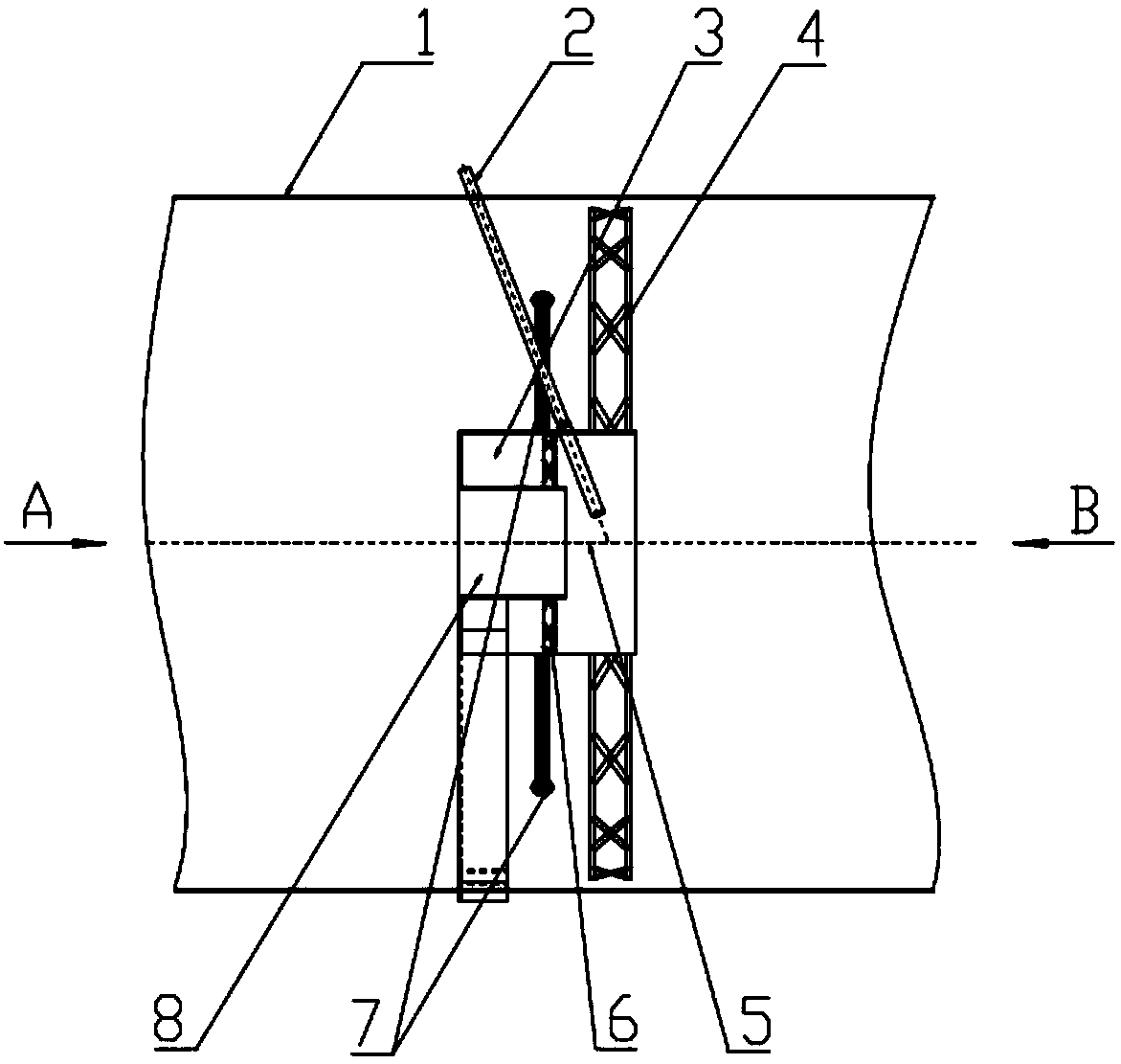

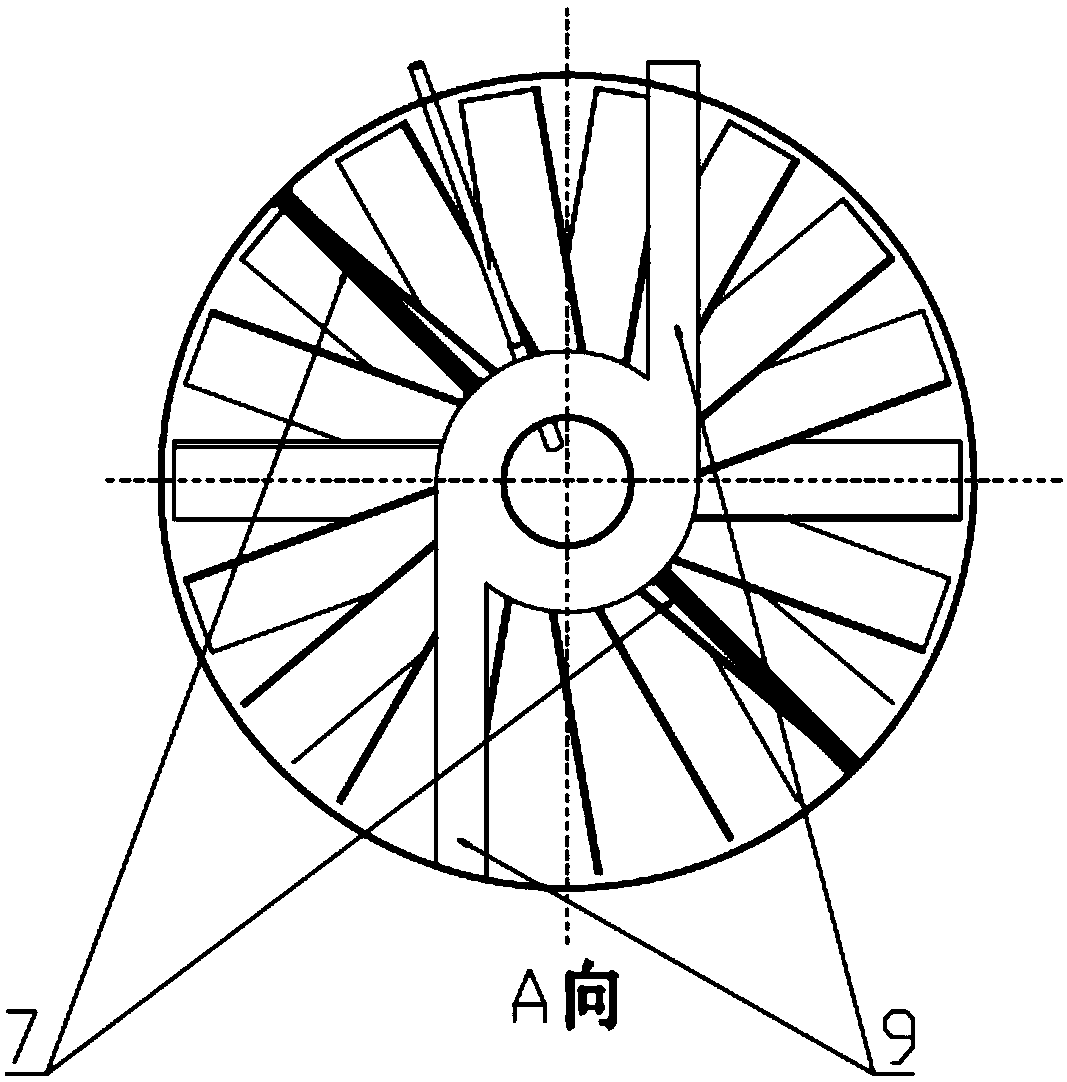

Improved vibrating premixed concentrate burner

ActiveCN108680029AIncrease productivityLow maintenanceCharge composition/stateCharge manipulationCombustionEngineering

Owner:HEFEI GENERAL MACHINERY RES INST

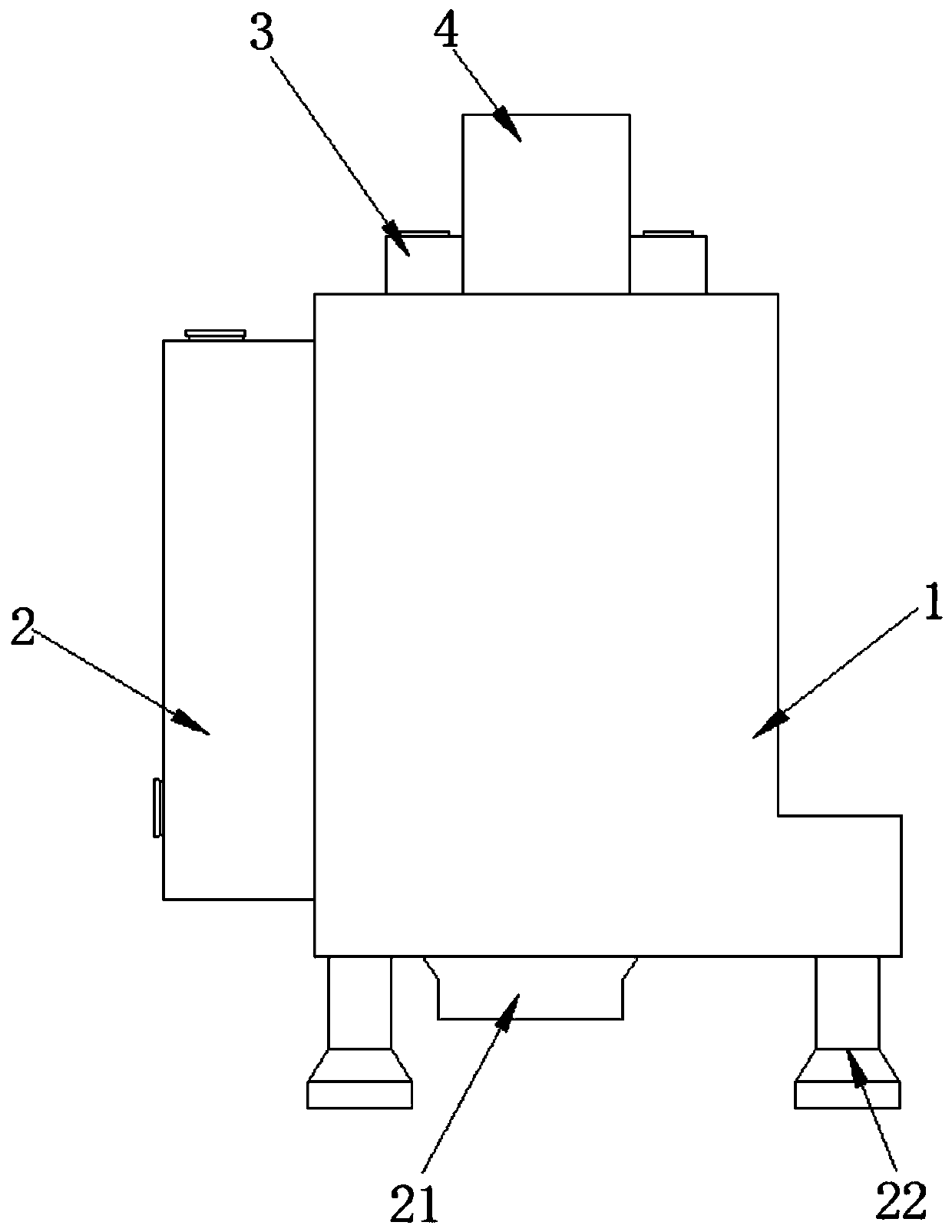

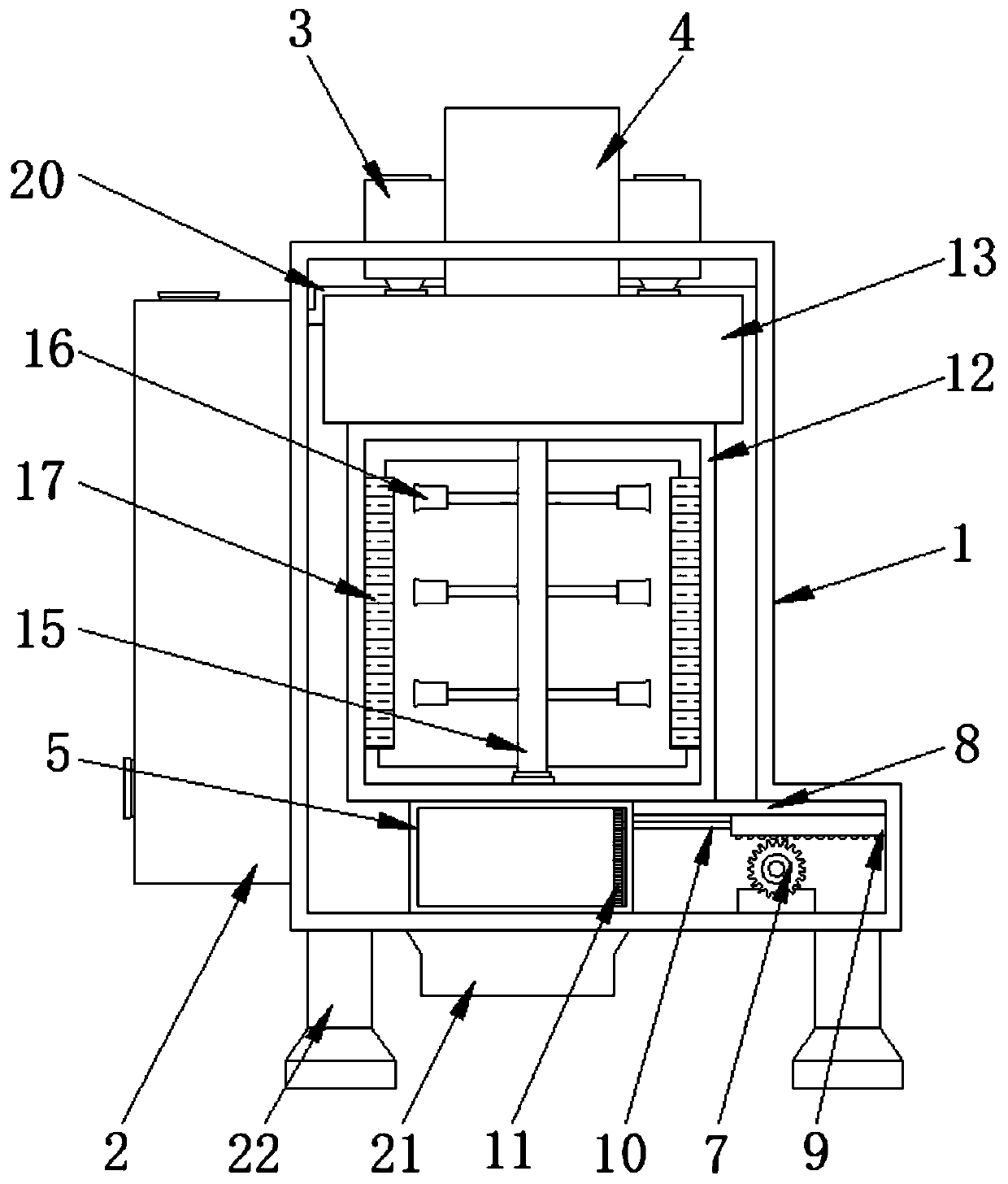

Material premixing device used for silane coupling agent

InactiveCN109876697AEasy to operateAvoid pollutionRotary stirring mixersHollow article cleaningGear wheelEngineering

The invention discloses a material premixing device used for a silane coupling agent, and belongs to the technical field of material premixing device. The material premixing device comprises a box body, a water tank, a raw material box, and a motor box; one side of the box body is fixedly connected with one side of the water tank; the bottom of the internal wall of the box body is fixedly connected with a discharge box; a first motor is fixedly connected with the bottom of the internal wall of the box body on one side of the discharge box through a supporting plate; an output shaft of the first motor is fixedly connected with a gear; the bottom of the internal wall of the box body is fixedly connected with a slide rail; the bottom of the slide rail is connected with a tooth bar through a slide block. In using process, users are capable of cleaning the internal wall of the discharge box using a brush plate can be driven by a fixed rod on the toothed bar, pollution of materials on the internal wall in mixing is avoided, blocking of the material premixing device by material residue is avoided, working efficiency is increased greatly, it is convenient for using, material scraping plates can be used for cleaning the internal wall of the mixing box, and stirring plates can be used for material mixing.

Owner:HUANGSHAN HUIZHOU TIANMA CHEM

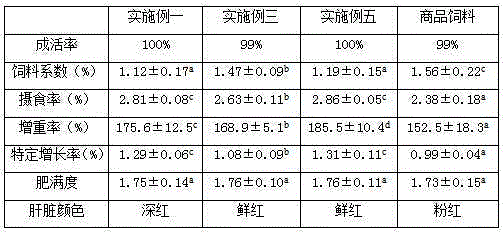

Sebastes schlegeli adult fish compound feed and preparation method thereof

The invention provides Sebastes schlegeli adult fish compound feed and a preparation method thereof. The compound feed is composed of fish meal, fermented soybean meal, husked soybean meal, high-gluten flour, fish oil, bean oil, vitamin premix, trace element premix, Vc, betaine, Chinese rhubarb powder, scutellaria root powder, golden cypress powder, allicin and beer yeast powder according to specific quantity. The compound feed belongs to the technical field of aquatic feed. A consistent technical means of adding fresh fish into Sebastes schlegeli feed in the prior art is changed, the compound feed is obtained by effectively combining specific components according to specific content, and a new optimal replacement ratio of fish meal and vegetable protein is provided, so that feed cost and feed coefficient are lowered, and water pollution is reduced.

Owner:TONGWEI

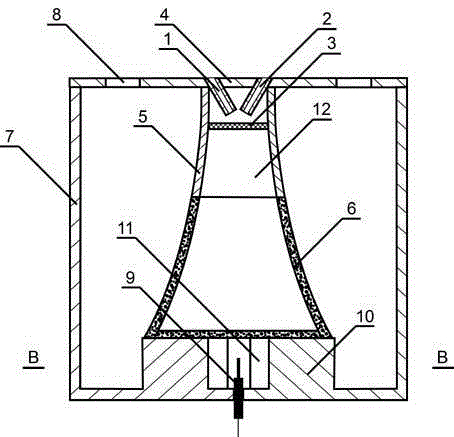

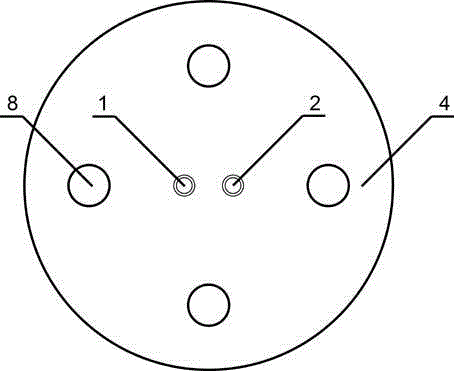

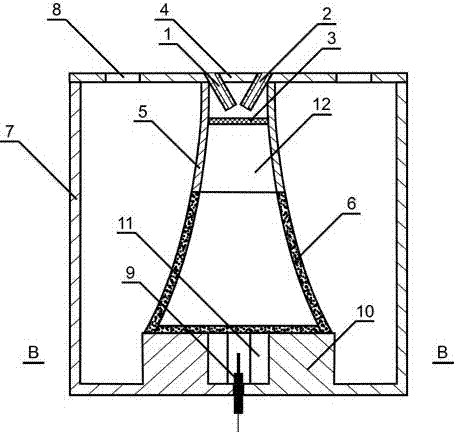

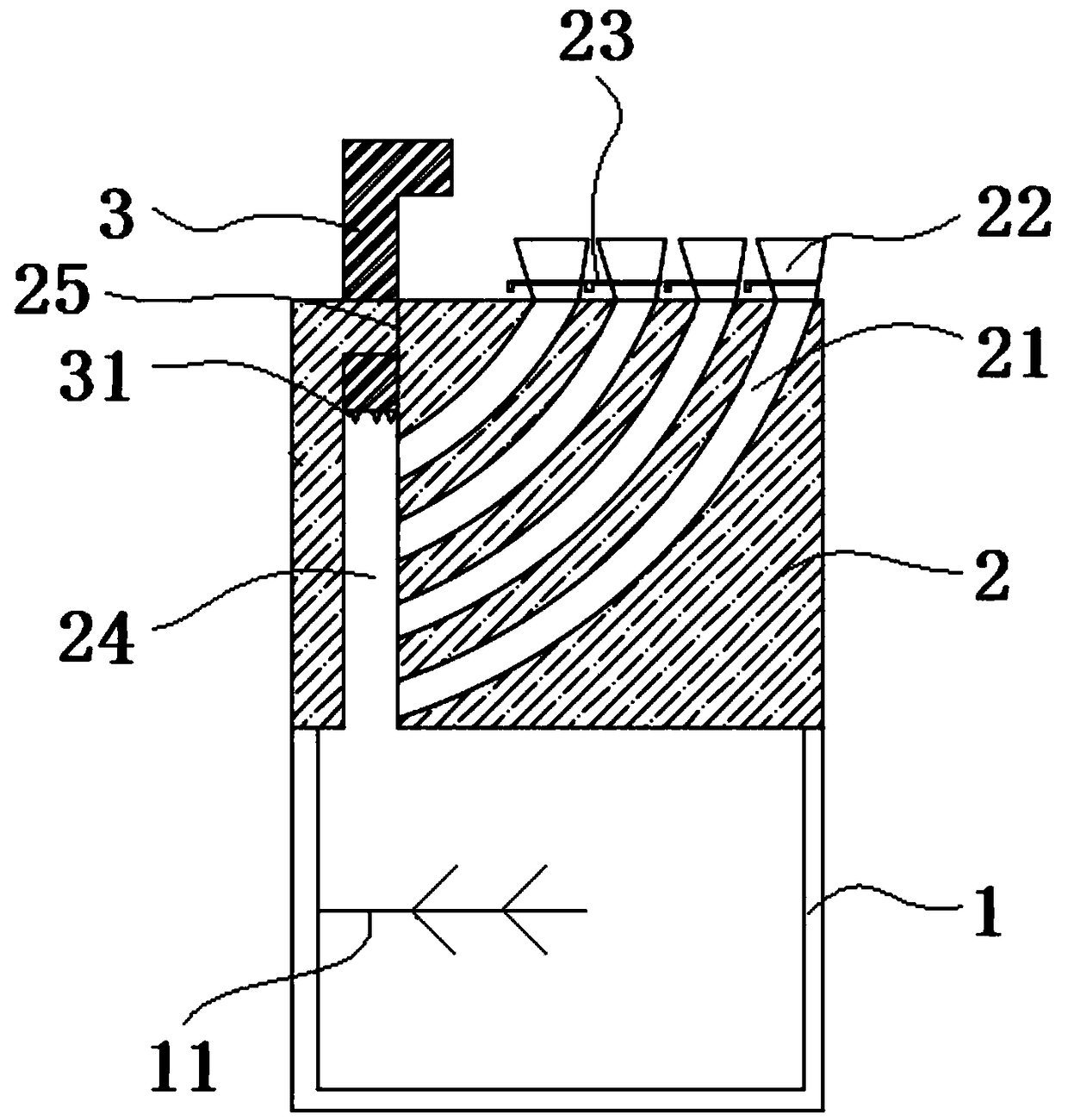

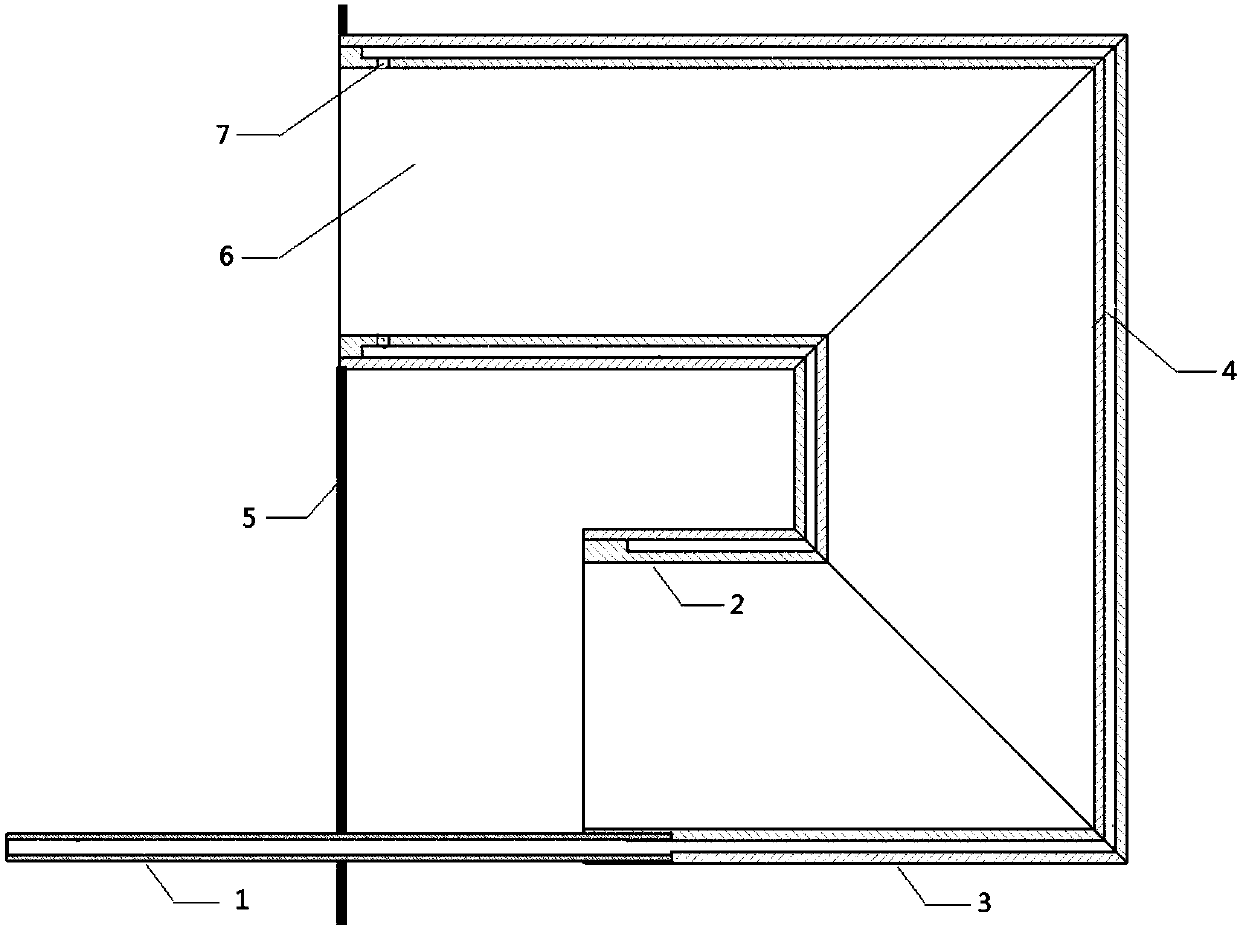

Micro diffuse type combustion apparatus for micro-thermphotoelectric system

InactiveCN105402725AReduce volumeImprove premix effectBurner material specificationsIndirect carbon-dioxide mitigationCombustion chamberEngineering

The invention provides a micro diffuse type combustion apparatus for a micro-thermphotoelectric system. The micro diffuse type combustion apparatus for the micro-thermphotoelectric system comprises an ignition device, an external sleeve, an internal sleeve and an upper panel, wherein the internal sleeve is positioned in the external sleeve; the upper panel is arranged at the top end of the external sleeve; the internal sleeve is a flared structure with big lower end; the lower end of the internal sleeve is provided with a porous bottom plate; the circumferential wall of the lower part of the internal sleeve; the interior of the internal sleeve is a preheating premixing chamber; a combustion chamber is formed between the internal sleeve and the external sleeve; the preheating premixing chamber is communicated with the combustion chamber through a porous wall and the porous bottom plate; and a gas exhaust opening, an air inlet and a fuel gas inlet are formed in the upper panel. According to the invention, as air enters the porous material from various surfaces, a temperature field is uniform and the combustion is enhanced to increase the device power; through the adoption of special combustion chamber wall surface design, heat obtained by the whole wall surface is much and uniform; the micro diffuse type combustion apparatus can stably respond to fine air inlet pulsation and combustion pulsation; and meanwhile, through the adoption of the porous material with reducing aperture, tempering and backflow problems of the porous material are also avoided.

Owner:CHONGQING UNIV

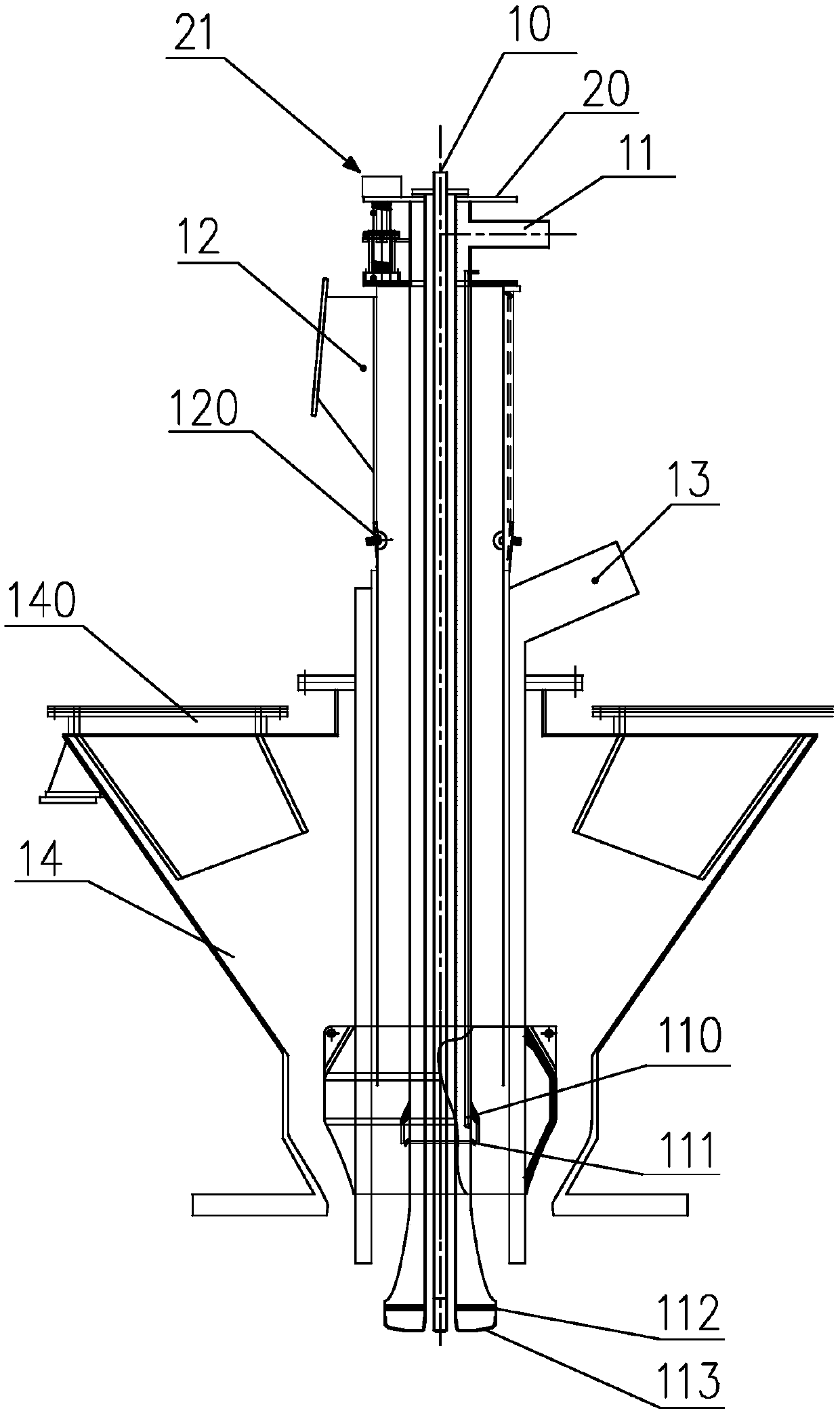

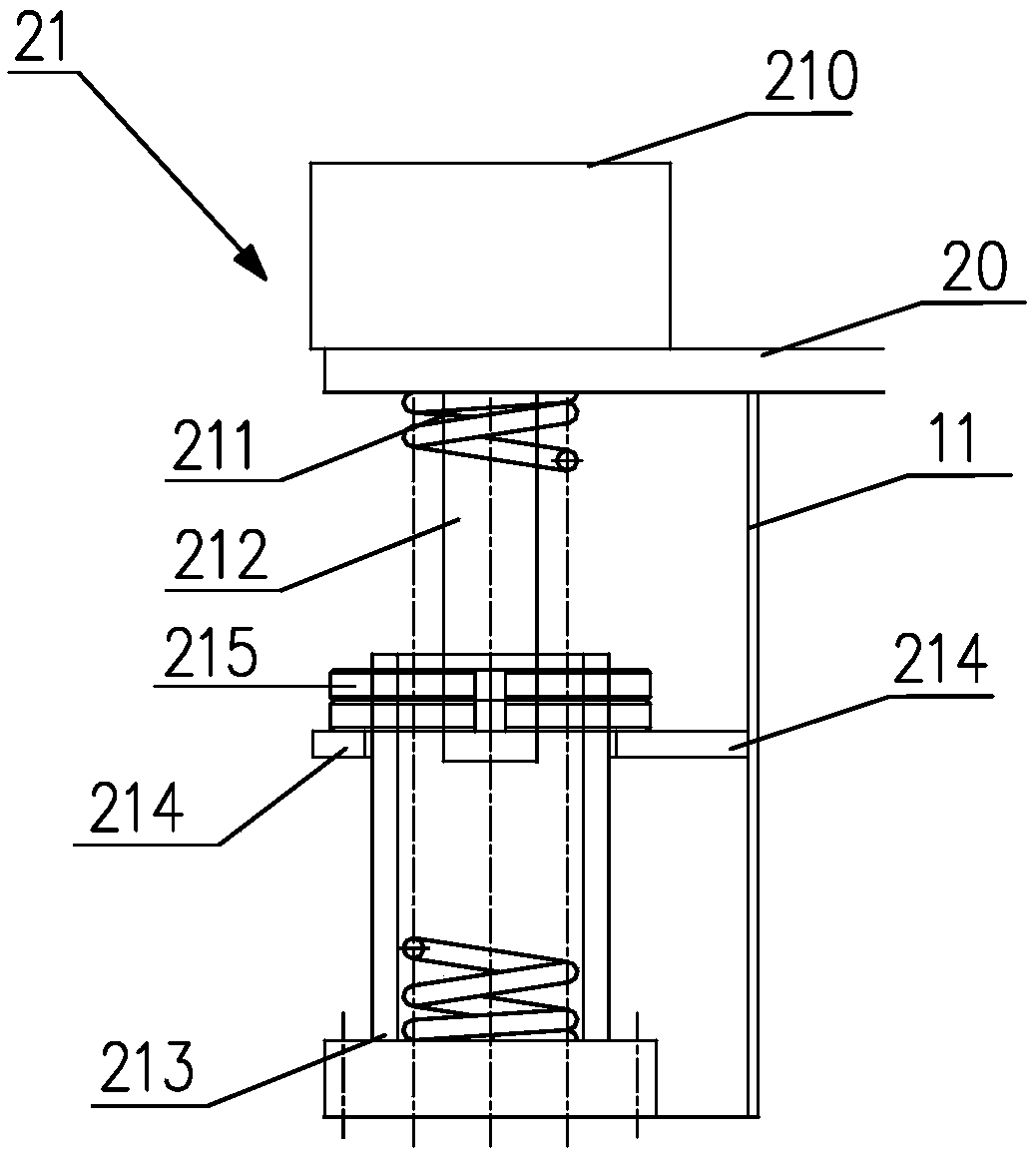

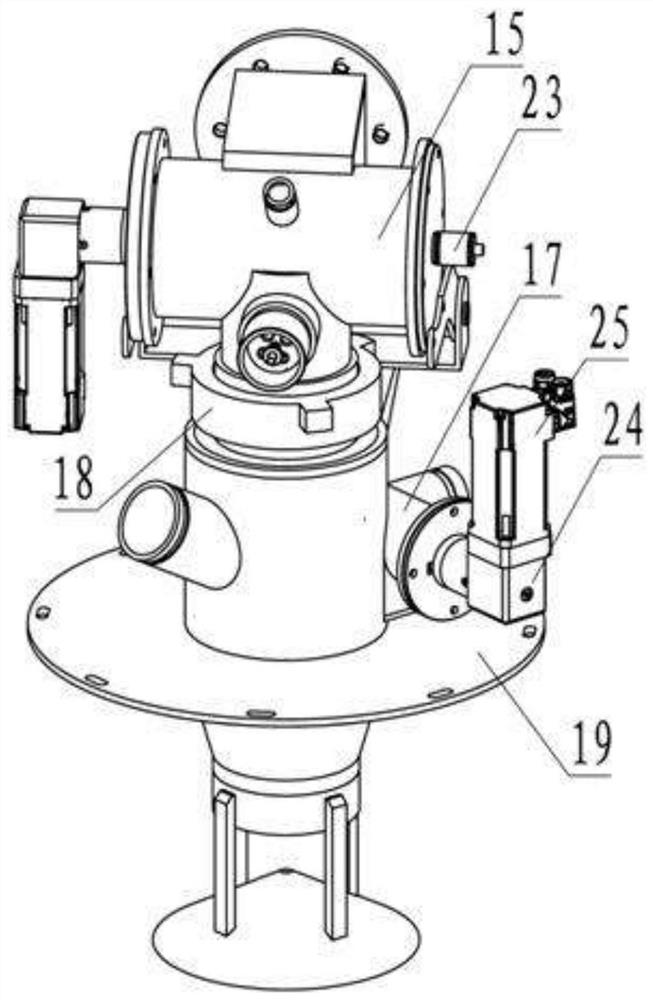

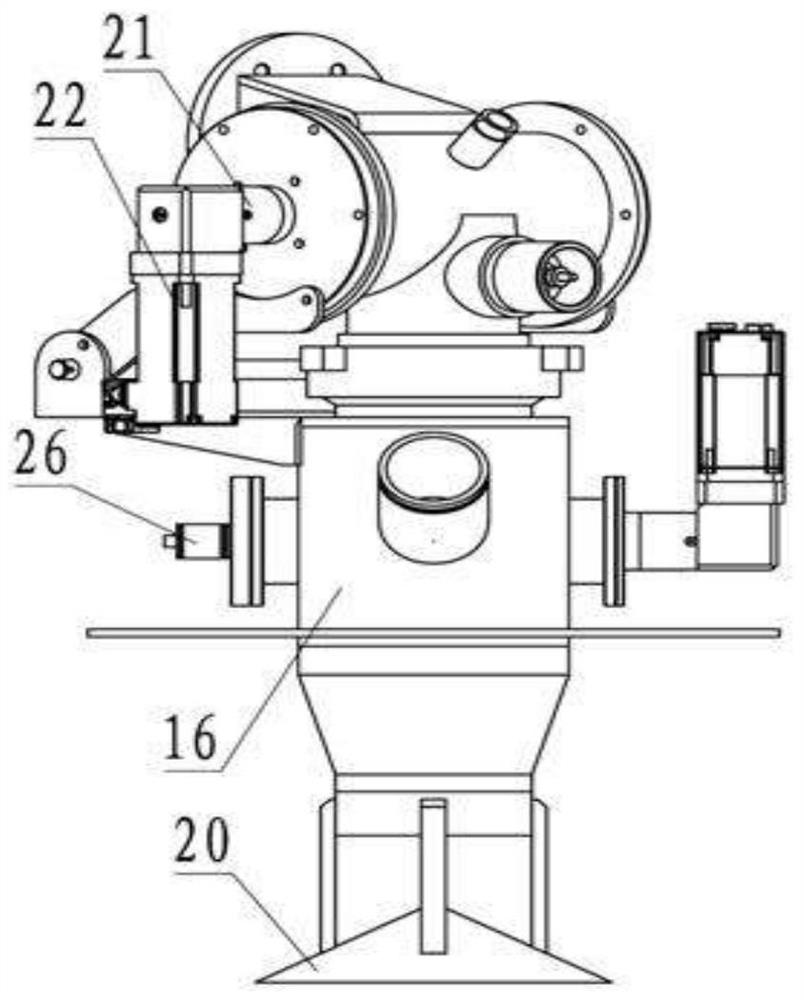

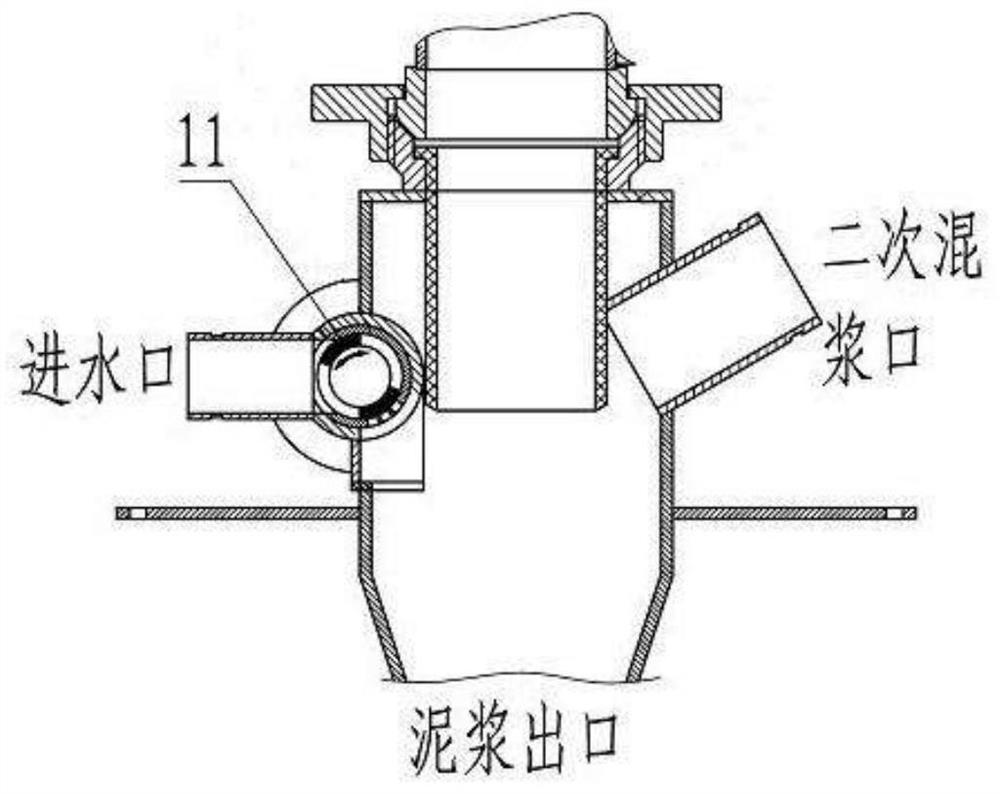

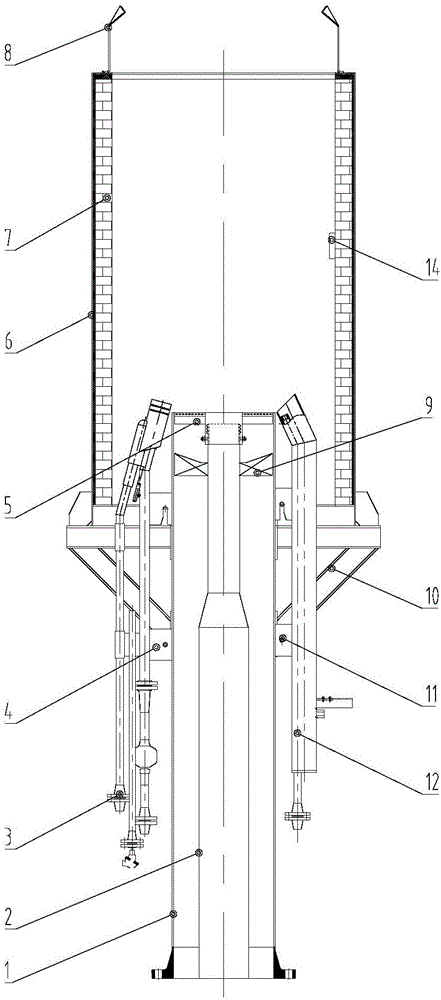

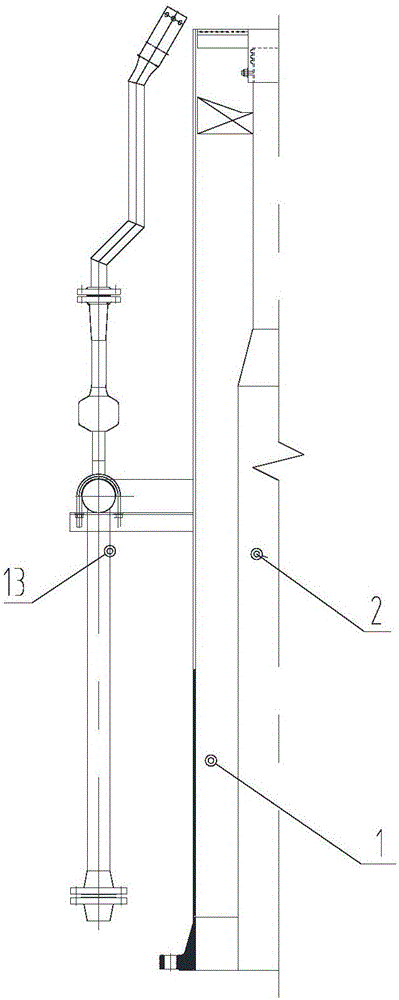

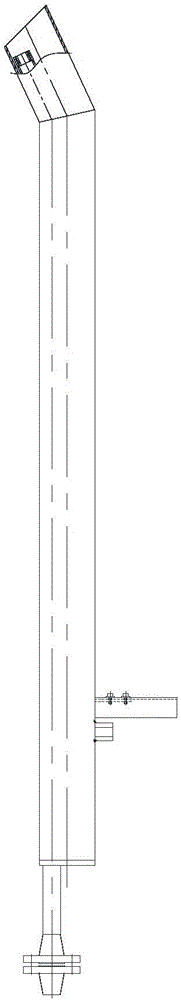

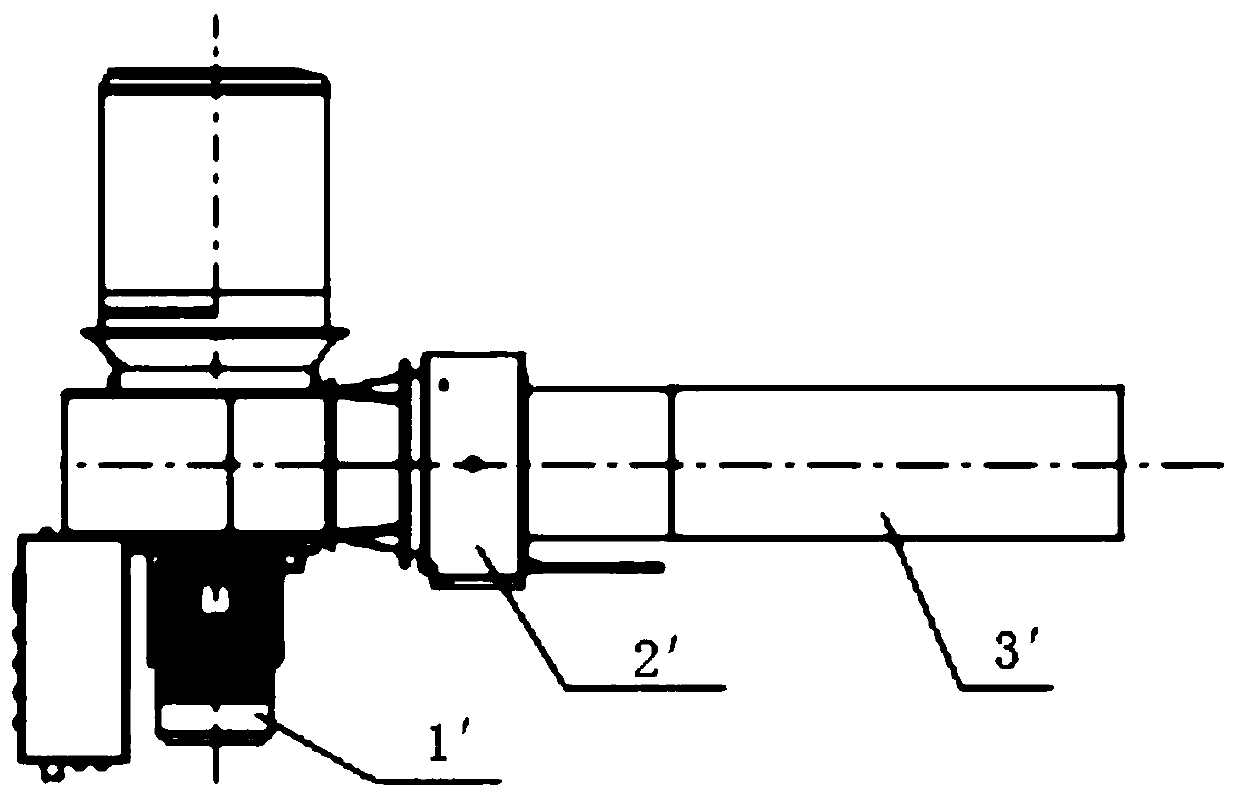

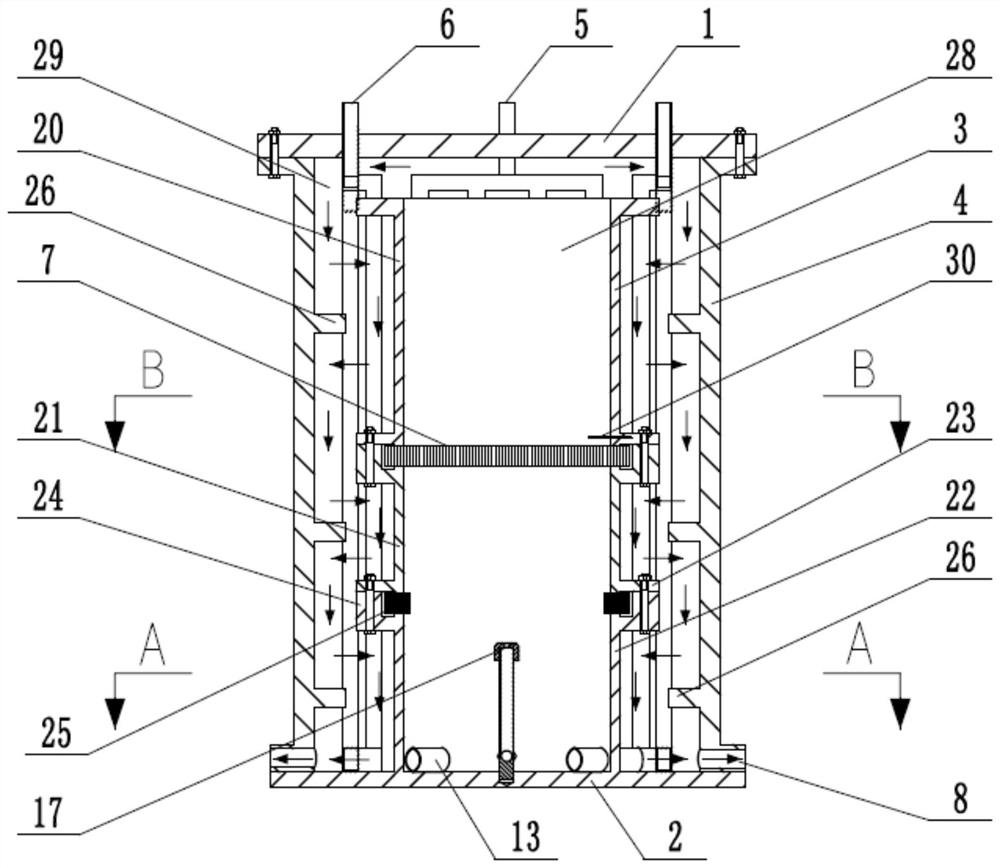

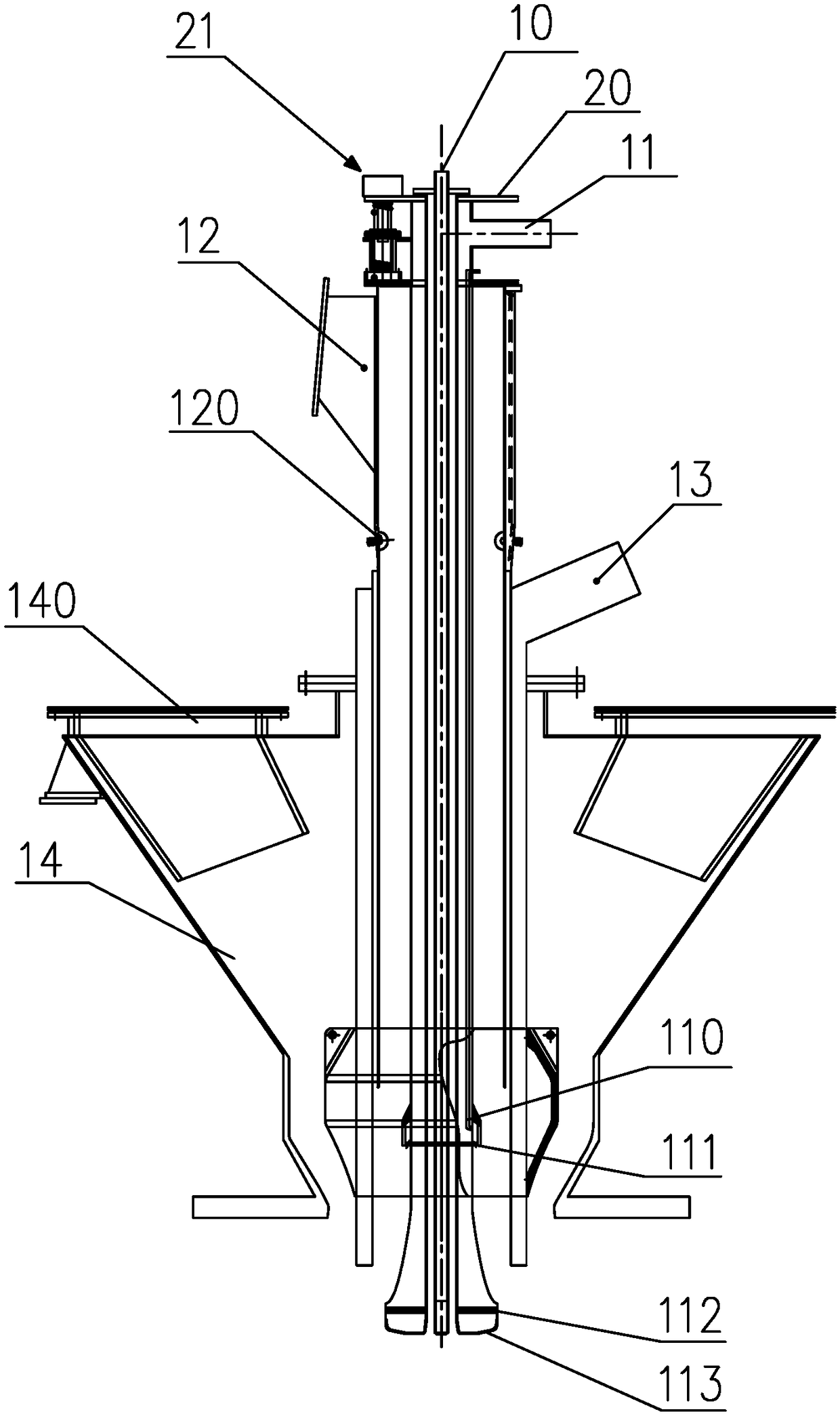

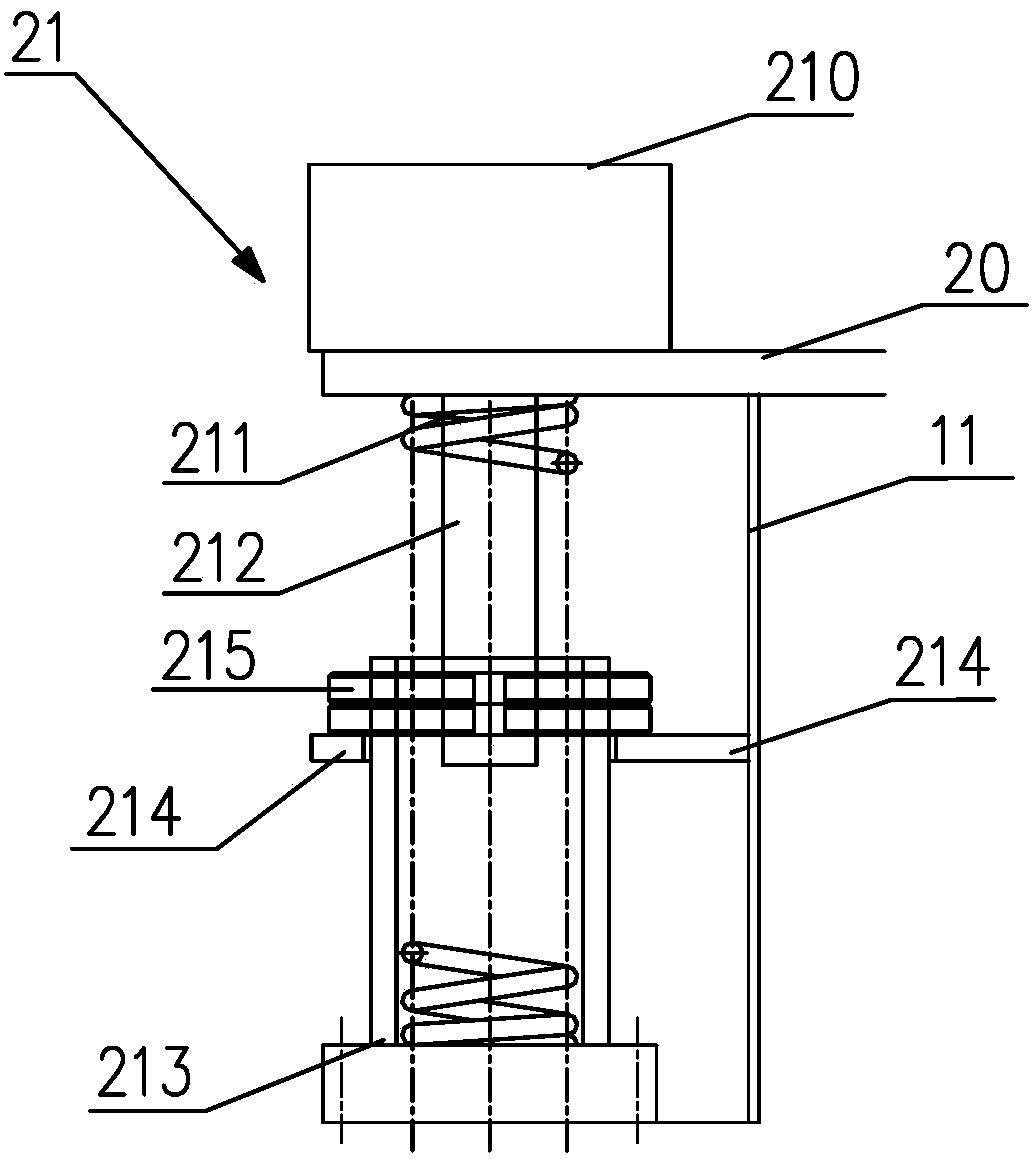

Electric drive type high-energy mixer for well cementation and mud premixing control method

ActiveCN112677314AHigh frequency responseHigh repeatabilityClay mixing apparatusSealing/packingElectric driveWell cementing

The invention discloses an electric drive type high-energy mixer for well cementation. The electric drive type high-energy mixer for well cementation comprises an ash valve main body, the bottom of the ash valve main body is provided with a mixer cavity through a connecting union, the side surface of the mixer cavity is fixedly connected with a water valve main body, a mixer cavity body is provided with a flange plate, the flange plate is positioned below the water valve main body, and the bottom of the mixer cavity is provided with a conical disc. The invention further discloses a mud premixing control method. The problems that in the prior art, a hydraulic drive type high-energy mixer is slow in response, poor in mud premixing effect and high in cost are solved.

Owner:中油国家油气钻井装备工程技术研究中心有限公司 +2

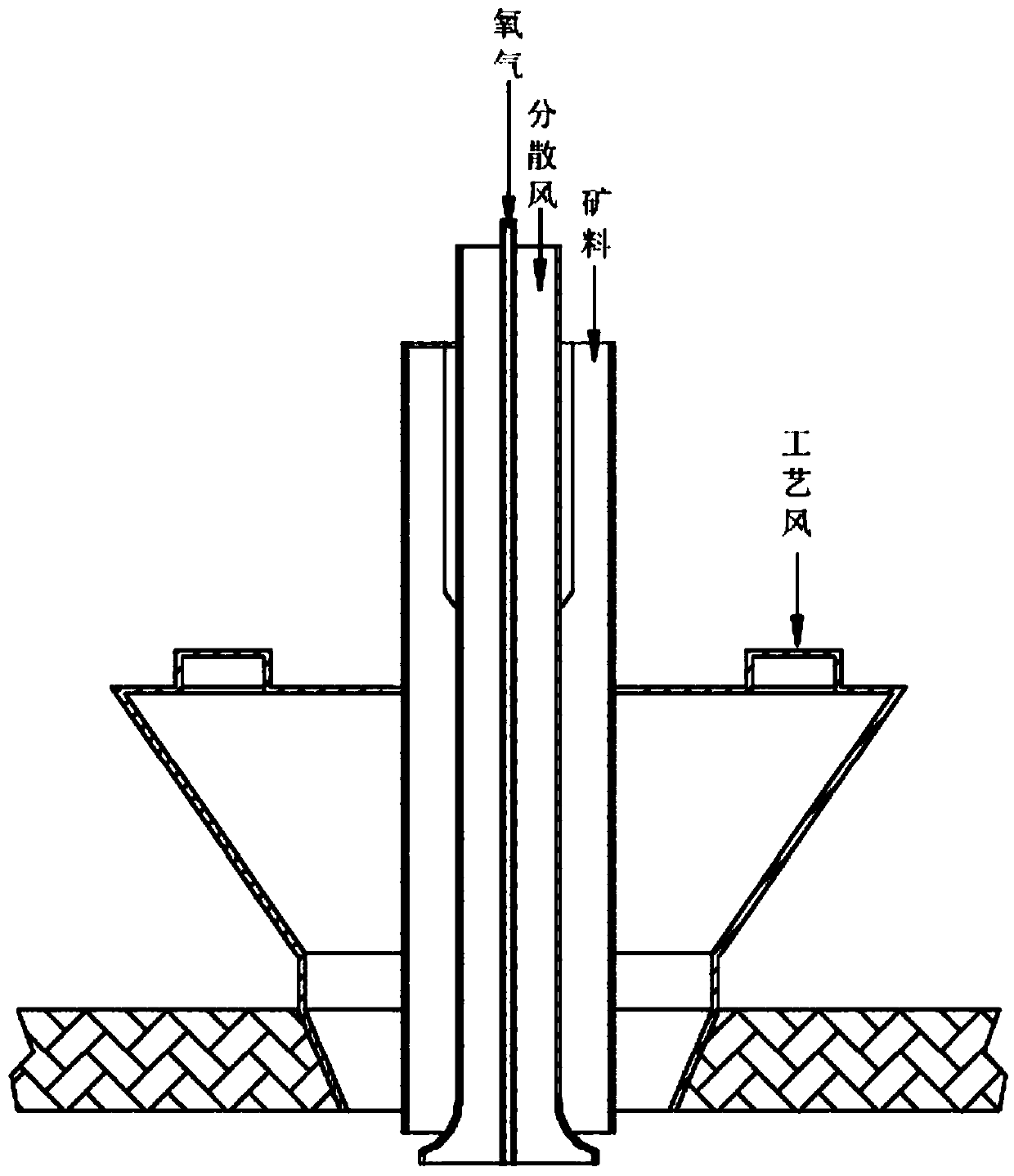

Air premixed type flare combustor capable of treating poisonous gas

InactiveCN105927992AGuaranteed decompositionImprove burnout rateIncinerator apparatusGaseous fuel burnerToxic gasCombustor

The invention relates to an air premixed type flare combustor capable of treating poisonous gas. A flare gas cylinder body of the combustor is arranged inside an air clamping sleeve body for forming a clamping sleeve body structure, and swirling plates are arranged inside the clamping sleeve body structure; a flare gas nozzle is installed at the upper end of the flare gas cylinder body; a combustion chamber is connected to the outer wall of the upper part of the air clamping sleeve body through a supporting assembly, and the air clamping sleeve body extends into the combustion chamber; a temperature monitoring element is installed on the inner wall of the combustion chamber; the combustion chamber is of a cylindrical shape, and a gap is formed between the lower part of the combustion chamber and the air clamping sleeve body and accepts entry of secondary air; an ever-burning lamp, an igniter and a combustion-assisting device are arranged outside the air clamping sleeve body in the circumferential direction, are connected to the air clamping sleeve body and extend into the combustion chamber. According to the flare combustor, the air partial combustion-supporting mode is adopted, flames are short, combustion is stable, and the burn-off rate of the poisonous exhaust gas is greatly increased; the height and the manufacturing cost of a torch can be effectively lowered on the same exhaust condition.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Titanium ore acidolysis method through sulfuric acid process

The invention relates to an improved method for the titanium ore acidolysis through sulfuric acid in the process of producing titanium white through a sulfuric acid process. The method is characterized in that: the method comprises the following steps: firstly premixing dilute waste acid produced by titanium white production after concentration and trash extraction with the titanium ore; and thenadding the premixed ore slurry into an acidolysis pot, and then adding concentrated sulfuric acid so as to initiate a main reaction through the dilution heat produced by the added concentrated acid. The method has the advantages of: 1) improving the reutilization amount of titanium white waste acid and reducing the cost of concentrated waste acid; 2) removing a sulfuric acid cooling link so as tosimplify the operation; 3) improving the operational conditions of premixing and acidolysis so as to reduce the risk of technical accidents; and 4) strengthening the premixing intensity, improving the premixing effect, so that the acidolysis reaction is sufficient and the acidolysis rate is remarkably improved.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

Miniature heat regeneration diffusion type uniform combustion device with combustion room shrunk gradually

InactiveCN105546583AExtend the motion pathImprove premix effectContinuous combustion chamberCombustion chamberEngineering

The invention provides a miniature heat regeneration diffusion type uniform combustion device with a combustion room shrunk gradually. The miniature heat regeneration diffusion type uniform combustion device comprises an ignition device, an outer sleeve, an inner sleeve and an upper panel. The inner sleeve is located in the outer sleeve. The combustion room is arranged in the inner sleeve. A preheating and premixing cavity is formed between the inner sleeve and the outer sleeve. The upper panel is arranged at the top end of the outer sleeve. A porous bottom plate is arranged at the lower end of the inner sleeve. The circumferential wall of the lower portion of the inner sleeve is a porous wall. An upper end opening of the inner sleeve serves as an exhaust opening. The combustion room communicates with the preheating and premixing cavity through the porous wall and the porous bottom plate. A plurality of air inlets and gas inlets are evenly distributed in the top end of the side wall of the outer sleeve in the circumferential direction. The combustion room of the miniature heat regeneration diffusion type uniform combustion device is in a reversely-buckled cylindrical inwards-concave horn shape so that fuel in the combustion room can be diffused, and inner combustion and temperature field distribution can be more uniform. According to the miniature heat regeneration diffusion type uniform combustion device, smoke waste heat is utilized, meanwhile, a porous material is adopted for multi-face air feeding, combustion is strengthened, a temperature field is more uniform, and therefore the power of the device is improved.

Owner:CHONGQING UNIV

Low-nitrogen combustion device with free dispersion pre-mixing combustion layer and combustion head thereof

ActiveCN111121021ANormal work will not affectReduce generationGaseous fuel burnerThermodynamicsNitrogen oxides

The invention discloses a low-nitrogen combustion device with a free dispersion pre-mixing combustion layer and a combustion head thereof. The combustion head comprises a combustion head main body; the combustion head main body is provided with a center pipe, multiple first ring layer pipes, multiple second ring layer pipes and the free dispersion pre-mixing combustion layer; and first ring layersand second ring layers are arranged on the outer side of the center pipe in sequence. Through arrangement of the first ring layer pipes and the second ring layer pipes at the outer periphery of the center pipe, the combustion head main body can form multiple independent premixing areas at the outer periphery of the center pipe in the radial direction, so that the normal work of other areas cannotbe influenced when one premixing area cannot normally work due to faults in the combustion process. Said gas and air can be fully premixed through the free dispersion pre-mixing combustion layer, sothat no local high-temperature point exists during combustion, and the generation of a nitric oxide can be prominently reduced.

Owner:史星宇

A Micro Dispersed Combustion Device for Micro-thermo-photovoltaic System

InactiveCN105402725BReduce volumeImprove premix effectBurner material specificationsIndirect carbon-dioxide mitigationCombustion chamberEngineering

The invention provides a micro diffuse type combustion apparatus for a micro-thermphotoelectric system. The micro diffuse type combustion apparatus for the micro-thermphotoelectric system comprises an ignition device, an external sleeve, an internal sleeve and an upper panel, wherein the internal sleeve is positioned in the external sleeve; the upper panel is arranged at the top end of the external sleeve; the internal sleeve is a flared structure with big lower end; the lower end of the internal sleeve is provided with a porous bottom plate; the circumferential wall of the lower part of the internal sleeve; the interior of the internal sleeve is a preheating premixing chamber; a combustion chamber is formed between the internal sleeve and the external sleeve; the preheating premixing chamber is communicated with the combustion chamber through a porous wall and the porous bottom plate; and a gas exhaust opening, an air inlet and a fuel gas inlet are formed in the upper panel. According to the invention, as air enters the porous material from various surfaces, a temperature field is uniform and the combustion is enhanced to increase the device power; through the adoption of special combustion chamber wall surface design, heat obtained by the whole wall surface is much and uniform; the micro diffuse type combustion apparatus can stably respond to fine air inlet pulsation and combustion pulsation; and meanwhile, through the adoption of the porous material with reducing aperture, tempering and backflow problems of the porous material are also avoided.

Owner:CHONGQING UNIV

Nutrient-enriched fish feed and preparing and mixing technology thereof

InactiveCN108719587AImprove the mixing effectImprove mixing efficiencyClimate change adaptationAnimal feeding stuffBlend timeMixing effect

The invention discloses a rich-enriched fish feed and a preparing and mixing technology thereof, and relates to the technical field of preparation of fish feeds. The nutrient-enriched fish feed comprises the following components in parts by weight of 10-20 parts of protein powder, 30-40 parts of flour, 10-20 parts of meat powder, 2-5 parts of vitamin powder, 2-10 parts of stone powder, 1-3 parts of table salt and an appropriate amount of water. In the process of raw material feeding, a material distributor is used for premixing, so that the mixing effect and the mixing efficiency of productionraw materials are improved, and the problems that in the prior art, the mixing is uneven and the mixing time is long, are solved.

Owner:合肥正特垂钓用品有限公司

Premixing-reinforced micro combustor and combustion method thereof

PendingCN111911919APromote atomizationIncrease temperatureBurnersIndirect carbon-dioxide mitigationBiodieselCombustor

The invention discloses a premixing-reinforced micro combustor. The premixing-reinforced micro combustor comprises an upper sealing cover, a lower sealing cover, an inner sleeve, an outer sleeve, an oil inlet pipeline, an air inlet pipeline and a catalytic grid, wherein the inner sleeve is arranged in an inner cavity of the outer sleeve, the upper sealing cover and the lower sealing cover are installed at the upper opening end and the lower opening end of the outer sleeve, the bottom end of the inner sleeve is connected with the lower sealing cover, a first interval is formed between the top end of the inner sleeve and the upper sealing cover, a second interval is formed between the outer circumferential wall of the inner sleeve and the inner circumferential wall of the outer sleeve, a waste gas outlet is formed in the bottom of the outer sleeve, the oil inlet pipeline and the air inlet pipeline are both arranged between the inner sleeve and the outer sleeve, and the catalytic grid isarranged in the inner sleeve. The invention further discloses a combustion method of the premixing-reinforced micro combustor. The premixing-reinforced micro combustor has the beneficial effects thattail gas is recycled, air and biodiesel are preheated, and the heat loss of the combustor is reduced so that combustion can be stably and efficiently carried out.

Owner:SOUTH CHINA UNIV OF TECH

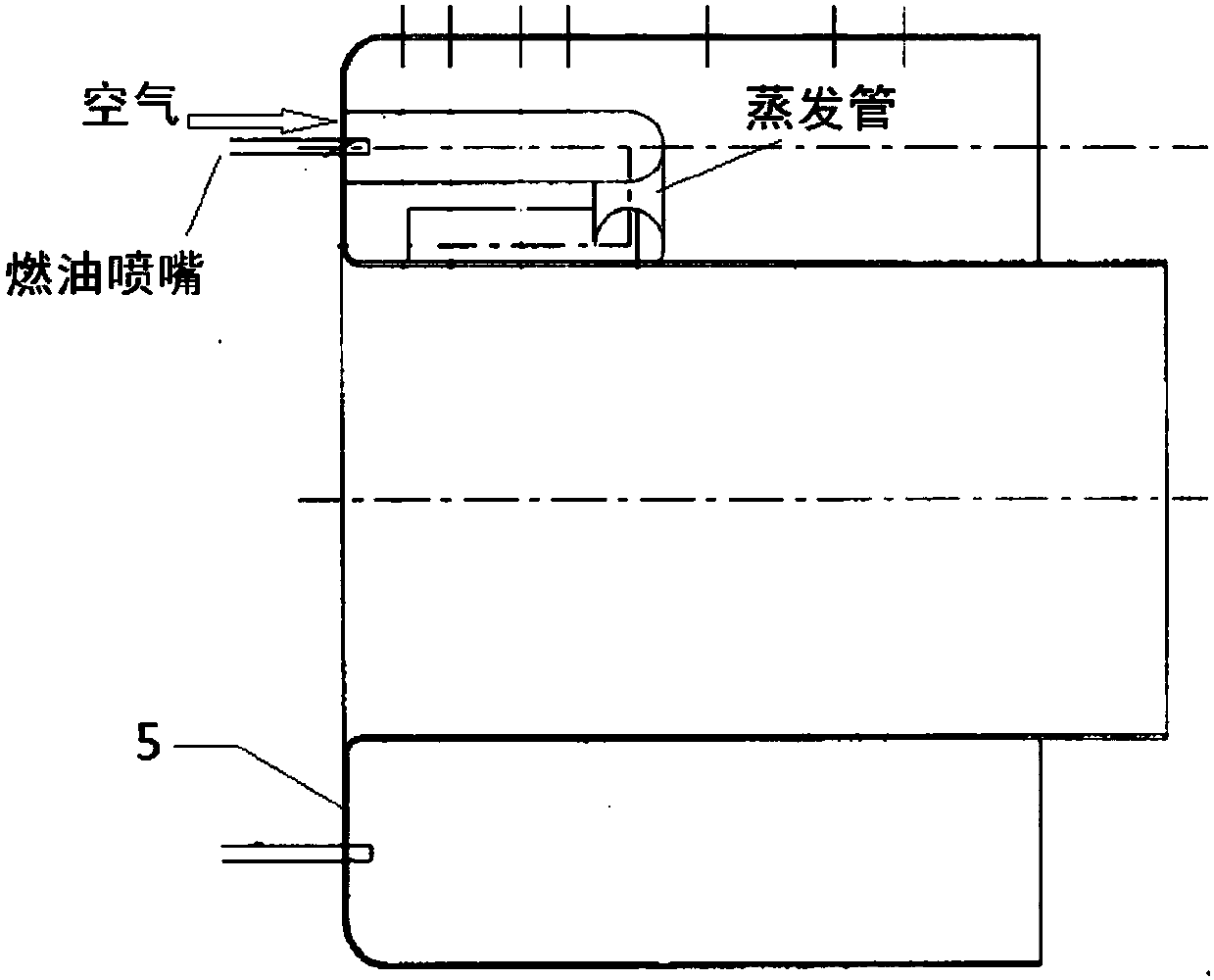

A fuel-cooled evaporator tube structure

ActiveCN105716120BGuaranteed fuel supplyIncrease warm-upContinuous combustion chamberCombustorThermal state

The invention relates to a fuel-cooled type evaporating pipe structure. The evaporating pipe structure is applicable to engines and combustion chamber components of other burners, a closed fuel cooling cavity is formed between an evaporating pipe inner sleeve and an evaporating pipe outer sleeve, a fuel inlet pipe extends into the fuel cooling cavity in the outlet section position of the evaporating pipe, at least one row of fuel nozzles evenly distributed in the circumferential direction are arranged along the inlet section of the evaporating pipe inner sleeve, grooves communicating with one another are formed in the outer surface of the evaporating pipe inner sleeve, and fuel is delivered to the outlet section from the inlet section of the fuel cooling cavity along the grooves and is sprayed into the evaporating pipe at the inlet section. According to the structure, the fuel arrives at the fuel nozzles at the inlet section of the evaporating pipe from the inner cavity of the outlet section of the evaporating pipe and cools the wall surface of the evaporating pipe, and thermal state ablation protection of the evaporating pipe is completed; each way of fuel is preheated independently, the preheating degree of the fuel is increased, and the evaporating and premixing effect of the fuel is enhanced. By the aid of the overall design, cooling protection of the evaporating pipe is realized, and the service life is prolonged; high-intensity preheating of the fuel is realized, and the evaporating and premixing degree is increased.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

A graded combustion chamber head with a swirling pre-diaphragm plate structure

ActiveCN113280367BOptimize spatial distributionImprove combustion effectContinuous combustion chamberCombustion chamberEngineering

The present disclosure provides a staged combustion chamber head with a swirling pre-diaphragm plate structure, comprising: a pre-combustion stage, and a main combustion stage sheathed outside the pre-combustion stage; the main combustion stage includes an inner ring, and a sleeve sleeved outside the inner ring; the inner ring has a plurality of nozzle holes distributed in the circumferential direction; an annular air passage is formed between the inner ring and the sleeve; Axial swirl vanes and swirling pre-film plates are arranged in sequence from front to back; a plurality of axial swirling vanes are provided, and the plurality of axial swirling vanes are arranged in the circumferential direction; the swirling pre-film The plate is annular, and the swirling pre-film plate is formed by a plurality of segmented arcs arranged in the circumferential direction; the spray holes are arranged directly on the arc ridge of the swirling pre-film plate, and any two adjacent ones are arranged. There are two segmented arcs between the nozzle holes; the radial heights of the front and rear ends of the arc ridges are both greater than the radius of the outer surface of the inner ring and smaller than the radius of the inner surface of the sleeve.

Owner:AERO ENGINE ACAD OF CHINA

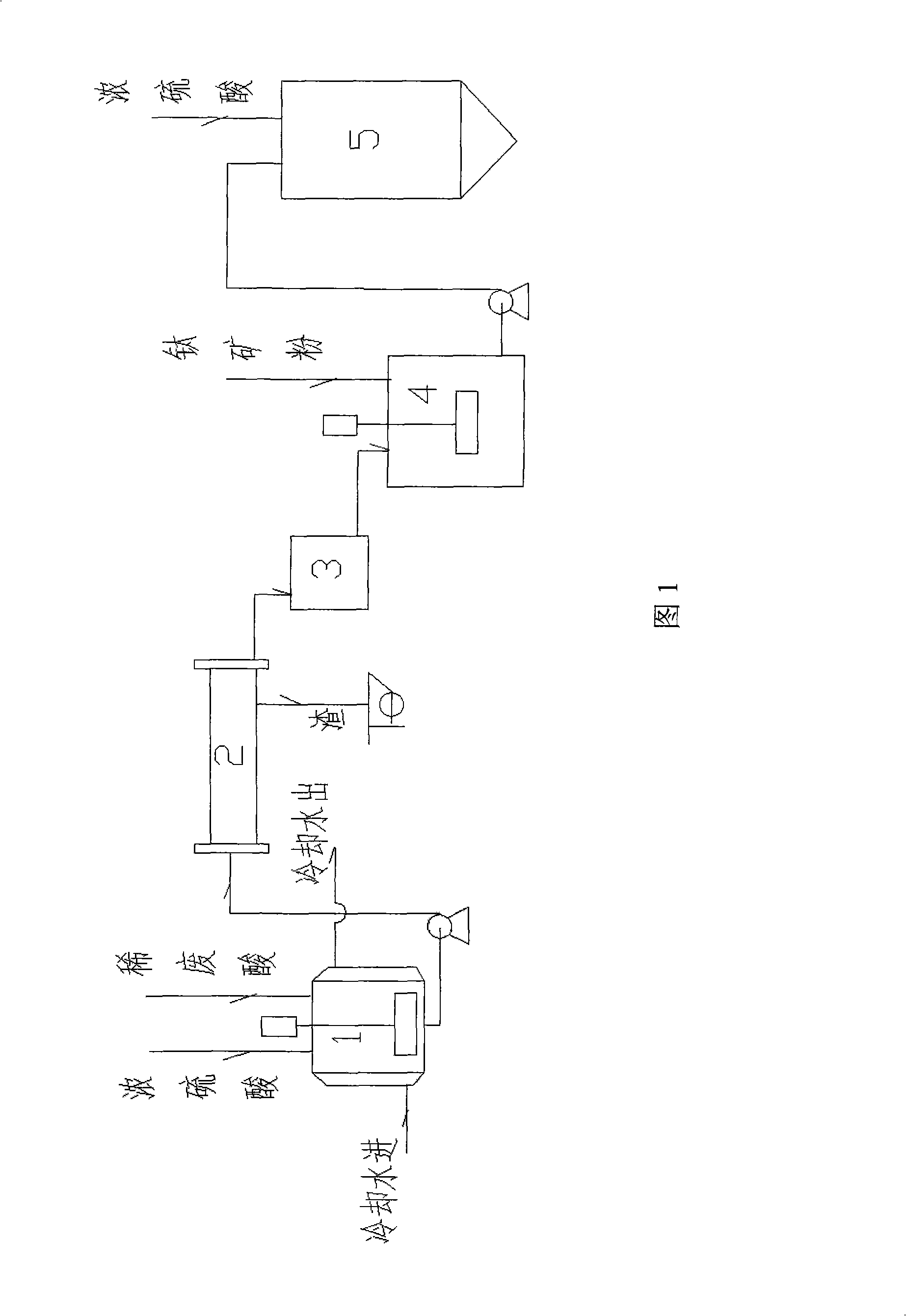

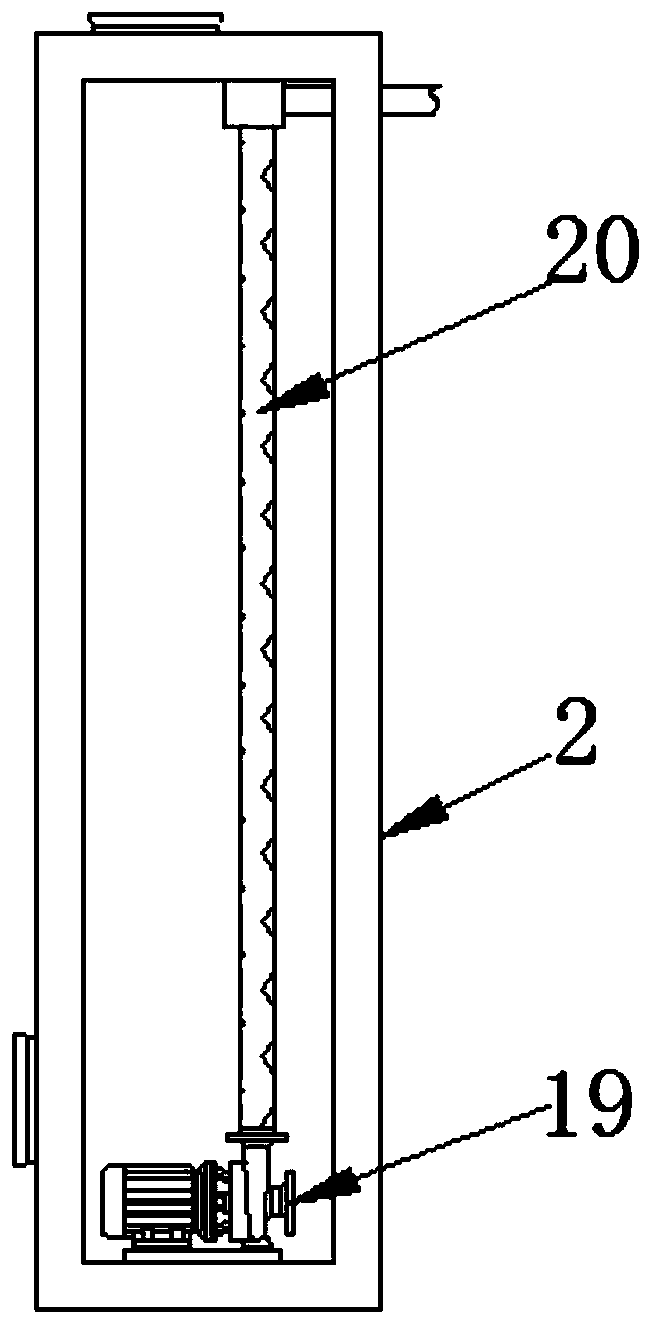

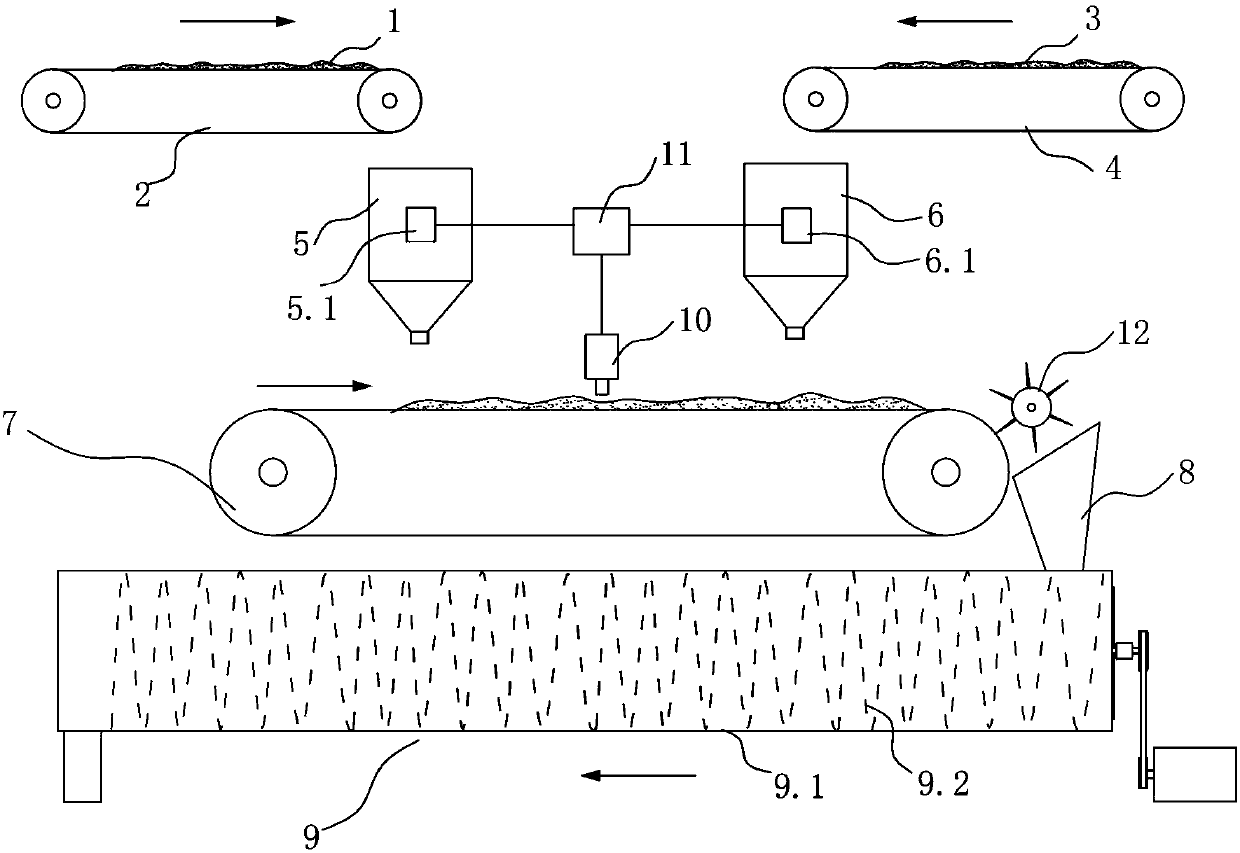

Compound fertilizer premixing and conveying system

InactiveCN109693925AImprove premix effectIncrease productivityConveyorsConveyor partsAdditive ingredientEngineering

The invention provides a compound fertilizer premixing and conveying system. The compound fertilizer premixing and conveying system comprises a first conveying belt and a second conveying belt, wherein the first conveying belt is used for conveying compound fertilizer ingredient I, and the second conveying belt is used for conveying compound fertilizer ingredient II, a first discharging cylinder is arranged below the conveying tail end of the first conveying belt, and a second discharging cylinder is arranged below the conveying tail end of the second conveying belt; a third conveying belt isarranged below the first discharging cylinder and the second discharging cylinder, the first discharging cylinder is located above the front end of the third conveying belt in the conveying direction,and the second discharging cylinder is located above the rear end of the third conveying belt in the conveying direction; and a sliding chute is arranged at the tail end of the third conveying belt in the conveying direction, and a discharging port of the sliding chute is communicated with a feeding port of a roller conveyor. The compound fertilizer premixing and conveying system effectively improves the premixing effect of all the ingredients of the compound fertilizer, the continuous operation is realized, and the production efficiency is improved.

Owner:HUBEI YISHIZHUANG AGRI TECH

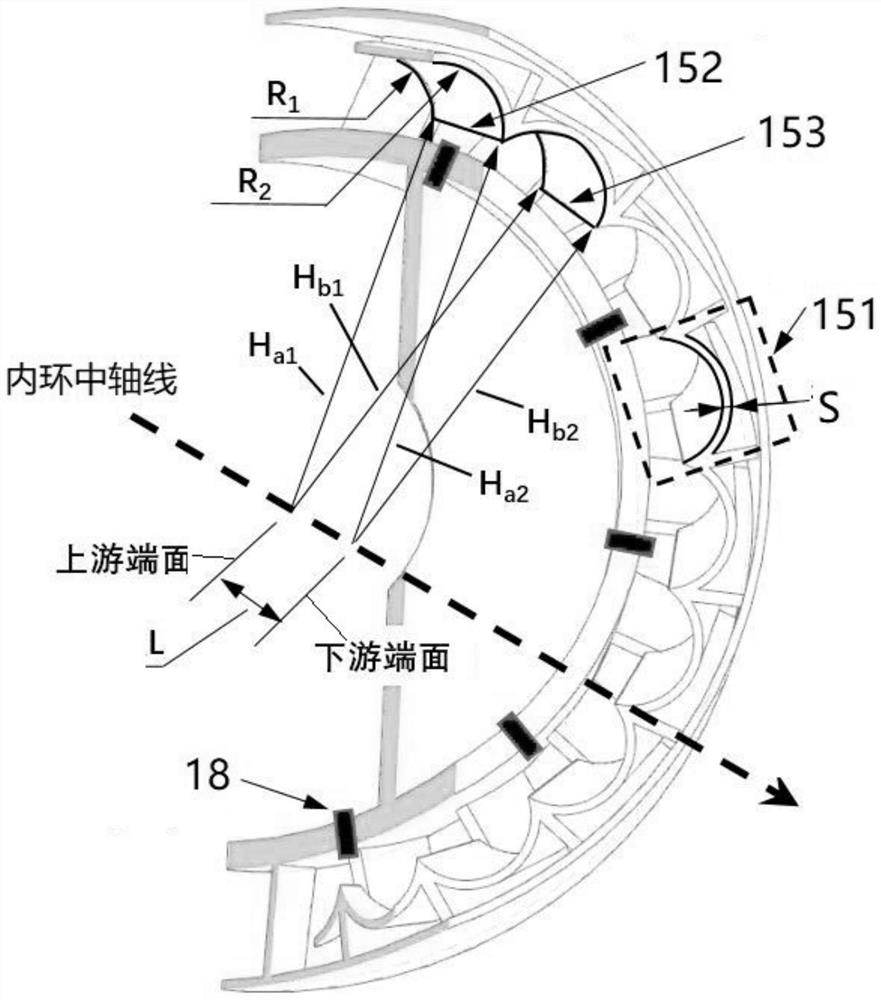

A liner assembly that regulates air flow in a combustion zone

ActiveCN108458366BChange flow rateIncrease air volumeContinuous combustion chamberThermodynamicsCombustor

The invention discloses a bush assembly capable of adjusting air flow of a combustion zone so as to solve the problem that lean-oil flameout of idling rating in a currently-occurring condition. The bush assembly comprises an bush out wall, a sealing sleeve, a floating body and a moving mechanism, wherein the bush outer wall is of a annular shape, and an installing hole is formed in an upstream endof the bush outer wall, the sealing sleeve is in a cylindrical shape and is coaxially fixed with the installing hole, and a floating channel is formed inside the sealing sleeve, the floating body isarranged on the inner side of the sealing sleeve in a coaxial mode, and can move up and down inside the floating channel, and the moving mechanism is connected with the floating body and controls thefloating body to move up and down. The bush assembly capable of adjusting air flow of combustion zone has the beneficial effects that the area of an air flow channel is changed by changing the heightof the bush outer wall, and therefore the air flow rate is changed, and the jet angle of an air inlet hole is finally influenced, the effect of adjusting the air flow of an annular region is achieved;the oil-gas ratio of the annular region can be adjusted by adjusting the air flow of the annular region, so that the phenomenon of lean-oil flameout of a combustor in the idling rating is prevented;and meanwhile, when the combustor works in a pre-mixing mode, the air amount of the annular region can be increased, so that the premixed effect of fuel and air is enhanced.

Owner:CAS HEFEI MICRO GAS TURBINE RES INST CO LTD

Preparation method of propellant slurry without precipitated bonding agent

The invention relates to a preparation method of propellant slurry without a precipitated bonding agent. The method comprises the steps of pre-baking hydroxyl-terminated polybutadiene and a diethanolamine melamine complex for 12h or more at 50+ / -10 DEG C so as to reduce the viscosity of the hydroxyl-terminated polybutadiene and the diethanolamine melamine complex; gradually mixing the hydroxyl-terminated polybutadiene with a viscous material by premixing in a small amount for a plurality of times so as to gradually achieve the purpose of evenly pre-mixing the materials; pouring the premixed slurry of the hydroxyl-terminated polybutadiene and the diethanolamine melamine complex into a premix container of the other raw materials for premixing, and fully and evenly mixing. The method guarantees the uniformity of the premixed propellant slurry in the weighing process by utilizing the existing hardware facilities of the process and by means of analysis, explosion and process improvement inthe aspects such as raw material preparation, a premixing process of the propellant slurry and the physical and chemical properties of the raw materials; the method has strong operability; furthermore, the uniformity of the premixed propellant slurry is basically the same, so that the quality of the propellant slurry is improved.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

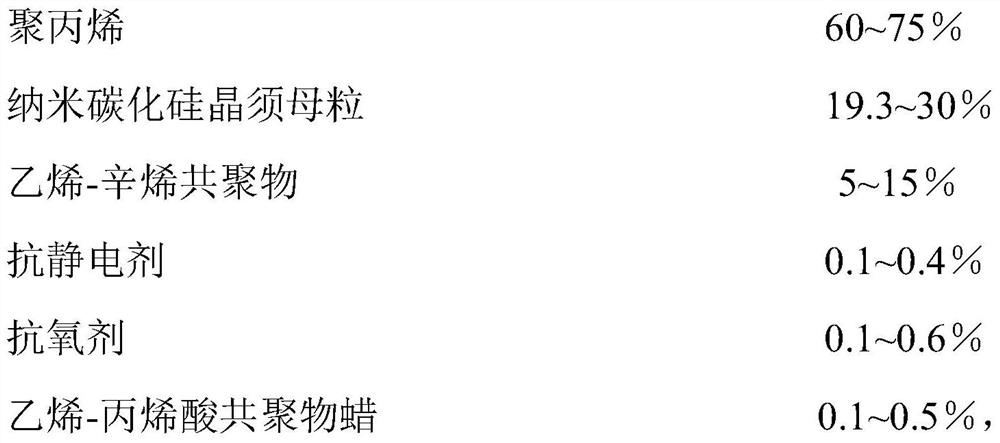

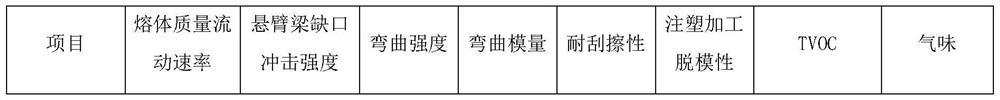

A low-volatility nano-filler modified polypropylene material and its preparation method and application

ActiveCN109679206BImprove scratch resistanceKeep the toughness the sameCarbide siliconPolymer science

The invention discloses a low-volatile nano filler modified polypropylene material, a preparation method and application thereof. The low-volatile nano-filler modified polypropylene material contains the following components in mass percentage: 60-75% of polypropylene, 19.3-30% of nano-silicon carbide whisker masterbatch, 5-15% of ethylene-octene copolymer, 0.1-0.4% of antistatic agent, 0.1-0.6% of antioxidant and 0.1-0.5% of ethylene-acrylic acid copolymer wax. The present invention uses random copolymerized polypropylene as the resin base material, and improves the scratch resistance of the polypropylene material by adding self-made nano-silicon carbide whisker masterbatch, antistatic agent and ethylene-octene copolymer for modification. Reduced performance. The modified polypropylene prepared by the invention can be widely used in the fields of automobiles and home appliances.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

A kind of preparation method of the medicine slurry without binding agent precipitation

A preparation method of a syrup without bonding agent precipitation, pre-baking the hydroxyl-terminated polybutadiene and diethanolamine melamine complex at 50°C±10°C for more than 12 hours to reduce the concentration of hydroxyl-terminated polybutadiene and diethanolamine Viscosity of the melamine complex; through a small amount of premixing multiple times, the hydroxyl-terminated polybutadiene is gradually blended with the viscous material, and the purpose of premixing it is gradually achieved; the hydroxyl-terminated polybutadiene and diethanolamine The melamine complex premixed slurry is poured into other raw material premix containers to participate in premixing, and fully stirred. The present invention utilizes the existing hardware facilities of the process, and improves the process through the analysis and exploration of the preparation of raw materials, the premixing process of the drug slurry, and the physical and chemical characteristics of the raw materials, so as to ensure the uniformity of the premixed drug slurry in the weighing process, and has the advantages of The operability is strong, and the uniformity of the pre-mixed slurry is basically the same, which ensures the quality of the slurry.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

A vibrating premixed concentrate nozzle

ActiveCN106288815BIncrease productivityLow maintenanceCharge composition/stateCharge manipulationProduct gasCopper

Owner:HEFEI GENERAL MACHINERY RES INST

Pipeline smoke heating device

The invention discloses a pipeline smoke heating device. The heating device is fixedly into a flue, and comprises a secondary smoke channel, a gas rotational flow cavity and a center air channel fromoutside to inside. Inclined gas rotational flow blades are arranged between the outer wall of the outlet of the center air channel and the inner wall of the gas rotational flow cavity. A combustion cavity is formed in the front ends of the gas rotational flow blades and the center air channel, and a gas rotational flow cavity is formed in the rear ends of the gas rotational flow blades and the center air channel. The gas pipeline communicates with the gas rotational flow cavity, and is filled with the gas. A burning torch penetrates through outer layer walls and is inserted into the combustioncavity. A plurality layers of inclined smoke rotational blades are arranged between the outer wall of the gas rotational flow cavity and the inner wall of the secondary smoke channel. Oxygen in the smoke is adopted to complete combustion and release heat to increase the temperature of the smoke. The shape and size of flame are controlled by the rotational flow blades, and therefore the length ofthe flame is reasonable and the radius of the flame is less than the diameter of a chimney. Damage caused by superheat of the flue is avoided. The temperature rising process of the smoke is completedby the heat exchanging between cold smoke and hot smoke. The process is direct, the cost is saved, energy is saved, and efficiency is achieved.

Owner:WUHAN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com