Improved vibrating premixed concentrate burner

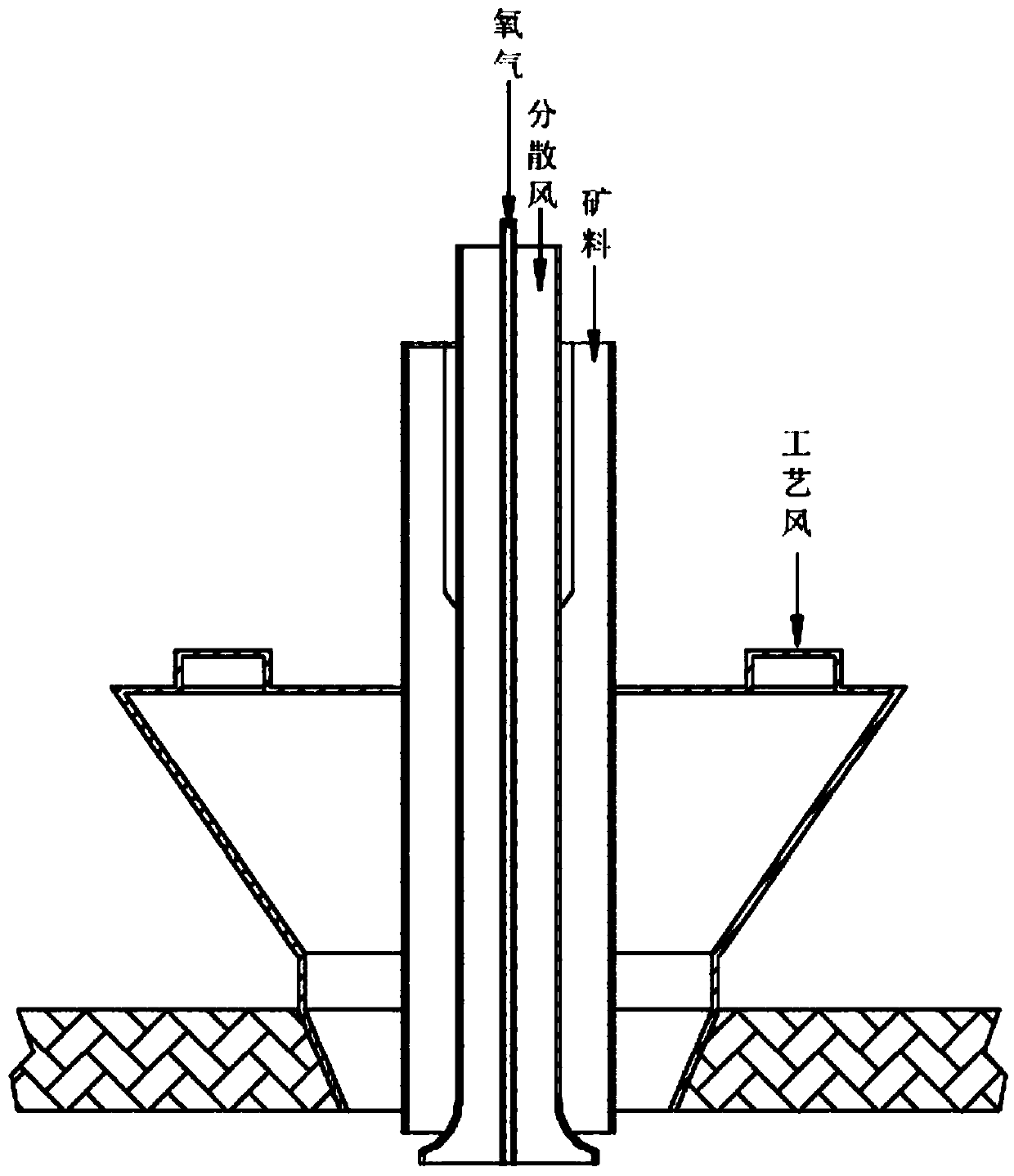

一种预混型、精矿的技术,应用在铜的冶炼领域,能够解决四氧化三铁含量增加、影响燃烧反应传质、传热速率、难以保证矿料与工艺风充分混合等问题,达到降低设备维护费用、提高生产效率、提高预混和停留时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

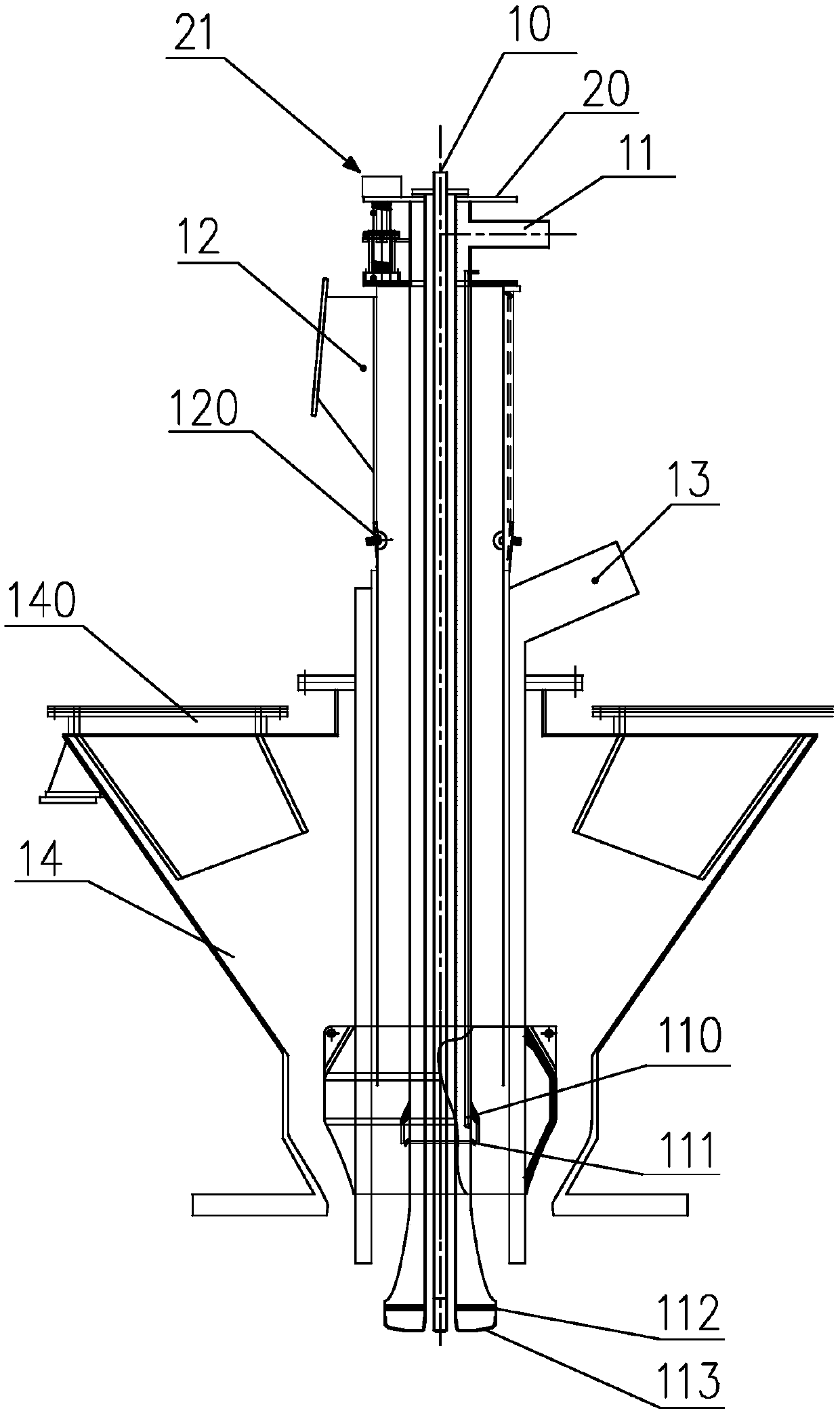

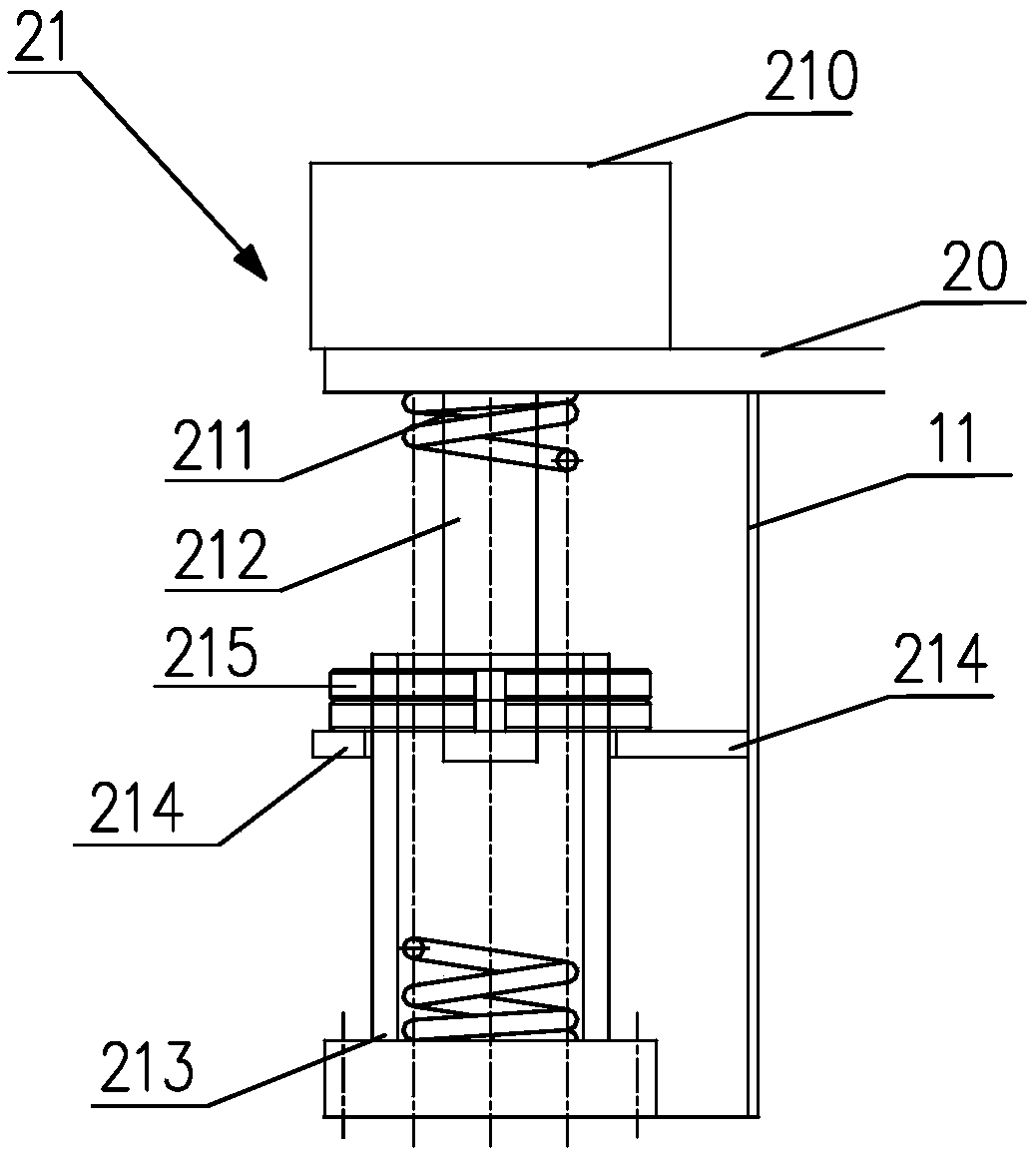

[0034] like figure 2 As shown, it is an improved vibrating premixing concentrate nozzle, which includes an oxygen supply pipe 10 with overlapped tube cores and arranged vertically in sequence, a hollow annular dispersion air pipe 11, and a cone-shaped air chamber forming Process bellows 14, the dispersing air duct 11 is a side air intake, and the outer wall of the dispersing air duct 11 is sleeved with a feed box 12 opening obliquely downward at its top, and the top of the hollow annular dispersing air duct 11 A horizontal fixed plate 20 is fixedly connected, and an air hamme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com