Low-odor polypropylene material for automobile interior decoration and preparation method and application thereof

A polypropylene material, low-odor technology, applied in the field of modification of polymer composite materials, can solve problems such as affecting physical health, and achieve the effect of solving the difficulty of adding liquid, improving the uniformity of distribution, and improving the dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The halloysite nanotube master batch used in the embodiments of the present invention and comparative examples is prepared by the following method:

[0050] (1) Proportion according to the following mass percentage composition: block copolymerized polypropylene (brand: PPEP548R, China Sea Shell Petrochemical Co., Ltd.) 18.6%, halloysite nanotubes (diameter 100-150nm, length 200nm-500nm , Zhengzhou Huize Biochemical Technology Co., Ltd.) 80%, hindered phenolic antioxidant (model: SONOX 1010, Linyi Sanfeng Chemical Co., Ltd., Shandong Province) 0.2%, phosphorus antioxidant (model: SONOX 168, Shandong Province Linyi Sanfeng Chemical Co., Ltd.) 0.2%, lubricant (N,N'-ethylene bisstearamide, brand: TLZJ-6, Chengdu Tongli Auxiliary Co., Ltd.) 1%.

[0051] (2) Add the above-mentioned materials into a pressurized tumbling internal mixer, control the temperature in the internal mixing chamber to 200-220°C, the rotor speed to 26r / min, and the internal mixing time to 15min. The ro...

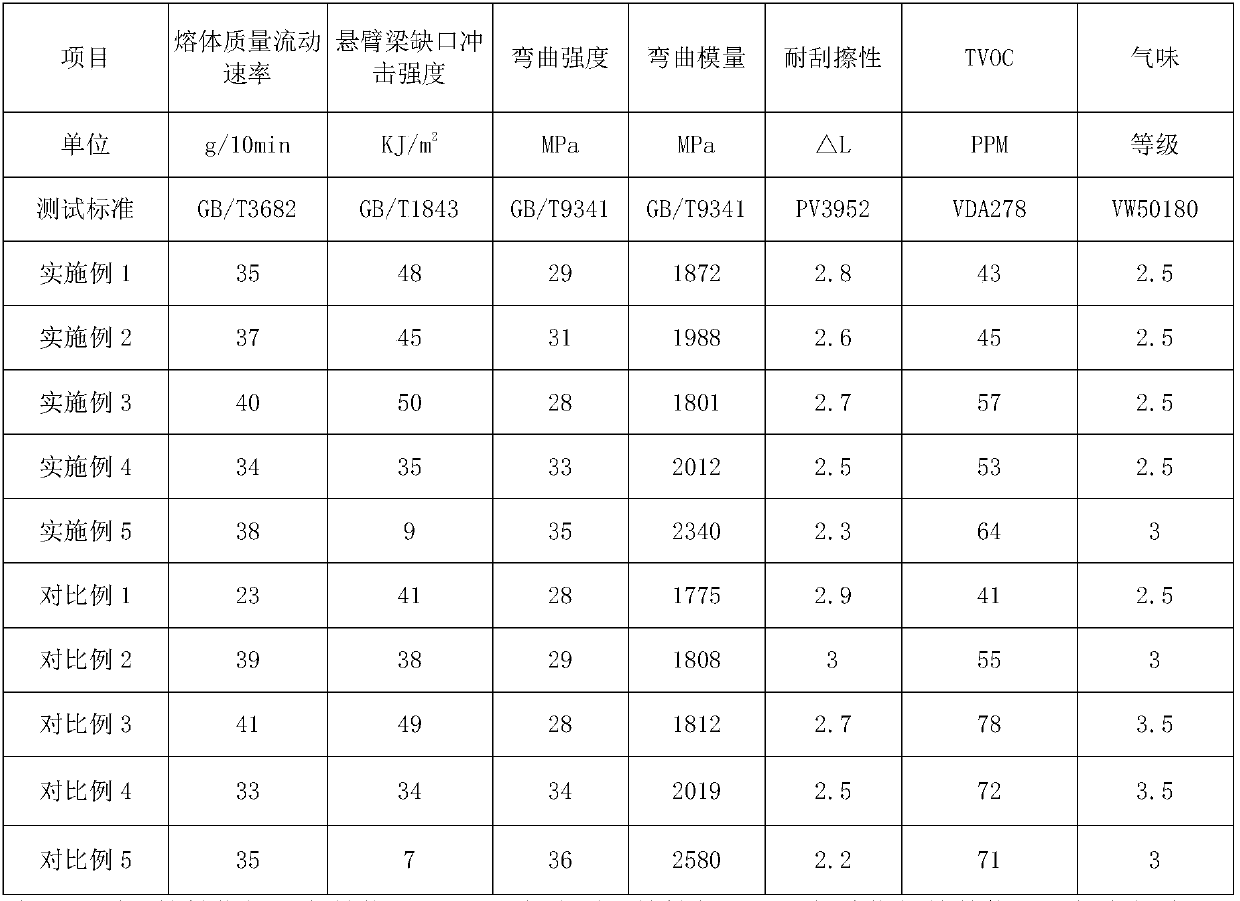

Embodiment 1

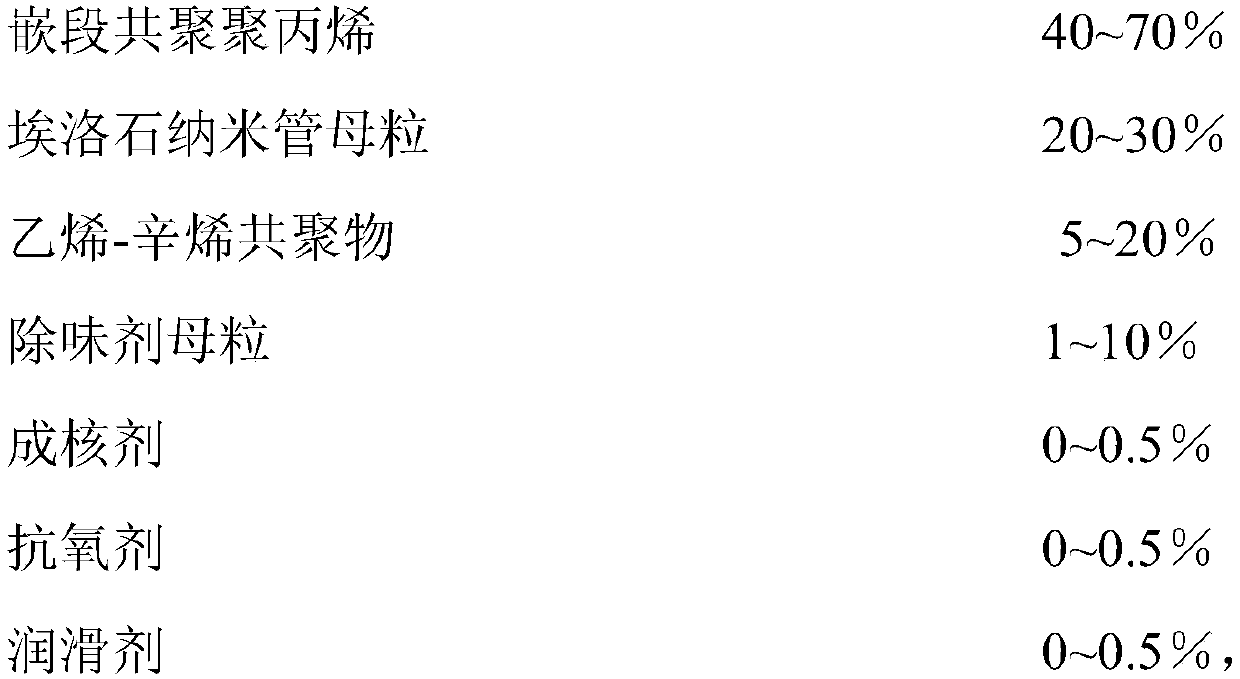

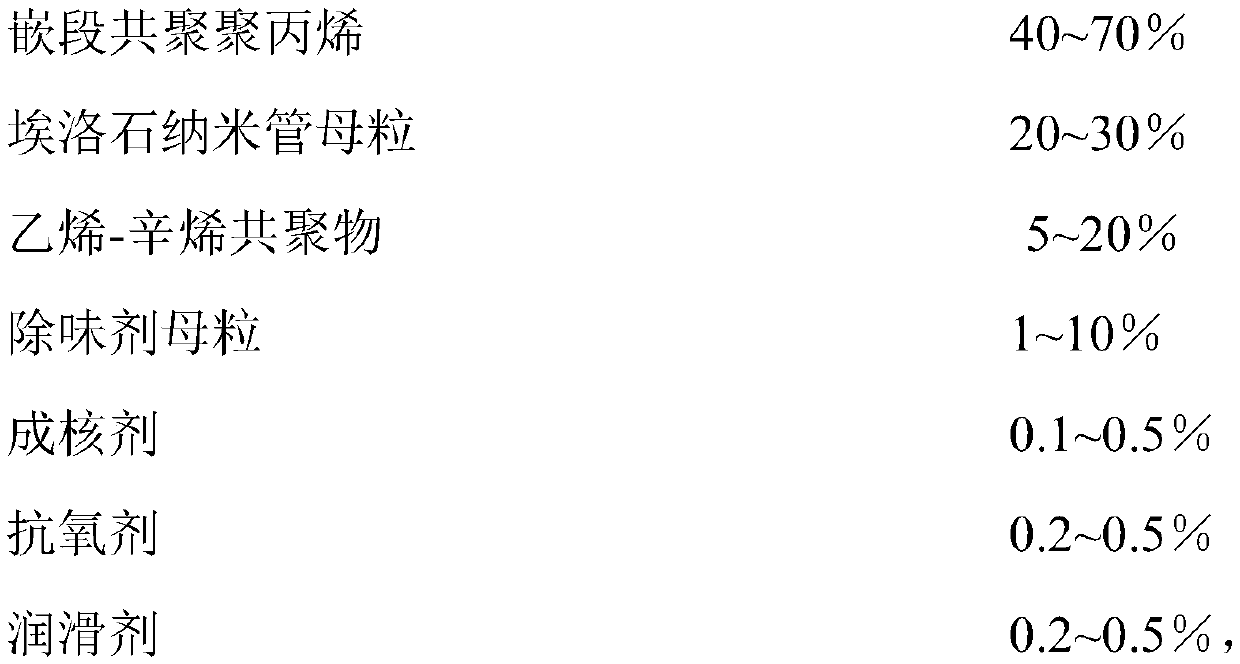

[0058] Proportioning is made according to the following mass percentages:

[0059] Block copolymerized polypropylene 40% (brand: PPBX3900, Korea SK Chemical Co., Ltd.), halloysite nanotube masterbatch 30% (self-made), ethylene-octene copolymer 20% (brand: POE8200, American Dow Chemical Company ), deodorant masterbatch 9.3% (self-made), nucleating agent 0.2% (model: NA-11, Japan Adike Company), antioxidant 1010 0.1% (model: SONOX1010, Sanfeng Chemical Industry, Linyi City, Shandong Province Co., Ltd.), antioxidant 168 0.1% (Model: SONOX 168, Linyi Sanfeng Chemical Co., Ltd., Shandong Province) and lubricant 0.3% (calcium stearate 3818, Zhongshan Huamingtai Chemical Co., Ltd.).

[0060] After weighing the above-mentioned materials, add them into a high-speed mixer (rotating speed 1000rpm) and stir for 5 minutes. Add the uniformly stirred materials into the main feeding hopper of a parallel twin-screw extruder with an aspect ratio of 48:1, and set the temperature of each section...

Embodiment 2

[0063] Proportioning is made according to the following mass percentages:

[0064] Block copolymerized polypropylene 45% (brand: PPBX3900, Korea SK Chemical Co., Ltd.), halloysite nanotube masterbatch 29.3% (self-made), ethylene-octene copolymer 15% (brand: POE8200, American Dow Chemical Company ), deodorant masterbatch 10% (self-made), nucleating agent 0.2% (Model: NA-11, Japan Adike Company), antioxidant 1010 0.1% (Model: SONOX1010, Sanfeng Chemical Industry, Linyi City, Shandong Province Co., Ltd.), antioxidant 168 0.1% (Model: SONOX 168, Linyi Sanfeng Chemical Co., Ltd., Shandong Province) and lubricant 0.3% (calcium stearate 3818, Zhongshan Huamingtai Chemical Co., Ltd.).

[0065] After weighing the above-mentioned materials, add them into a high-speed mixer (rotating speed 1500rpm) and stir for 6 minutes. Add the uniformly stirred materials into the main feeding hopper of a parallel twin-screw extruder with an aspect ratio of 48:1, and set the temperature of each sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com