A low-volatility nano-filler modified polypropylene material and its preparation method and application

A polypropylene material and nano-filler technology, applied in the field of modification of polymer composite materials, can solve the problem that the strict requirements of the odor, atomization and other properties of automobile interior parts cannot be met, the surface scratch resistance is poor, and the appearance of the product is reduced. degree and other issues, to achieve excellent scratch resistance, improve low temperature resistance, and improve antistatic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

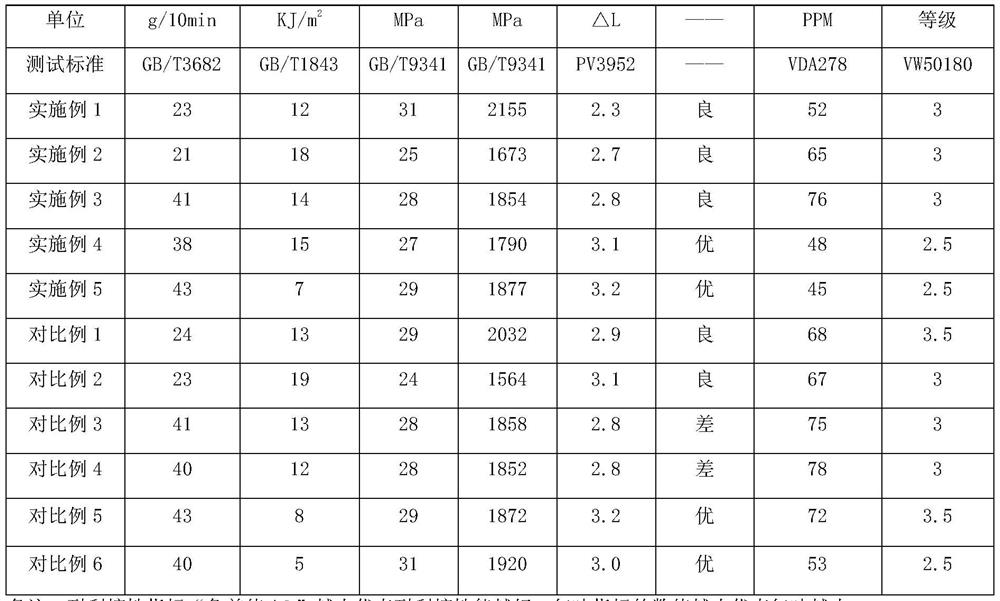

Examples

Embodiment 1

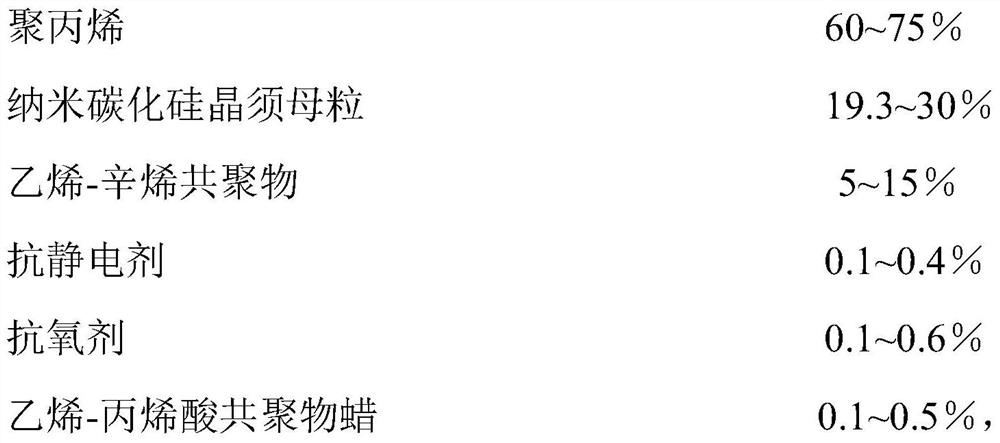

[0045] Compared with the following mass percentage:

[0046] 60% of anti-stress white polypropylene (grade: pprp346r, medium sea shell petrochemical Co., Ltd.), nanotonic silicon carbide crystal material 5% (self-made), ethylene-octene copolymer 9.4% (graphic: DF7350, Japan Sanjing Chemical company), antistatic agent 0.1% (grade: atmer129, British Heavy company), affected phenolic antioxidant 0.1% (Model: Sonox1010, Shandong Linyi Sanfeng Chemical Co., Ltd.), phosphorus-containing antioxidant 0.1 % (Model: Sonox 168, Shandong Linyi Sanfeng Chemical Co., Ltd.), Ethylene-acrylic copolymer wax 0.3% (grade: AC 540A, US Honeywell).

[0047] After the above material was weighed, it was added to the high speed mixer (Rotary 1500 rpm) for 3 minutes. The above material that is uniformly mixed into a parallel twin-screw extruder of 48: 1 is added to the main feed bouquet of the parallel twin screw extruder, and the temperature of each of the extruders from the hopper to the die is (Total 12...

Embodiment 2

[0050] Compared with the following mass percentage:

[0051] 60% of anti-stress white polypropylene (grade: pprp346r, Zhonghai Shell Petroleum Chemical Co., Ltd.), nano-carbicarn carbide crystal must master 5.4% (self-made), vinyl-octene copolymer 15% (graphic: DF7350, Japan Many Chemical company), antistatic agent 0.1% (grade: atmer129, British Heavy company), affected phenolic antioxidant 0.1% (Model: Sonox1010, Shandong Linyi Sanfeng Chemical Co., Ltd.), phosphorus-containing antioxidant 0.1 % (Model: Sonox 168, Shandong Linyi Sanfeng Chemical Co., Ltd.), Ethylene-acrylic copolymer wax 0.3% (grade: AC 540A, US Honeywell).

[0052] After the above material was weighed, it was added to a high-speed mixer (rotational speed 2000 rpm) for 5 minutes. The above material that is uniformly mixed into a parallel twin-screw extruder of 48: 1 is added to the main feed bouquet of the parallel twin screw extruder, and the temperature of each of the extruders from the hopper to the die is (To...

Embodiment 3

[0055] Compared with the following mass percentage:

[0056] Anti-stress white polypropylene 65% (grade: pprj766mo, Nordic Chemical Co., Ltd.), nano-carbonated silicon crystal abduction of 24.4% (self-made), ethylene-octene copolymer 10% (grade: DF7350, Japan Sanjing Chemical Company) Anti-static agent 0.1% (grade: TS-5, Japan Flower King Co., Ltd.), affected phenolic antioxidant 0.1% (model: 1790, US Cyanide Chemical Co., Ltd.), phosphorus antioxidant 0.1% (model:: SONOX 168, Shandong Linyi Sanfeng Chemical Co., Ltd.), Ethylene-acrylic copolymer wax 0.3% (grade: AC 540A, US Honeywell).

[0057] The above material was weighed and stirred in a high-speed mixer (rotational speed 2500 rpm) for 5 minutes. The above material that is uniformly mixed into a parallel twin-screw extruder of 48: 1 is added to the main feed bouquet of the parallel twin screw extruder, and the temperature of each of the extruders from the hopper to the die is (Total 12) : 180 ° C, 180 ° C, 190 ° C, 210 ° C, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com