Premixing-reinforced micro combustor and combustion method thereof

A micro-combustion and premixing technology, applied in the combustion method, burner, combustion type, etc., can solve the problems of incomplete combustion, difficult carbon deposition cleaning, large atomized droplet size, etc. Reduce the wet wall effect and enhance the effect of the premix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with drawings and embodiments.

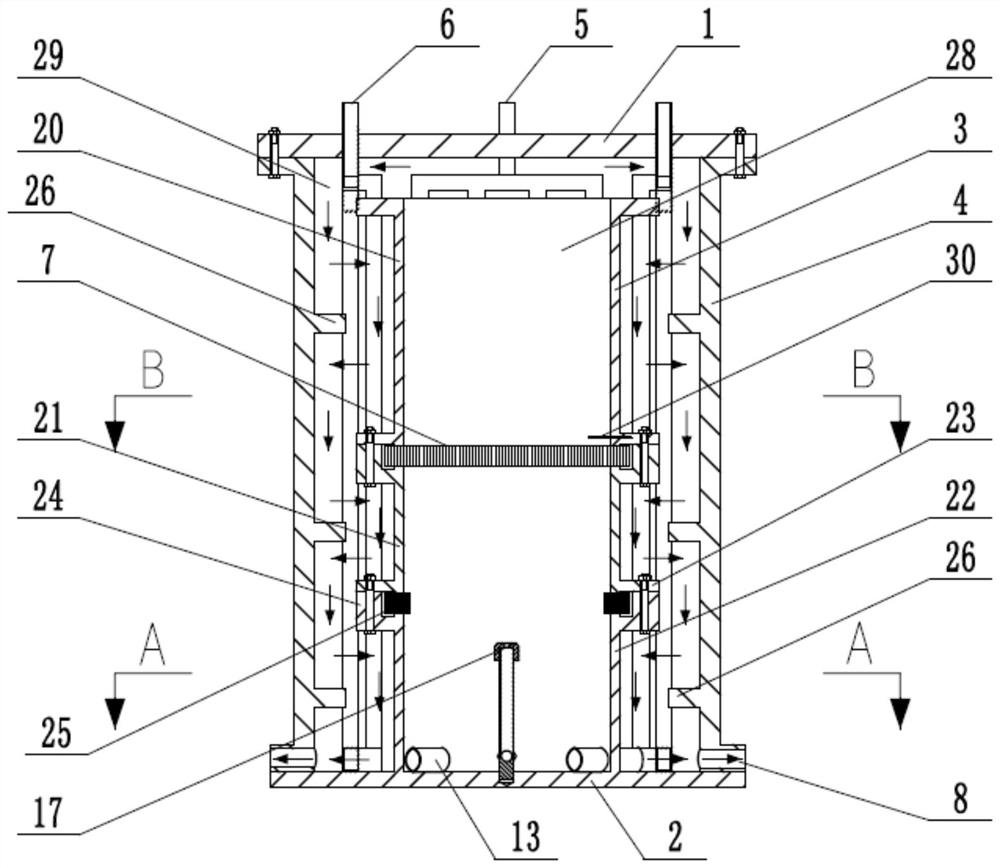

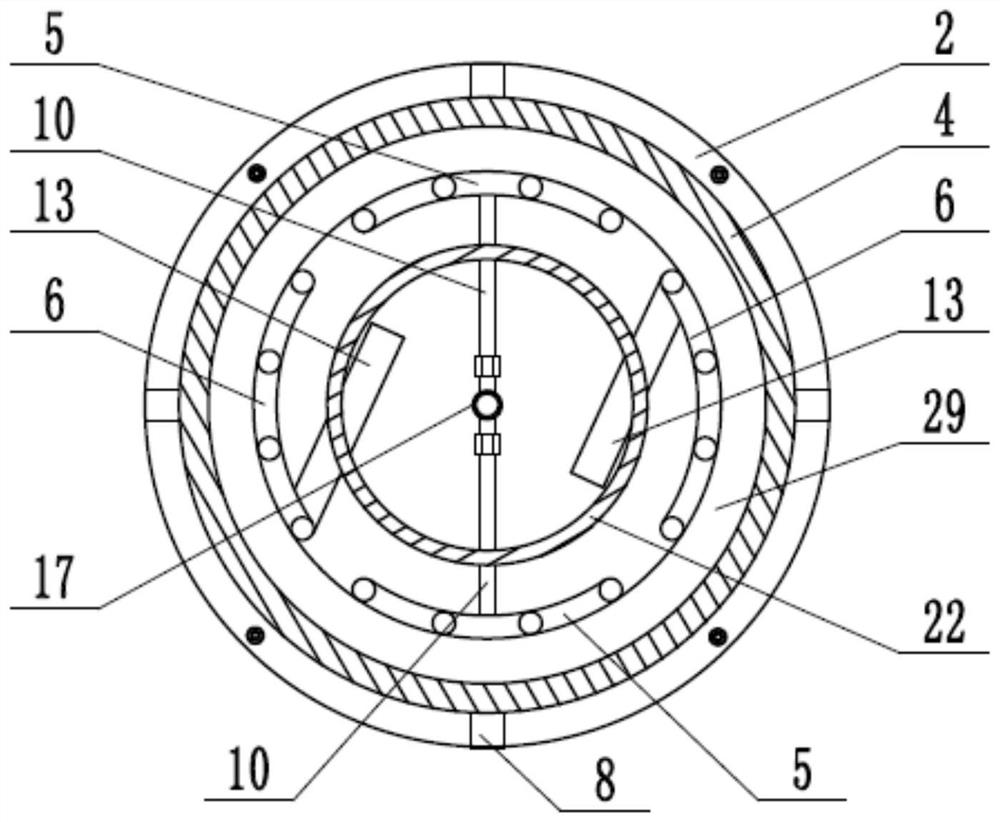

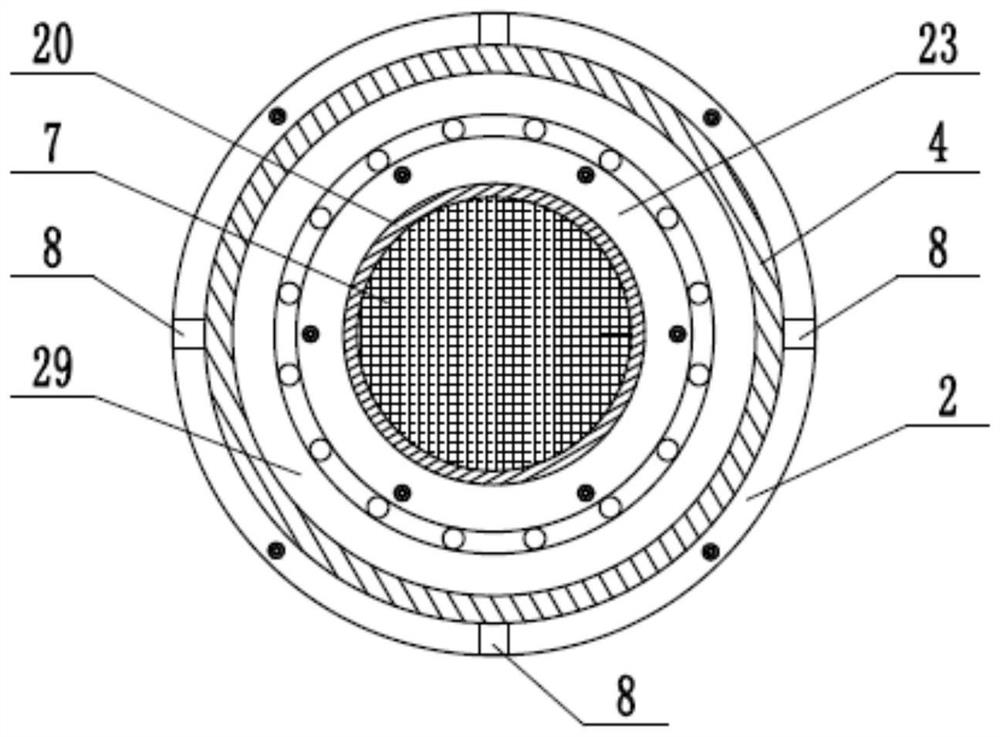

[0041] Such as figure 1 , Figure 7 with Figure 12The shown enhanced premixed micro-combustor includes an upper cover 1, a lower cover 2, an inner sleeve 3, an outer sleeve 4, an oil inlet pipe 5, an air inlet pipe 6 and a catalytic grid 7; The sleeve 3 is arranged in the inner cavity of the outer sleeve 4, the upper cover 1 and the lower cover 2 are installed on the upper and lower open ends of the outer sleeve 4 respectively, and the bottom end of the inner sleeve 3 is connected to the lower end of the lower cover. The cover 2 is connected, there is a first interval between the top end of the inner sleeve 3 and the upper cover 1, there is a second interval between the outer peripheral wall of the inner sleeve 3 and the inner peripheral wall of the outer sleeve 4, and the The bottom of the outer sleeve 4 is provided with a waste gas outlet 8, and the first interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com