A fuel-cooled evaporator tube structure

An evaporating tube and cooling type technology, which is applied in the field of fuel-cooled evaporating tube structure, can solve the problems of long flame area, overheating and smoking at the outlet section of the evaporating tube of the evaporating tube, so as to improve the preheating degree of fuel and improve the evaporation rate. The effect of premixing and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

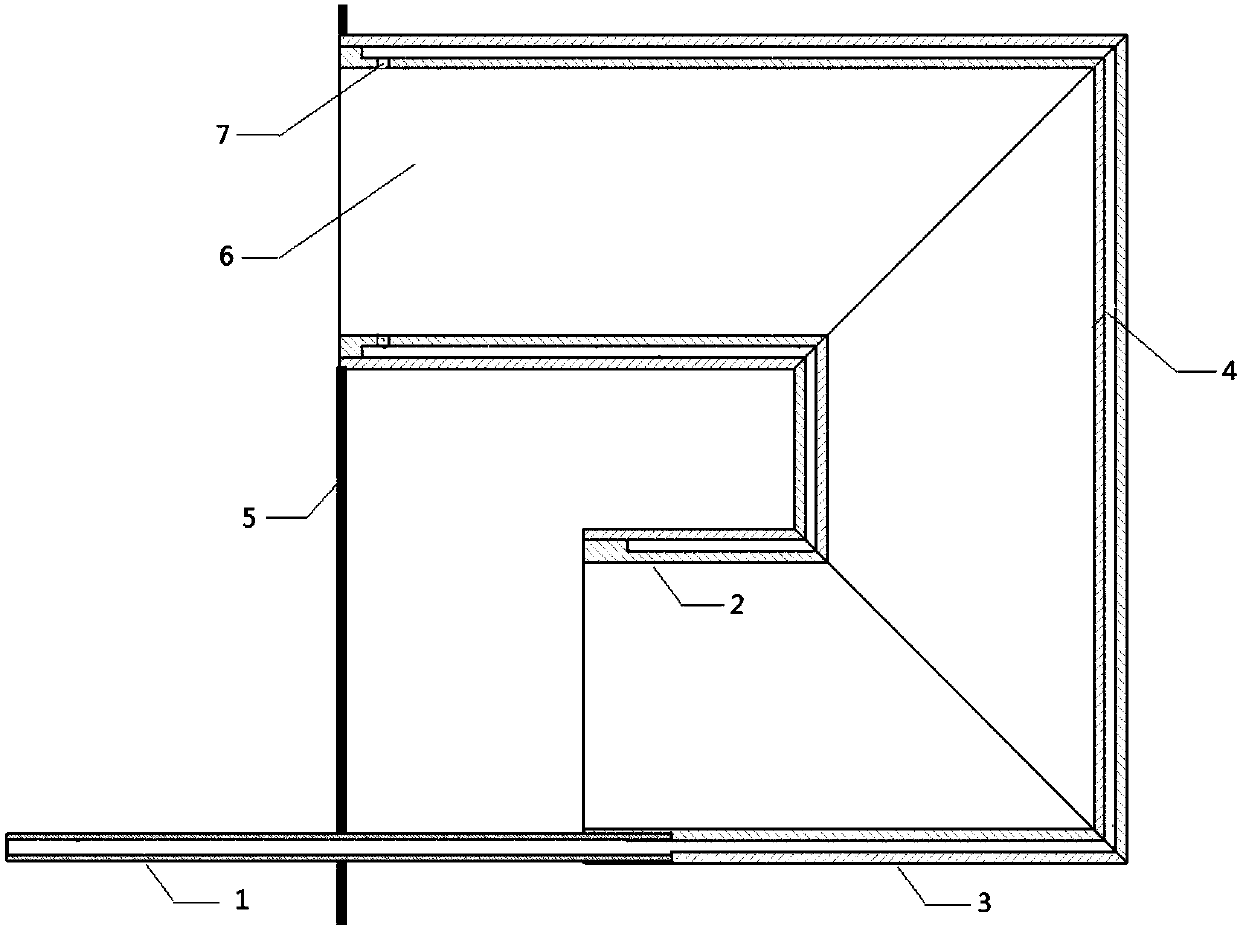

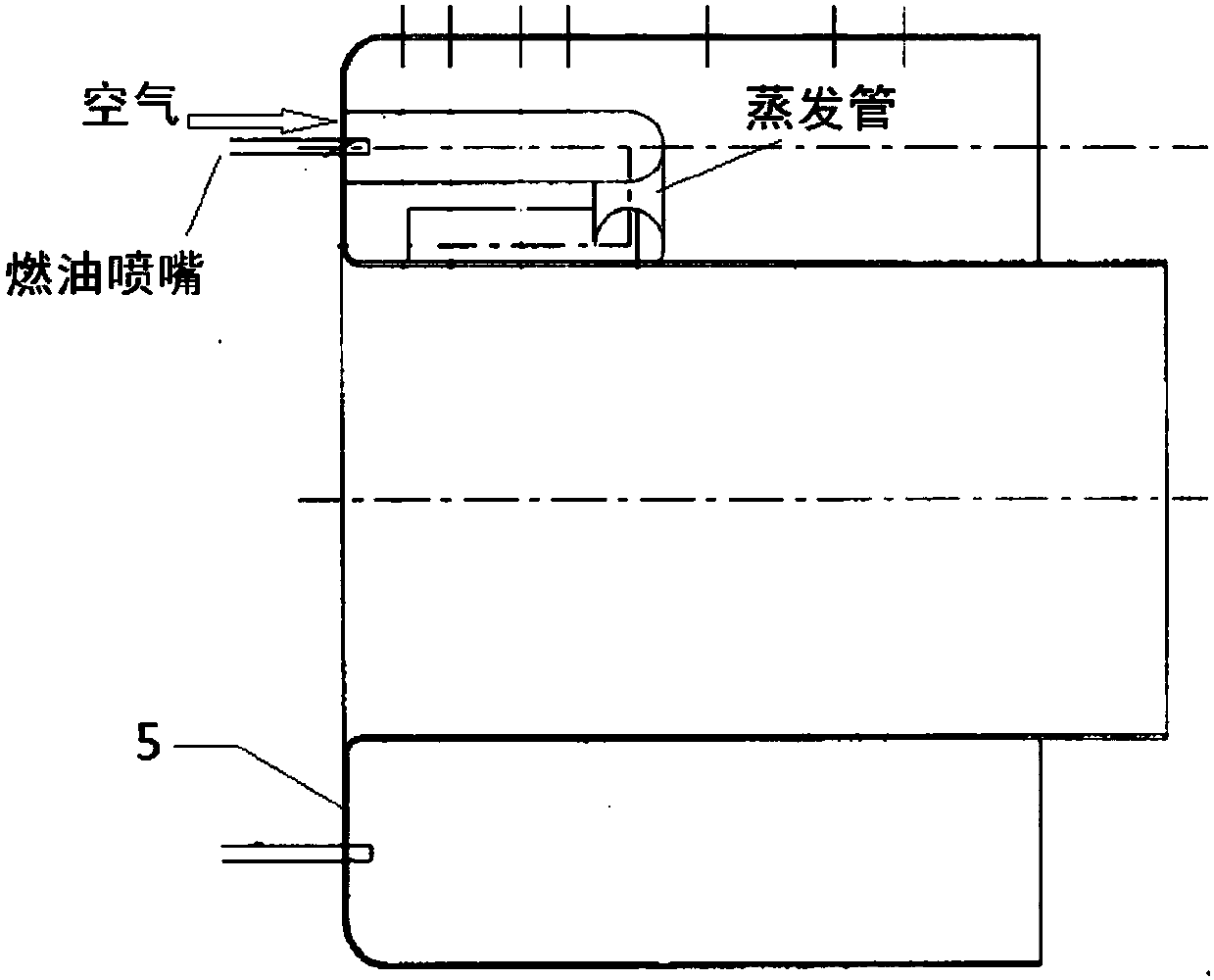

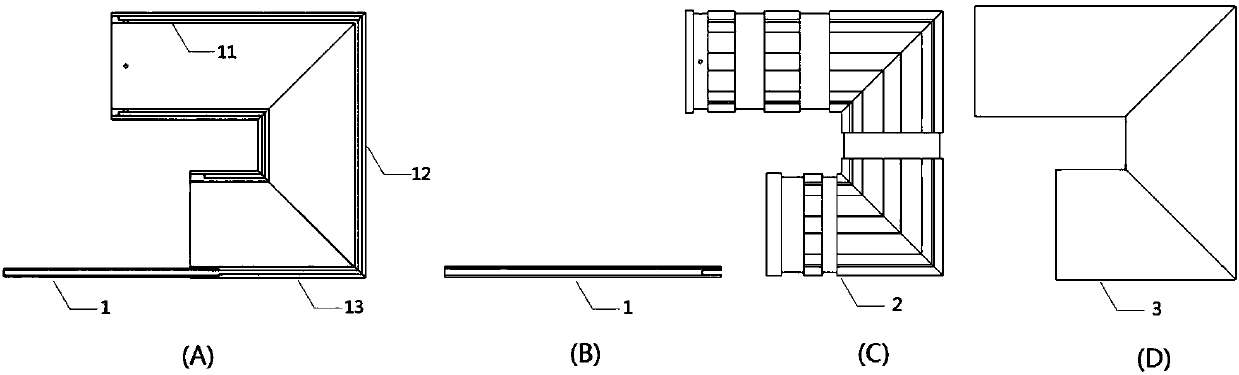

[0026] Such as Figures 1 to 6 As shown, the fuel-cooled evaporating tube structure of the present invention is suitable for combustion chambers of gas turbines or other engines, and includes a fuel inlet tube 1 and an evaporating tube, and the evaporating tube includes an inlet section 11, a transition section 12 and an outlet section 13 connected in sequence The evaporation tube is fixedly arranged on the wall surface 5 of the combustion chamber through its inlet section 11, and there is a certain distance between the outer end of the outlet section 13 of the evaporation tube and the wall surface 5 of the combustion chamber.

[0027] The wall surface of the evaporating tube is from the inside to the outside in order of the evaporating tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com