Liquefied gas vehicle gas supply insulation system

A heat preservation system and liquefied gas technology, applied in the direction of charging system, oil supply device, vehicle parts, etc., can solve the problems of insufficient gasification of liquefied gas in the gas storage tank, affecting the gas supply of the engine, and inconvenient daily use, etc., to achieve The effect of extending the oil replacement cycle, low noise, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

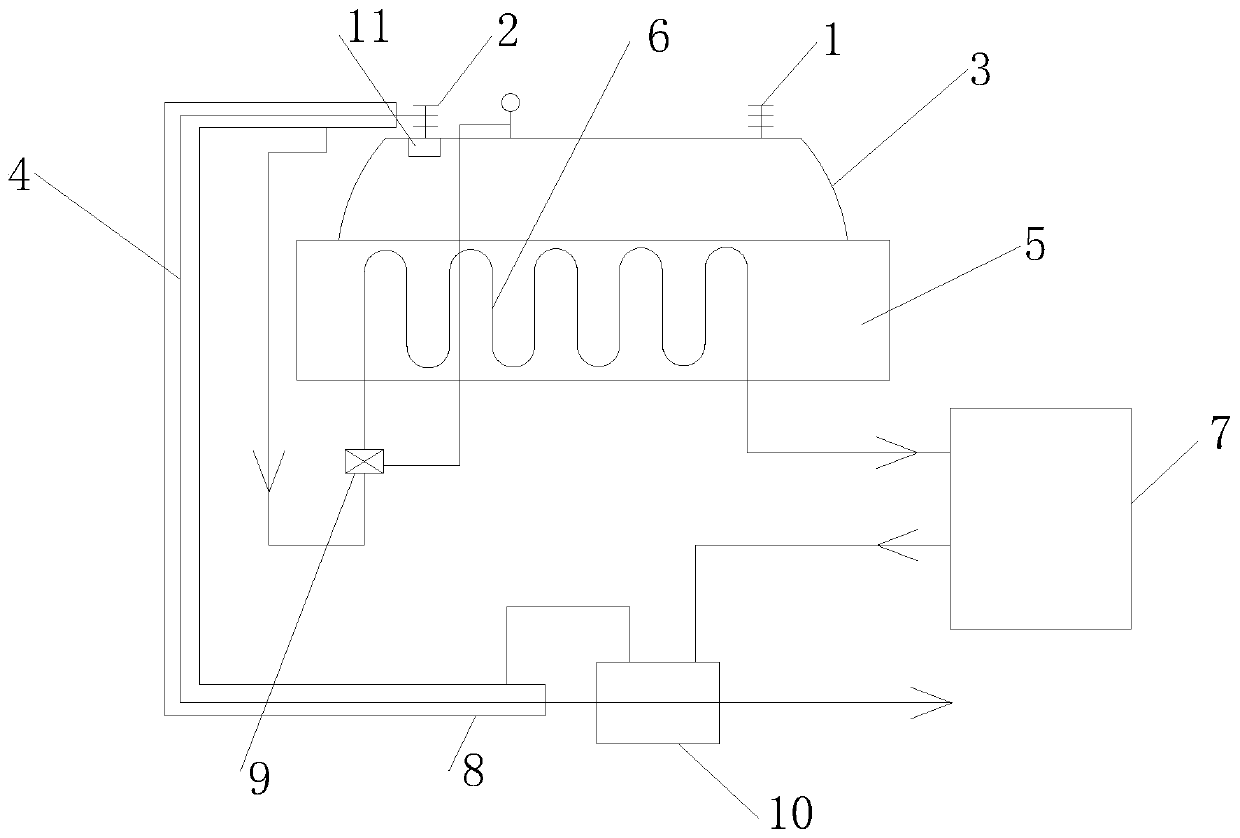

[0023] as attached figure 1 As shown, a liquefied gas vehicle gas supply insulation system includes a gas storage tank 3 with a filling valve 1 and an air outlet valve 2, the gas outlet valve 2 is connected to the engine through a feed pipe 4, and the gas storage tank 3 is installed in the heating box 5, the heating box 5 is provided with a coil 6 attached to the gas storage tank 3, the inlet and outlet of the coil 6 are connected to the cooling water system 7 of the engine, the feed pipe 4 passes through the hollow casing 8 inside, and the casing 8 The gap between the two ends and the feed pipe 4 is sealed, and the sleeve pipe 8 is provided with an inlet and outlet water outlet and the inlet and outlet water outlet is connected to the engine cooling water system 7 . The water outlet of the engine cooling water system 7 is connected to the heat exchanger 10, the heat exchanger is connected to the casing, and the casing is connected to the water inlet of the heating box, and th...

Embodiment 2

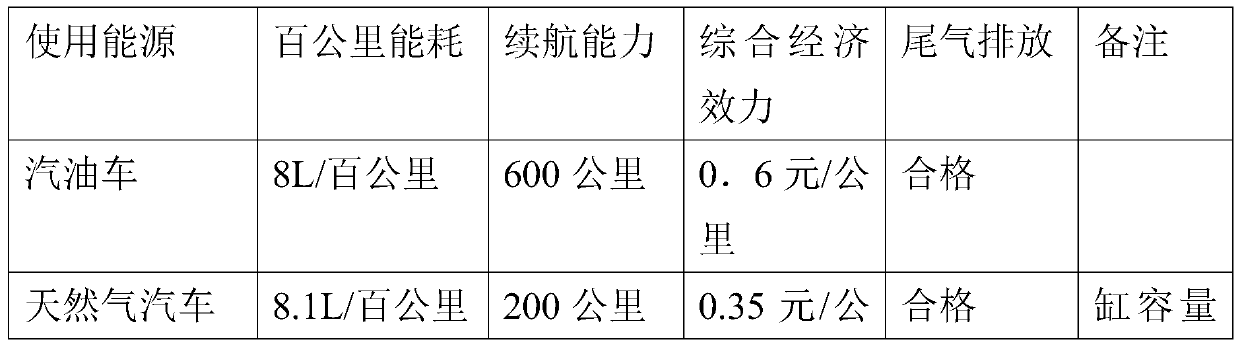

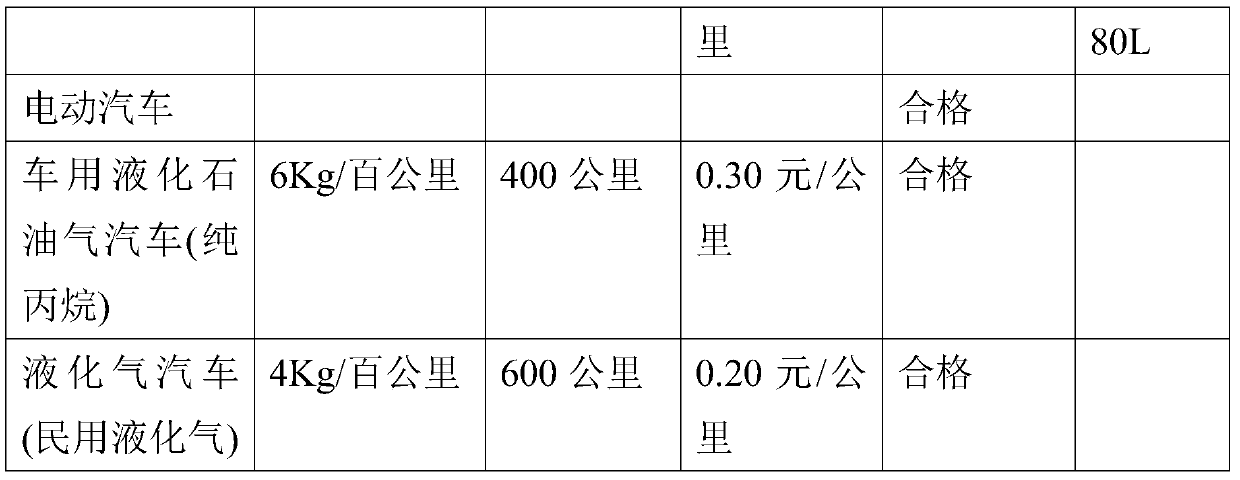

[0030] After long-term research and testing, comparing the respective characteristics of liquefied petroleum gas, propane, and natural gas, as well as the use standards of vehicle gas fuels, and testing the system of the present invention, the test results show that it is comparable to fuel vehicles in terms of power and endurance, and is safe. Similar to natural gas vehicles, the comprehensive economic benefits are less than 50% of fuel vehicles, and about 30% less than natural gas vehicles. Moreover, the exhaust gas is tested and the exhaust emission is fully up to the standard. Ease of use is more convenient than natural gas and electric vehicles. In addition, there are many existing liquefied gas supply points, so it is more convenient for cars to refuel. The specific performance comparison between this system and the existing fuel vehicles is shown in Table 1:

[0031] Table I

[0032]

[0033]

[0034] It can be seen from Table 1 that the gas supply system of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com